Water inlet flow channel of axially split pump

A water inlet flow channel and flow channel technology, which is applied in the direction of pumps, pump components, non-variable pumps, etc., can solve the problems of excessive vibration of the pump rotor, chaotic water flow, and affecting the life of the pump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

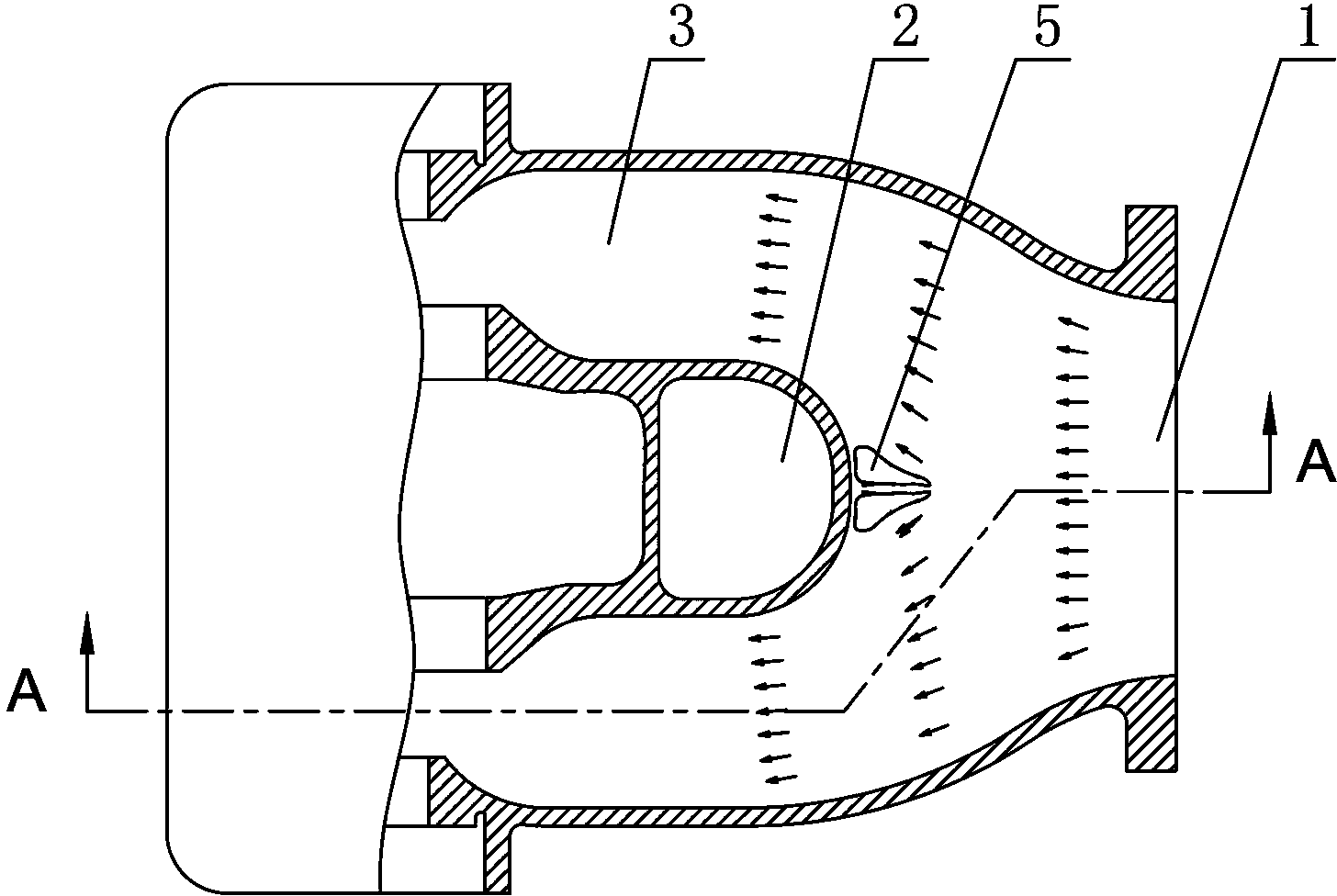

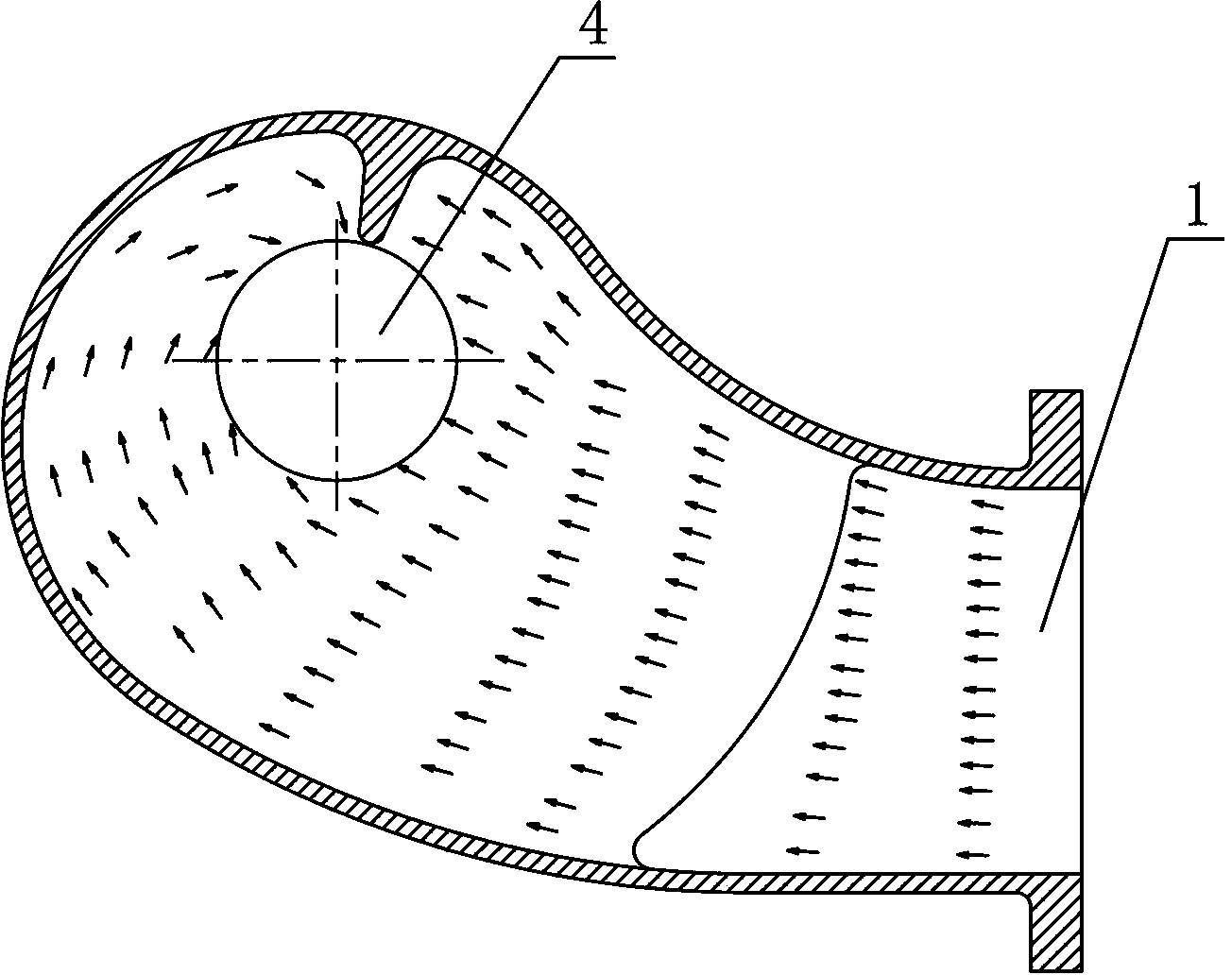

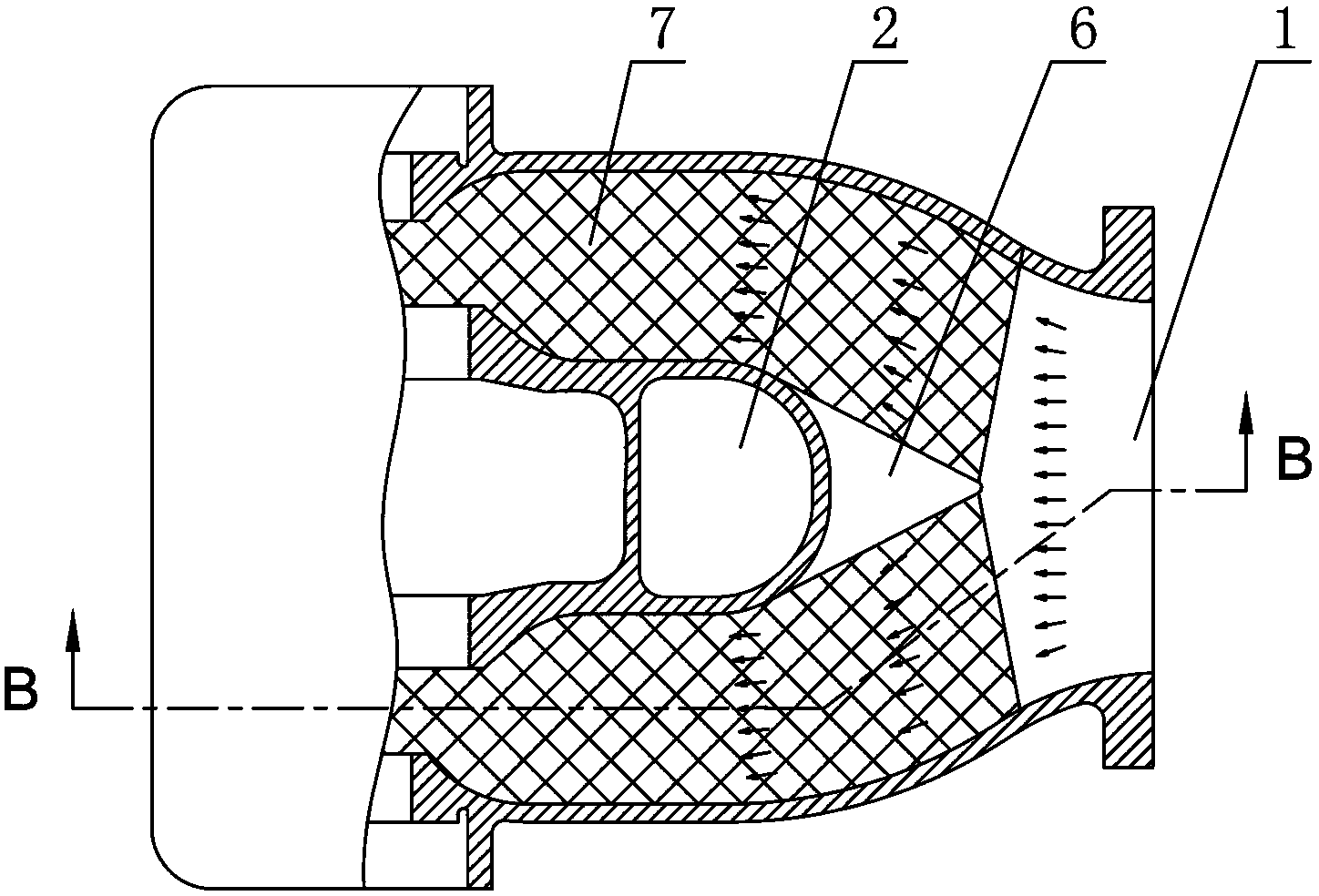

[0015] Such as Figure 1-4 As shown, the water inlet channel of a split pump according to the embodiment of the present invention mainly includes a water inlet 1, a volute area 2 and a flow channel area 3, and a longitudinal water diversion channel is arranged between the water inlet 1 and the volute area 2 Ribs 6 and longitudinal water diversion ribs 6 make the cross-sectional area change more uniform in the flow channel, eliminating dead water areas and vortex areas 5; the flow channel area 3 is provided with horizontal flow guide ribs 7, which not only improve the uniformity of liquid flow And flow stability, improve the water inlet conditions, and at the same time strengthen the structural strength, improve the pressure bearing capacity of the pump inlet, play a role in reducing harmful deformation and improving vibration resistance when the pump is working.

[0016] In a preferred embodiment, the starting end of the longitudinal water-distributing rib 6 is a rib-shaped pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com