Vacuum insulation ultralow-temperature medium land conveying device

A vacuum heat insulation and conveying device technology, which is applied in the direction of liquid distribution, conveying or transfer device, distribution device, transportation and packaging, etc., to reduce loss, reduce pressure, and prevent the interface from freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

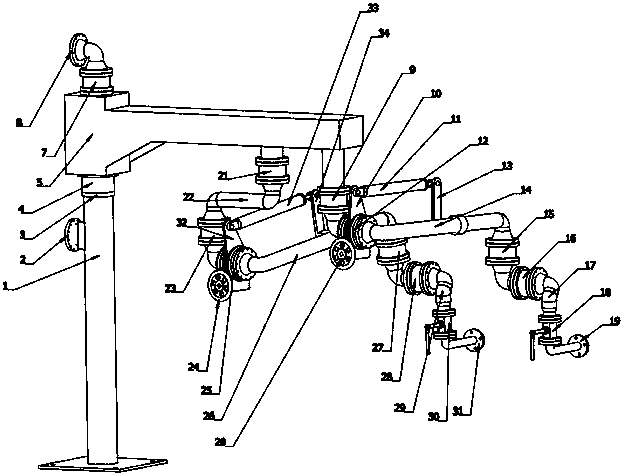

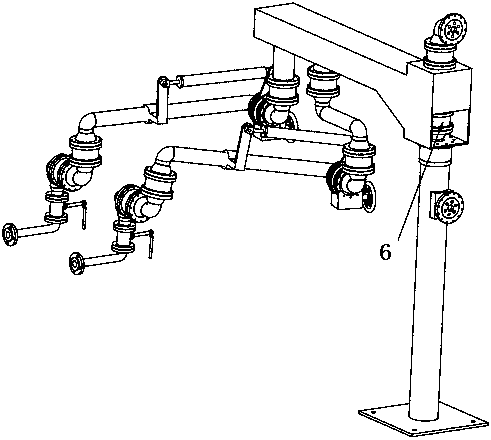

[0016] Such as figure 1 , as shown in 2, the vacuum insulation type ultra-low temperature medium land transportation device of the present invention consists of a column 1, a gas phase interface 2, a rotary inner ring 3, a rotary outer ring 4, a vacuum rotary inner tube 5, a gas phase rotary joint A6, and a liquid phase rotary joint A7, liquid phase interface 8, liquid phase rotary joint B9, liquid phase turbine plate 10, liquid phase balance cylinder 11, liquid phase rotary joint C12, liquid phase balance bracket 13, liquid phase vacuum outer tube 14, liquid phase rotary joint D15, Liquid phase rotary joint E16, liquid phase interface center of gravity adjustment tube 17, liquid phase valve 18, liquid phase connecting flange 19, liquid phase turbine worm device 20, gas phase rotary joint B21, gas phase rotary tube 22, gas phase rotary joint C23, Gas p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com