Clamp, lock nut, lock assembly, welding torch having same and fastening method

A technology for locking nuts and clamps, which is applied in the direction of threaded fasteners, nuts, connecting components, etc., which can solve the problems of cumbersome installation and disassembly of clamps, cumbersome installation and disassembly of clamps, etc., and achieve convenient installation and installation and the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

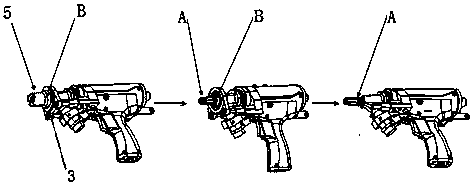

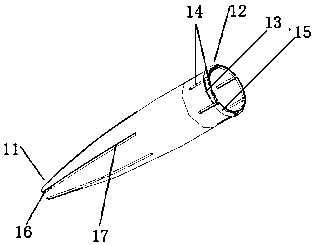

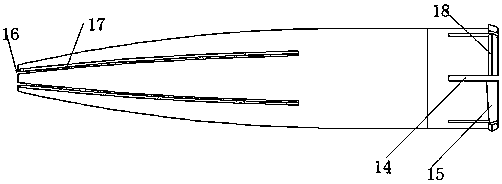

[0052] Such as figure 2 , image 3 As shown, this embodiment provides a clamp, which includes a hollow clamp body 1, the clamp body 1 has a clamping part 11, and the clamping part 11 has a clamping opening for clamping foreign objects 16. The cross-sectional area of the locking part 11 gradually decreases along the direction from its root to the clamping opening 16, and the locking part 11 is formed with several grooves 17 along its axial direction, and the grooves 17 are in line with the clamping opening 16. The clamping port 16 is connected, and the groove 17 provides convenience for the deformation of the clamping port 16, so that the clamping port 16 can clamp objects of different sizes.

[0053] The clamp of this embodiment also includes a mounting part 12 fixedly connected with the clamping part 11, the clamping part 11 and the mounting part 12 are integrally formed, and the minimum cross-sectional area of the mounting part 12 is The size is not smaller than the m...

Embodiment 2

[0063] Such as Figure 4 , Figure 5 As shown, this embodiment provides a lock nut, the lock nut is used for locking with the clamp described in Embodiment 1, and includes a hollow nut body 2, and the nut body 2 has a The locking body 13 of the locking device is inserted into several insertion parts 21, and the matching locking part 22 that is arranged between adjacent insertion parts 21 and is connected with the insertion part 21 through a transition part 23, and the matching locking part 22 is used for When the locking body 13 located in the insertion portion 21 is rotated at a certain angle and slides into the mating locking portion 22 through the transition portion 23, the locking surface 15 of the locking body 13 is relative to the insertion portion. 21 provides a greater locking force to cooperate with the locking body 13 to lock.

[0064]When the lock nut of this embodiment is used for locking fit with the lock nut in Example 1, the locking surface 15 of the clamp is ...

Embodiment 3

[0070] Such as Image 6 As shown, this embodiment provides a locking assembly, including a hollow lock nut and the hollow clamp located inside the lock nut, the clamp has a clamping portion 11 for clamping foreign objects And the installation part 12 fixedly connected with the clamping part 11, the installation part 12 has a structure that enables itself to be elastically deformed at least along the circumferential direction and the radial direction, and the installation part 12 is provided with several folds along the outer circumference. To the locking body 13 of the clamping part 11, the locking body 13 has a locking surface 15; the locking nut has several insertion parts 21 for inserting the locking body 13 of the clamp, and is arranged on The mating locking portion 22 between adjacent insertion portions 21 and connected to the insertion portion 21 through the transition portion 23, the locking body 13 located in the insertion portion 21 is rotated at a certain angle and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com