Electrically-controlled lamp picture film pasting system

A technology of stickers and diaphragms, which is applied in the field of stickers and diaphragms for electronically controlled lights, to achieve the effects of convenient battery replacement, increased support range, and overcoming the inconvenience of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

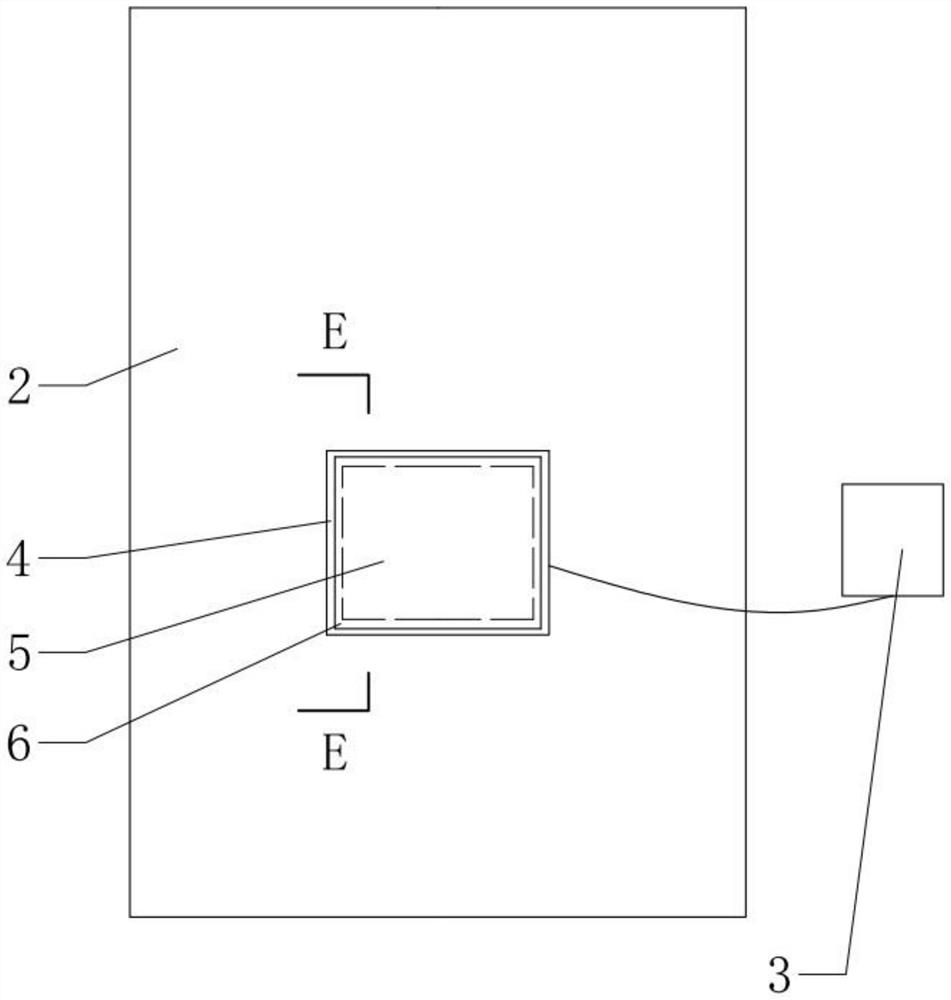

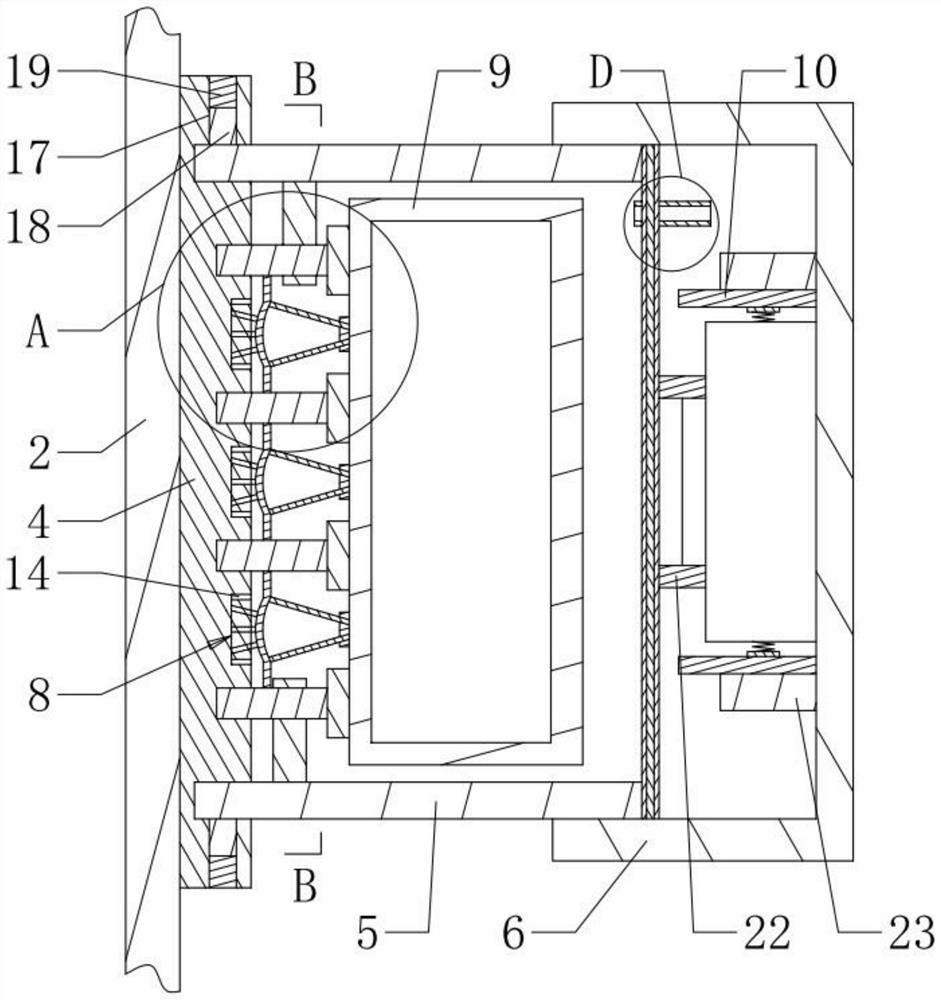

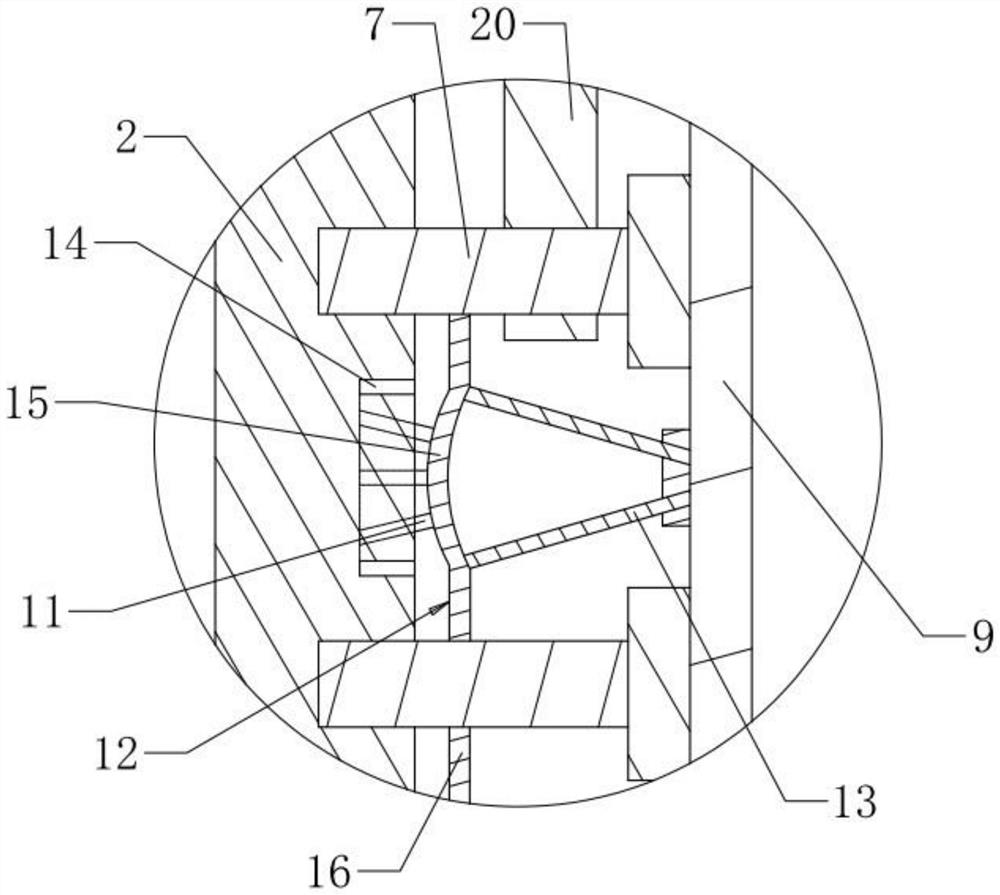

[0030] Such as figure 1 , 2 , 4, 7, and 8, an electronically controlled lamp pasting film system, including picture 1 2, picture 3 with light, connecting piece 4, protective cover 5, clamping plate 6, battery box 10, the upper part of picture 1 2 The surface is connected to the connecting piece 4, the upper surface of the connecting piece 4 is connected to the protective cover 5, the upper surface of the protective cover 5 and the connecting piece 4 forms a cavity, and a connecting column 7, a supporting device 8 and a control box 9 are arranged in the cavity, and the connecting column 7 , and the supporting devices 8 are evenly distributed on the upper surface of the connecting piece 4 . The distances between the transverse connecting columns 7 are equal, and the distances between the transverse support devices 8 are equal. The central axis...

Embodiment 2

[0042] Such as Figure 9 As shown, picture 3 (candle) with lights is located on the upper surface of picture 1 2 (Santa Claus 2) and is bonded to picture 1 2.

[0043] Bond the upper surface of picture 3 with light and picture 1 2, then connect the upper surface of connecting piece 4 and picture 1 2 with hot melt adhesive, and fix the protective cover 5 through the connecting cavity 17 at the end of connecting piece 4 The column 18 , the sealing block 19 and the connecting piece 4 are connected, and one end of the connecting column 7 is embedded with the upper surface of the connecting piece 4 . Others are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com