Pretreatment method for reduction of strong brine in iron and steel industry

A technology for iron and steel industry and concentrated brine, which is applied in water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc. It can solve the problem of high operating costs, no consideration of organic pollution and inorganic scaling of reverse osmosis membranes, and limited promotion. and application problems, to achieve the effect of simple equipment, stable processing effect and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

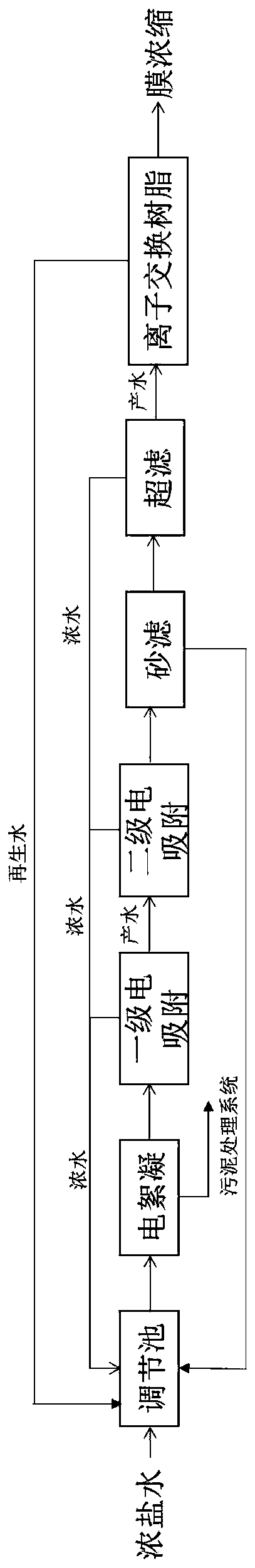

[0021] See figure 1 , The concentrated brine from the iron and steel industry first enters the regulating tank to balance the water quality and quantity. The effluent from the regulating tank enters the electrocoagulation equipment. The electrode material of the electrocoagulation equipment is aluminum-iron plate, the reaction voltage is controlled at 3V, the distance between the plates is controlled at 2cm, the reaction time is 25min, the pH of the wastewater is controlled at 7.0, and the power supply adopts periodic commutation power supply. The period is 8s. After electrocoagulation treatment, the suspended solids and calcium and magnesium metal ions in the wastewater are effectively reduced. The effluent from electrocoagulation enters the first-stage electro-adsorption equipment, the plate voltage is controlled at 1.0V, the distance between the plates is 1.5cm, and the pH of the wastewater is 7.0. In the second stage of electrosorption, the voltage of the control plate i...

Embodiment 2

[0024] See figure 1 , The concentrated brine from the iron and steel industry first enters the regulating tank to balance the water quality and quantity. The effluent from the adjustment tank enters the electrocoagulation equipment. The electrode material of the electrocoagulation equipment is aluminum-iron plate, the reaction voltage is controlled at 4V, the distance between the plates is controlled at 2.5cm, the reaction time is 30min, the pH of the wastewater is controlled at 7.5, and the power supply adopts periodic commutation power supply. To the cycle 9s. After electrocoagulation treatment, the suspended solids and calcium and magnesium metal ions in the wastewater are effectively reduced. The effluent from electrocoagulation enters the first-stage electro-adsorption equipment, the plate voltage is controlled at 1.4V, the distance between the plates is 2.0cm, the pH of the wastewater is 7.5, the concentrated water from the first-stage electro-adsorption returns to the ...

Embodiment 3

[0027] See figure 1 , The concentrated brine from the iron and steel industry first enters the regulating tank to balance the water quality and quantity. The effluent from the regulating tank enters the electrocoagulation equipment. The electrode material of the electrocoagulation equipment is aluminum-iron plate, the reaction voltage is controlled at 5V, the distance between the plates is controlled at 3cm, the reaction time is 35min, the pH of the wastewater is controlled at 8.0, and the power supply adopts periodic commutation power supply. The period is 10s. After electrocoagulation treatment, the suspended solids and calcium and magnesium metal ions in the wastewater are effectively reduced. The effluent from electrocoagulation enters the first-stage electro-adsorption equipment, the plate voltage is controlled to 1.8V, the distance between the plates is controlled to 2.5cm, the pH of the wastewater is 8.0, the concentrated water from the first-stage electro-adsorption r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com