Metal elastic connection module used for installing automobile interior plastic board

An automotive interior, elastic connection technology, applied in connecting components, vehicle parts, transportation and packaging, etc., can solve the problems of high scrap rate, increased labor costs, high material costs, and achieve faster installation and disassembly, assembly and disassembly. Convenience and good connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] A metal elastic connection module for the installation of automotive interior plastic panels, used to connect the automotive interior plastic panel 1 with the plastic mounting bracket 2, the plastic mounting bracket structure is as follows Figure 4 , 5 As shown, the structure of the automotive interior plastic plate is as follows Image 6 As shown, the automotive interior plastic panel 1 is provided with a card slot 11 .

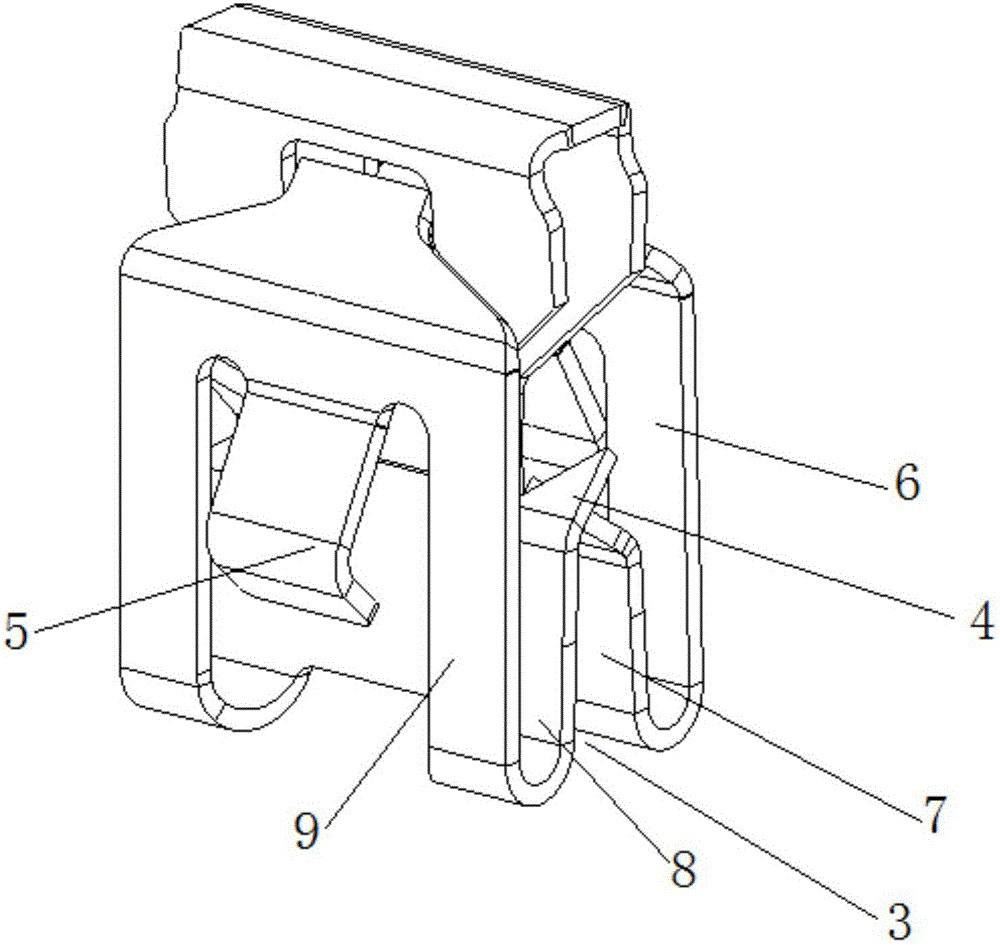

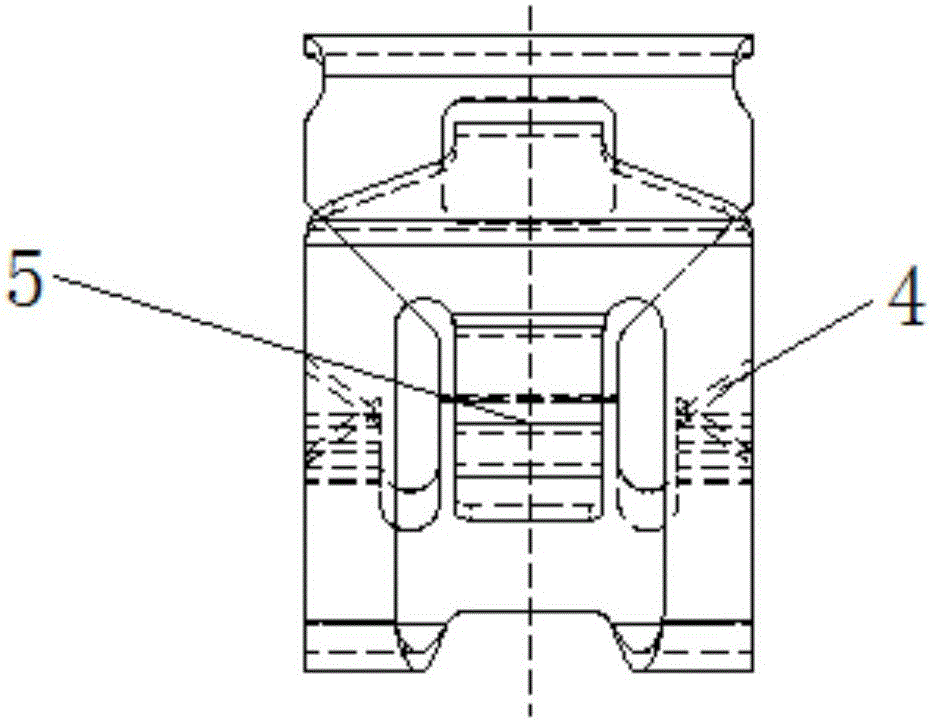

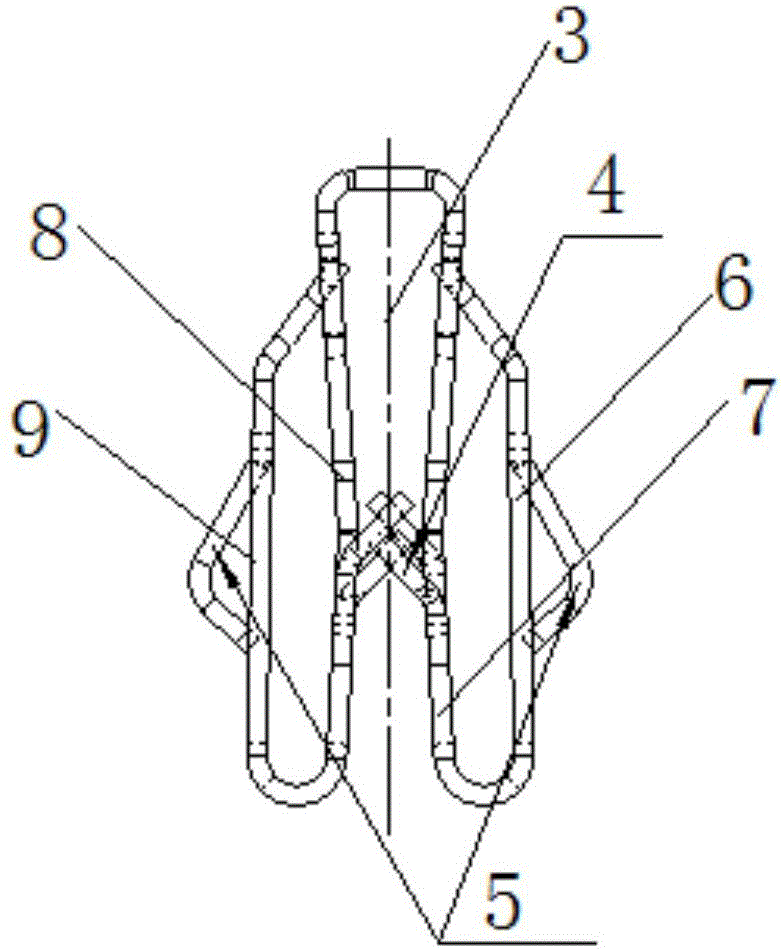

[0029] Metal elastic connection modules such as Figure 1-3 As shown, the metal elastic connection module includes a first side plate 6 , a second side plate 7 , a third side plate 8 and a fourth side plate 9 arranged in parallel and connected to each other. An insertion groove 3 is formed between the second side plate 7 and the third side plate 8 , and the insertion groove 3 is used for insertion of the plastic mounting bracket 2 . Both the second side plate 7 and the third side plate 8 are provided with claws that are bent into the insertion gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com