Split type storage battery chute carrier capable of being quickly disassembled to enter and exit from cage

A split type, battery technology, used in underground transportation, transportation and packaging, lifting devices, etc., can solve the problems of cumbersome vehicle dismantling process and lower cage process, endangering the health of workers, and large external dimensions. Speed up the speed of disassembly and the difficulty of disassembly, improve the speed of connection and disassembly, and fix the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

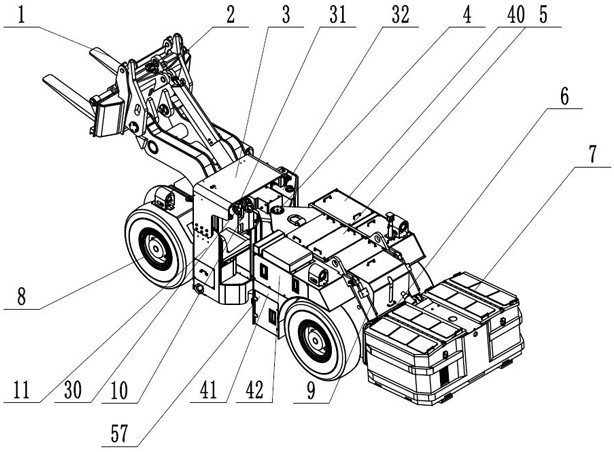

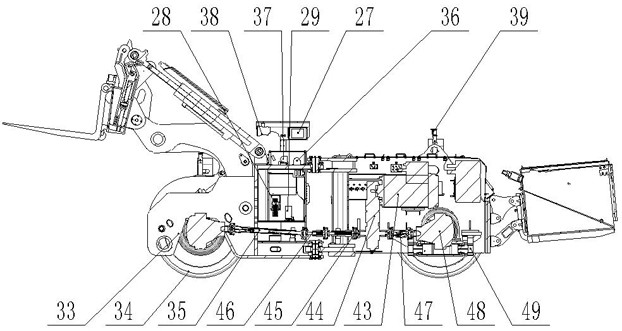

[0036] like figure 1 As shown, the present invention is a split-type battery chute transport vehicle that can be quickly disassembled into and out of the cage, including a control system and a transport mechanism 1 at the front, a transport mechanism quick change device 2 connected to the transport mechanism 1, and a quick changeover device 2 with the transport mechanism The front frame 3 connected with the device 2, the middle pin shaft quick release device 4 connected with the front frame 3, the rear frame 5 connected with the middle pin shaft quick release device 4, the battery bracket quick release connected with the rear frame 5 device6.

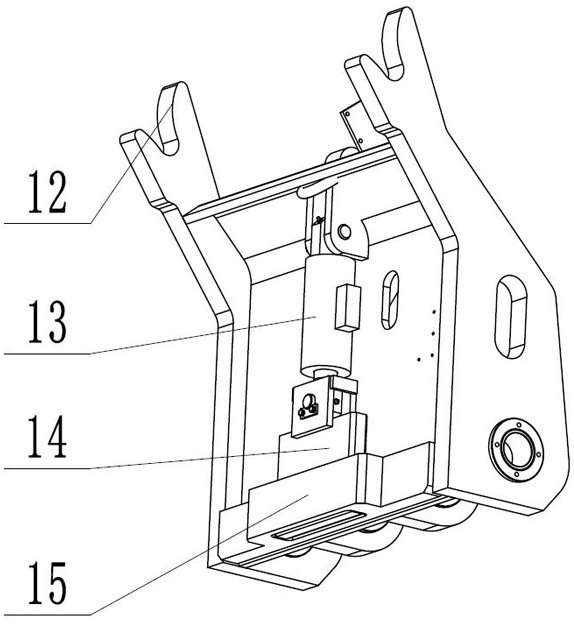

[0037] like image 3 , Figure 4 As shown, the transport mechanism 1 is provided with a lock pin hole 58, and the transport mechanism quick change device 2 is provided with a lock pin plate 14 and a pressure sensor 15. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com