Detachable connection box between ship modules

A connection box and module-to-module technology, applied in foldable/inflatable hulls, hulls, salvage of ships, etc., can solve problems such as poor safety, long time, unreliable hull installation, etc., and achieve the effect of easy disassembly and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Taking a detachable connection box between ship modules as an example, the present invention will be further described in detail.

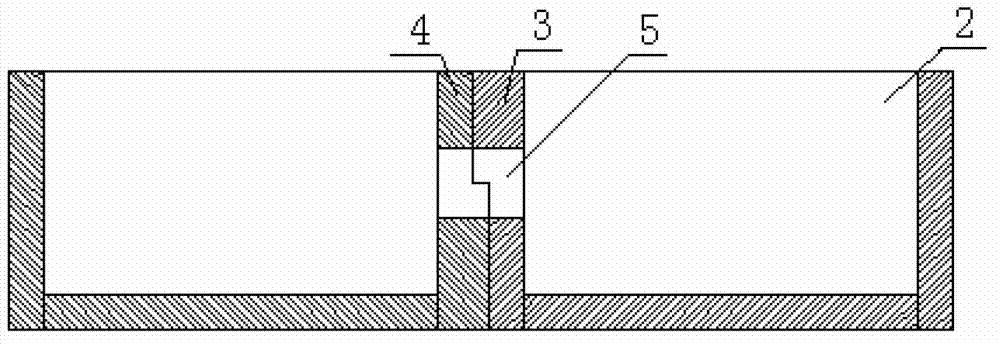

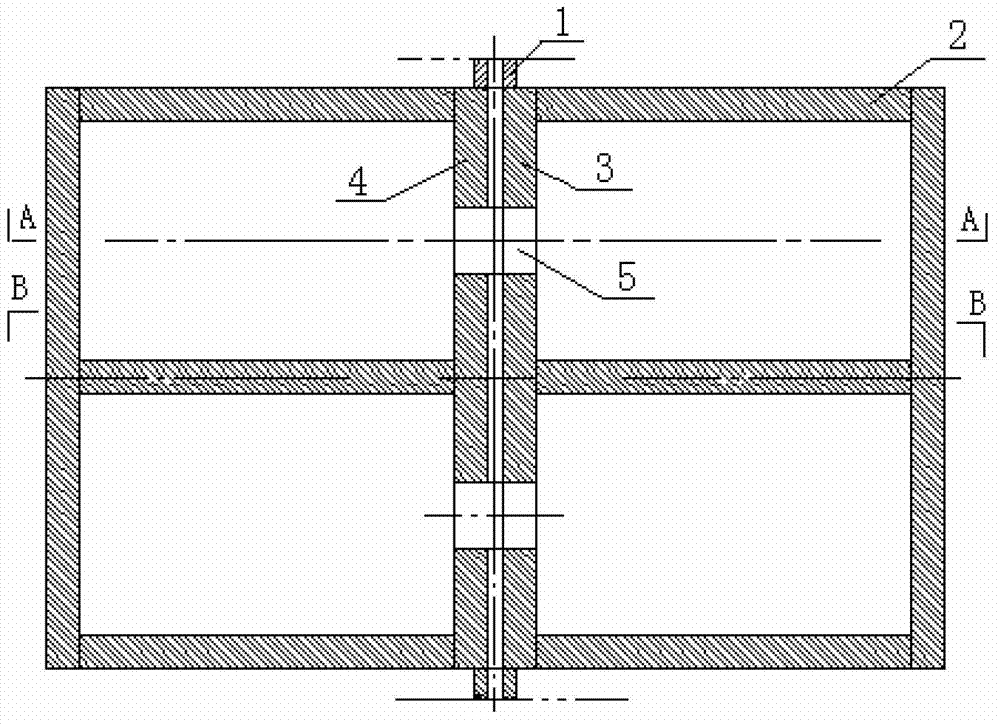

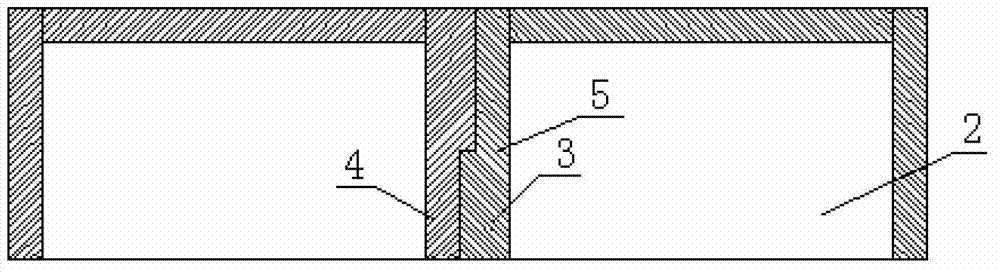

[0015] refer to figure 2 . The detachable connection box between the ship modules of the present invention includes a connection box 2, the connection box 2 adopts steel plates welded into a cuboid shape, the outer wall length of a connection box 2 is 267 mm, the width is 352 mm, and the height is 150 mm. There are four side plates around the connection box 2, a base plate is arranged at the bottom, and a partition is welded in the connection box 2.

[0016] There are transverse bolt holes 5 on the opposite side plates of the two connection boxes 2, the transverse bolt holes 5 on the side plates of the two opposite connection boxes 2 are on the same straight line, and the connecting bolts pass through the transverse bolt holes 5 , the diameter of the bolt hole 5 can be between 30 mm and 60 mm. What present embodiment adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com