Patents

Literature

152results about How to "Increase the speed of disassembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

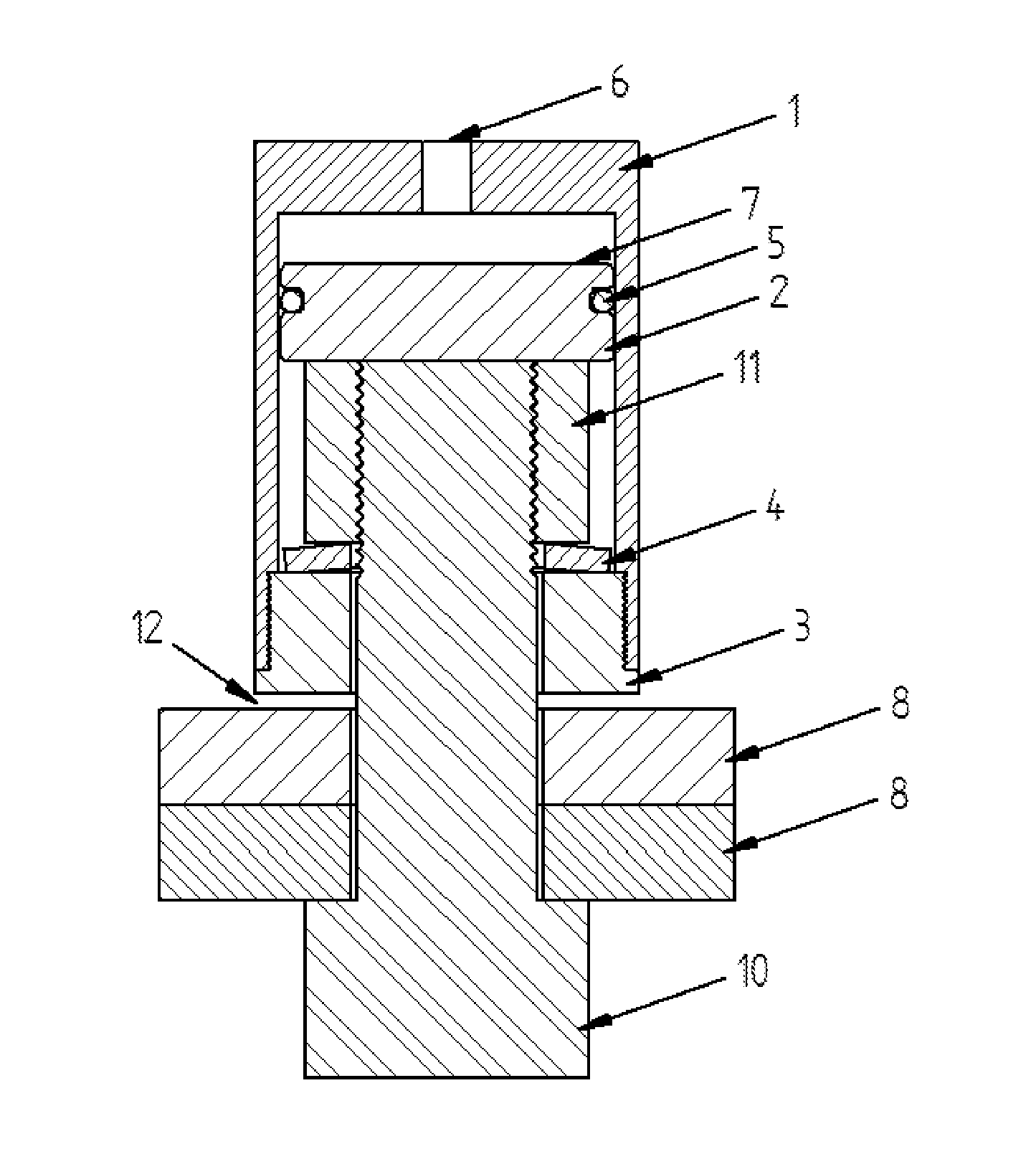

Hydraulically Activated Tension Relief System for Threaded Fasteners

InactiveUS20120180280A1Reduce loadPrevention of galling featureMetal working apparatusPower driven toolsRelative motionPiston

A tension relief system for threaded fasteners comprises a main body housing a piston for generating a clamping load, seals to maintain the hydraulic pressure within the pressure chamber, an external pressure port extending through the body to the pressure chamber and adapted to be connected to an external pressure source, a connector on which the main body may be mounted, and a spring which may be compressed through the relative motion of the piston and the connector.

Owner:INTEGRA SERVICES TECH

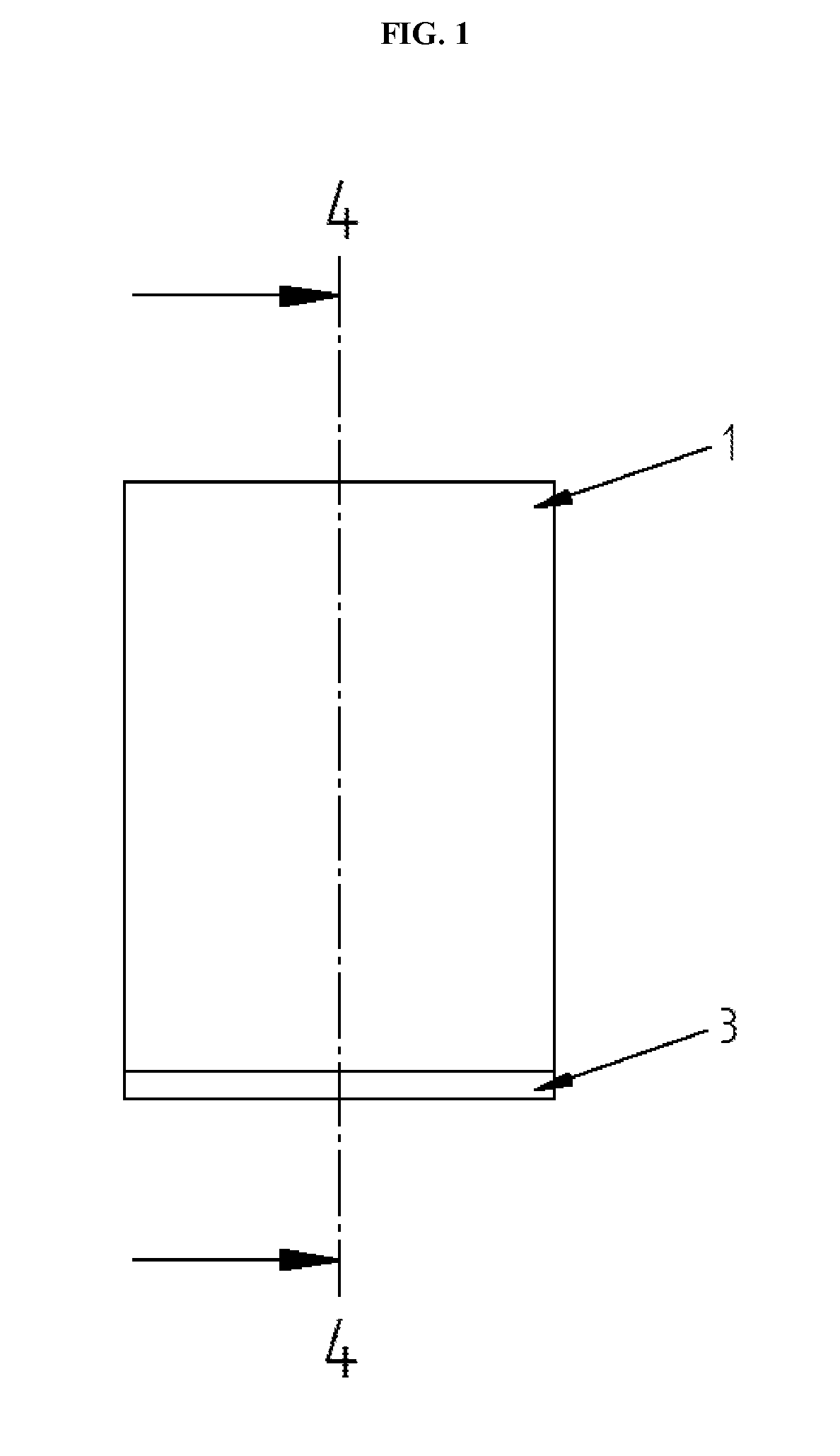

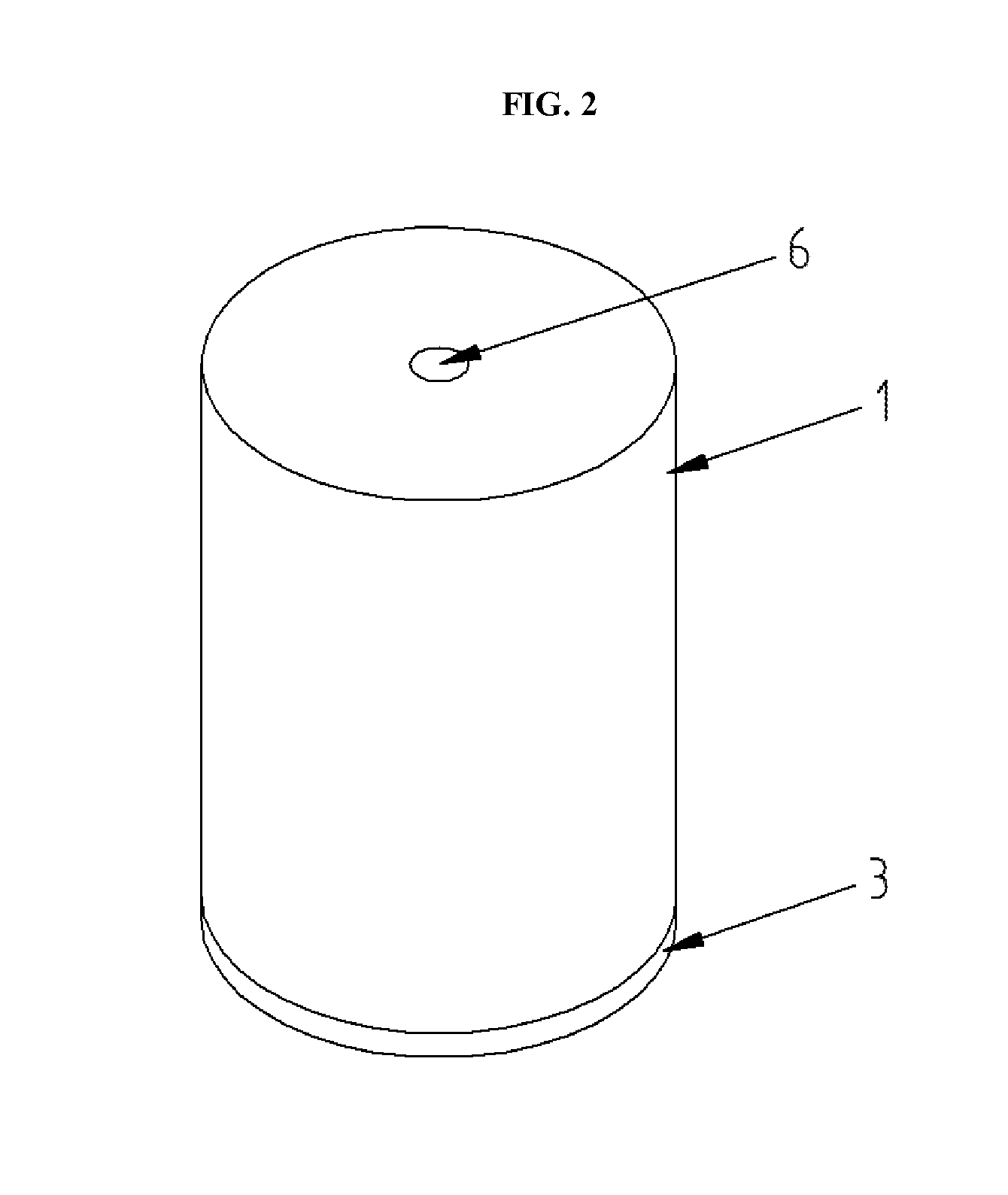

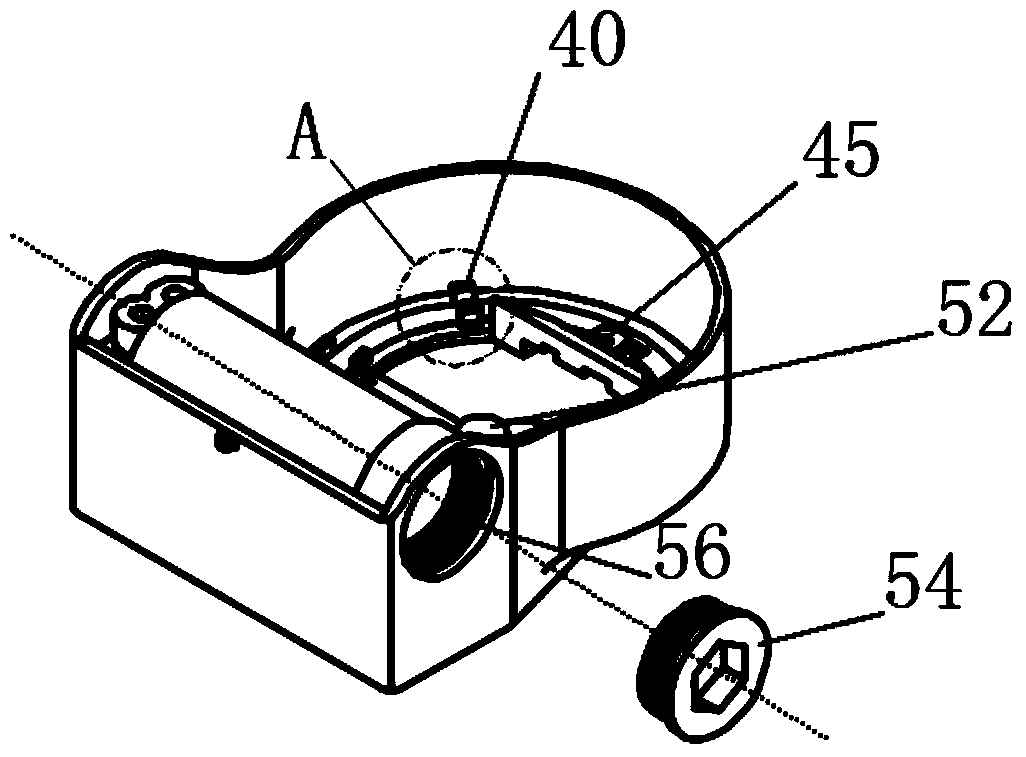

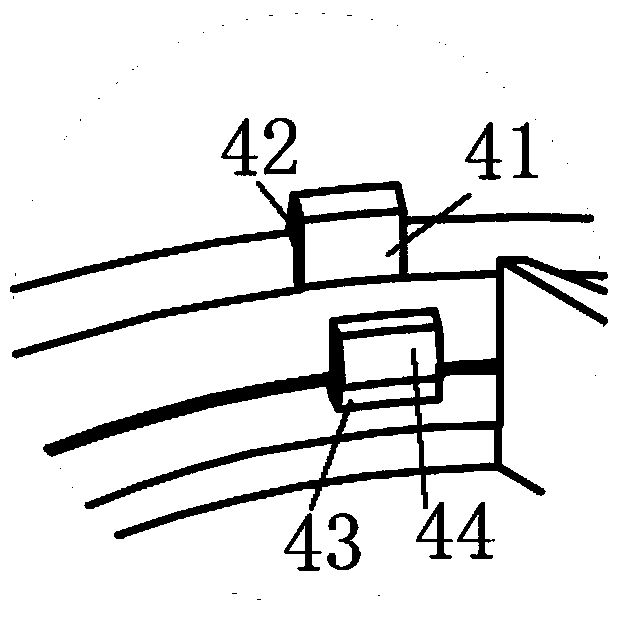

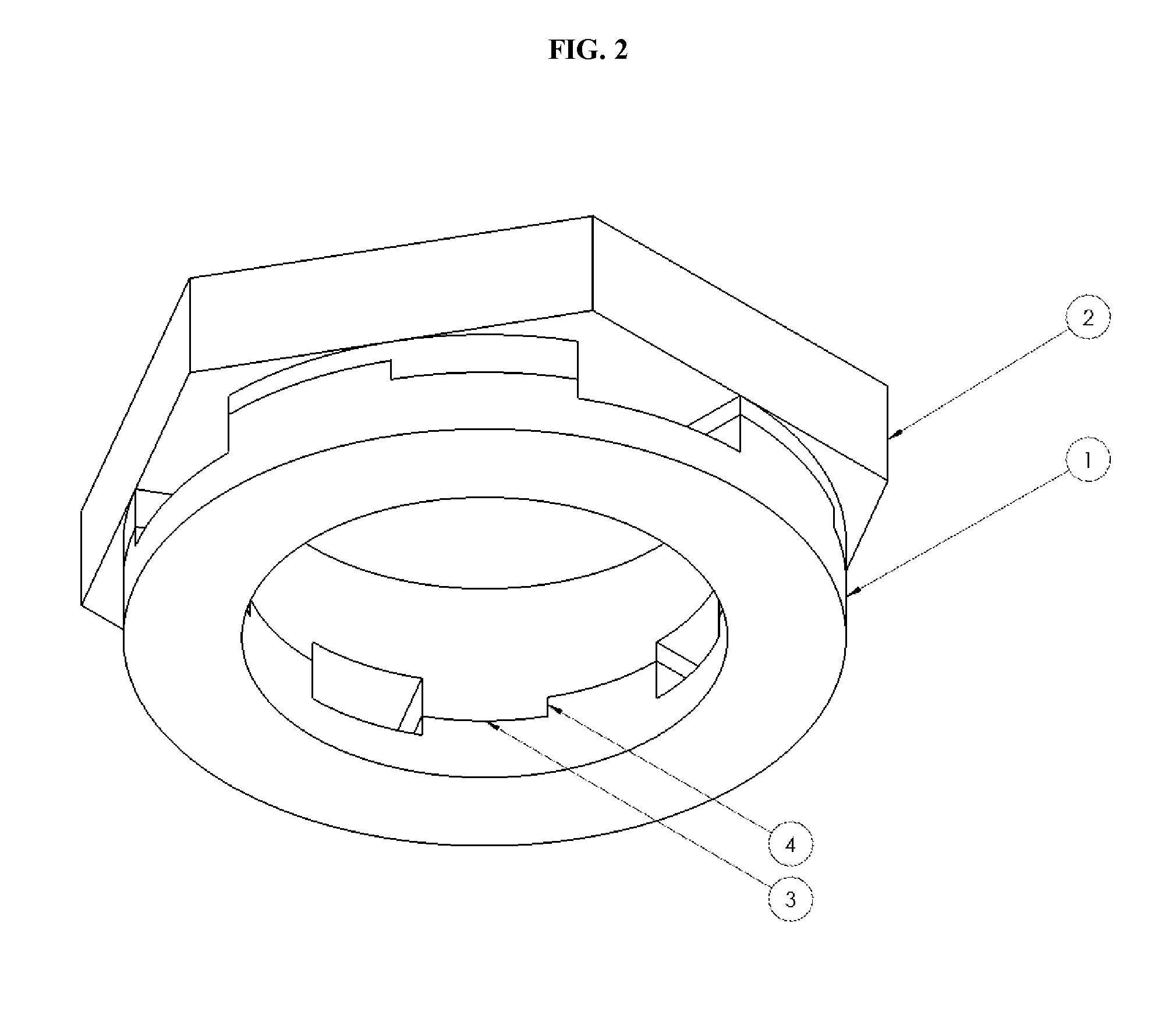

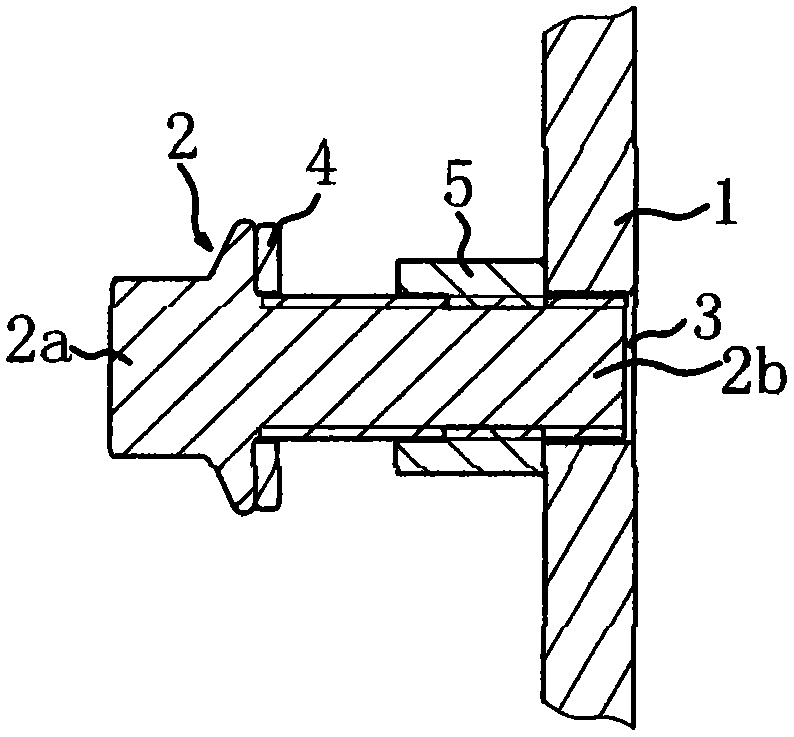

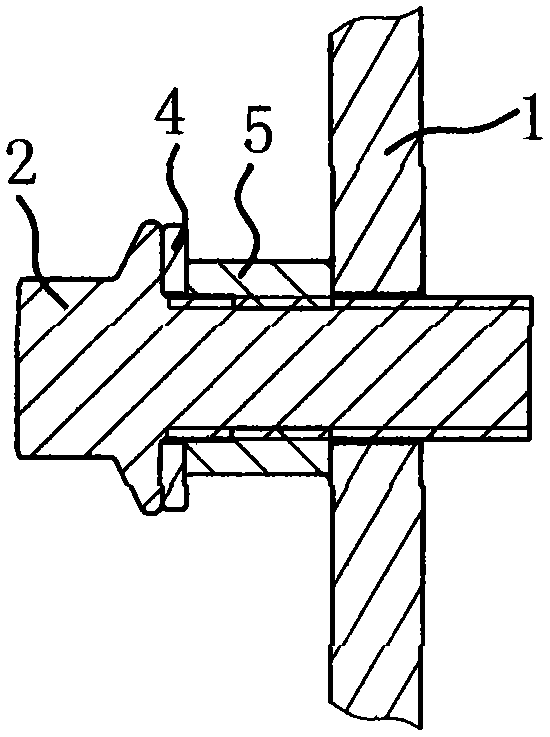

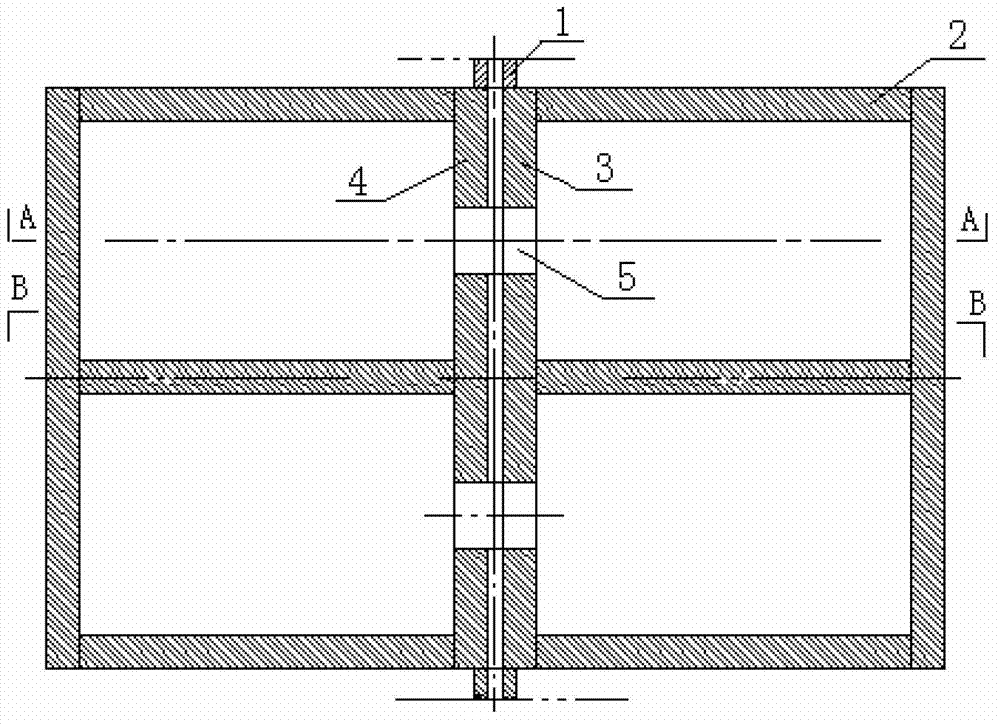

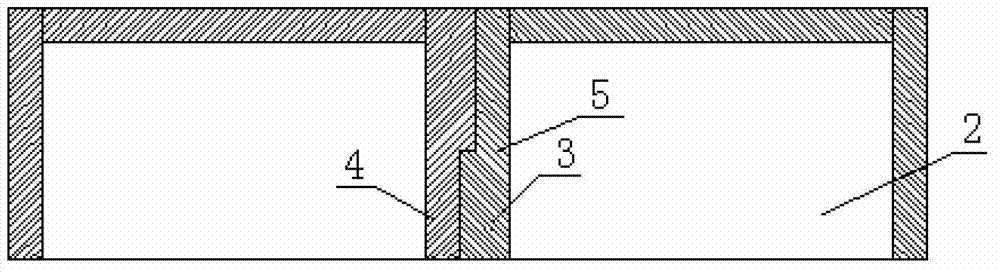

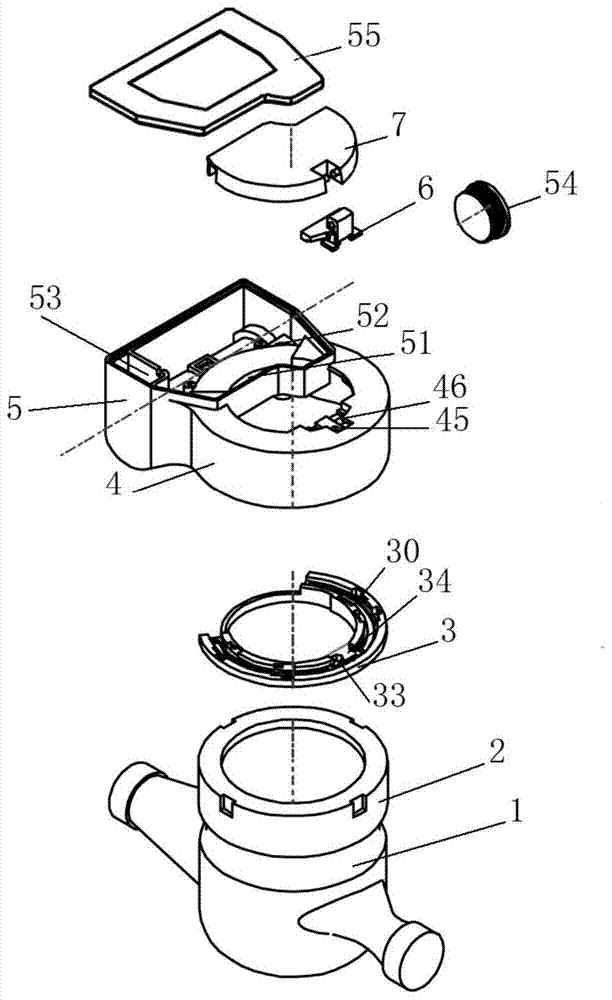

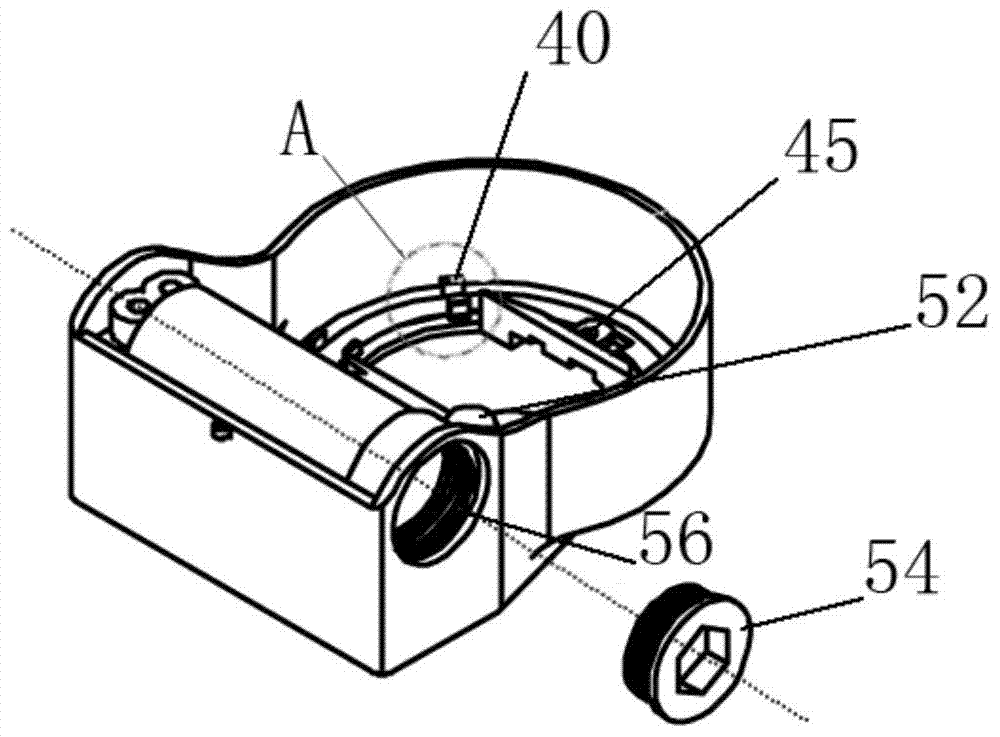

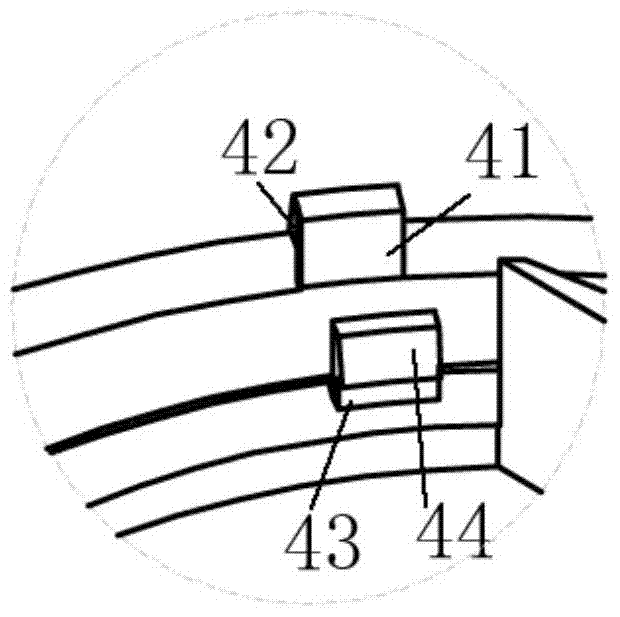

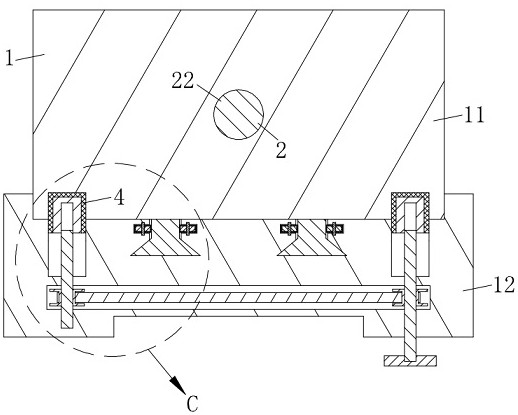

Water meter

ActiveCN104048719AImprove installation speedIncrease the speed of disassemblyVolume meteringAgricultural engineeringCopper

The invention discloses a water meter which comprises a water meter mechanical body, a copper cover and an outer cover. An upper cover is arranged on the outer cover. The water meter further comprises a connecting piece for connecting the copper cover with the outer cover. The connecting piece is fastened on the copper cover through screws. A buckling device is arranged between the outer cover and the connecting piece. By means of the water meter, the mode that an additionally-installed part of a traditional mechanical water meter is directly fixed to the copper cover through the screws is changed, the additionally-installed part is connected in a buckling type connecting mode, rapid clamping and rapid separating between the additionally-installed part and a mechanical part are achieved, and the assembling and disassembling speed of the additionally-installed part is increased.

Owner:JIANGSU SAIDA ELECTRONICS SCI & TECH

Load-relief washer assembly for threaded fasteners

ActiveUS8579572B1Reduce loadPrevention of galling featureWashersLoad modified fastenersThreaded fastenerEngineering

A load relief washer assembly for threaded fasteners comprises a lower washer piece, an upper washer piece, a plurality of complementary stepped features which further comprise the mating surfaces of the lower washer and the upper washer, such that sufficient rotation of the upper body relative to the lower body aligns the complementary stepped features allowing the upper body and the lower body to move toward each other, thereby reducing the overall height of the load relief washer assembly.

Owner:INTEGRA SERVICES TECH

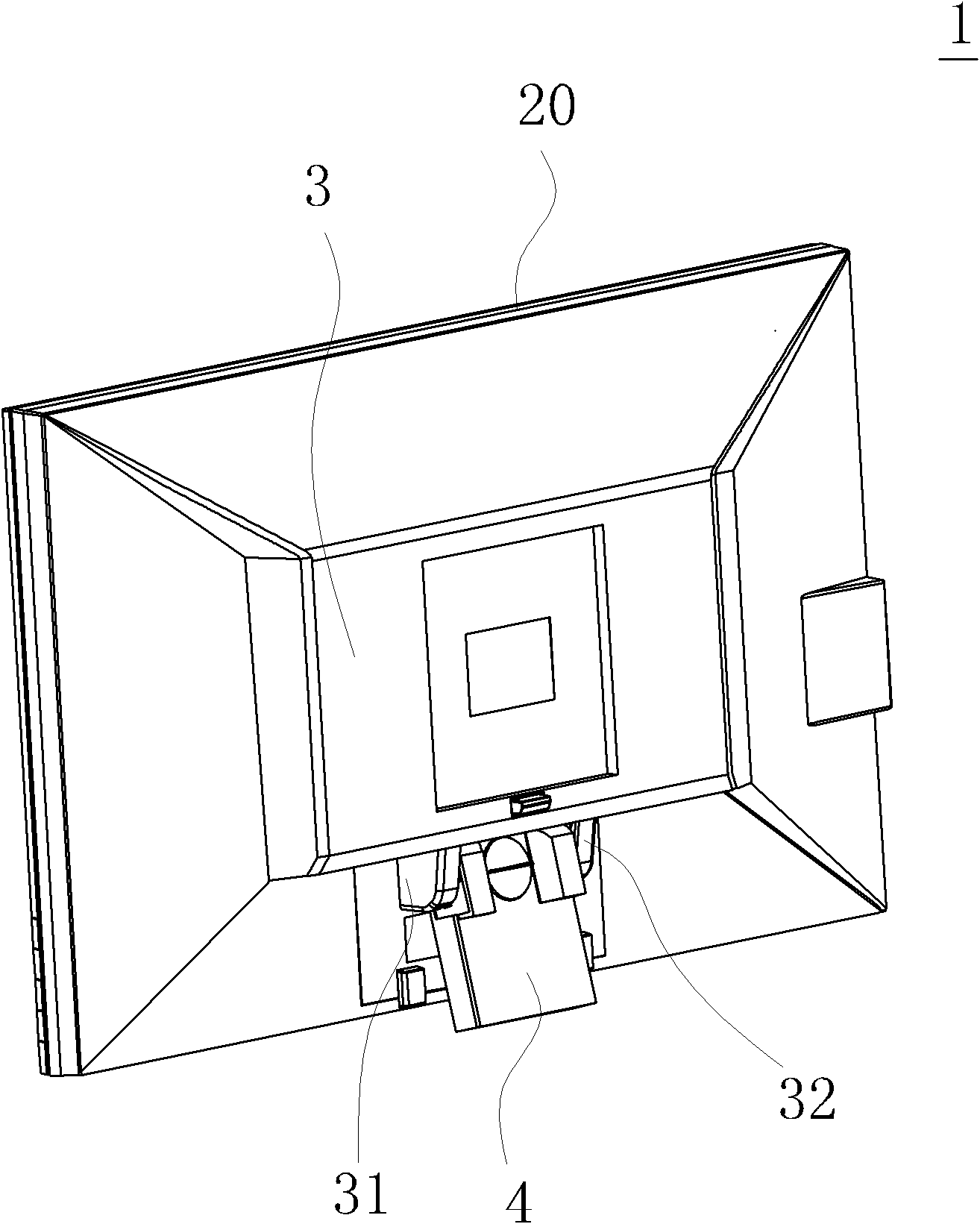

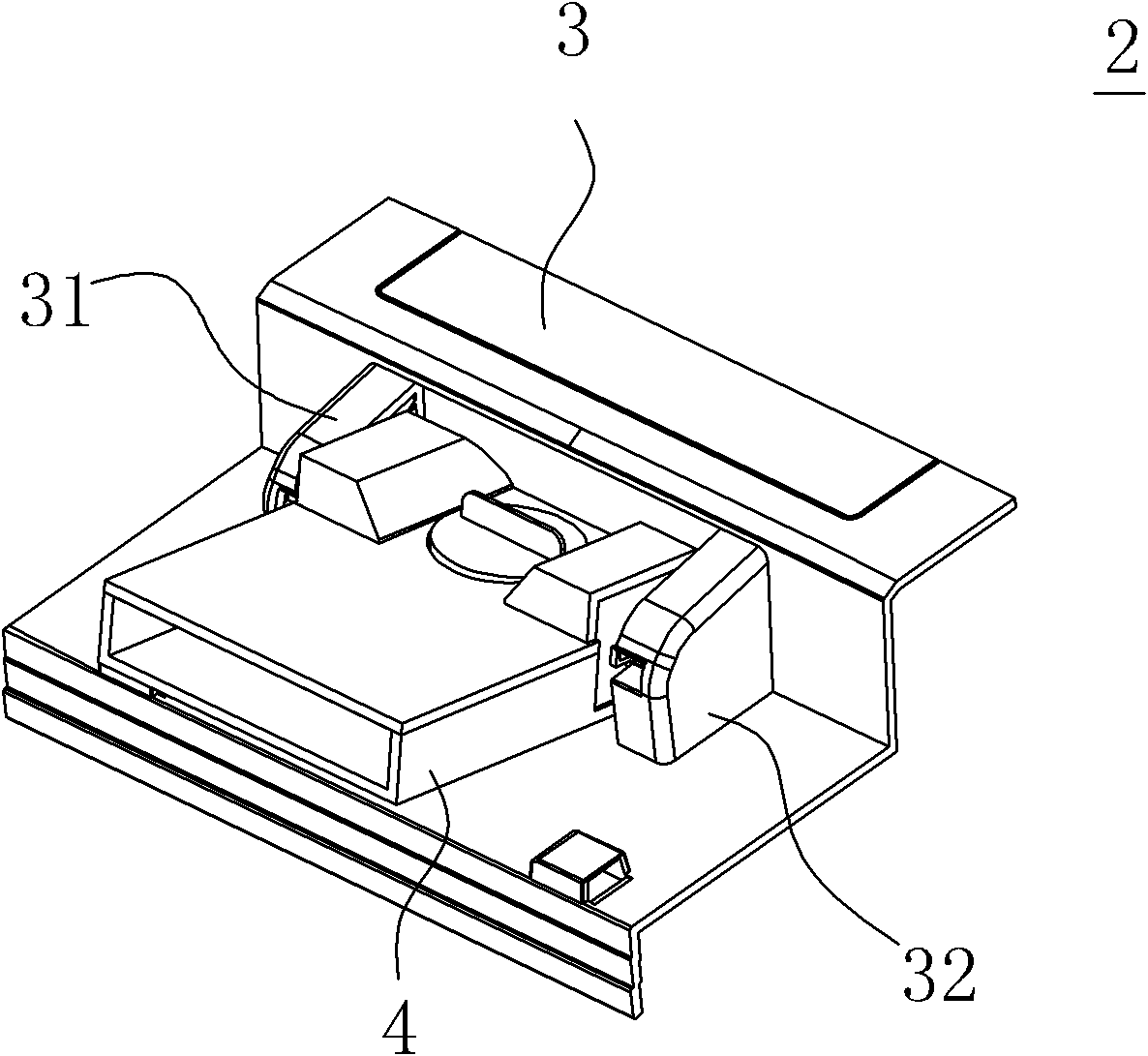

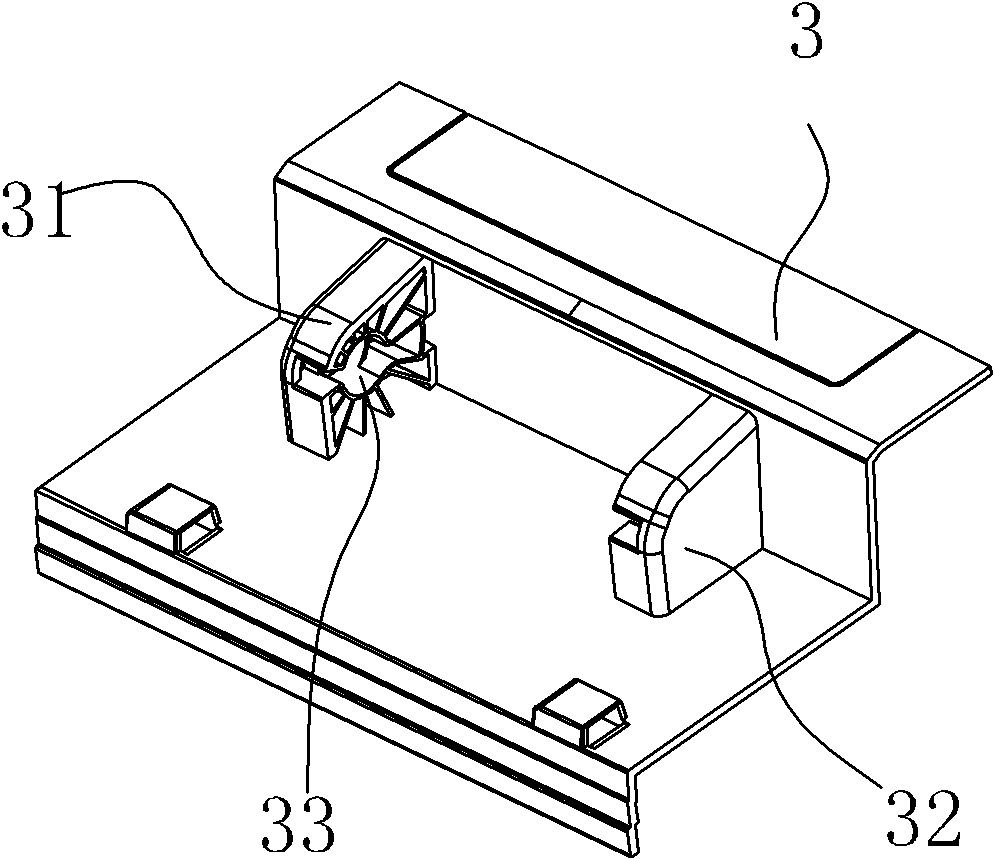

Support device

InactiveCN102088832AReduce manufacturing costImprove assembly speedLighting support devicesCasings/cabinets/drawers detailsElastomerFriction force

The invention discloses a support device which comprises a pivoting body and a support seat, wherein, the pivoting body is provided with a first pivoting part. The support seat comprises a support seat body, a first chute, a first sliding rod and a first elastomer, wherein, a first side of the support seat body is equipped with a first through hole; the first chute is arranged in the support seatbody; the first sliding rod enters the support seat body via the first through hole to be matched with the first chute and can slide along the first chute so that a first end part of the first sliding rod is exposed outside the first through hole to be rotatably connected with the first pivoting part; the first elastomer is sheathed at the first end part; and when the first end part is rotatably connected with the first pivoting part, the first elastomer is positioned between the first pivoting part and the first end part so as to provide friction force for fixing the support seat at arbitrary angle relative to the pivoting body. In the invention, the support seat of the support device can be assembled at the pivoting body in a screw-free joint manner, which can lower the manufacturing cost of fixed components and effectively improve the assembly or disassembly speed between the support seat and the pivoting body.

Owner:QISDA SUZHOU +1

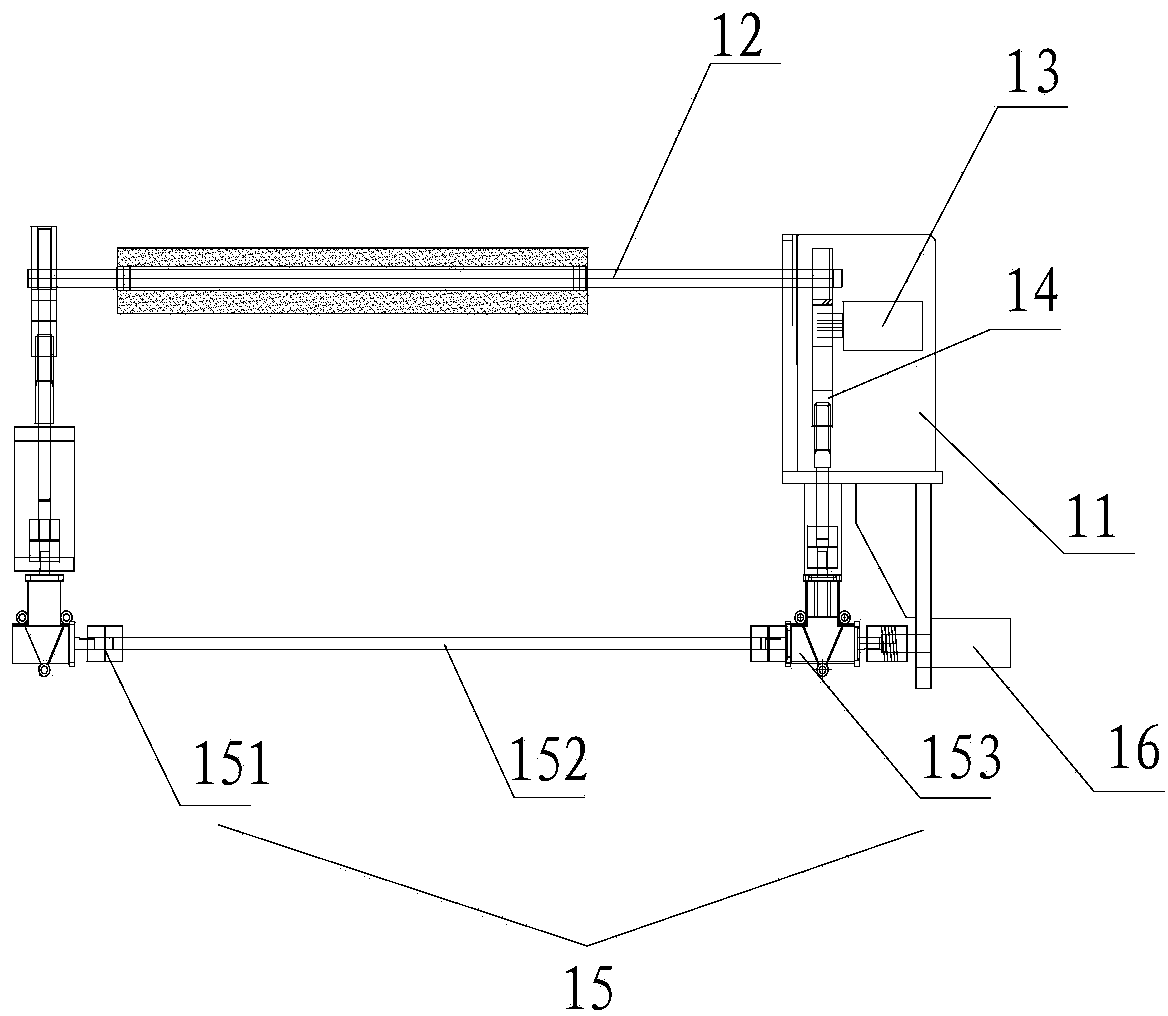

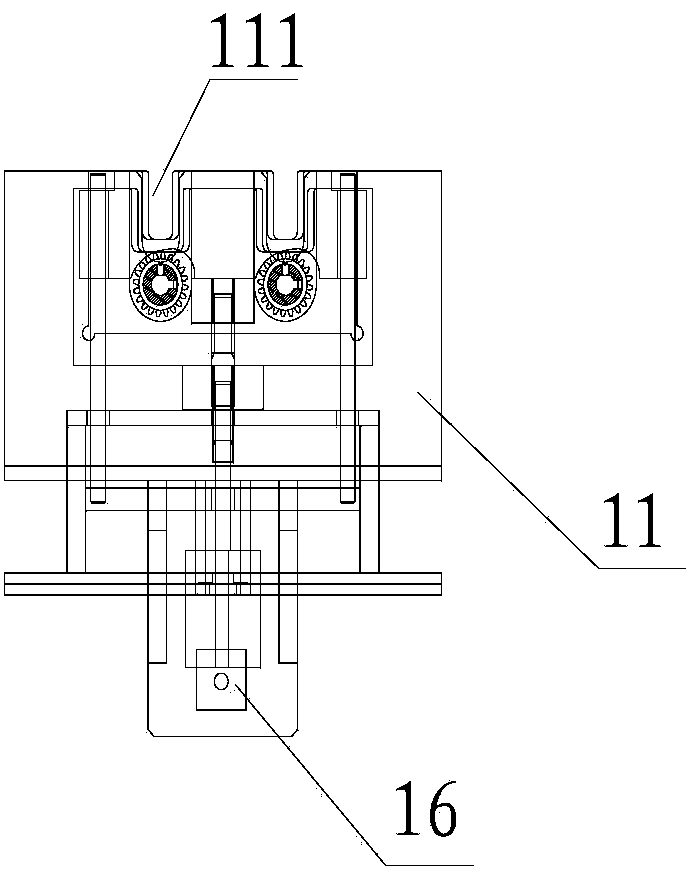

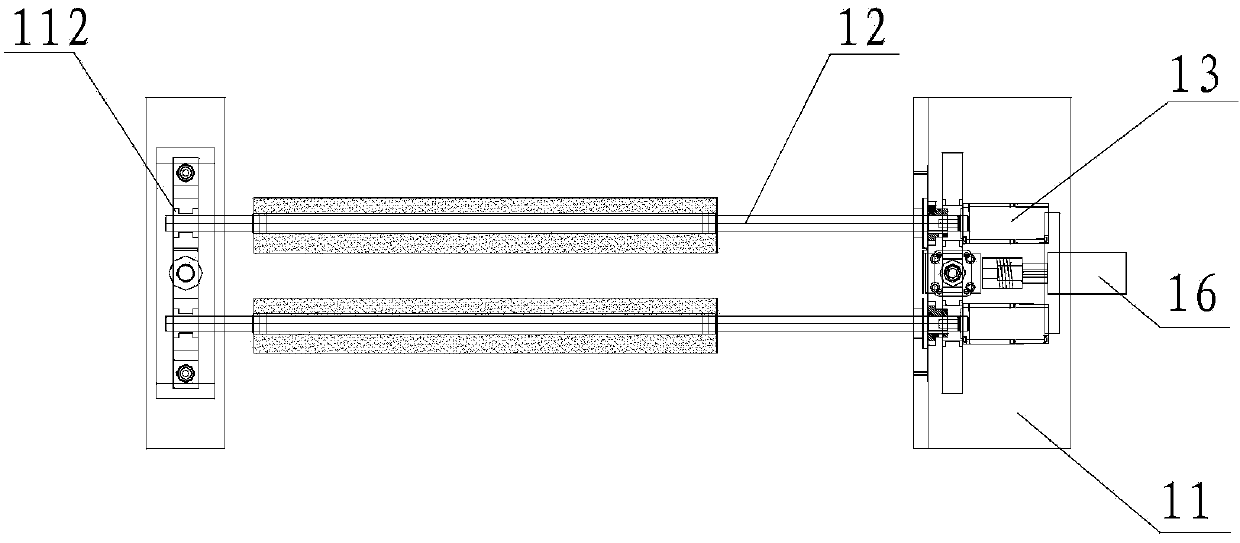

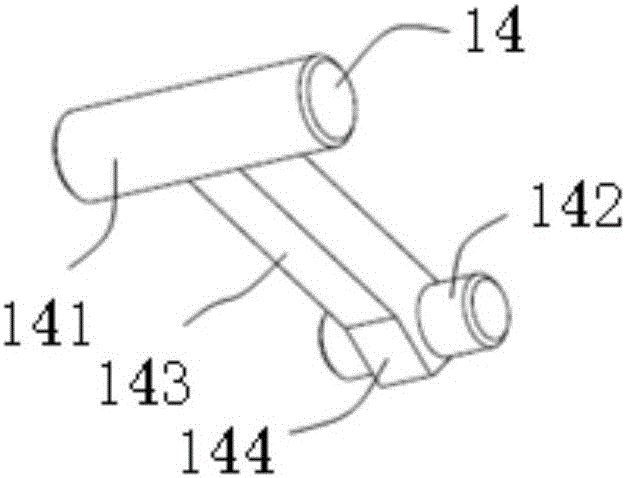

Quick disassembly type rolling brush mechanism on roll type thin film cleaning machine

The invention relates to a quick disassembly type rolling brush mechanism on a roll type thin film cleaning machine. The quick disassembly type rolling brush mechanism comprises two supporting frames, a plurality of rolling brushes, fixing grooves, fixing holes and a plurality of motors, wherein the supporting frames are arranged in parallel and perpendicular to the horizontal plane; the rolling brushes are placed on the supporting frames; the fixing grooves and the fixing holes are formed in the two supporting frames respectively, are the same as the rolling brushes in number, and are used for containing the rolling brushes; the motors are fixed on the supporting frames and matched with the rolling brushes to be used for driving the rolling brushes to rotate, and the rolling brushes are connected with the motors in a meshed mode through gears. According to the quick disassembly type rolling brush mechanism, on one hand, the rolling brushes are connected with the motors in the meshed mode through the gears, the motors are fixed on the supporting frames, the motors do not need to be disassembled when the rolling brushes are disassembled, therefore, time is saved, and production efficiency is improved; on the other hand, due to the fact that the rolling brushes are directly placed in the fixing grooves and the fixing holes of the supporting frames, when PVA sponge is stained by dust and needs cleaning, the rolling brushes just need to be lifted out of the fixing grooves and the fixing holes, and the disassembly and replacement speed is greatly increased.

Owner:SUZHOU KZONE EQUIP TECH

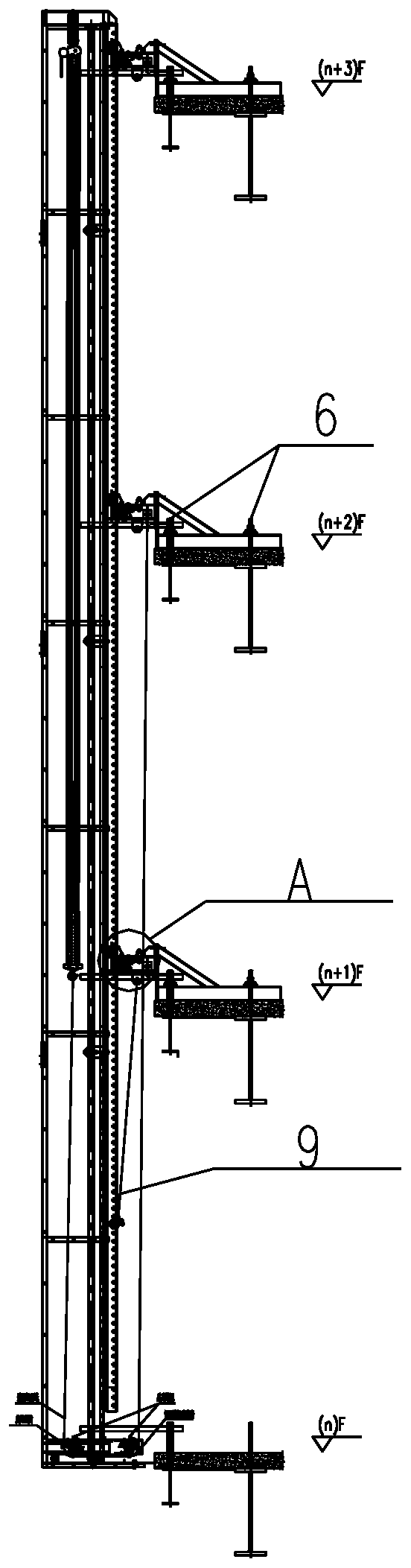

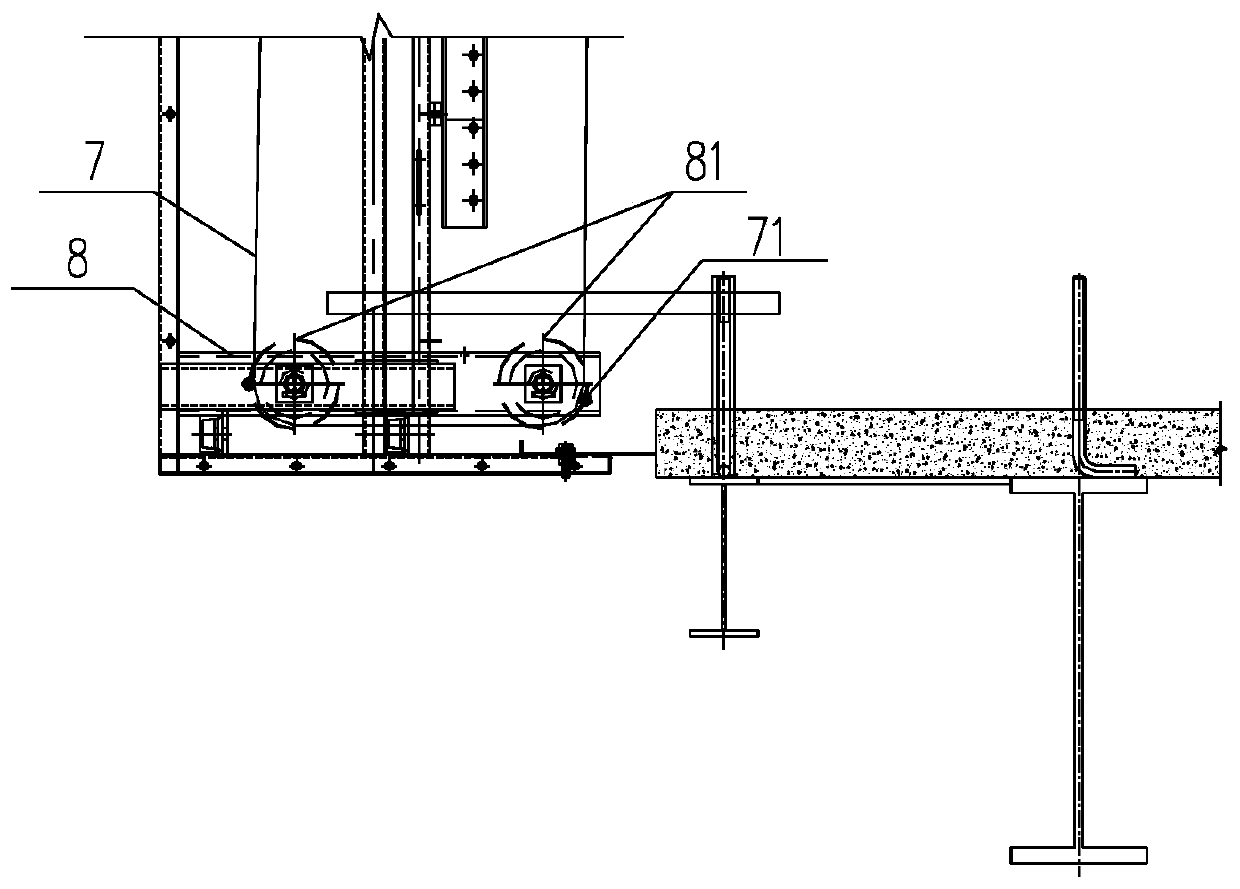

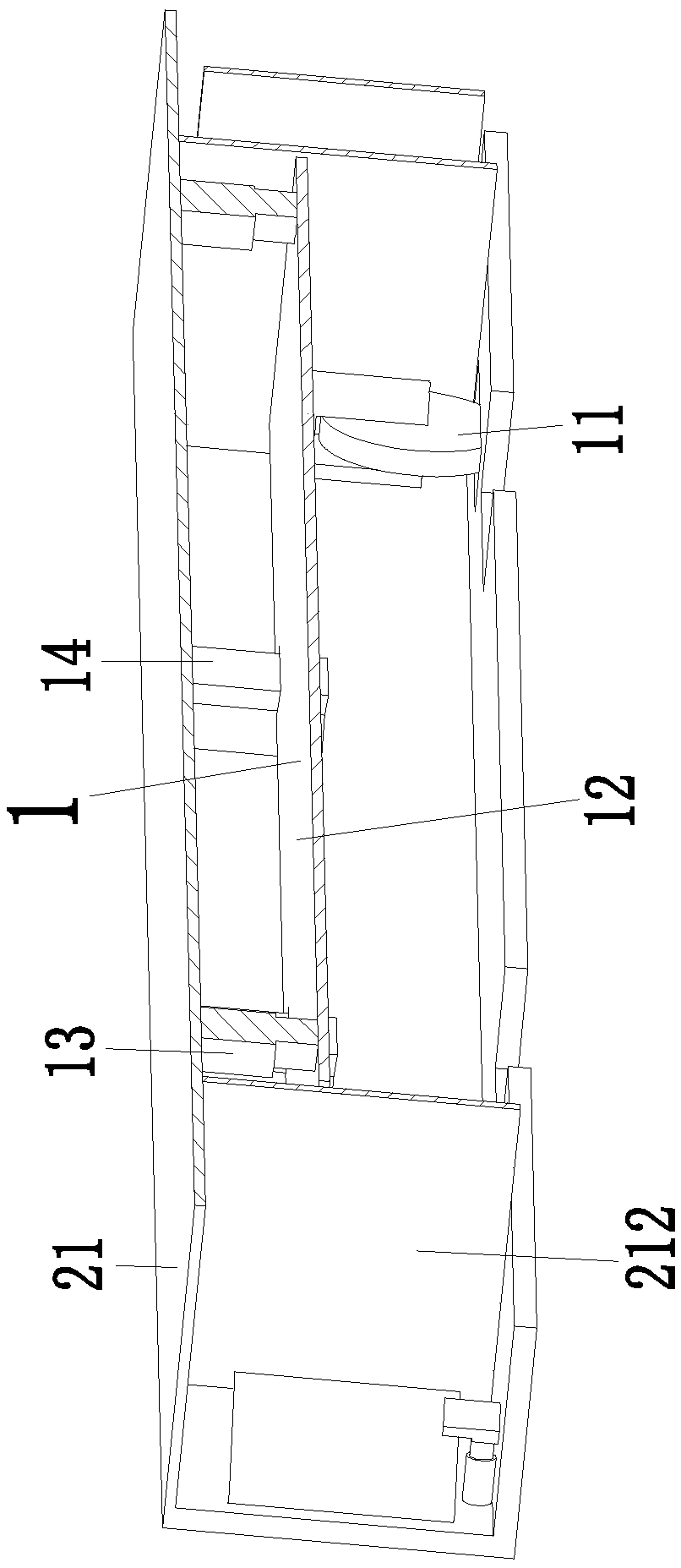

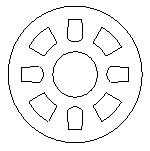

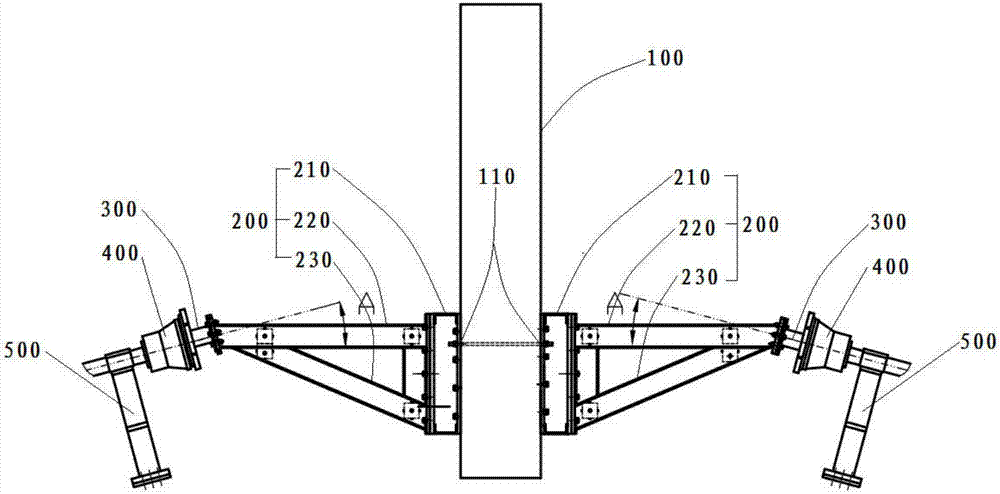

Light self-climbing shield frame system and construction method thereof

PendingCN110043020ASimple structureSmall sizeBuilding material handlingScaffold accessoriesSupporting systemEngineering

The invention discloses a light self-climbing shield frame system and a construction method thereof, and relates to the technical field of formwork systems. The light self-climbing shield frame systemand the construction method thereof are used for solving the problems of the tedious lifting process of a lifting system and an anti-falling device and low safety. The light self-climbing shield frame system includes a scaffold system, a supporting system, a lifting system and an anti-tilting and anti-falling system. The supporting system includes a bearing frame which is fixed on a structural steel beam; the lifting system includes an electric block, a bottom guiding wheel and a steel wire rope, wherein the electric block is arranged at the top of the scaffold system, the bottom guiding wheel is fixed to the bottom of the scaffold system, one end of the steel wire rope is connected with the electric block, and the other end of the steel wire rope passes through the bottom guiding wheel to be arranged at the bottom of the bearing frame in a hung mode; the anti-tilting and anti-falling system includes a guiding rail installed on a scaffold frame body, and an anti-falling pawl wheel, alimiting spring, an anti-falling pawl and a limiting baffle are arranged on the bearing frame; the anti-falling pawl wheel meshes with the guiding rail, the limiting spring is used for limiting the stroke of the anti-falling pawl, and the anti-falling pawl and the limiting baffle are used for preventing the anti-falling pawl wheel from rotating counterclockwise. Therefore, falling of the scaffoldframe body and the guiding rail is prevented, and the anti-falling effect is achieved advantageously.

Owner:SHANGHAI CONSTR NO 1 GRP

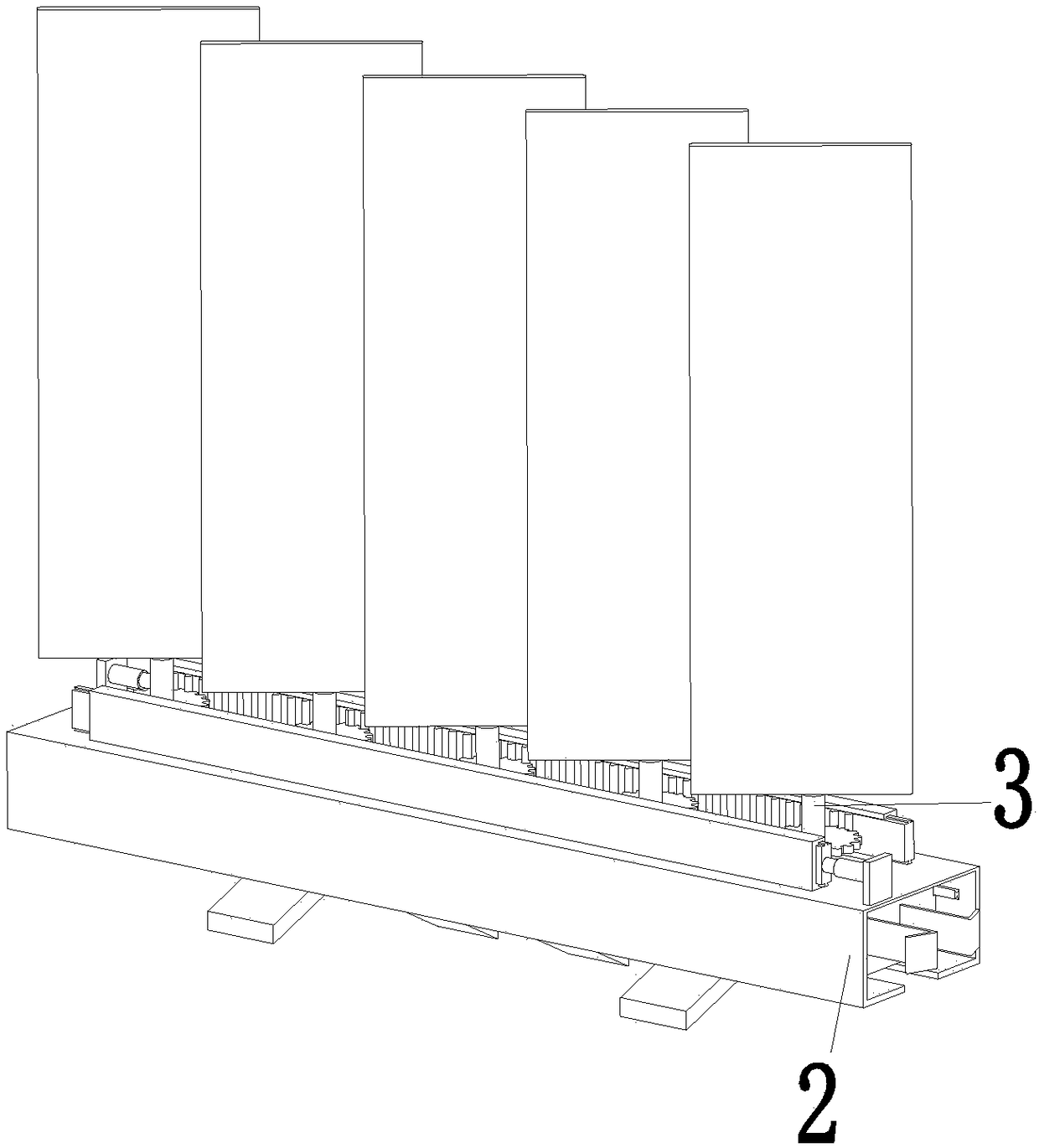

Novel architectural glass enclosing wall

ActiveCN109083499ANot easy to moveQuick fixFencingBuilding constructionsArchitectural glassEngineering

The invention relates to a novel architectural glass enclosing wall. The architectural glass enclosing wall comprises a moving device, a fast fixing device and a rotating device. The moving device ismounted on the inner side face of the fast fixing device, and the rotating device is mounted on the upper end face of the fast fixing device. The architectural glass enclosing wall can solve the problems that time and labor are wasted when existing glass enclosing walls are installed and fixed, the glass enclosing walls cannot be fast spliced and folded, and the air permeability cannot be adjustedunder the condition of ensuring an anti-theft effect; the glass enclosing wall can achieve the functions of fast installation and foldability.

Owner:SUZHOU HUAJIAN GLASS

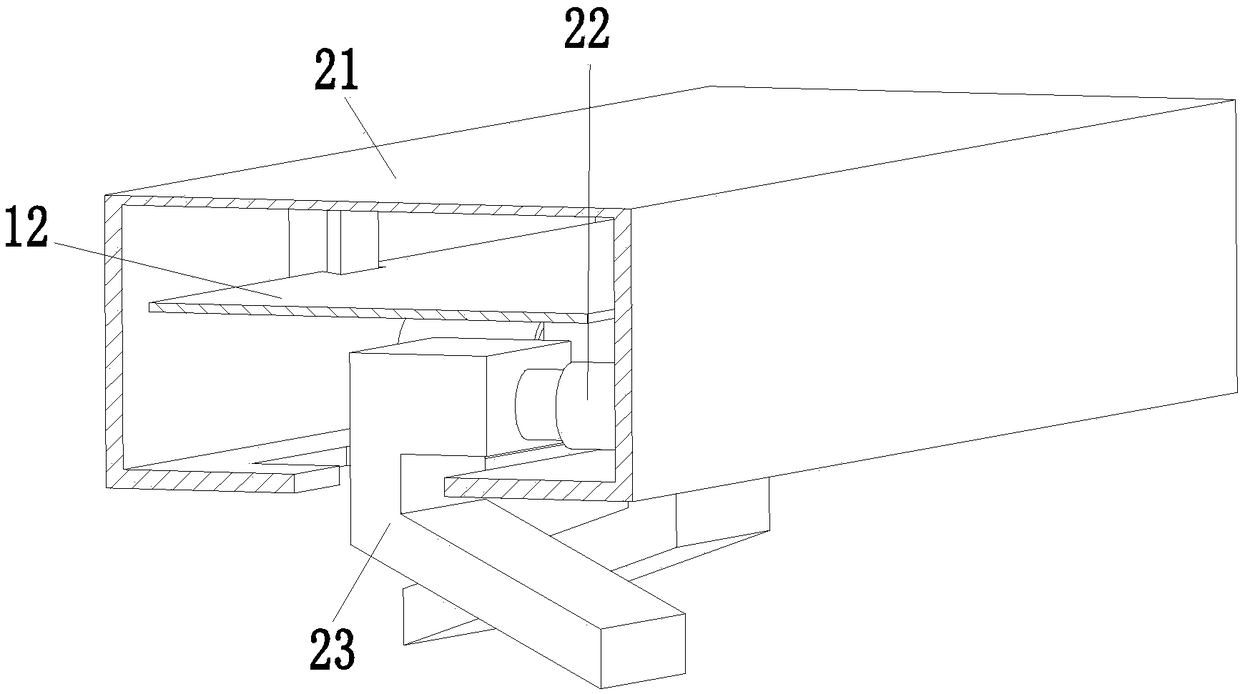

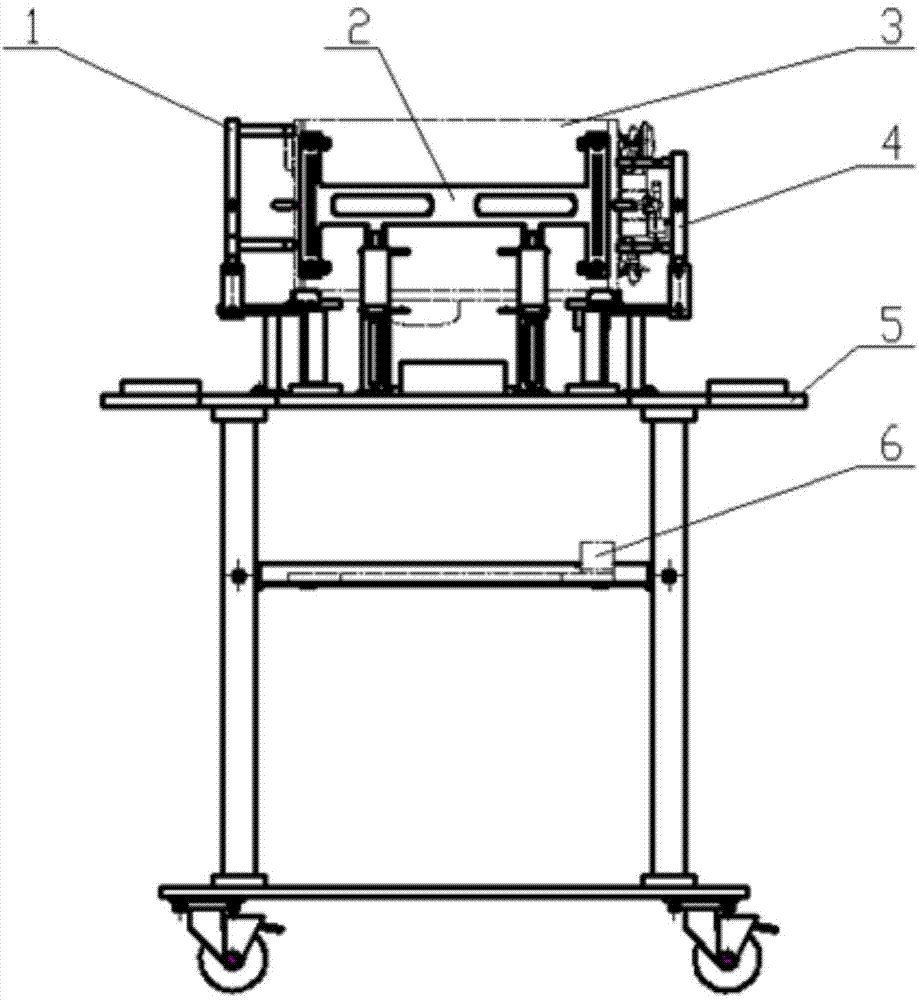

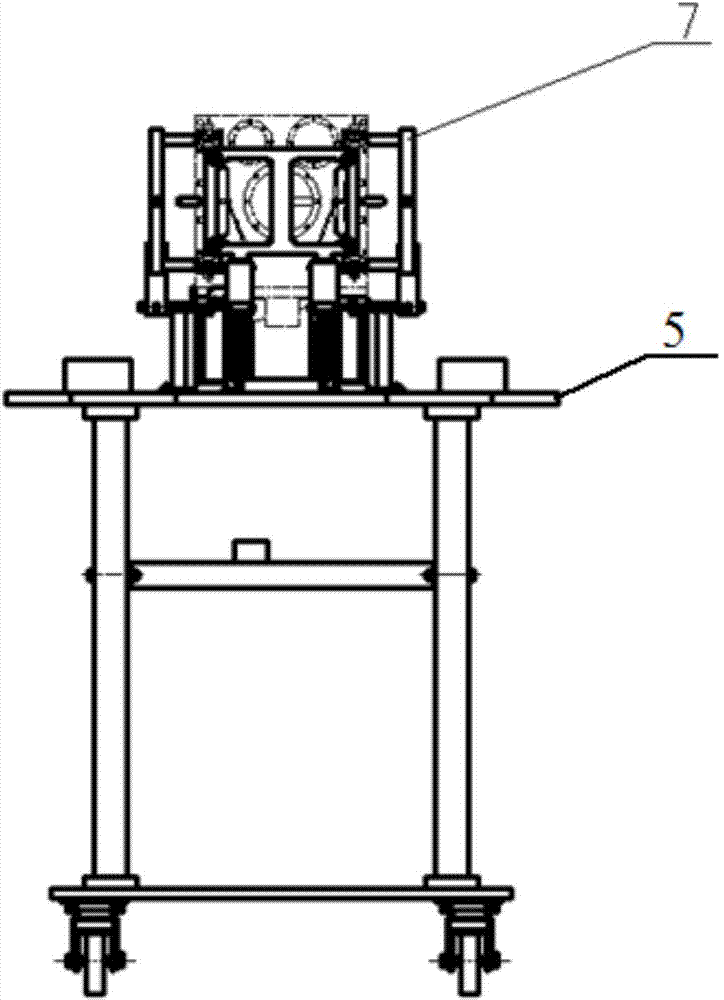

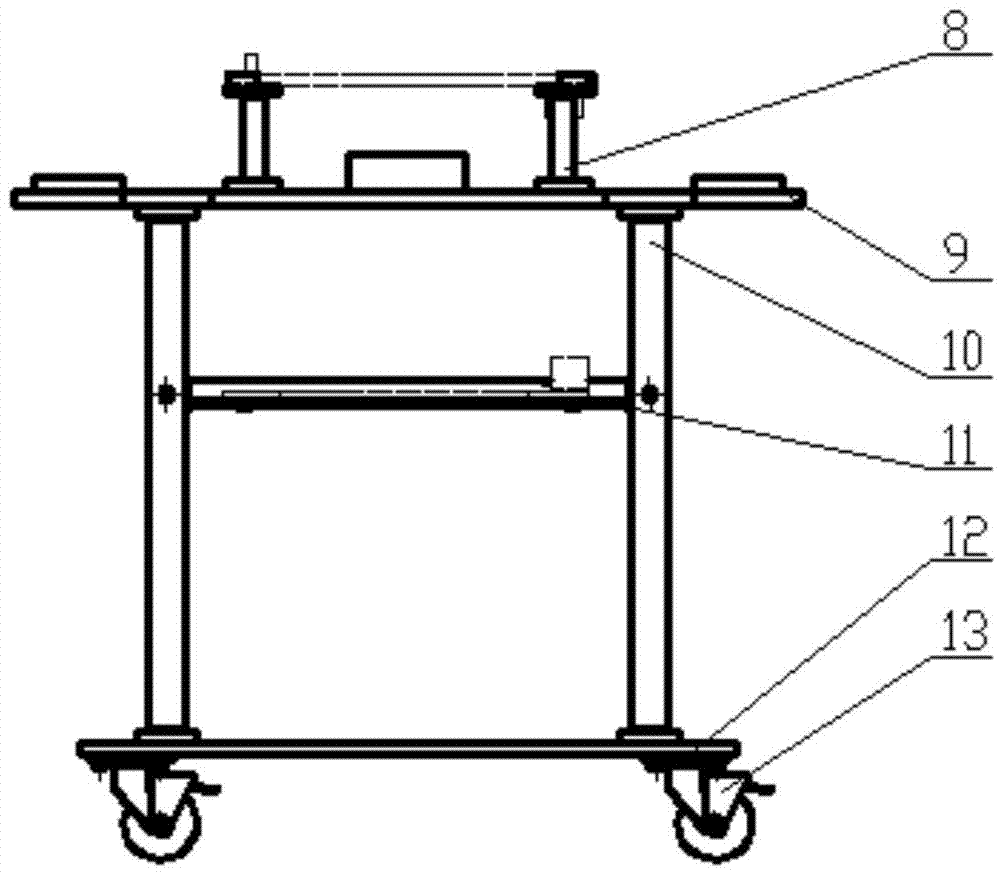

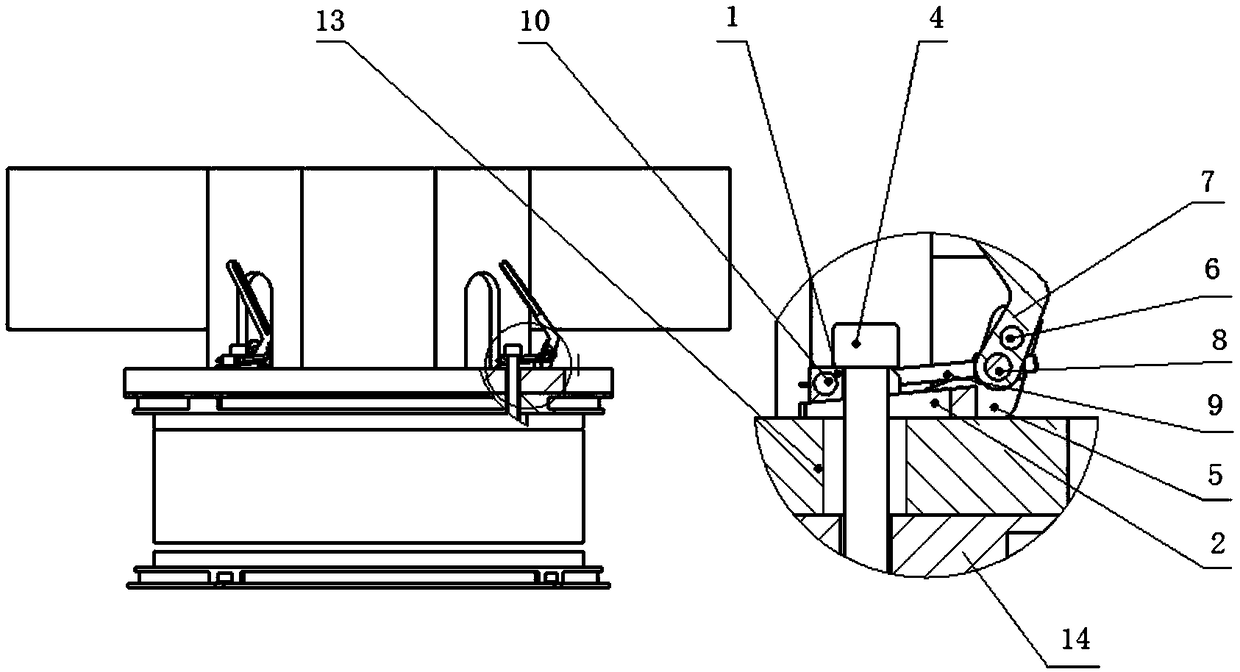

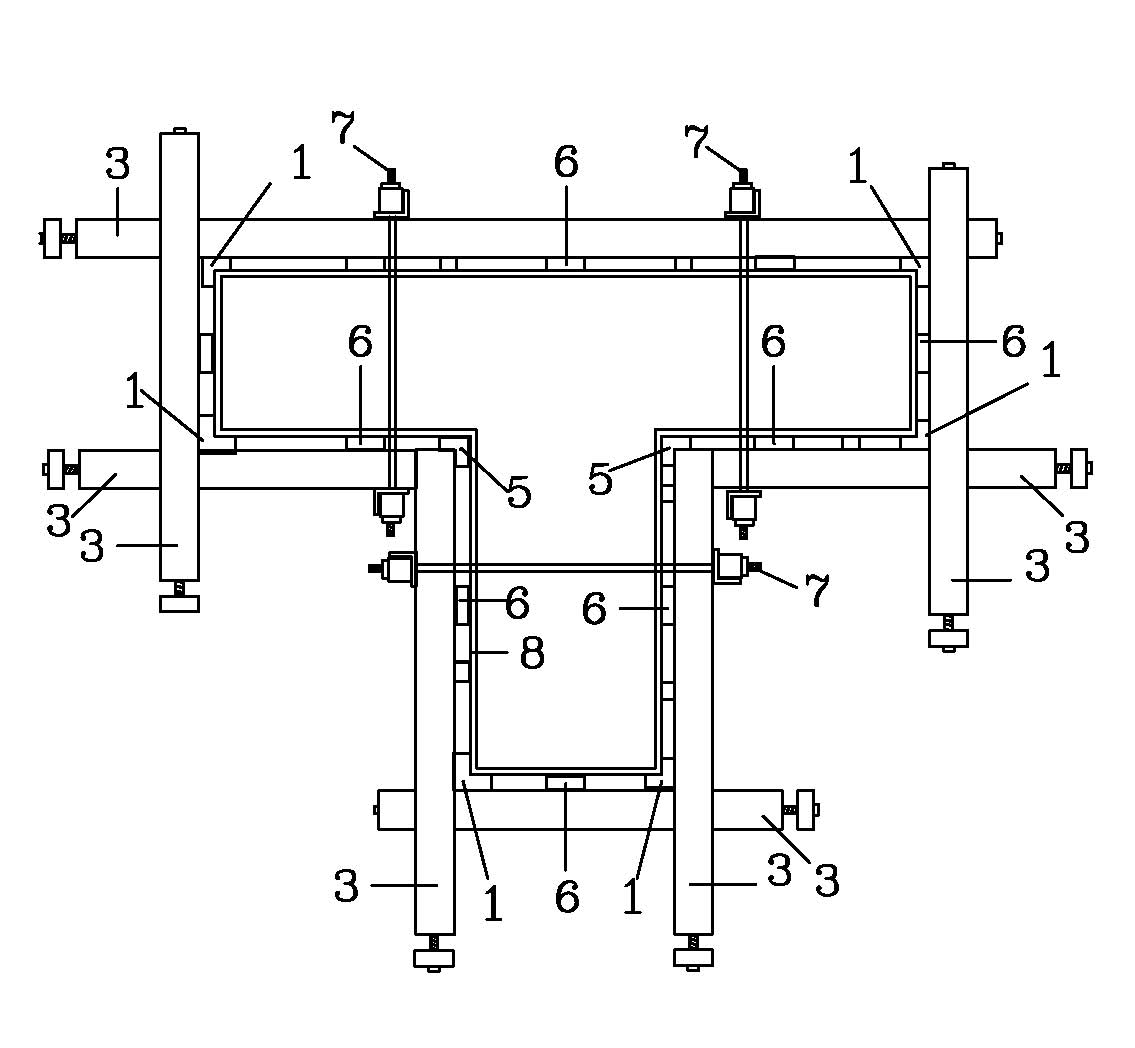

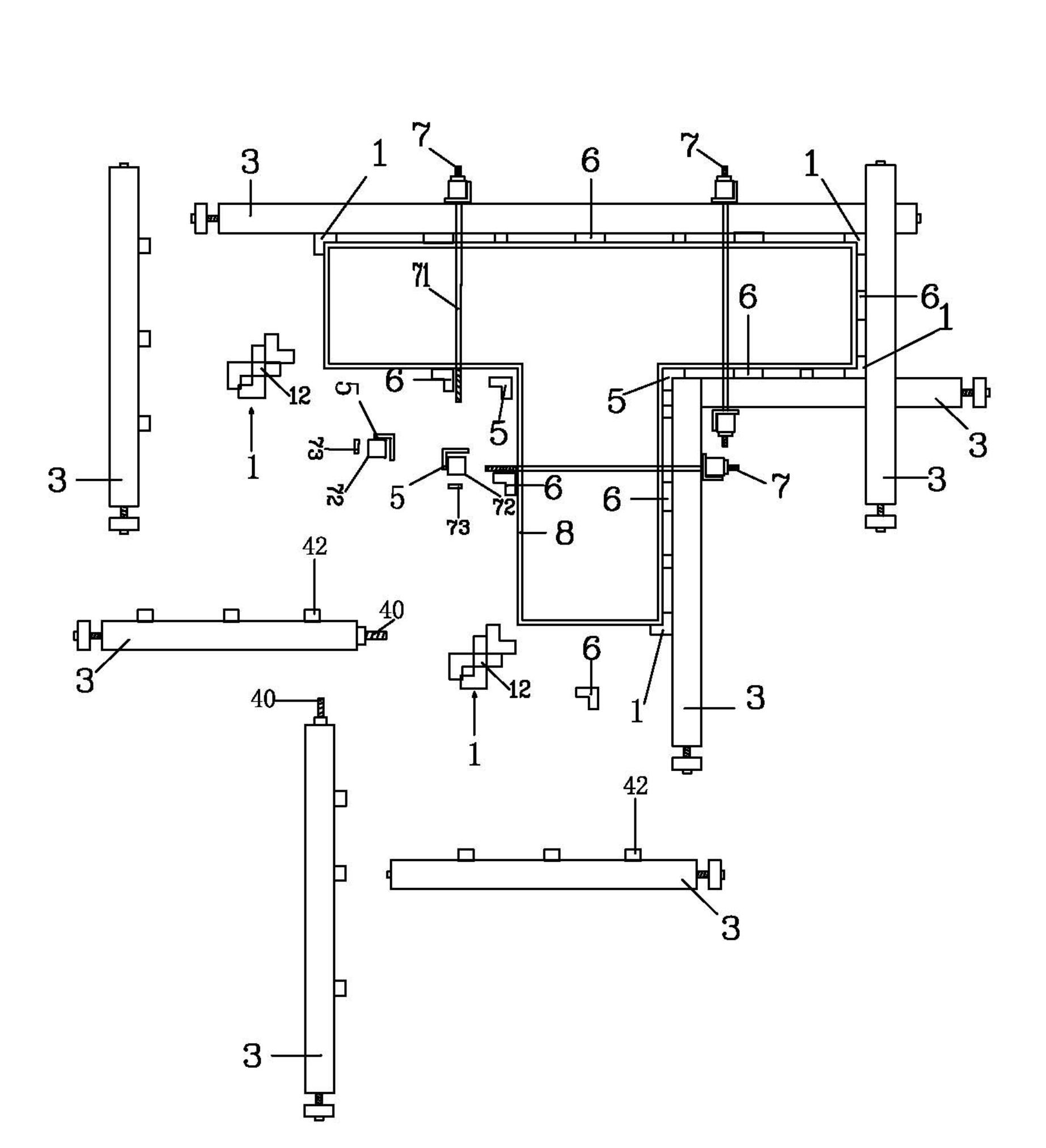

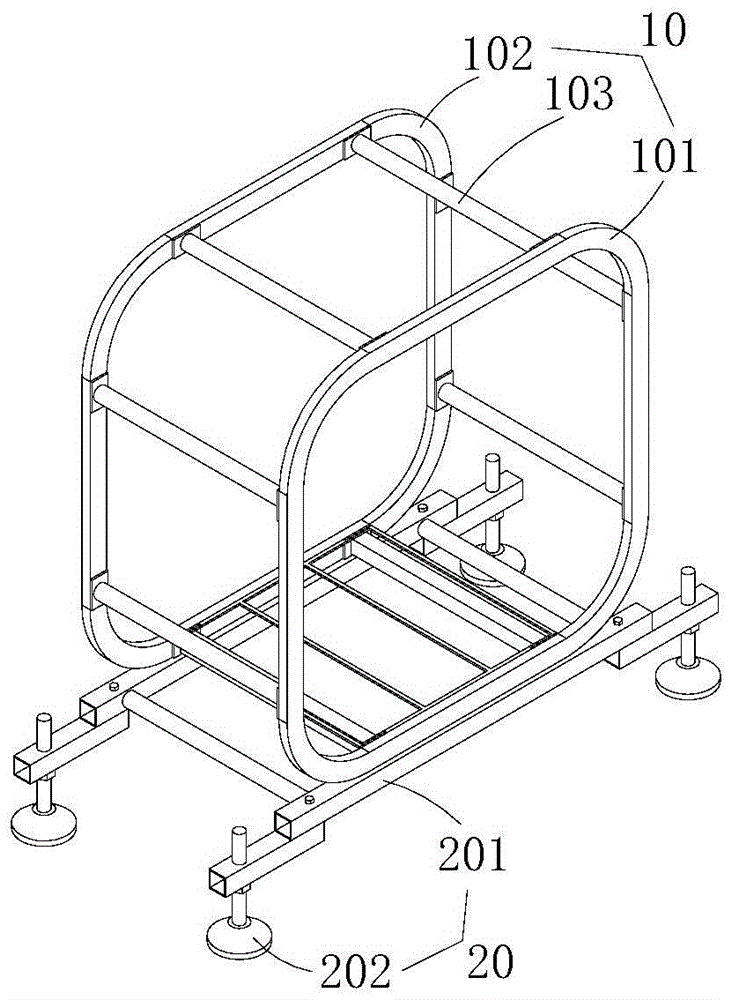

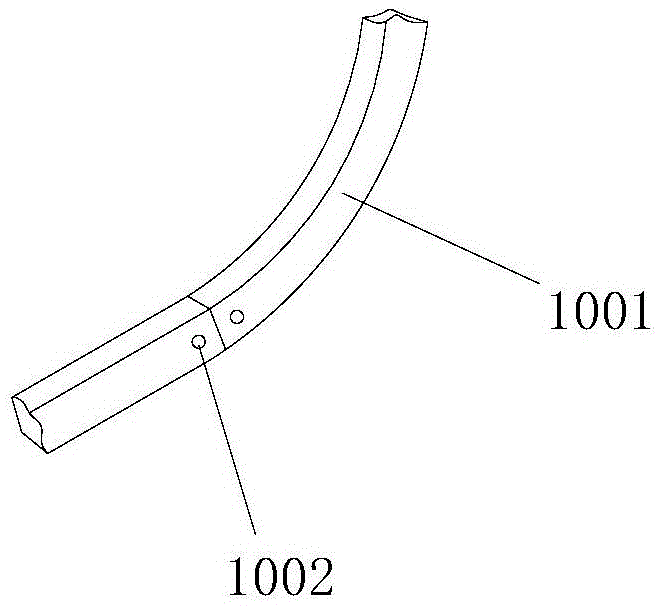

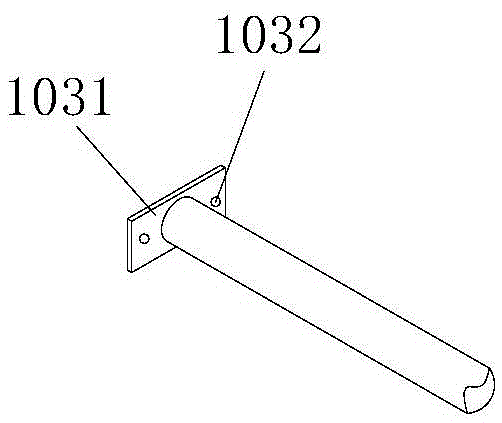

Table top type microsatellite rapid final assembly operation table

ActiveCN104191231AEasy to operateImprove efficiencyAssembly machinesWork benchesSatelliteMaterial resources

The invention discloses a table top type microsatellite rapid final assembly operation table. The table top type microsatellite rapid final assembly operation table is composed of a left side plate mounting mechanism and the like. A front side plate mounting mechanism is arranged on the front side above an operation table body, a right side plate mounting mechanism is arranged on the right side above the operation table body, a rear side plate mounting mechanism is arranged on the rear side above the operation table body, one satellite body is surrounded by the left side plate mounting mechanism, the front side plate mounting mechanism, the right side plate mounting mechanism and the rear side plate mounting mechanism, bottom plate mounting supporting columns and rubber gaskets are all fixedly arranged on the upper surface of a table board mounting plate, and stand columns are arranged between a table body bottom plate and the table board mounting plate. According to the operation table, the microsatellite rapid assembling requirement can be met, the operation table has the advantages of being rapid and convenient to operate, high in efficiency, safe, reliable and the like, and a large amount of man power and a large number of material resources are saved.

Owner:SHANGHAI INST OF SATELLITE EQUIP

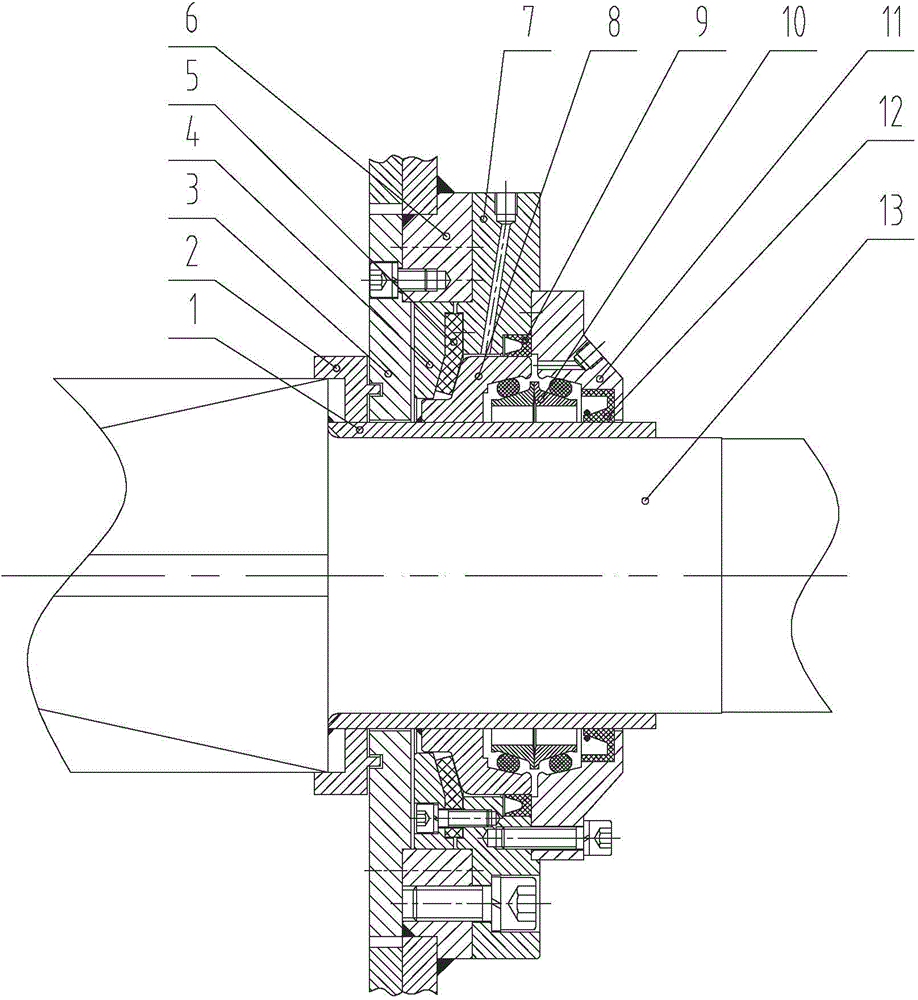

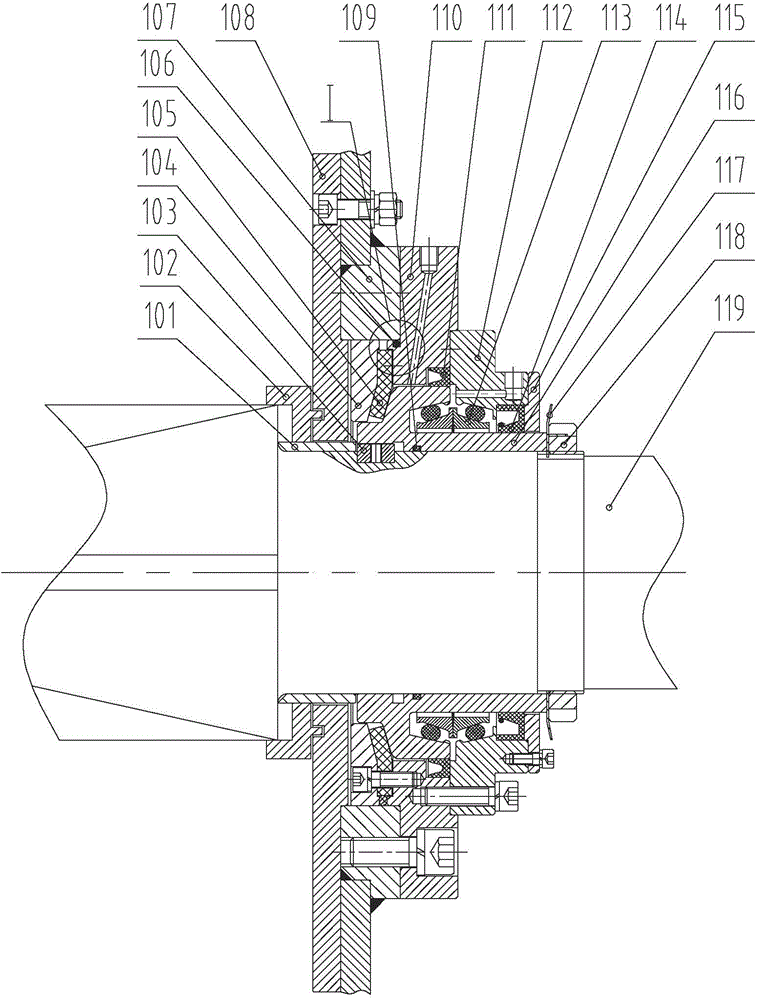

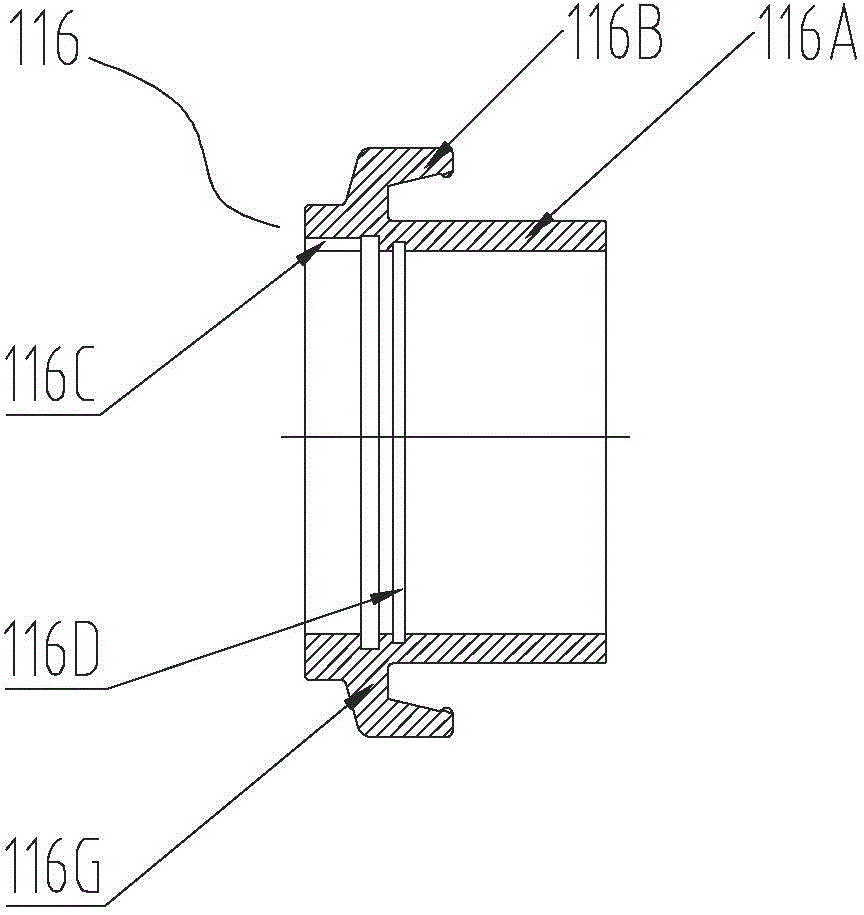

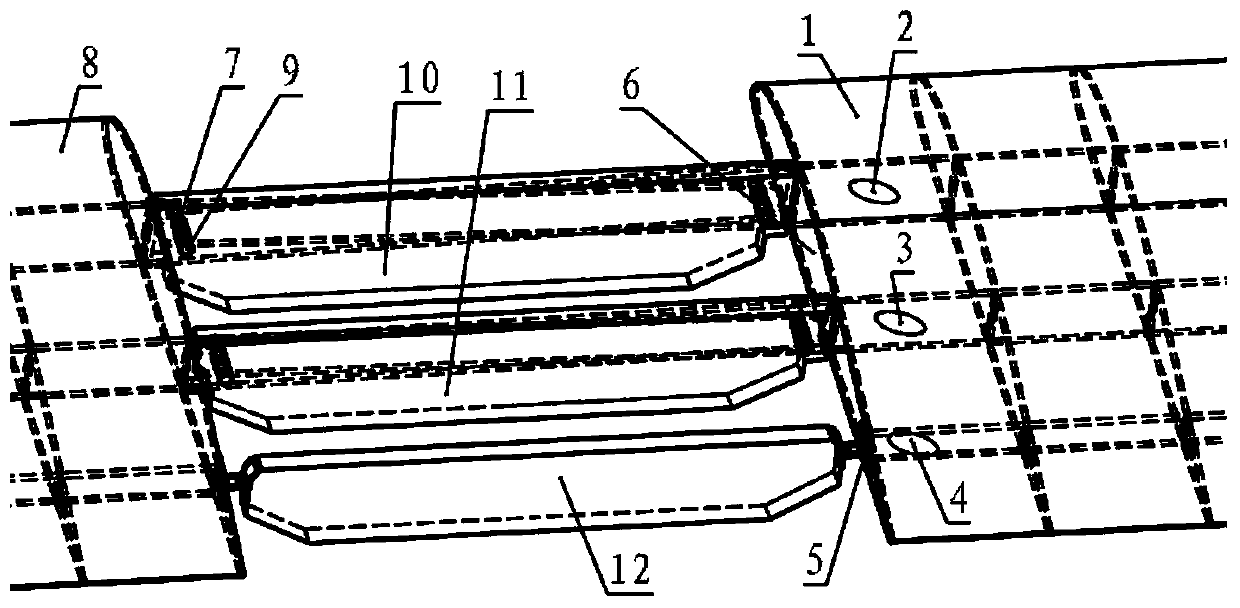

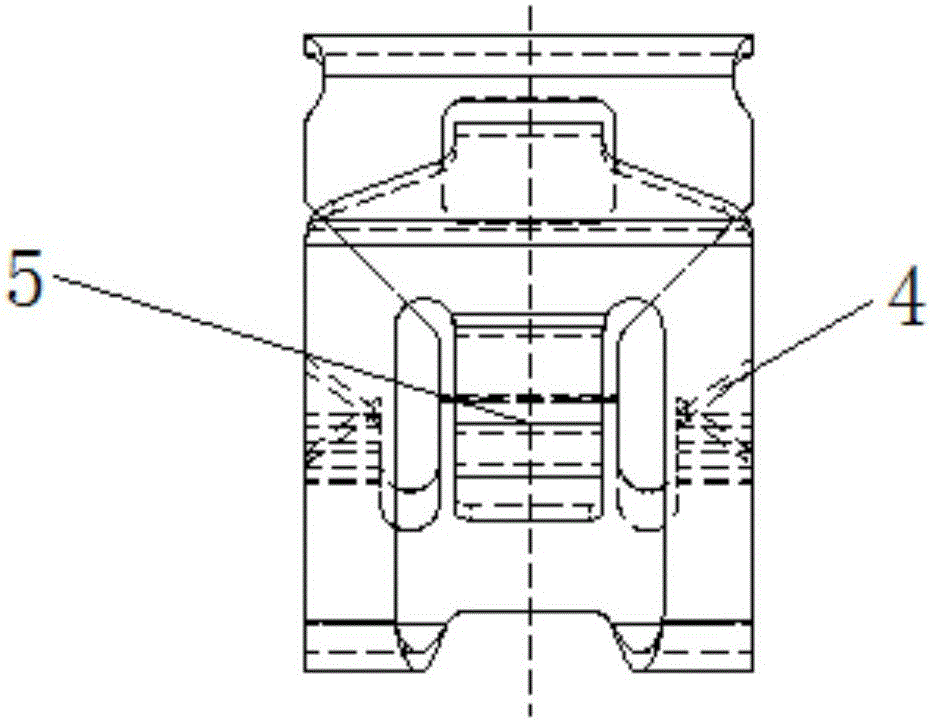

Agitator and shaft end sealing structure thereof and shaft end sealing structure installation method

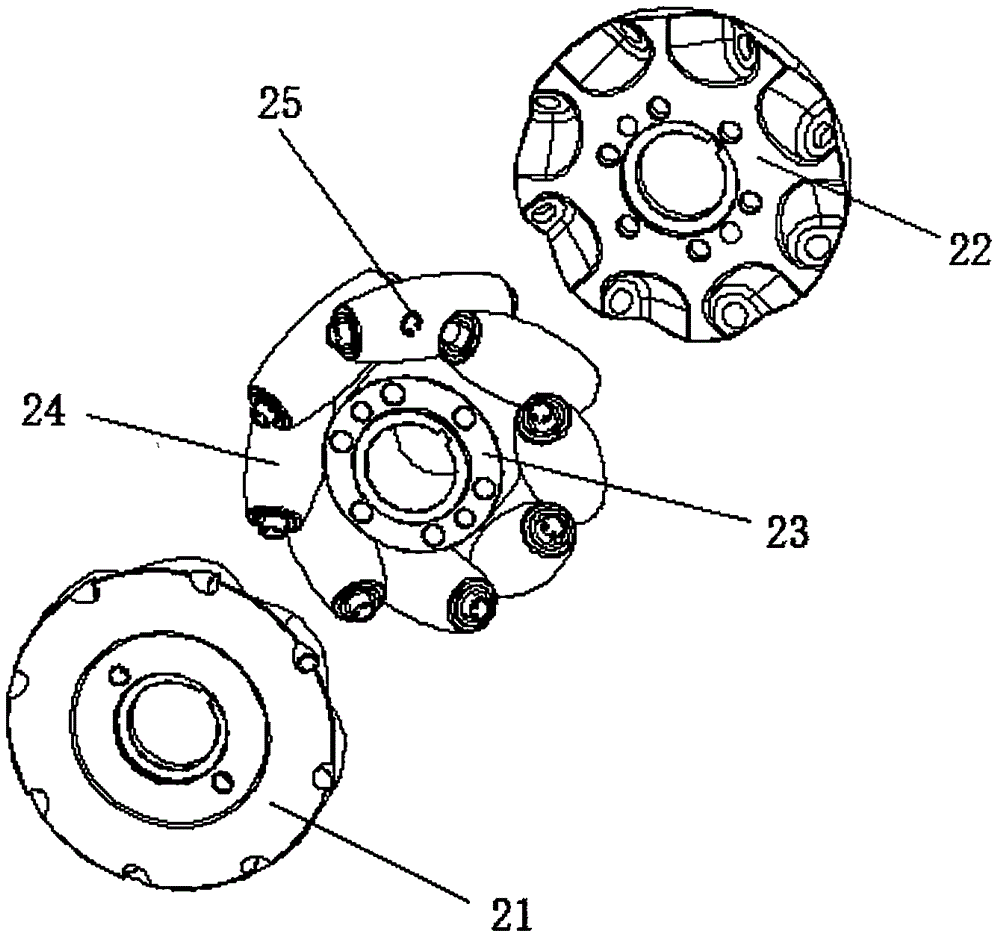

ActiveCN105090516AImprove installation speedIncrease the speed of disassemblyEngine sealsEngineeringMechanical engineering

The invention provides an agitator and a shaft end sealing structure thereof and a shaft end sealing structure installation method. The shaft end sealing structure is arranged at the shaft end of a main shaft of the agitator, and comprises a sealing module and an anti-rotation connecting piece, wherein the sealing module is used for sealing the shaft end of the main shaft, and comprises a rotating hub sleeving the shaft end of the main shaft; the rotating hub and the main shaft are in clearance fit; the sealing module as an integer is detachably connected with the main shaft; and the anti-rotation connecting piece connects the rotating hub of the sealing module to the main shaft so as to enable the rotating hub and the main shaft to synchronously rotate. The sealing module of the shaft end sealing structutre and the main shaft can be assembled together and disassembled repeatedly, the part heating treatment is not needed in installation, and shaft end sealing parts are not needed to be damaged due to disassembly demands, so that the assembly and disassembly time can be shortened, and quick disassembly of the shaft end sealing structure can be realized in repair of the shaft end, so that the repair speed can be increased.

Owner:ZOOMLION HEAVY IND CO LTD

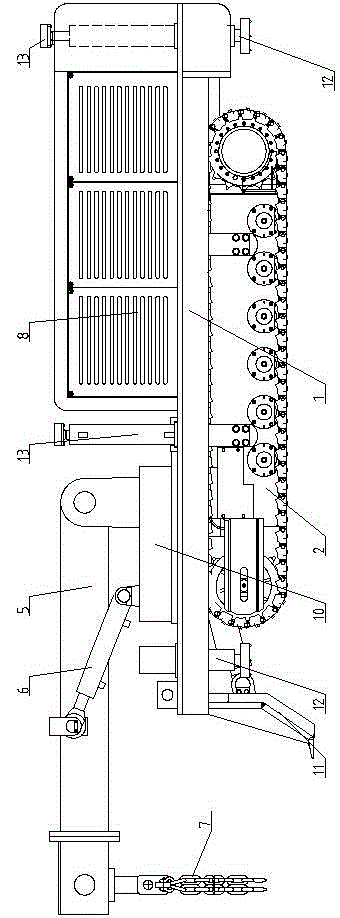

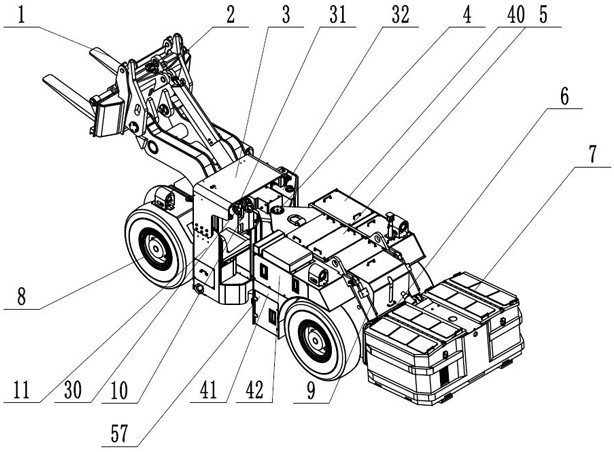

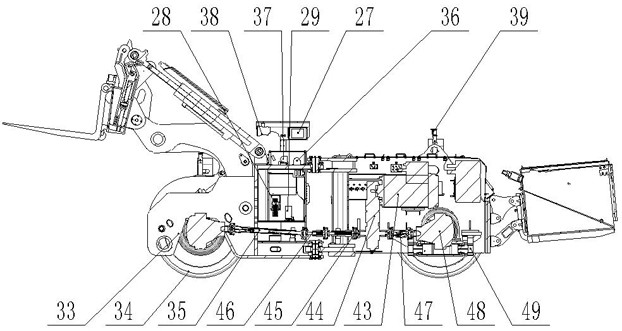

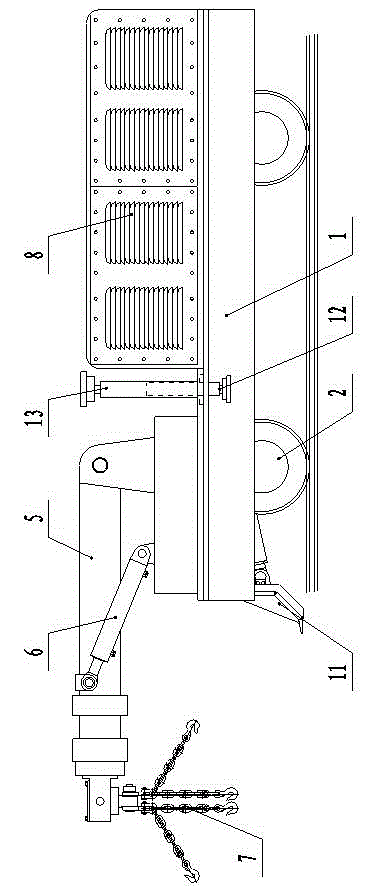

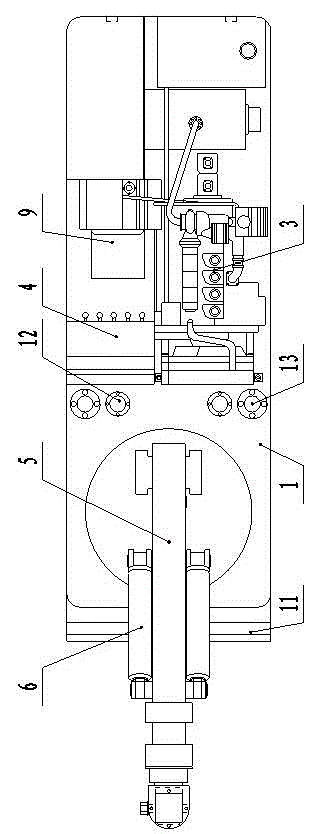

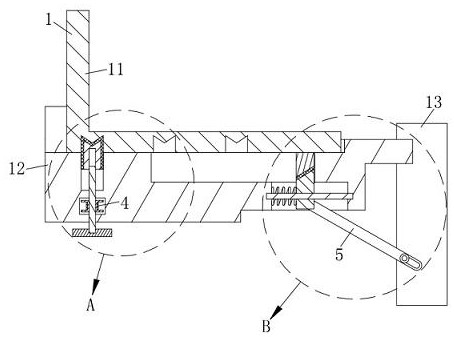

Front cleaning crawler type middle trough multi-azimuth handling machine

InactiveCN103982235AImprove installation speedIncrease the speed of disassemblyEarth drilling and miningUnderground transportAgricultural engineeringEngineering

The invention relates to a front cleaning crawler type middle trough multi-azimuth handling machine, belongs to the technical field of material handling of a roadway, and provides the front cleaning crawler type middle trough multi-azimuth handling machine which is used for conveying materials, can clean coal cinder in the roadway during walking and has the advantages that the construction safety performance and convenience are improved. The invention adopts the technical scheme that the front cleaning crawler type middle trough multi-azimuth handling machine is characterized in that the lower part of a rack is provided with a crawler type walking device, a suspension arm part is arranged at the front part of the rack through a rotary table, the rotary table is fixedly arranged at the front part of the rack, the rear end of the suspension arm part is hinged to the rotary table, the front end of the suspension arm part is provided with a chain type lifting hook, a cylinder body of a suspension arm oil cylinder is hinged to the rotary table, the end part of a piston rod of the suspension arm oil cylinder is hinged to the middle part of the suspension arm part, the rear part of the rack is provided with an anti-explosion diesel engine for providing power and a hydraulic system, the rack is also provided with a control panel and a driver seat, and the front end of the bottom of the rack is provided with a bucket. The front cleaning crawler type middle trough multi-azimuth mounting handling machine is mainly used for handling materials in the roadway.

Owner:SHANXI DONGHUA MACHINERY

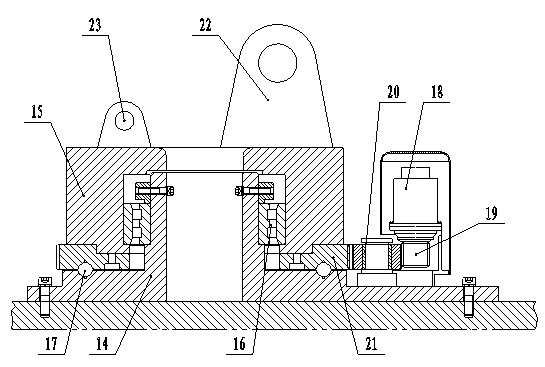

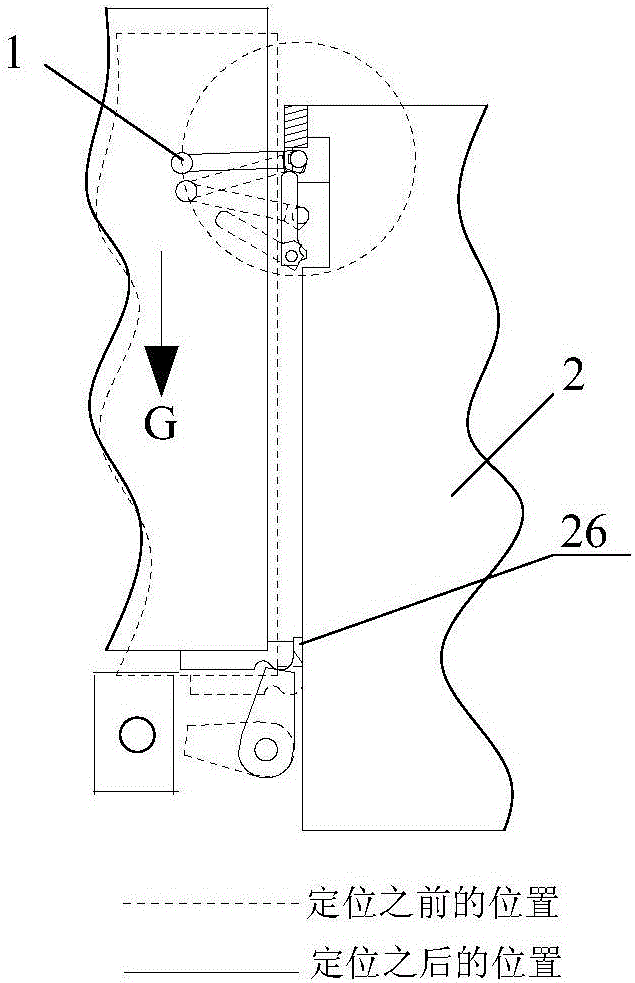

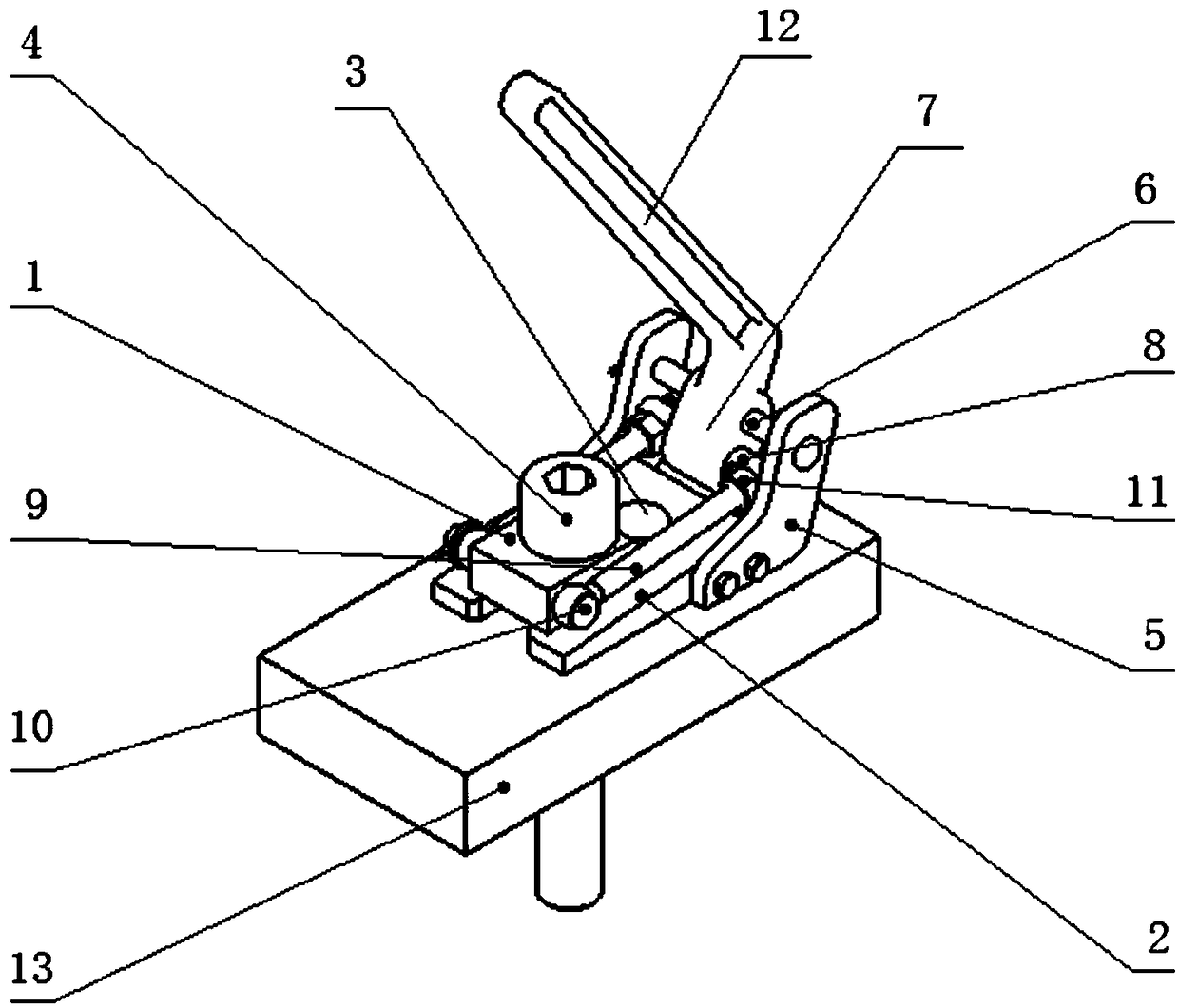

Suspension positioning mechanism

ActiveCN106291853AImprove stabilityImprove reliabilitySemiconductor/solid-state device manufacturingMountingsEngineeringPulley

The invention discloses a suspension positioning mechanism, which comprises a motion assembly and a fixed assembly, and is characterized in that the motion assembly comprises a body, at least two contact blocks arranged at one side of the body, a groove, a hook with one end being accommodated in the groove, and a plurality of height adjustable sliding wheel assemblies arranged at the bottom of the body; one side of the fixed assembly comprises supporting assemblies, a lifting assembly, a hook positioning assembly, a hook shifting lever assembly, an X-direction positioning member and a Y-direction positioning member, wherein the supporting assemblies and the lifting assembly are matched with the contact blocks, the hook positioning assembly and the hook shifting lever assembly are matched with the hook, and the X-direction positioning member and the Y-direction positioning member are used for positioning the motion assembly. According to the invention, the positioning stability and the reliability of the motion assembly can be effectively improved through setting the contact blocks and the supporting assemblies with a balancing function, and the lifting assembly is set at the same time so as to improve the repeat positioning, assembling and disassembling speed of an optical system; and the plurality of height adjustable sliding wheel assemblies are adopted, so that the overall position of the motion assembly is effectively adjusted, the motion assembly is prevented from colliding with a part above the fixed assembly in the positioning process, the operation is simple and convenient, and the effect is stable and reliable.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

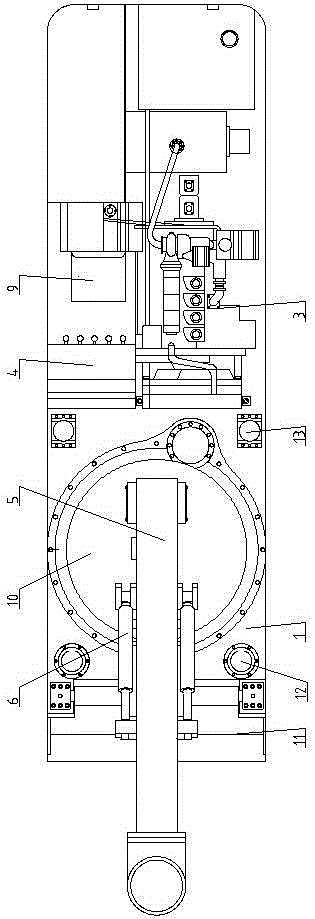

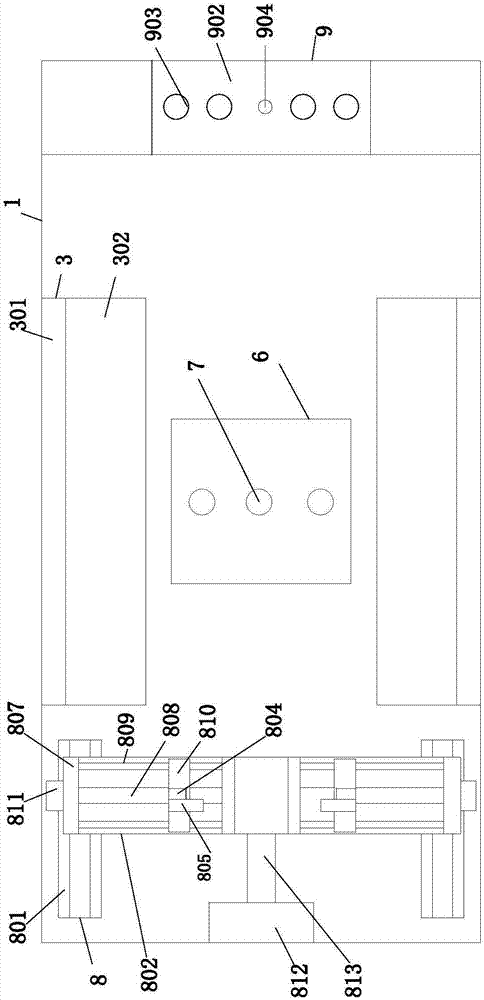

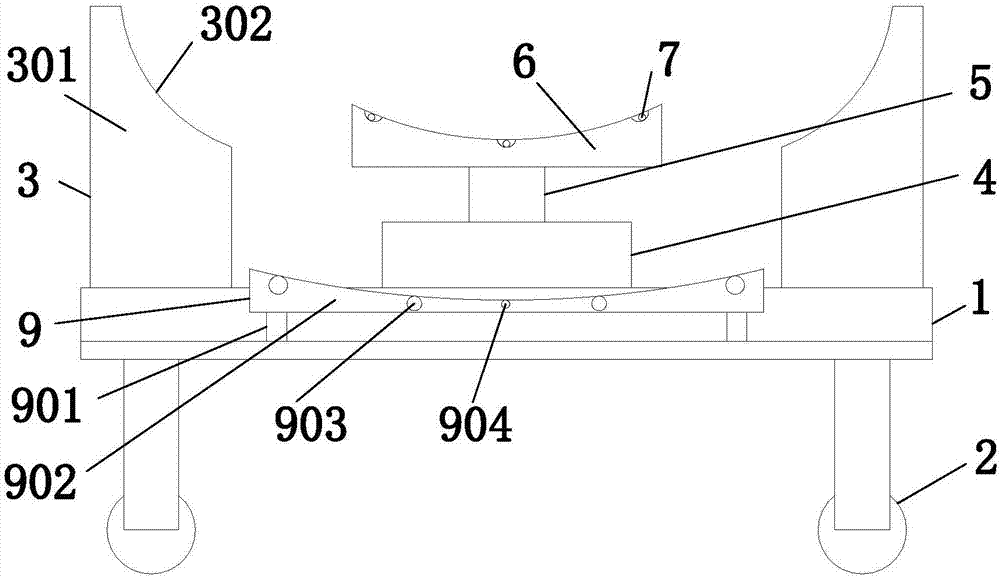

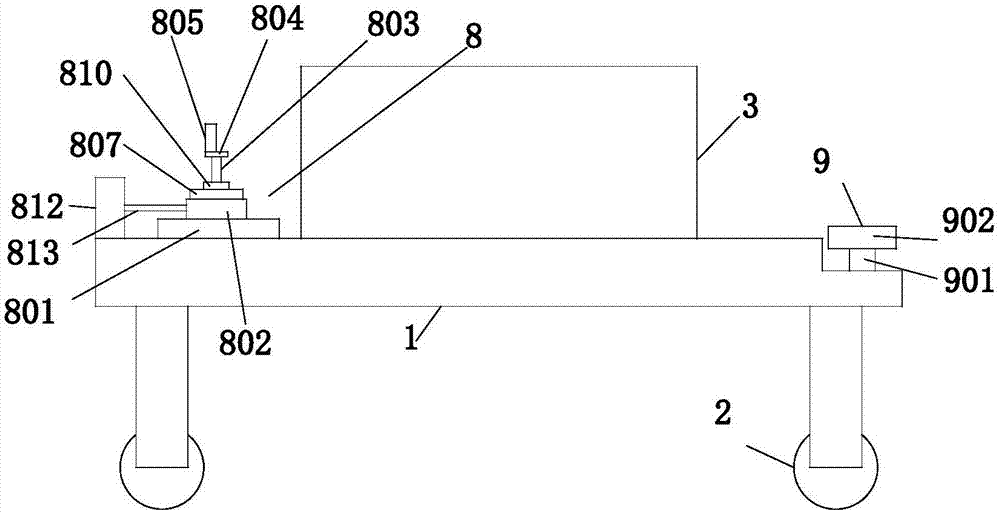

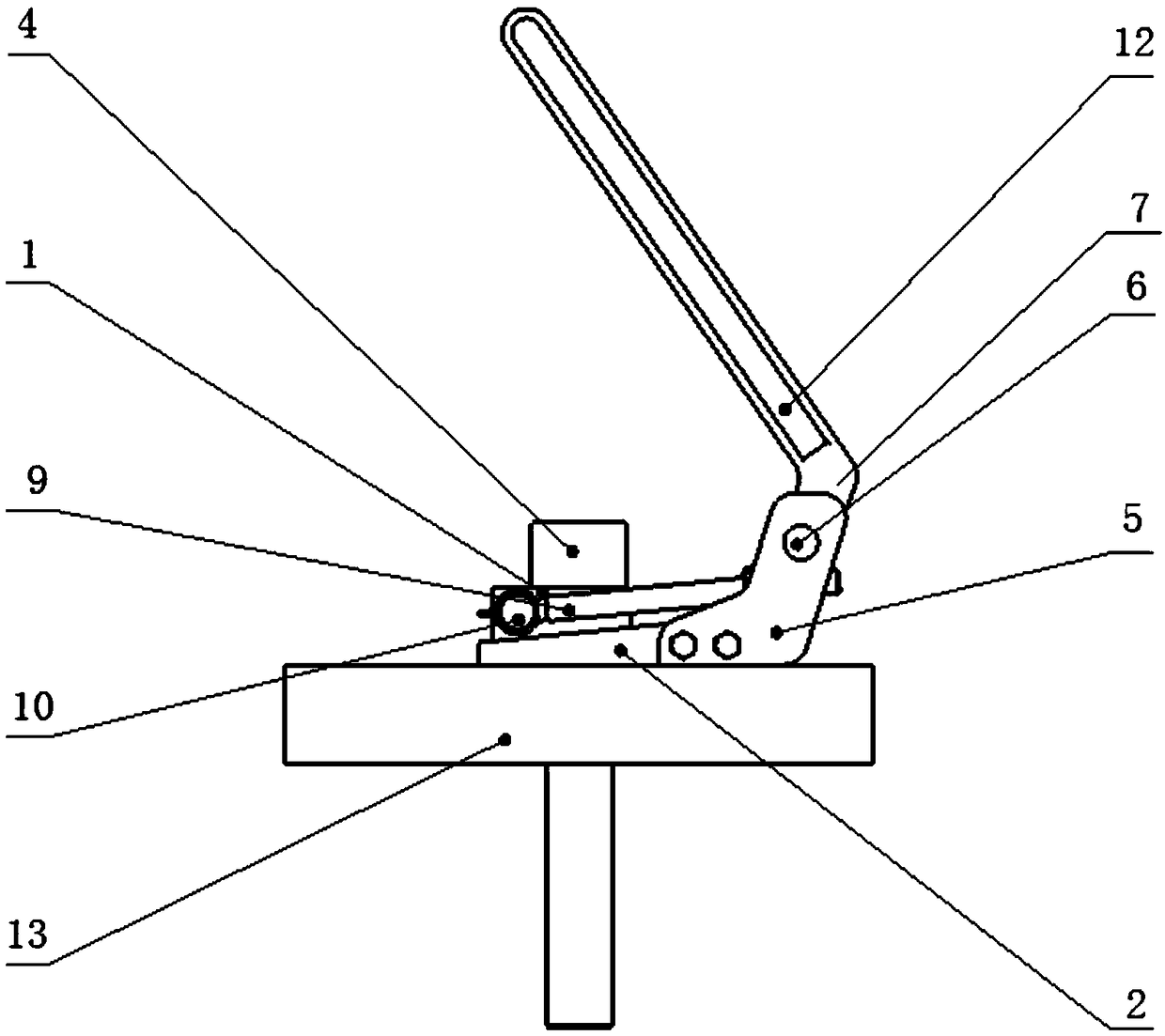

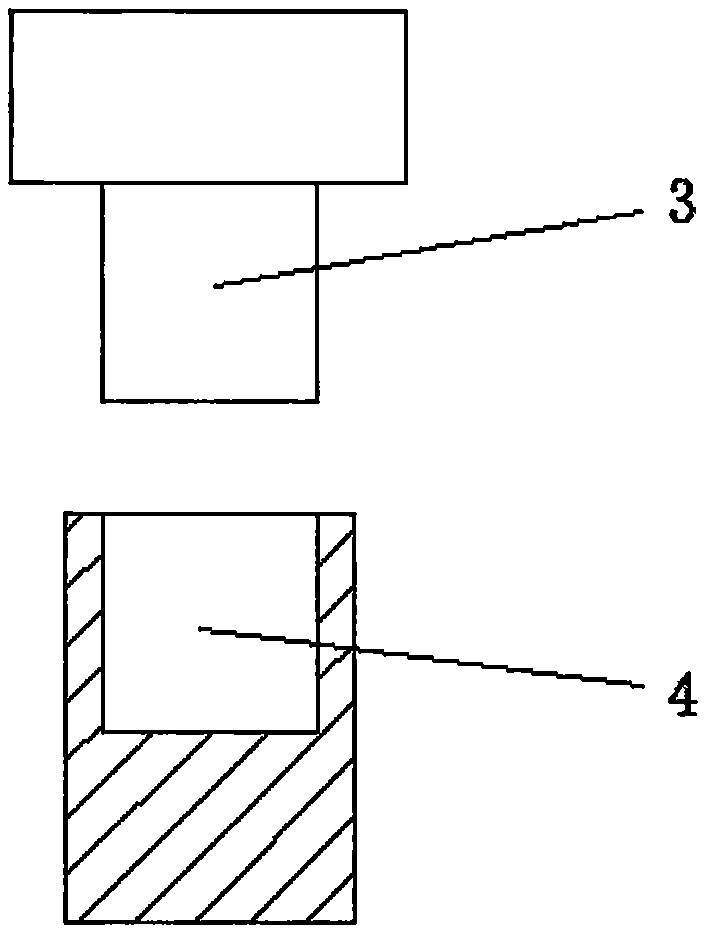

Quick dismounting and mounting equipment for expansion joint of ball valve

ActiveCN107877120AHigh precisionImprove shipping stabilityMetal working apparatusVehicle frameClassical mechanics

The invention discloses quick dismounting and mounting equipment for an expansion joint of a ball valve. The quick dismounting and mounting equipment comprises a vehicle frame (1), wherein moving wheels (2) are arranged at the bottom of the vehicle frame (1); supporting blocks (3) are correspondingly arranged at the front and rear ends of the upper part of the vehicle frame (1); a lifting air cylinder (4) is arranged between the two supporting blocks (3); a supporting frame (5) is arranged at the extending end of the lifting air cylinder (4); an arc-shaped plate (6) is arranged at the upper end of the supporting frame (5); a plurality of grooves are formed in the inner wall of the arc-shaped plate (6); magnets (7) are arranged in all the grooves; a bolt dismounting and mounting mechanism (8) is arranged at the left end of the vehicle frame (1); and an expansion joint fixing mechanism (9) is arranged at the right end of the vehicle frame (1). The quick dismounting and mounting equipmentdisclosed by the invention has the characteristics that the operation difficulty can be lowered, the labor intensity of workers can be reduced, and the dismounting efficiency can be improved.

Owner:STATE GRID CORP OF CHINA +2

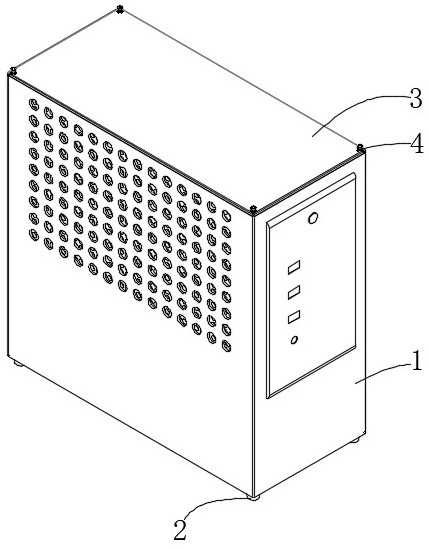

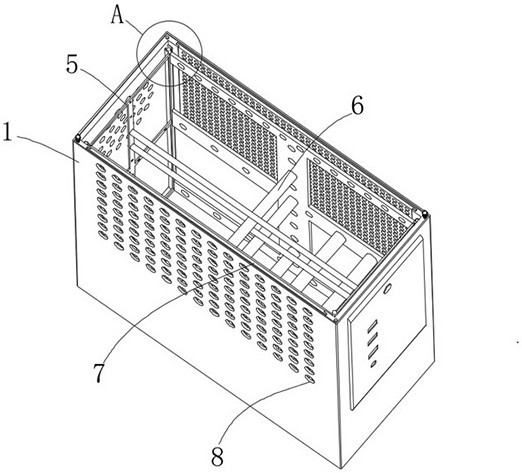

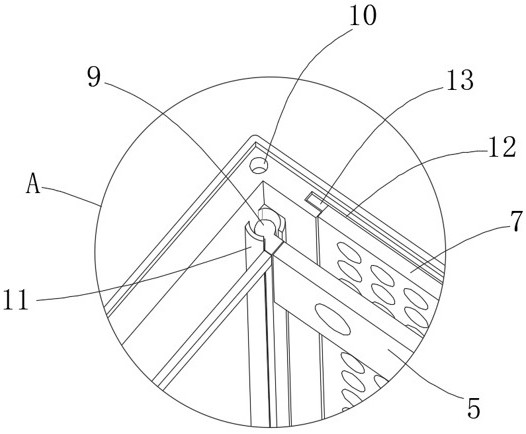

Computer mainframe box used for computer hardware development and convenient for mainboard installation

PendingCN113485533AReduce limitationsIncrease the speed of disassemblyDigital processing power distributionComputer hardwareComputer architecture

The invention provides a computer mainframe box used for computer hardware development and facilitating mainboard installation, and belongs to the technical field of computers. The computer mainframe box used for computer hardware development and facilitating mainboard installation comprises a box body and a cover plate, a sleeve shell is fixedly connected to the inner side of the box body, and a mounting frame is arranged in the box body; and the outer side of the mounting frame is fixedly connected with a fixing column, the mounting frame is movably connected with the box body through the fixing column, and the inner side of the mounting frame is fixedly connected with a connecting rod. According to the computer mainframe box facilitating mainboard installation for computer hardware development, by arranging the box body and the installation frame structure which can be separated, when the mainboard needs to be disassembled and assembled, the installation frame can be separated from the box body, the installation frame is moved out of the box body, and therefore the operation space is increased, the limitation of mainboard disassembly and assembly is reduced, the maintenance cost of the mainboard is reduced, and popularization and application are facilitated.

Owner:HENAN POLYTECHNIC

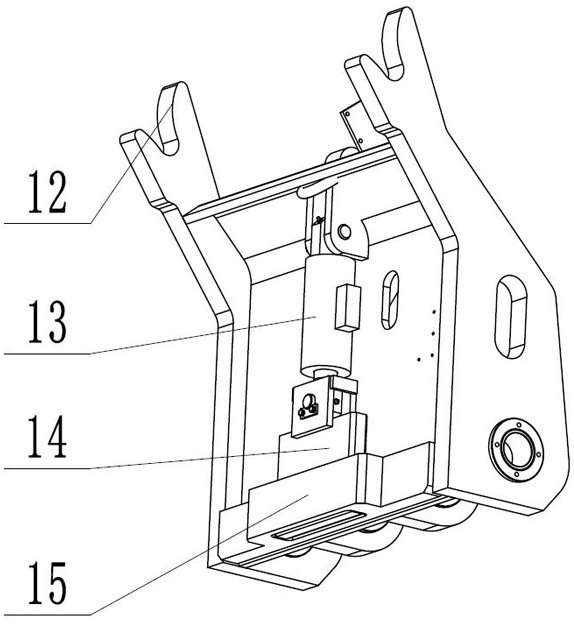

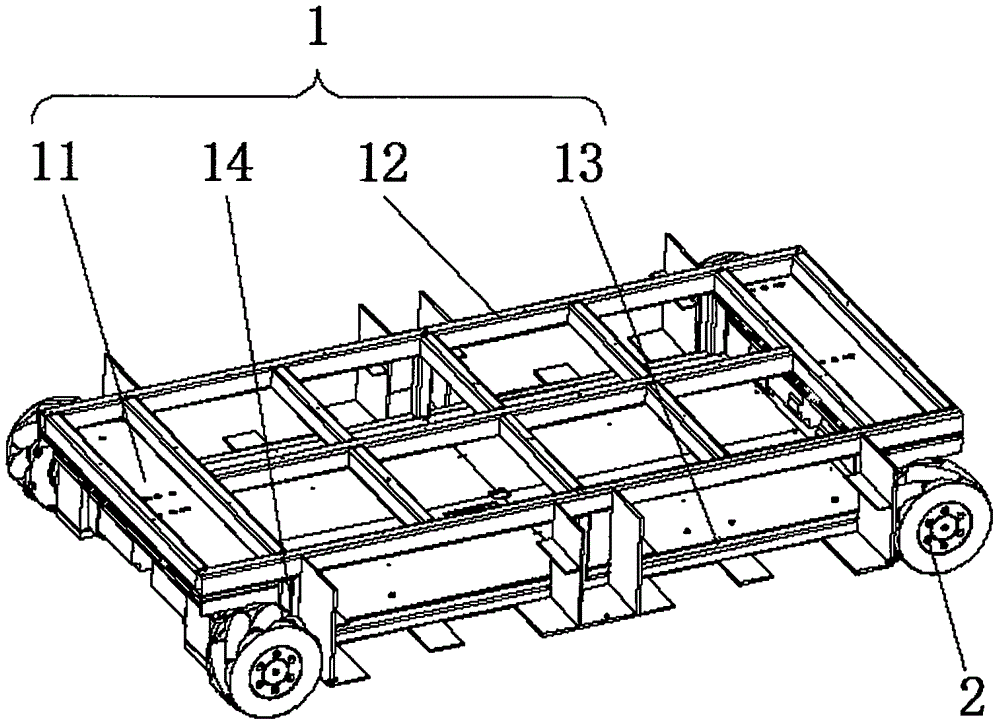

Split type storage battery chute carrier capable of being quickly disassembled to enter and exit from cage

ActiveCN112324491AIncrease the speed of the connectionIncrease the speed of disassemblyMining devicesLifting devicesControl systemForce sensor

The invention discloses a split type storage battery chute carrier capable of being rapidly disassembled to enter and exit from a cage, and belongs to the technical field of design and manufacturing of coal mine underground auxiliary transportation equipment. The carrier comprises a control system, a carrying mechanism at the front part, a carrying mechanism quick-change device connected with thecarrying mechanism, a front rack connected with the carrying mechanism quick-change device, a middle pin shaft quick-release device connected with the front rack, a rear rack connected with the middlepin shaft quick-release device, and a battery bracket quick-release device connected with the rear rack. The carrying mechanism is provided with a lock pin hole, the carrying mechanism quick-change device is provided with a lock pin plate and a pressure sensor, and the pressure sensor is used for detecting the pressure value between the carrying mechanism and the carrying mechanism quick-change device. The control system is used for executing coupling or separation of the lock pin plate and the lock pin hole according to the pressure value. The vehicle body disassembling speed is increased, the tank discharging speed is increased, and the working efficiency is improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

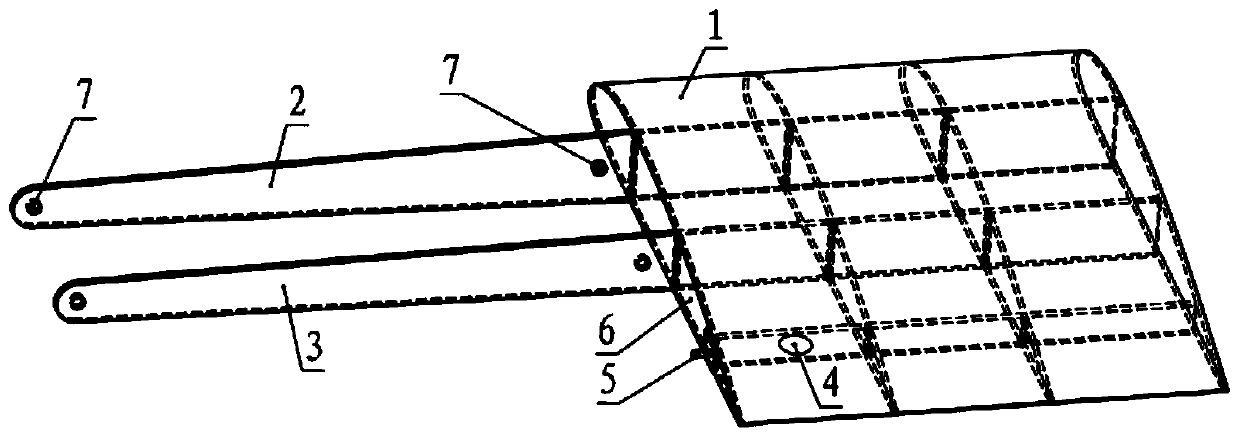

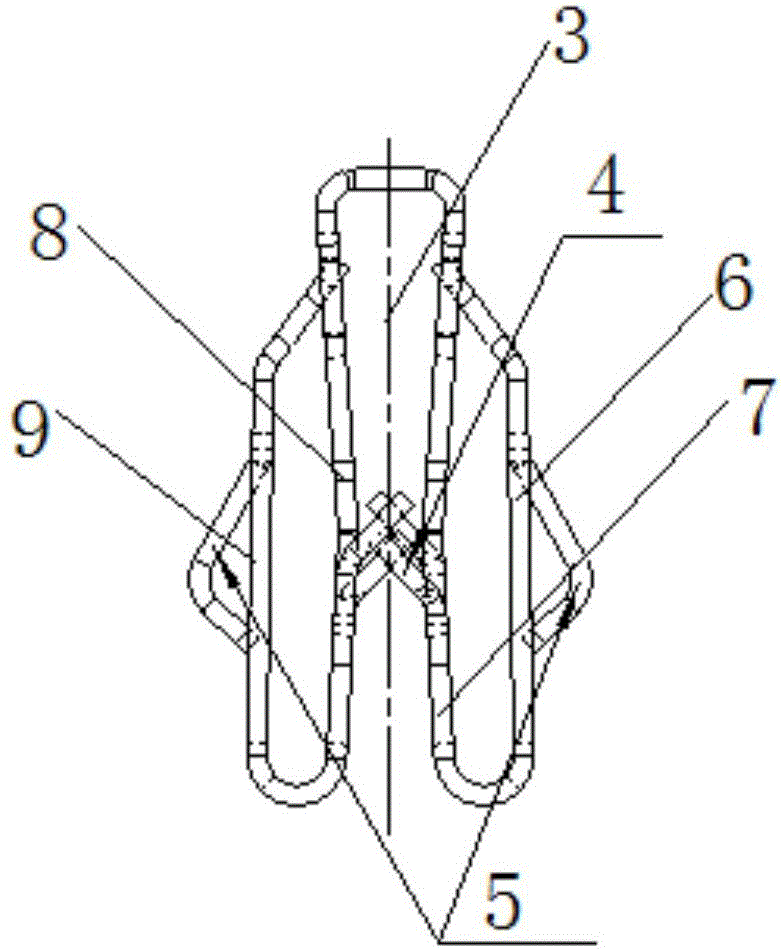

Ground effect vehicle wing structure capable of being quickly disassembled

PendingCN110920884AReduce installation difficultyReduce the difficulty of disassemblySpars/stringersFuselagesMarine engineeringFlight vehicle

The invention belongs to the field of small ground-effect aircraft body structures, and provides a ground-effect aircraft wing structure capable of being quickly demounted, the wing structure comprises a left wing 8 and a right wing 1, and the left wing 8 and the right wing 1 are the same in structure; the left wing 8 and the right wing 1 are detachably connected to the left side and the right side of the hull reinforcer respectively; wherein the right wing 1 comprises a front beam 2, a middle beam 3 and at least one root rib 6, and one end of the front beam 2 and one end of the middle beam 3are connected with the root rib 6; the other ends of the front beam 2 and the middle beam 3 are inserted into the ship body reinforcer and are detachably connected with the ship body reinforcer through pin shafts 9; positioning parts are arranged on the root ribs 6, and when the front beam 2 and the middle beam 3 are inserted into the ship body reinforcing parts, the positioning parts are insertedinto the limiting holes of the ship body reinforcing parts to limit the wings. The installation and disinstallation difficulty of the wing is reduced, and the installation and disinstallation speed is increased.

Owner:CHINA SPECIAL TYPE FLIER RES INST

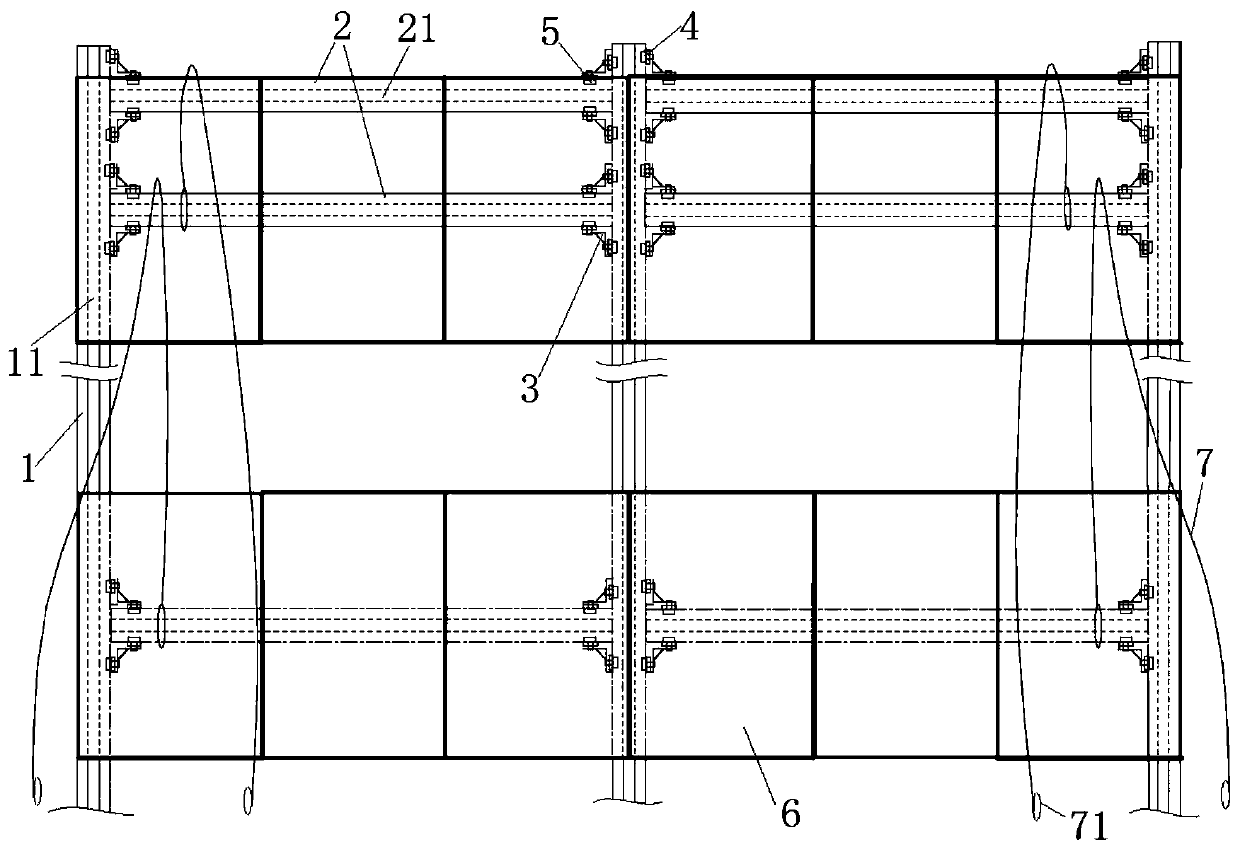

Assembly type television splicing screen mounting device and mounting method thereof

The invention relates to an assembly type television splicing screen mounting device and a mounting method thereof. The assembly type television splicing screen mounting device comprises vertical brackets, transverse brackets, connectors, lifting ropes and splicing screens; the bottoms of the vertical brackets are connected onto the ground; the transverse brackets are parallelly erected between the adjacent vertical brackets; first mounting rails are arranged on the vertical brackets; second mounting rails are arranged on the transverse brackets; one end of each connector is connected with thecorresponding first mounting rail by a first locking piece; the other end of each connector is connected with the corresponding second mounting rail by a second locking piece; one lifting rope is arranged between the two adjacent transverse brackets, and is wound on the transverse bracket on the upper side; one end of each lifting rope is connected with the corresponding transverse bracket on thelower side; a pull handle is arranged at the other end of each lifting rope and the other ends of the lifting ropes extend to the bottoms of the vertical brackets; the splicing screens are connectedwith the second mounting rails by hooks; all the splicing screens are on the same plane. The mounting device and the mounting method have the advantages of convenience in adjusting, high assembling accuracy, convenience in dismounting and mounting, and high safety.

Owner:GUANGZHOU MECHANICAL & ELECTRICAL INSTALLATION +2

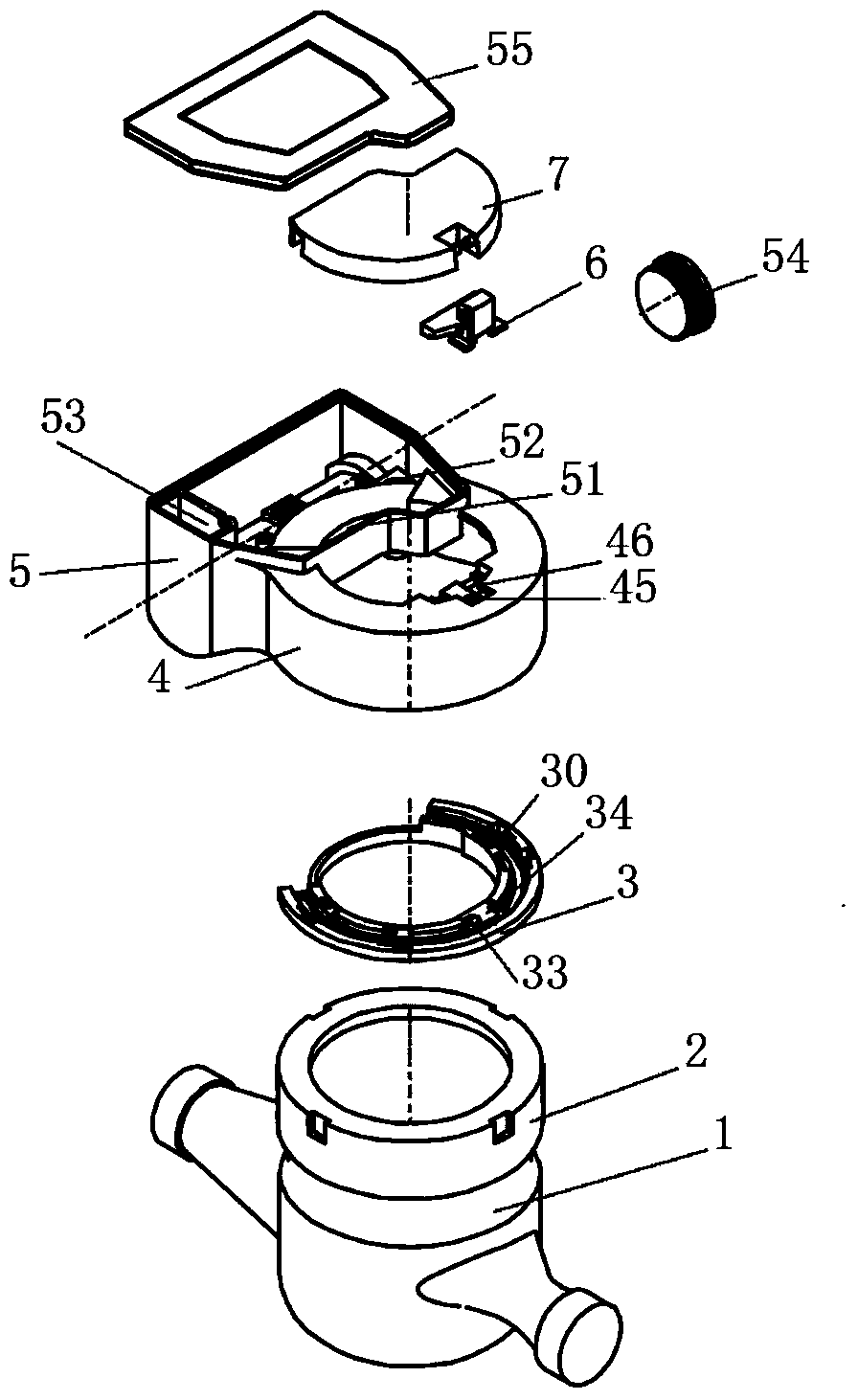

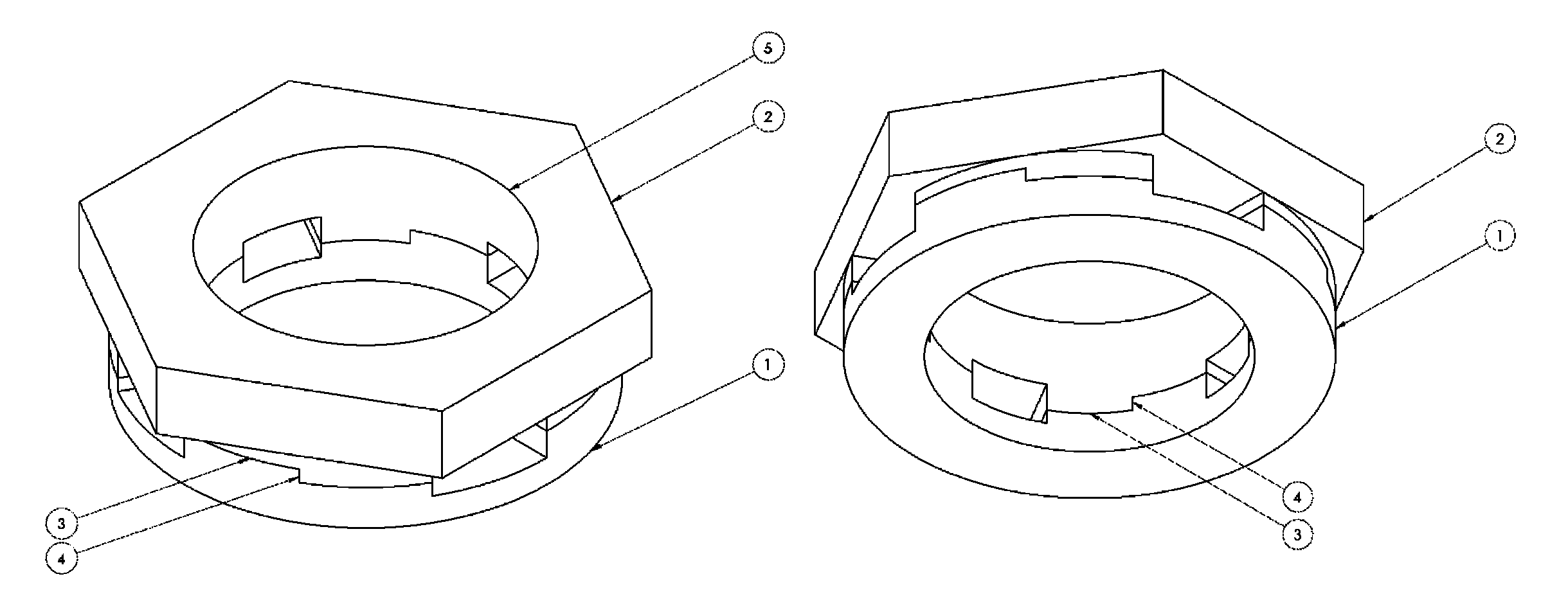

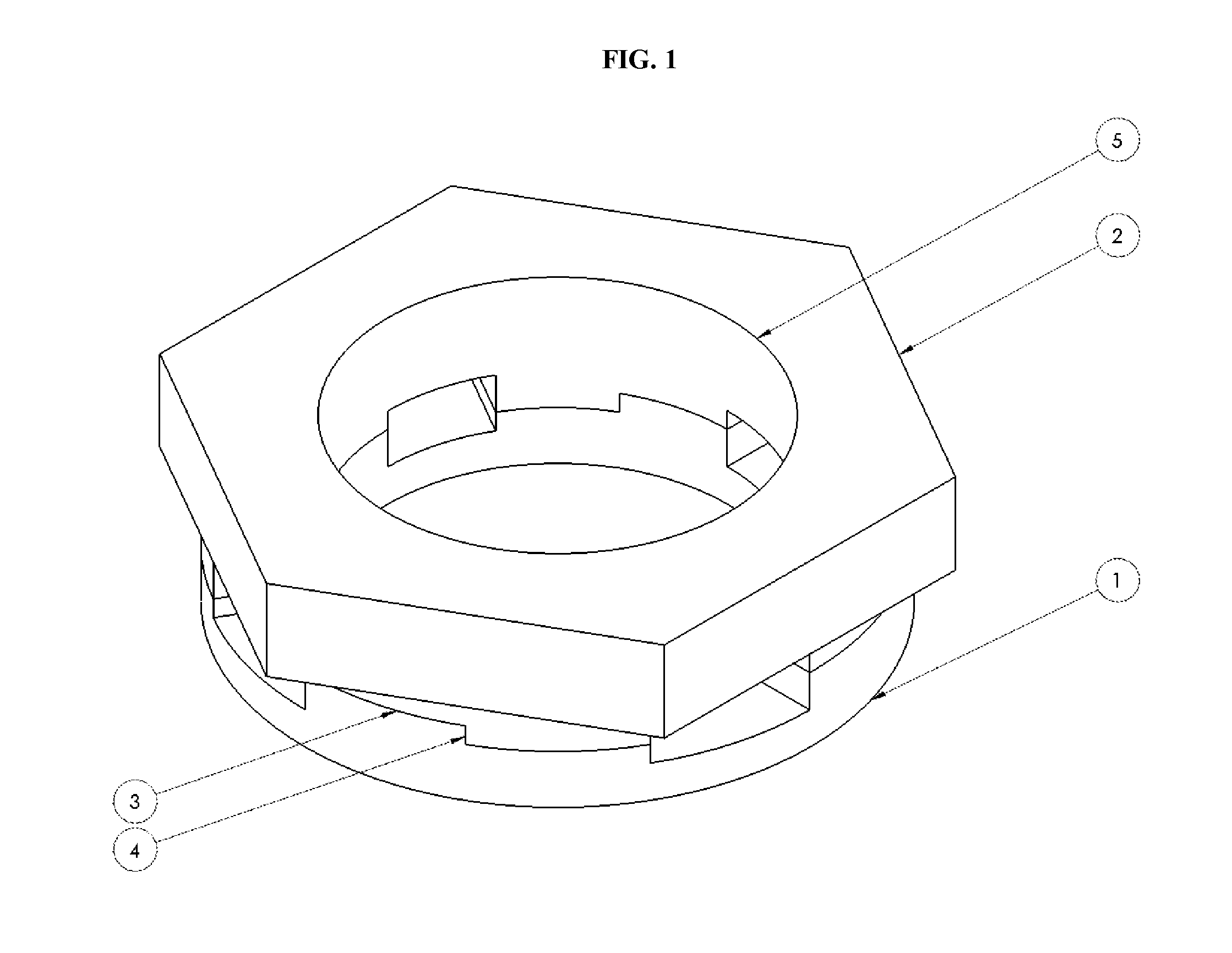

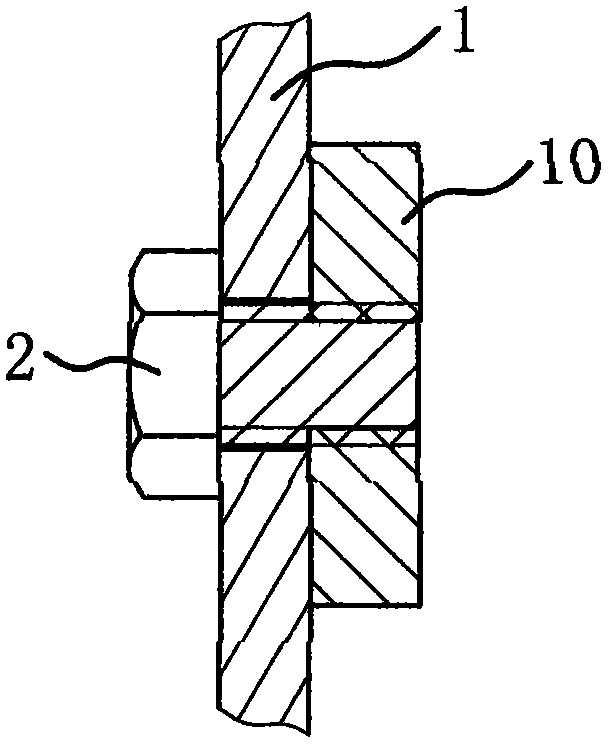

Thread connecting device convenient to operate, thread connecting structure convenient to operate and pre-tightening method of connecting structure convenient to operate

ActiveCN109356920AIncrease the speed of disassemblyImprove installation speedScrewsRelative motionEngineering

The invention relates to a thread connecting device convenient to operate, a thread connecting structure convenient to operate and a pre-tightening method of the thread connecting structure convenientto operate. The thread connecting device includes an upper and a lower wedge of the trapezoidal prism structure. The inclined surfaces of the upper and lower wedges are attached with each other, thethicker end of the lower wedge is on the same side as the less thicker end of the upper wedge, the less thicker end of the lower wedge is on the same side as the thicker end of the upper wedge,. slotsare arranged in the upper and the lower wedges, a fixing bolt passes through the slots, the cap of the fixing bolt and the lower wedge are correspondingly arranged on both sides of the upper wedge, the relative motion of the upper wedge and the lower wedge will drive the fixing bolt to move in the axial direction, the lower wedge is connected with a lever mechanism, and the lever mechanism can drive the upper wedge and the lower wedge to produce relative motion. The structure is simple, using is convenient, and the disassembly speed of bolts between connecting units can be greatly improved.

Owner:SHANDONG UNIV

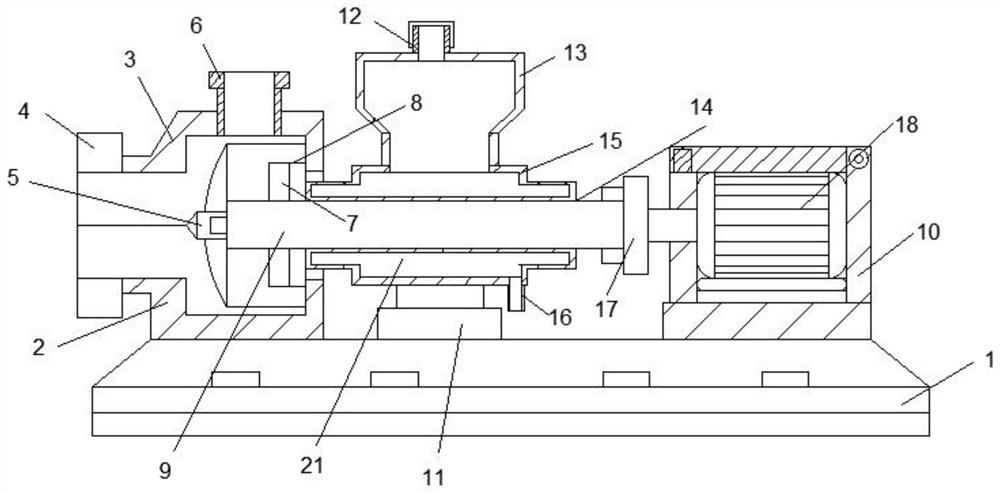

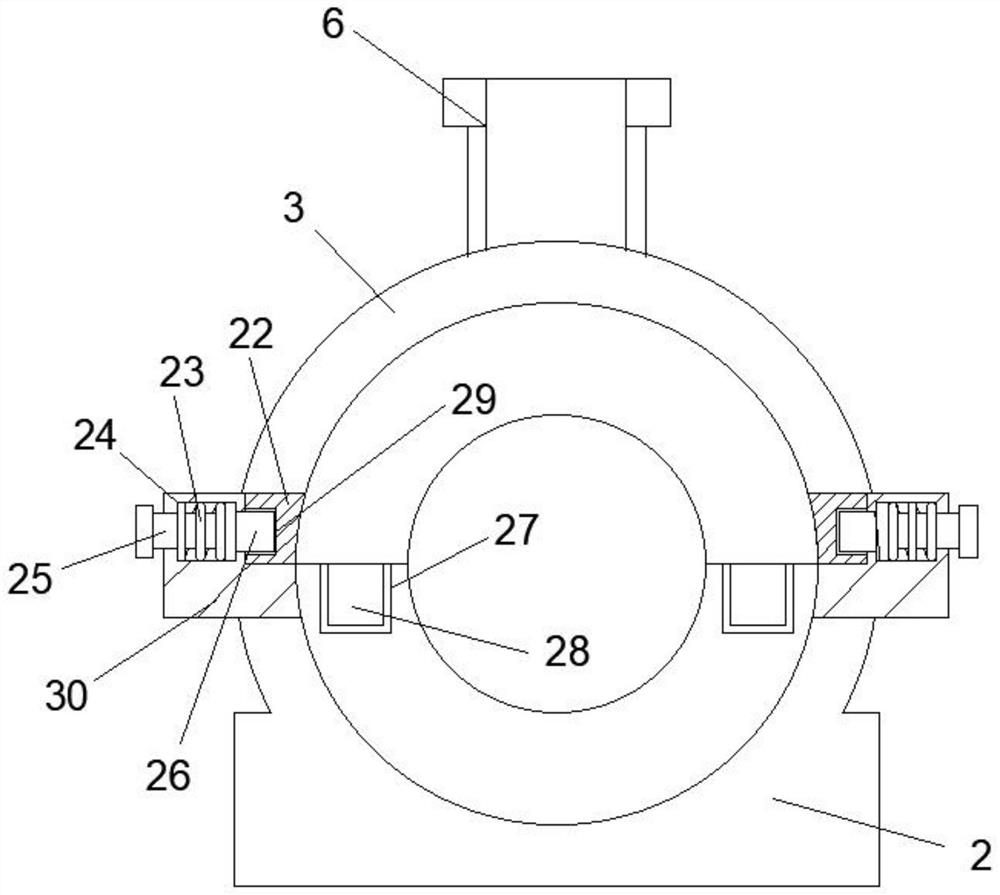

Abrasion -resistant mortar pump

InactiveCN111963445ASimple structureImprove installation speedSpecific fluid pumpsPump componentsImpellerStructural engineering

The invention discloses an abrasion-resistant mortar pump, and belongs to the field of mortar pumps. The abrasion-resistant mortar pump includes a supporting base, a lower pump cover is fixedly installed on the supporting base, an upper pump cover is arranged on the lower pump cover, first connecting seats are fixedly installed on the two sides of the upper pump cover, cotter ways are arranged onthe sides, away from each other, of the two first connecting seat, and second connecting seats are fixedly installed on the two sides of the lower pump cover. The abrasion-resistant mortar pump has the beneficial effects that the structure of the mortar pump is simple, through the mutual cooperation of a pull rod, pin rods, cotter ways and return springs, the installation and disassembly between the first connecting seats and the second connecting seats are more convenient, and the speed of installation and disassembly of the mortar pump is further improved; when the mortar pump fails in operation, disassembly and repair can be quickly carried out, the maintenance time is greatly reduced, and the work efficiency is further improved; and meanwhile, the mutual cooperation of limiting rods, limiting slots and nuts is used to enable multiple connections to be formed between an impeller and a pump shaft, so that the equipment stability is greatly improved.

Owner:邵阳宝兴化工设备有限公司

Rotomolding molds and strategies for using rotational molds

The invention provides a rotational mold and a use strategy of the same, and belongs to the technical field of operation. The problems that the production efficiency is low and the product yield is low when a conventional rotational mold is provided with multiple inserts are solved. The rotational mold comprises a mold plate and a bolt, wherein a bolted hole is formed in the mold plate; the head of the bolt is positioned on the outer side of the mold plate; a screw rod part of the bolt can penetrate through the bolted hole; a nut is in threaded connection with the screw rod part of the bolt; the nut is positioned on the outer side of the mold plate and is fixedly connected with the mold plate; and the head of the bolt can be pressed against the nut. According to the rotational mold and the use strategy of the same, disclosed by the invention, the inserts in products can be rapid to mount and detach, the operations such as mounting and detaching the inserts can be finished by a single person, the bolt can be screwed by adopting a pneumatic wrench, labor force and cost can be effectively reduced, the insert mounting and detaching speed is increased, the production efficiency of the product is further effectively improved, the production cost is reduced, and the yield of the product is improved.

Owner:WENLING RISINGSUN ROTATIONAL MOLDING TECH

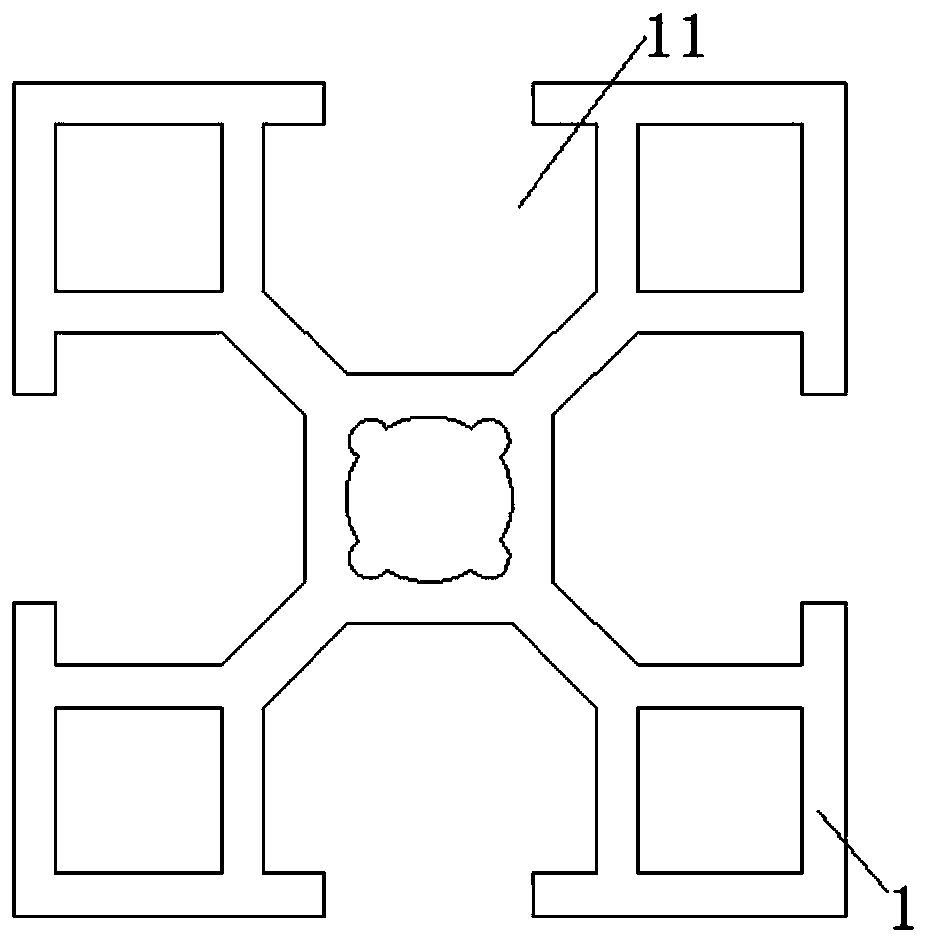

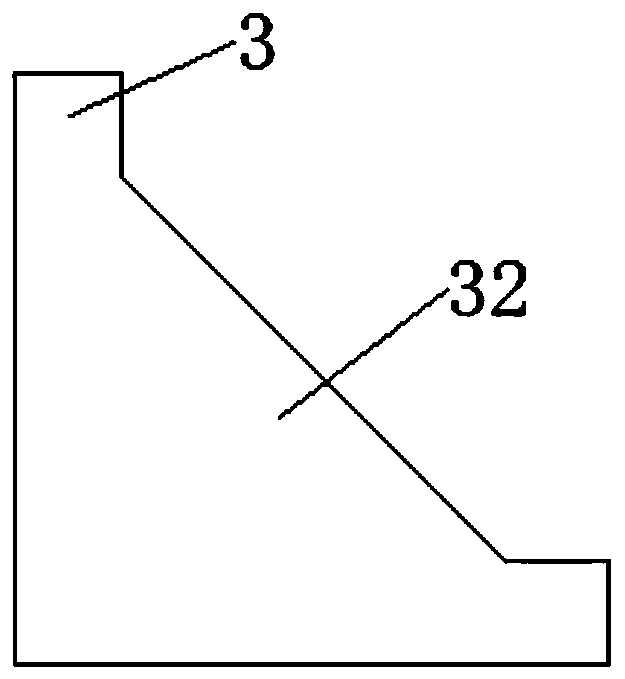

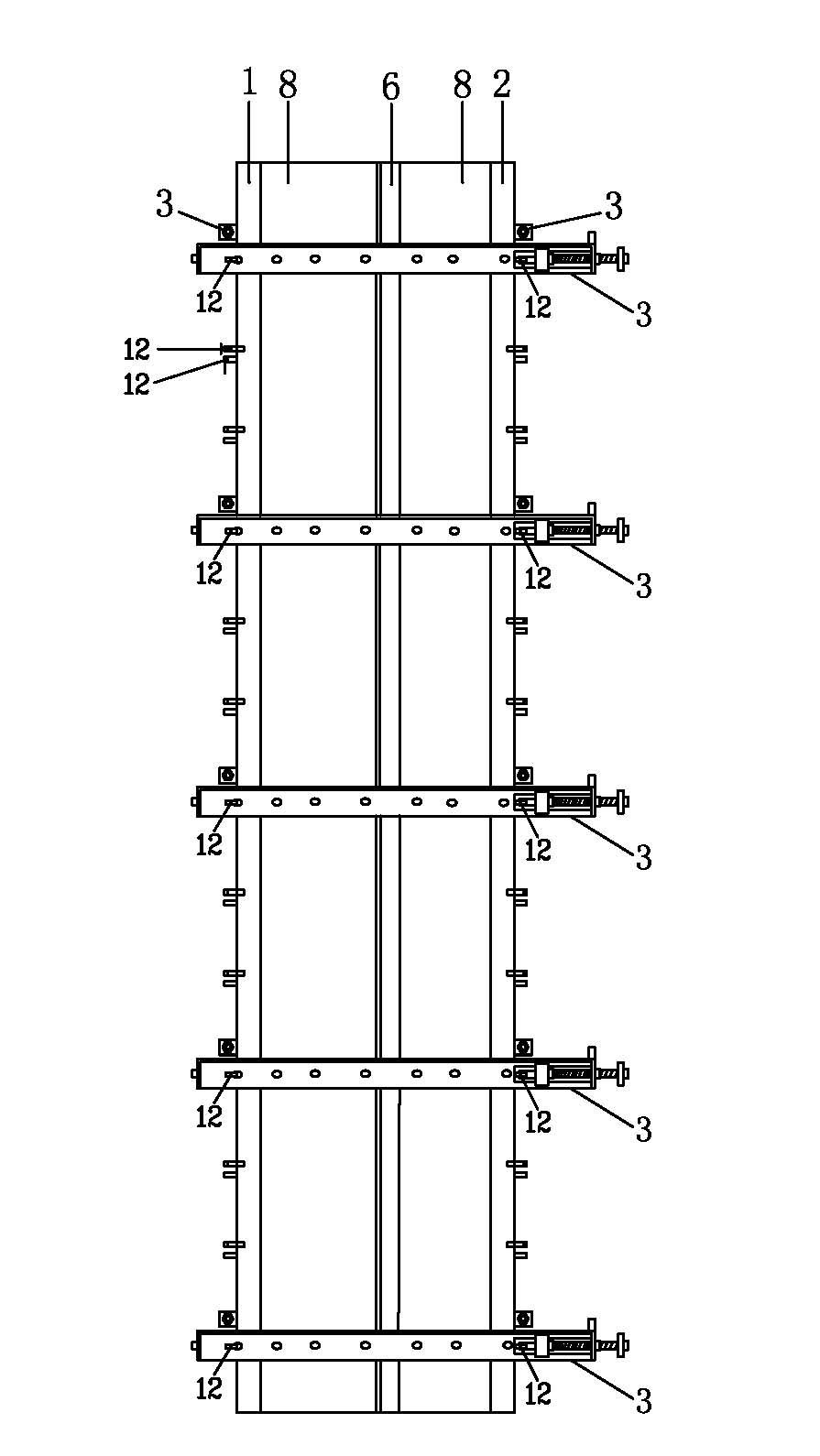

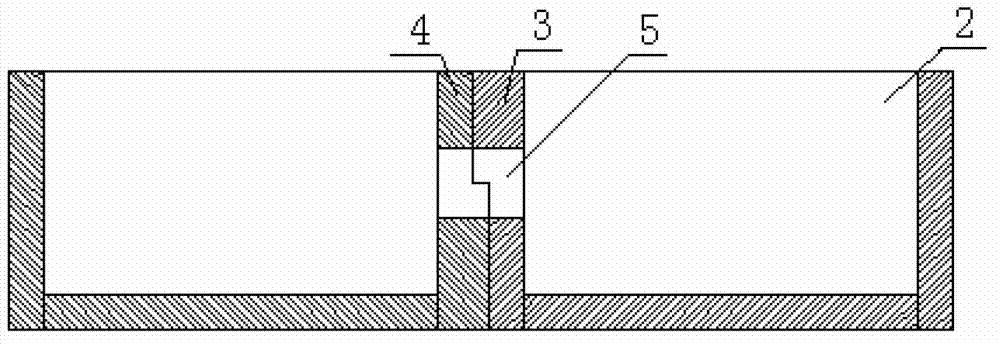

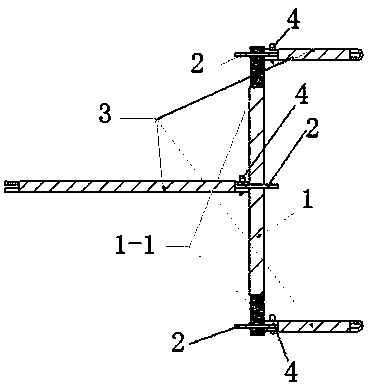

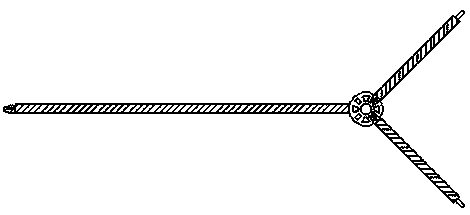

Corner protector structure of cylindrical mold reinforcing device

InactiveCN102661044AImprove installation speedIncrease the speed of disassemblyForms/shuttering/falseworksSlurryEngineering

The invention provides a corner protector structure of a cylindrical mold reinforcing device. The reinforcing device mainly comprises a plurality of clamping draw bars, a plurality of pressure plate sealing parts, a plurality of grooved fastener and screw combinations, a plurality of external corner protectors and a plurality of internal corner protectors, wherein the external corner protectors respectively longitudinally wrap external corners of a cylindrical mold, four positioning pin holes are respectively longitudinally disposed on two side surfaces of each external corner protector, fixing hooks are longitudinally disposed on two sides of each external corner protector and used for being transversely connected with the corresponding clamping draw bars, service distances of the clamping draw bars are adjusted by the hooks, and fixed convex connecting ports which can be conveniently connected with a higher work face are arranged at ends of the external corner protectors; and the internal corner protectors respectively longitudinally wrap internal corners of the cylindrical mold, four positioning pin holes are respectively longitudinally arranged on two side surfaces of each internal corner protector, screw holes which are uniformly distributed are longitudinally arranged on one side surface of each internal corner protector, and the internal corner protectors and the grooved fastener and screw combinations are longitudinally pressed on the outer sides of the clamping draw bars after being combined. The cylindrical mold is reinforced by the corner protectors, probability of slurry leakage and mold expansion of the corners of the cylindrical mold is reduced, the corner protector structure is operated simply and conveniently, and assembling speed and disassembling speed of the cylindrical mold are increased.

Owner:曹健厂

Detachable connection box between ship modules

ActiveCN102785758AImprove securityEasy to disassembleVessel salvagingFoldable/inflatable hullsSteel platesShear force

The invention discloses a detachable connection box between ship modules, which is applied to the connection between marine geological prospecting ship bodies. The detachable connection box comprise the connection box, wherein the connection box is in a rectangular shape formed by welding steel plates; side plates are arranged on the periphery of the connection box; a bottom plate is arranged at the bottom of the connection box; a baffle plate is arranged in the connection box; horizontal bolt holes are formed in the two opposite side plates on the connection box and located on the same straight line; connecting bolts penetrate through the horizontal bolt holes; and lapped steps are formed in the outer walls of the two opposite side plates on the connection box. The detachable connection box has the effects as follows: the two adjacent ship modules can be quickly butted and mounted to be in place, so that the shearing force of fluctuated waves on the connecting bolts for fixing can be reduced, and the damage to the ship bodies can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

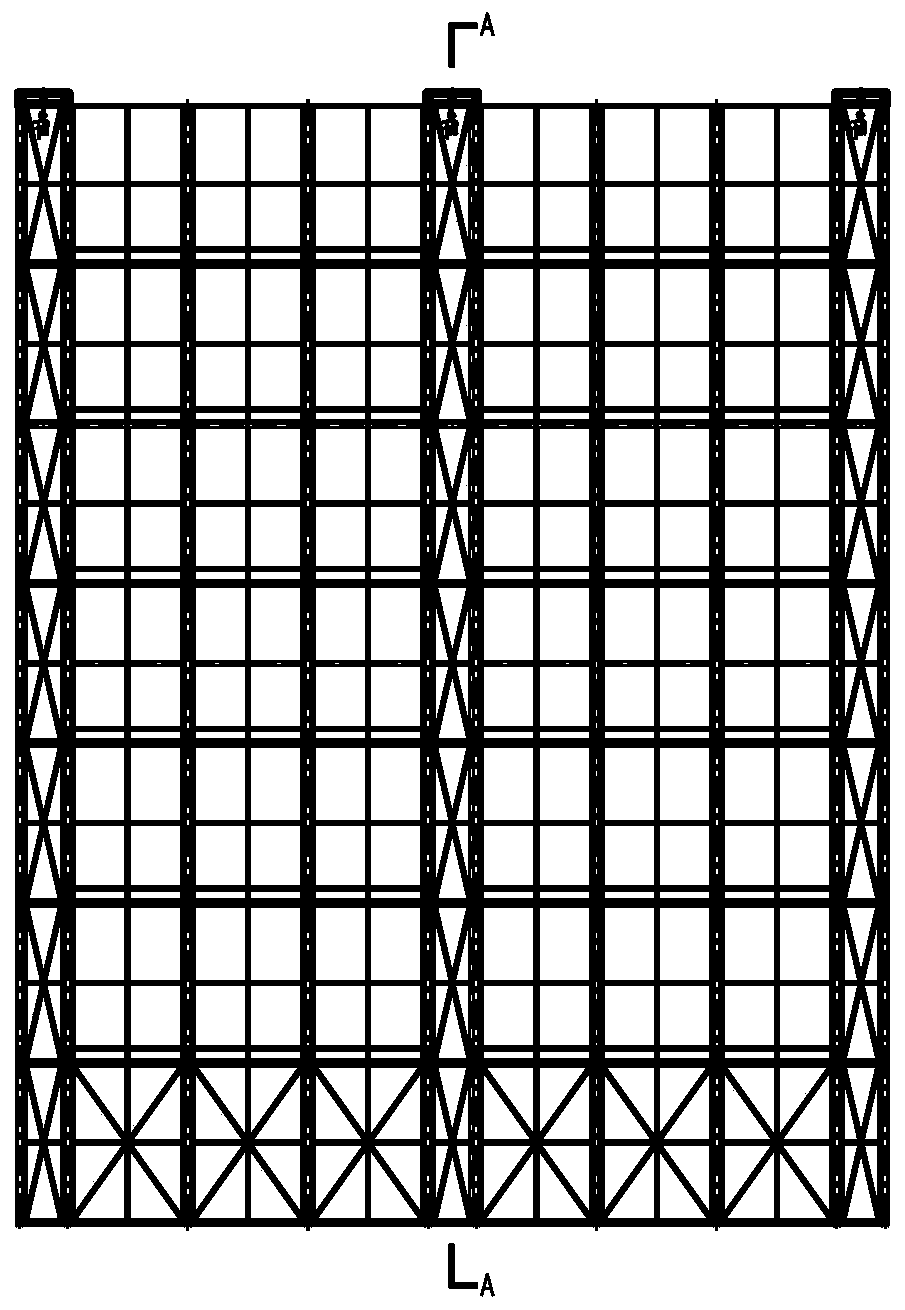

Assembled disc lock prefabricated panel supporting structure

The present invention relates to an assembled disc lock prefabricated panel supporting structure. The structure comprises a steel tube vertical rod, cross bars, connection discs and a plug pin. The upper, middle and lower portions of the steel tube vertical rod are connected with the connection discs, the connection discs located at the upper and lower portions are in threaded connection with thesteel tube vertical rod and are connected with the two cross bars through the plug pins, the connection disc at the middle portion is connected with the cross bar through the plug pin. The support structure can allow the construction process to be more convenient, and can reduce the occupation for the construction space; and moreover, the support of the prefabricated panel is enhanced in some extreme conditions so as to avoid the condition that a structure without completion of the construction is not enough in carrying capacity in a condition such as carrying capacity and the like and improvethe stability of support responding to different work conditions.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

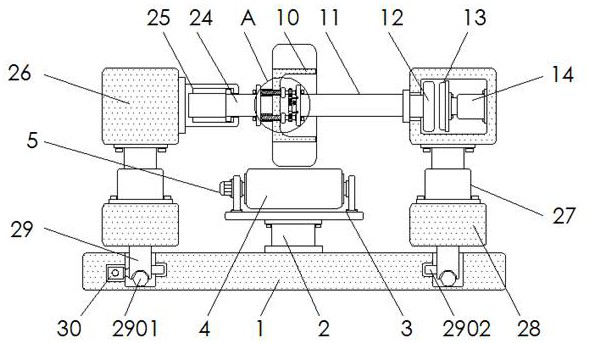

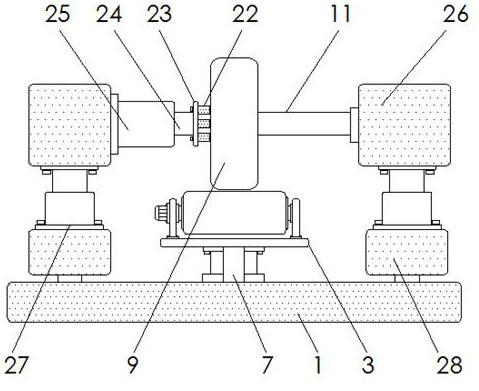

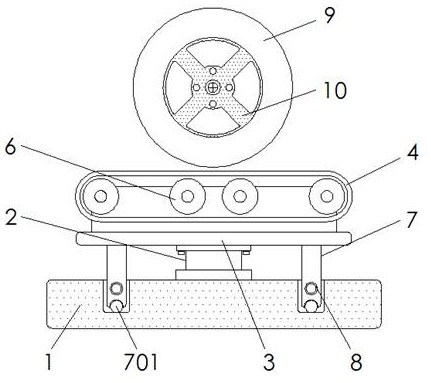

Automobile tire production wear resistance detection device capable of simulating steering

InactiveCN112747943AEasy to wearRealize simulationVehicle tyre testingInvestigating abrasion/wear resistanceElectric machineryControl theory

The invention discloses an automobile tire production wear resistance detection device capable of simulating steering. The automobile tire production wear resistance detection device comprises a base, a support column, a mounting rack, a wheel main body and a hub, the support column is arranged above the base, the mounting rack is fixed above the support column, and the inner side of the mounting rack is provided with a conveying belt; and a first motor is arranged on the left side of the conveying belt, a supporting roller is arranged on the inner side of the conveying belt, and a supporting roller bearing is mounted on the inner side surface of the mounting rack. The automobile tire production wear resistance detection device capable of simulating steering is provided with a transmission plate and a movable plate, the movable plate can be driven to move through the movement of the transmission plate, and the movable plate can perform circular motion, so that the wheel main body positioned above the conveying belt can rotate in the horizontal direction, and the steering of a vehicle can be simulated; and when the wheel main body rotates, the conveying belt can be driven to move through friction force between the wheel main body and the conveying belt, so that simulation of steering of the wheel main body is realized.

Owner:杨健

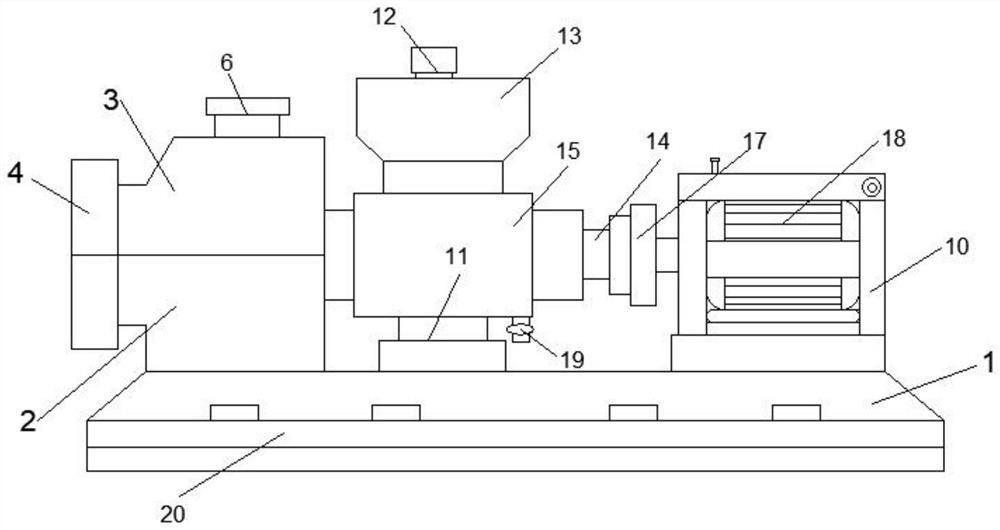

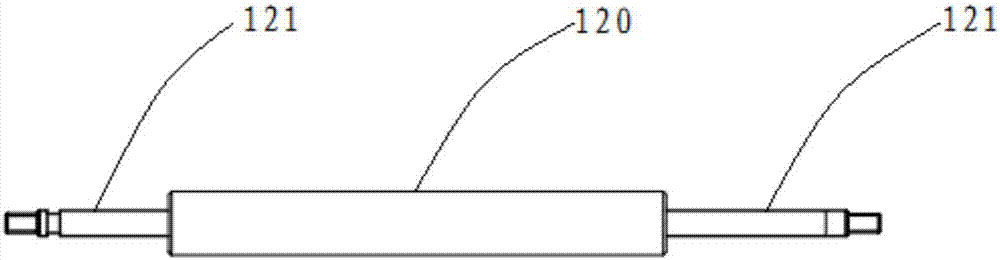

Wheel type middle groove carrying device with front clearing function

InactiveCN103982233AIncreased installation and removal speedReduce labor intensityEarth drilling and miningUnderground transportCoal miningControl table

The invention discloses a wheel type middle groove carrying device with a front clearing function, belongs to the technical field of material carrying on roadways and fully mechanized coal mining faces, and aims to provide a wheel type middle groove carrying device with a front clearing hopper capable of rapidly lifting a chute to a mounting position, which contributes to lowering the labor intensity of workers and improving the construction convenience. In the wheel type middle groove carrying device with the front clearing function, multiple groups of rail type wheel sets are arranged on the lower part of a frame; the back end of a cantilever component is hinged to the front part of the frame, and a chain type hook is arranged at the front end of the cantilever component; the middle part of the cantilever component is hinged to the end part of a piston rod of a cantilever oil cylinder; the cylinder body of the cantilever oil cylinder is hinged to the frame; an explosion-proof diesel engine for providing power and a hydraulic system are arranged on the back part of the frame; a control table and a driving seat are further arranged on the frame; a hopper is arranged at the front end of the bottom of the frame. The wheel type middle groove carrying device is mainly used for carrying materials in roadways.

Owner:SHANXI DONGHUA MACHINERY

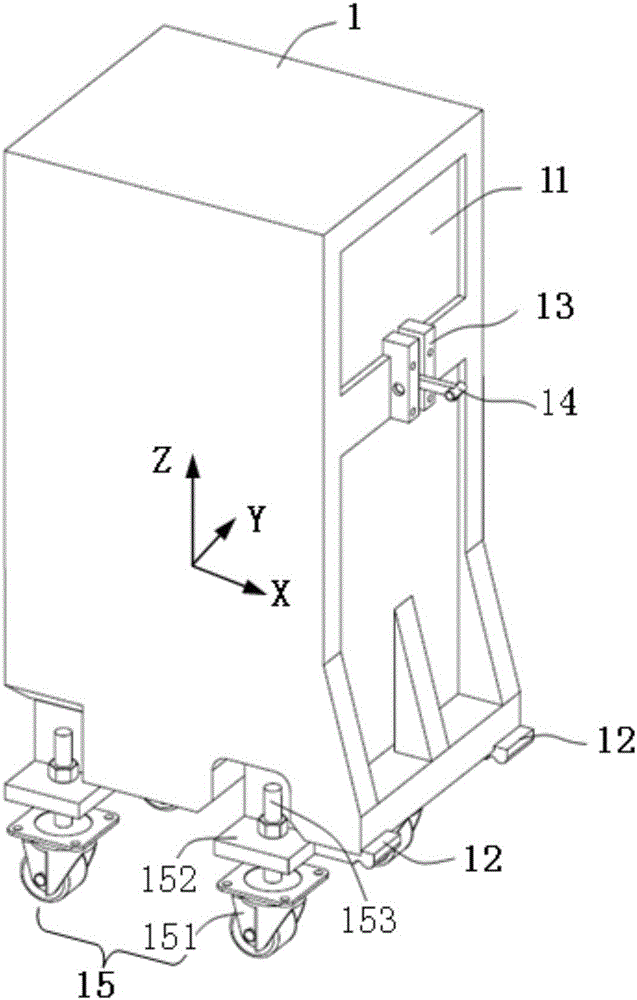

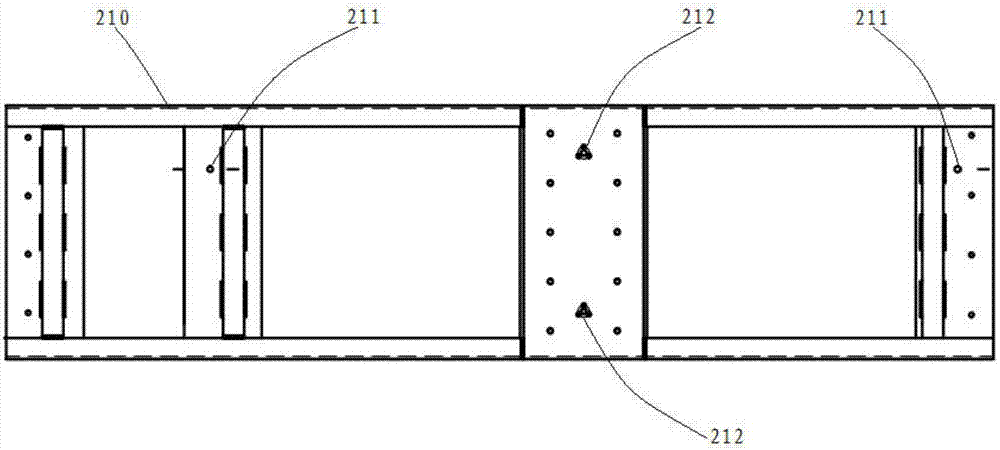

Intelligent omni-directional carrying robot

InactiveCN106828662AGuaranteed positioning and installationImprove assembly accuracyWheelsVehiclesAgricultural engineeringOmni directional

The invention relates to an intelligent omnidirectional handling robot, which has a frame and omnidirectional wheels; the omnidirectional wheels are installed on the frame; the frame includes a reference bottom plate and an upper frame; There are positioning connection holes; the upper frame is fixedly connected to the reference base plate. The invention has high manufacturing precision, efficient and fast assembly, high structural strength, long service life and convenient later maintenance.

Owner:常州模威科技有限公司

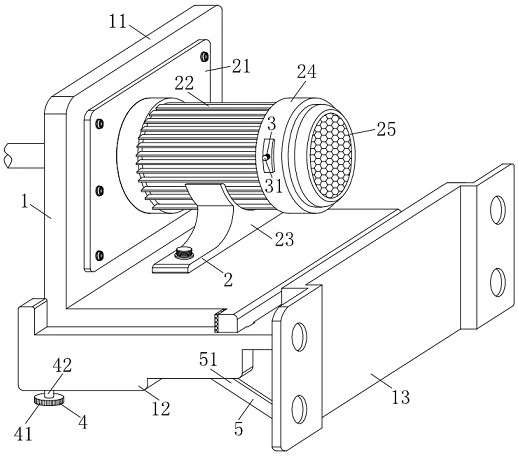

Feed source assembling and angle adjustment apparatus

ActiveCN107968243AEasy to operateImprove assembly efficiencyAntenna supports/mountingsAntennas earthing switches associationEngineeringAntenna array

The invention relates to a feed source assembling and angle adjustment apparatus. The feed source assembling and angle adjustment apparatus comprises an antenna array plane, at least one fixed apparatus, at least one feed source mounting part, and feed sources, wherein the antenna array plane is fixedly arranged on an antenna base; one side of the fixed apparatus is connected with one side of theantenna array plane while the other side of the fixed apparatus is a mounting side; the mounting side is inclined towards the antenna array plane from the top to bottom and forms a preset angle with the vertical direction; one end of the feed source mounting part is connected with the mounting side; the feed sources are connected with the antenna base through the feed source bracket and positionedon one side of the antenna array plane; and one sides, close to the antenna array plane, of the feed sources are fitted with the other end of the feed source mounting part. By virtue of the fixed apparatus and the feed source mounting part, the feed source assembling and angle adjustment operation processes are simplified; mounting adjustment of multiple feed sources can be completed synchronously through mounting in one time, so that assembling efficiency is improved; and the overall apparatus is relatively low in weight, can be carried by a single person, and can be positioned, fixed and used very conveniently in the mounting process.

Owner:BEIJING INST OF RADIO MEASUREMENT

a water meter

ActiveCN104048719BImprove installation speedIncrease the speed of disassemblyVolume meteringAgricultural engineeringCopper

Owner:JIANGSU SAIDA ELECTRONICS SCI & TECH

A permanent magnet motor with easy replacement of the motor cover

ActiveCN113224886BStable supportEasy to disassembleSupports/enclosures/casingsElectric machineryPermanent magnet motor

The invention relates to the technical field of permanent magnet motors, in particular to a permanent magnet motor that is easy to replace a motor cover, including a mounting mechanism, on which a fixing mechanism slides; on the mounting mechanism there is a support mechanism; The main mechanism is fixed on the installation mechanism; the limit mechanism is connected with the main mechanism; when the permanent magnet motor is overhauled, the operator can turn the fixing mechanism by hand, so that the fixing mechanism can slide out from the inside of the installation mechanism, which is convenient for twitch installation mechanism, which helps to prevent the motor from being installed too close to the wall, which makes it inconvenient for the operator to extend the screwdriver in for maintenance when removing the cover; The positioning mechanism slides out from the inside of the main mechanism, so that when the operator turns the main mechanism, the cover of the motor can be disassembled and the internal components of the motor can be repaired, which is conducive to improving the efficiency of the operator in installing and disassembling the cover.

Owner:JIANGSU HENGKANG ELECTRICAL

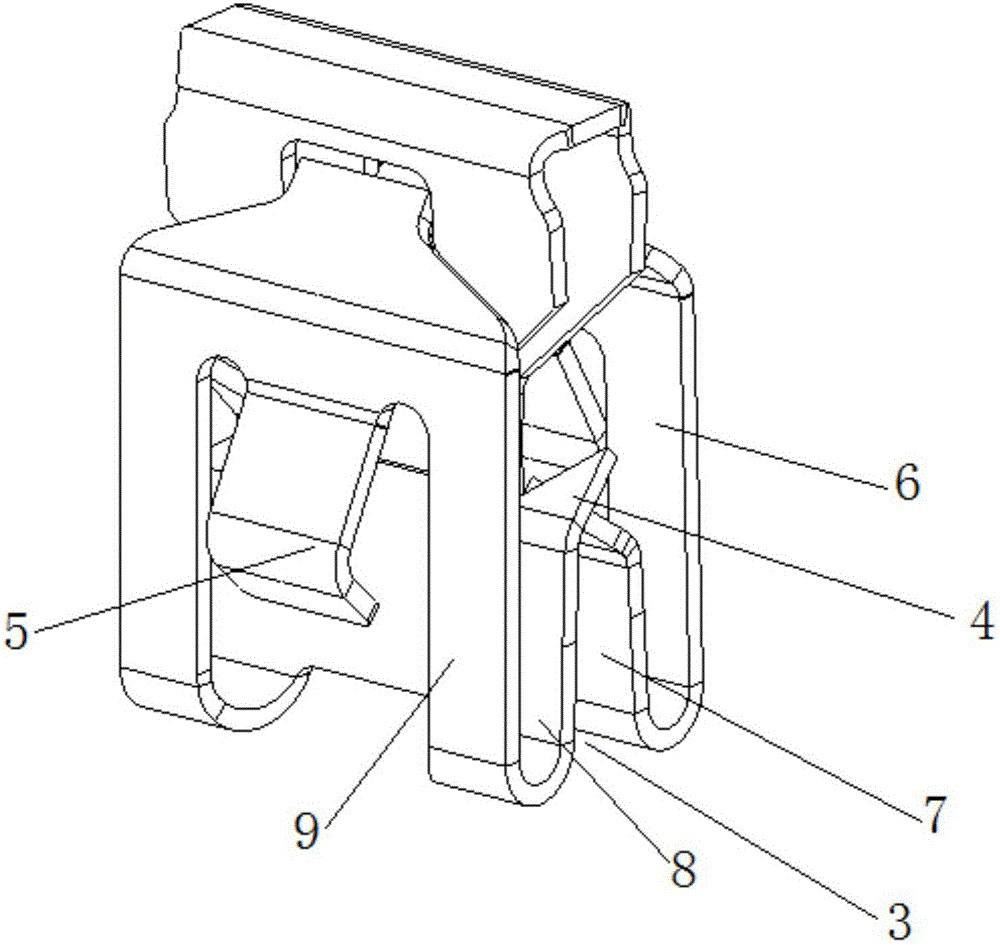

Metal elastic connection module used for installing automobile interior plastic board

ActiveCN106015245AGood connection stabilityEasy to assemble and disassembleSnap-action fastenersSuperstructure subunitsEngineeringMechanical engineering

The invention relates to a metal elastic connection module used for installing an automobile interior plastic board. The metal elastic connection module used for installing the automobile interior plastic board is used for connecting the automobile interior plastic board with a plastic installing support together; the automobile interior plastic board is provided with a clamping groove; the metal elastic connection module is internally provided with an inserting connection groove used for the plastic installing support to be connected in an inserted manner; the inserting connection groove is internally provided with inner clamping feet used for clamping the plastic installing support; and the outer side of the metal elastic connection module is used for being connected into the clamping groove in an inserted manner and provided with outer clamping feet used for being connected with the automobile interior plastic board in a clamped manner. Compared with the prior art, the metal elastic connection module used for installing the automobile interior plastic board has the beneficial effects of being simple in structure, integrally formed, steady in connection, convenient to disassemble and the like.

Owner:SHANGHAI QIUMING STANDARD PARTS +2

Tent structure

InactiveCN105484567AImprove build speedIncrease the speed of disassemblyTents/canopiesAgricultural engineeringEngineering

Owner:GUANGZHOU XINSAIERTE TENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com