Quick disassembly type rolling brush mechanism on roll type thin film cleaning machine

A washing machine and quick-release technology, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as cleaning, affecting product quality, and high hardness of brushes, so as to improve production Efficiency, improved removal and replacement speed, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

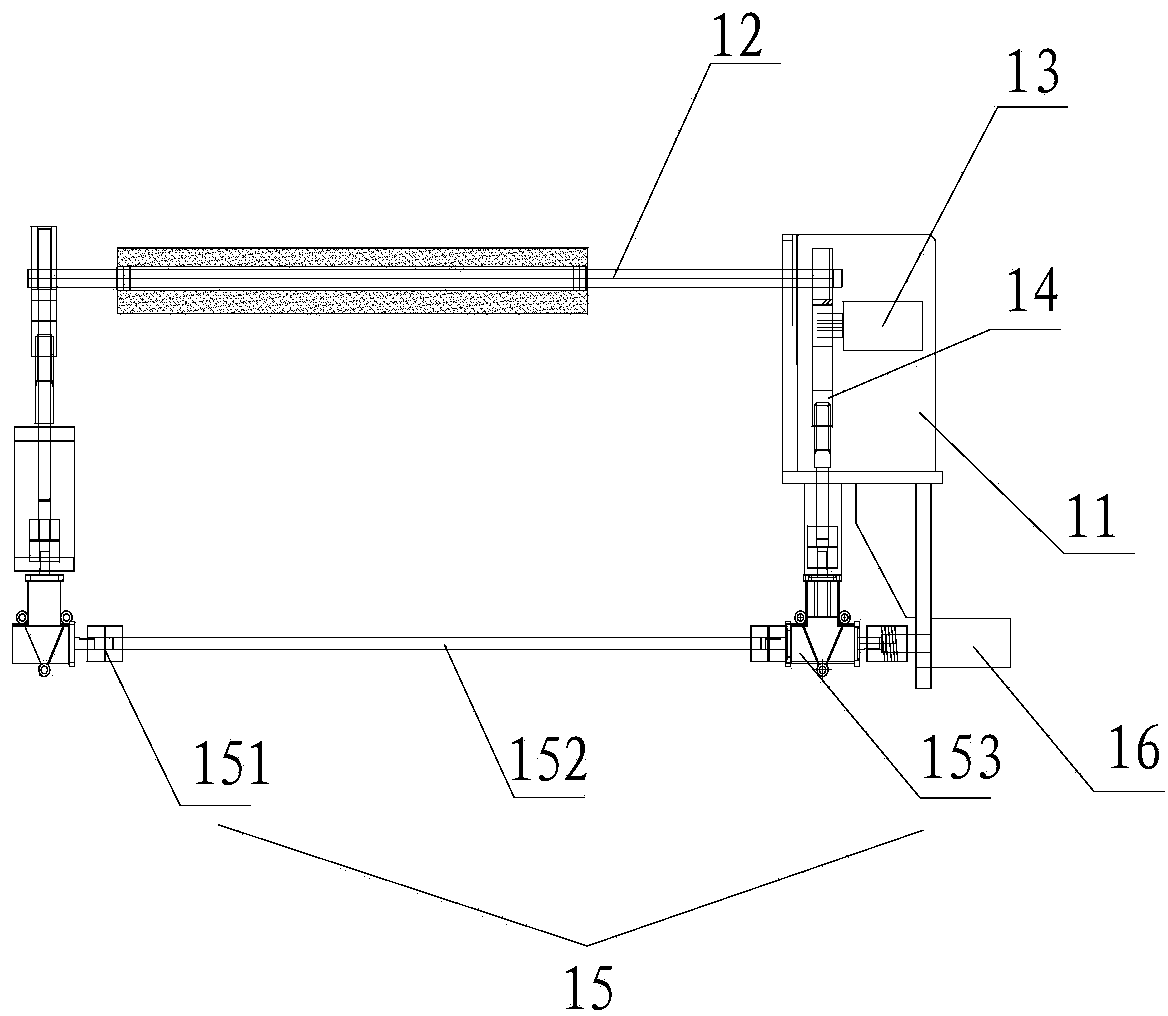

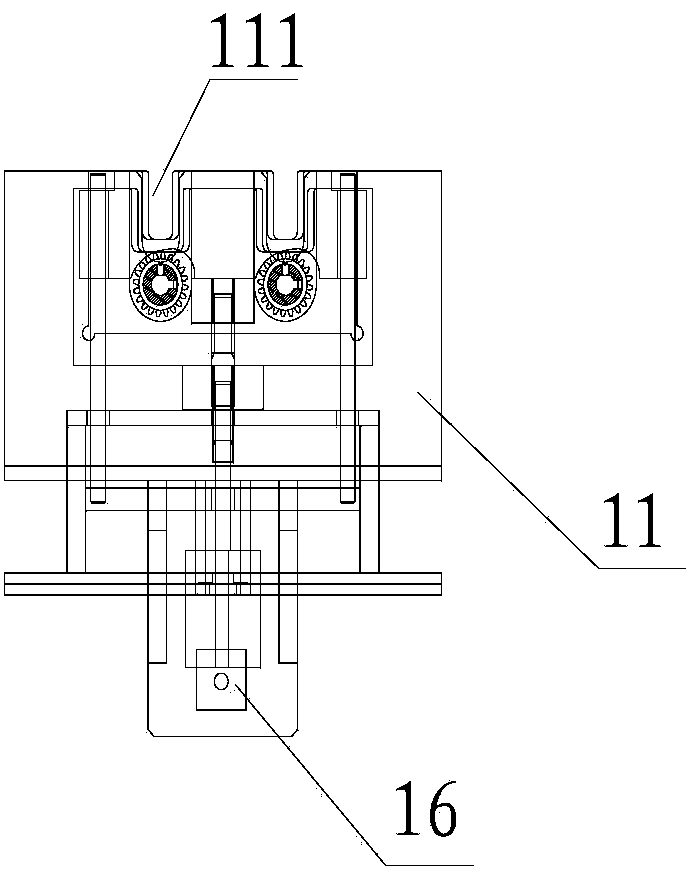

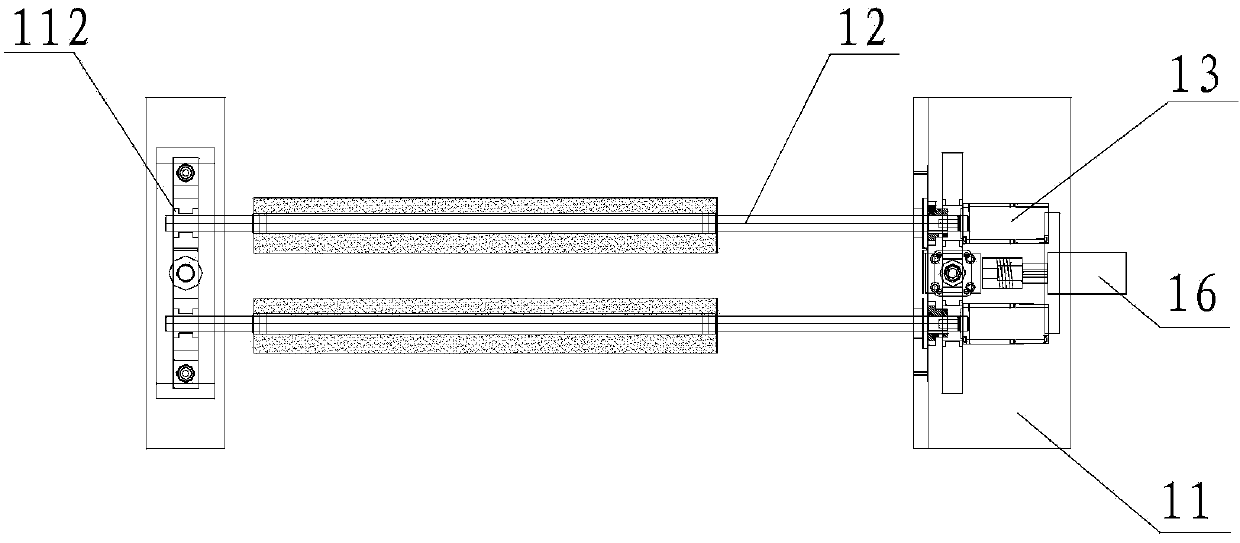

[0013] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0014] Such as Figure 1-3 The quick-detachable roller brush mechanism on the roll-type film cleaning machine shown mainly includes a support frame 11, a plurality of roller brushes 12, and a plurality of motors 13 used in conjunction with the roller brushes 12. Wherein the support frame 11 is arranged in parallel and is perpendicular to the horizontal plane, and the two support frames 11 are respectively provided with a fixed groove 111 and a fixed hole 112 for placing the roller brush, and their quantity is consistent with the quantity of the roller brush 12; the roller brush 12 and the motor 13 One roller brush 12 corresponds to one motor 13 through gear meshing connection.

[0015] When the roller brush 12 needs to be cleaned, because the roller brush 12 is connected with the motor 13 through gear engagement, and the motor 13 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com