Patents

Literature

49results about How to "Reduce secondary processing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light-color quenching oil complexing agent composition and preparation method thereof

ActiveCN101603118AImprove cooling effectExcellent high temperature cooling performanceQuenching agentsAntioxidantOxygen

The invention relates to a light-color quenching oil complexing agent composition and a preparation method thereof. The light-color quenching oil complexing agent composition comprises the following materials according to proportion by weight: 40 to 88 parts of refrigerant catalyst, 1 to 10 parts of brightener, 1 to 15 parts of antioxidant and 10 to 40 parts of anti-precipitation agent. The prepared composition product has high-temperature and low-temperature refrigeration catalysis functions and favorable brightness property and high-temperature and low-temperature anti-oxygen property and is suitable for preparing common and fast quenching oil with fast brightening.

Owner:锦州康泰润滑油添加剂有限公司

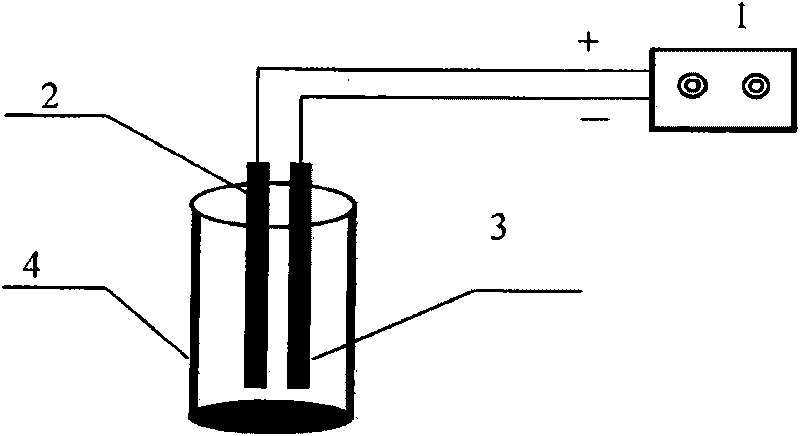

Electrochemical method for removing nitrate from drinking water source

InactiveCN101746871AHigh nitrate removal efficiencyNo generationWater/sewage treatmentNitrateWater source

The invention relates to an electrochemical method for removing nitrate from a drinking water source. In the invention, the method comprises a step of electrolyzing the water to be treated for 1 to 5 hours at a current density of between 10 and 50 mA / cm<2> by using an electrode containing Fe, Ti, Al, Pd, Cu, Zn, Sn, Cu / Zn, Cu / Pd or Ti / Pd as a cathode and using an insoluble electrode containing Pt, Ir, Ru, Pd or Pb as an anode in an electrolytic bath. The method of the invention also comprises a step of adding an ionic compound of chlorine in the electrolytic process. The electrochemical method reduces the cost of the electrochemical reduction of the nitrate and improves the treatment efficiency, so the practicability of removing the nitrate from the drinking water by the electrochemical method is improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

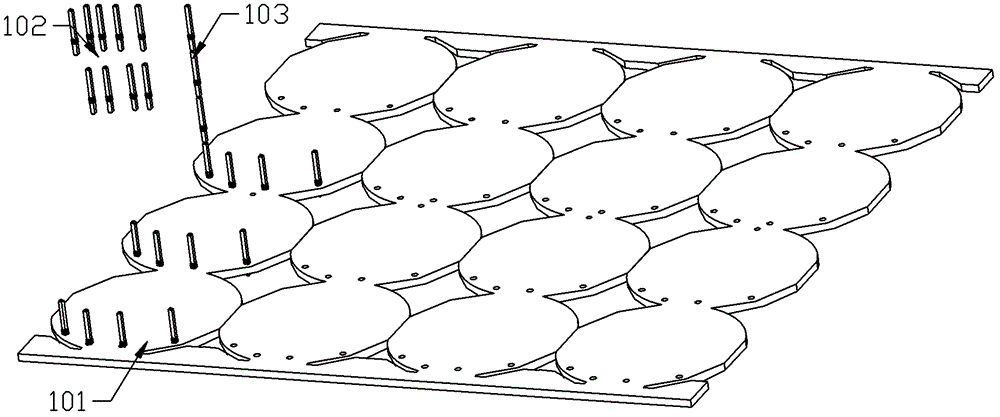

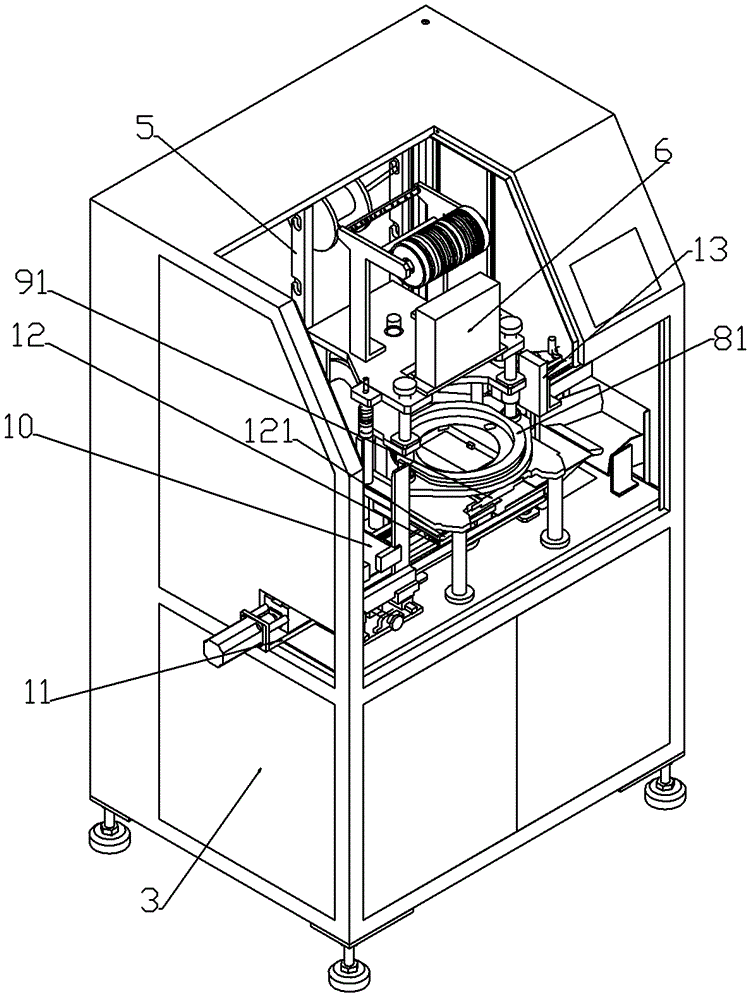

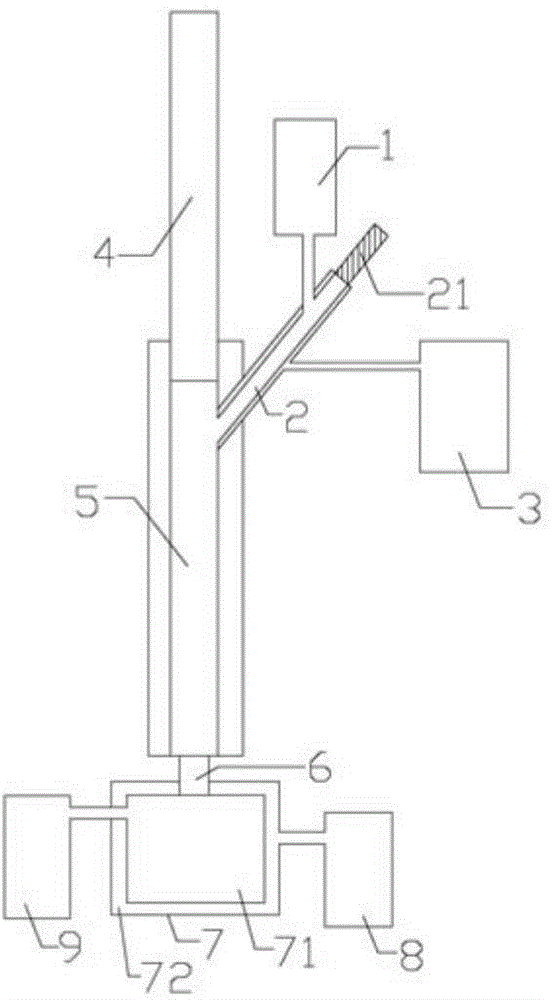

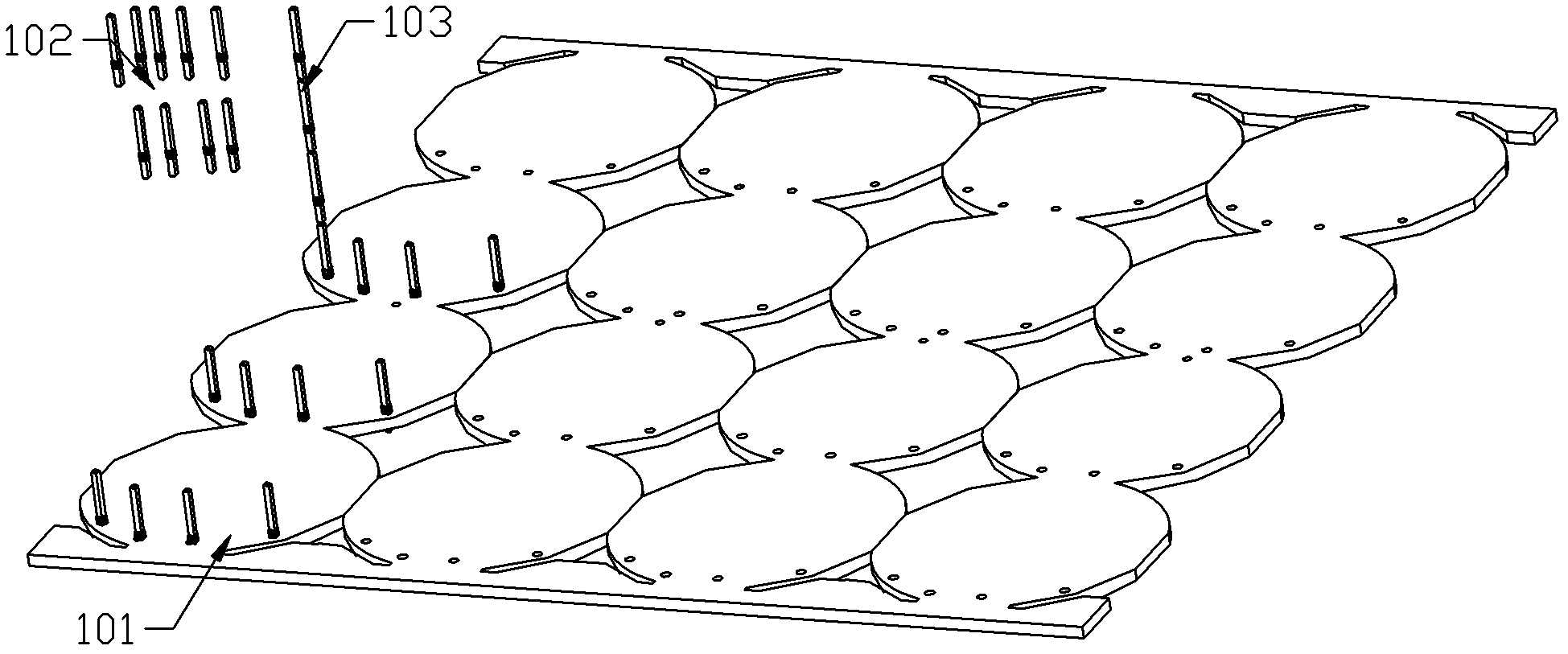

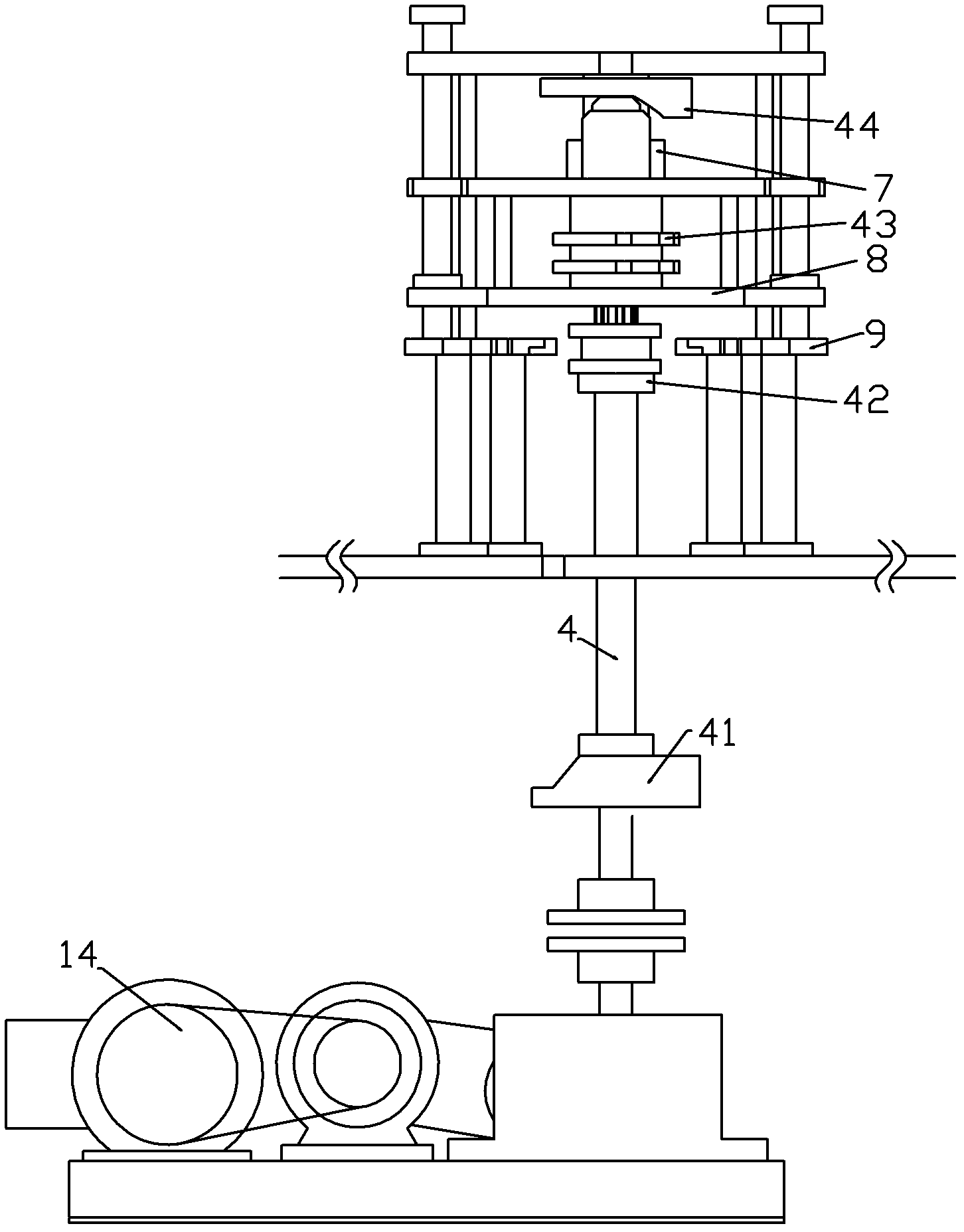

Automatic pin machine of PCB board

ActiveCN102724816AAccelerateIncrease productionPrinted circuit assemblingCutting needleTransmission system

The invention discloses an automatic pin machine of a PCB board. The automatic pin machine of the PCB board comprises a frame, a power system, a main shaft transmission system, a wire rod clamping relaxing module, a cutting needle module, a plate putting warehouse, a numerical control division plate system, a numerical control shift plate positioning system and an automatic material returning system. The automatic pin machine of the PCB board possesses a completely automatic production function which comprises that: the automatic division plate, the automatic shift plate, the automatic positioning and automatic plate returning can be achieved; a main shaft transmission mechanism drives the machine to automatically clamp a wire, send the wire and be cut off after automatic insertion. A plurality of pins are simultaneously inserted at once. A speed is fast, an output is high, cost is low and pin efficiency is high. In addition, the pins have a same length during a pin process. Verticality of the pins is good and pin quality is high, which provides a solid foundation for a subsequent automatic production technology. The wire rod used by the pin machine is a whole roll of steel wire which is automatically cut into the pins through the machine so that secondary processing cost of processing the wire rod into the pins can be saved. The raw material cost can be substantially reduced.

Owner:颍上县永安塑业有限公司

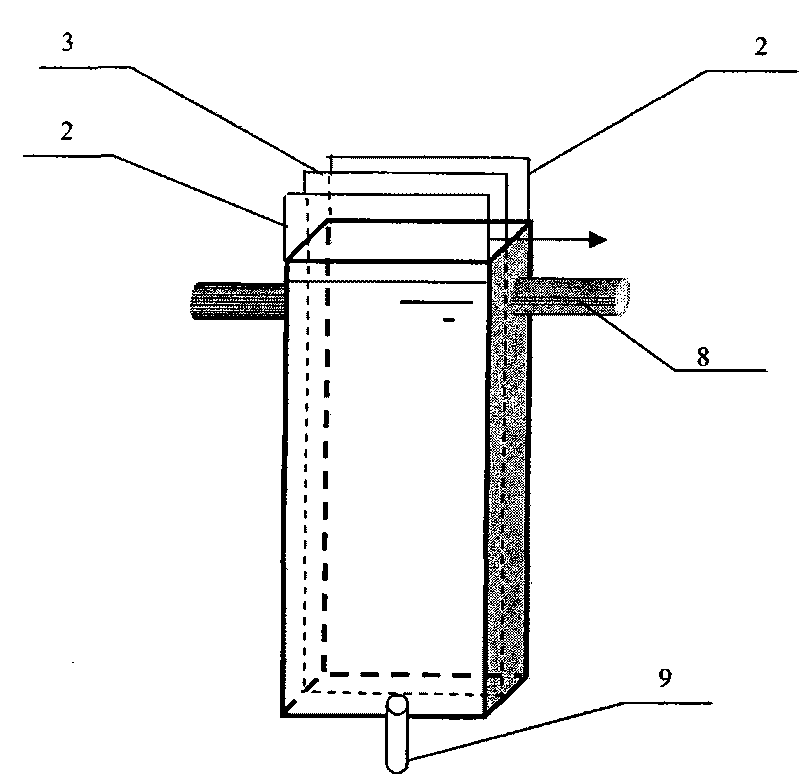

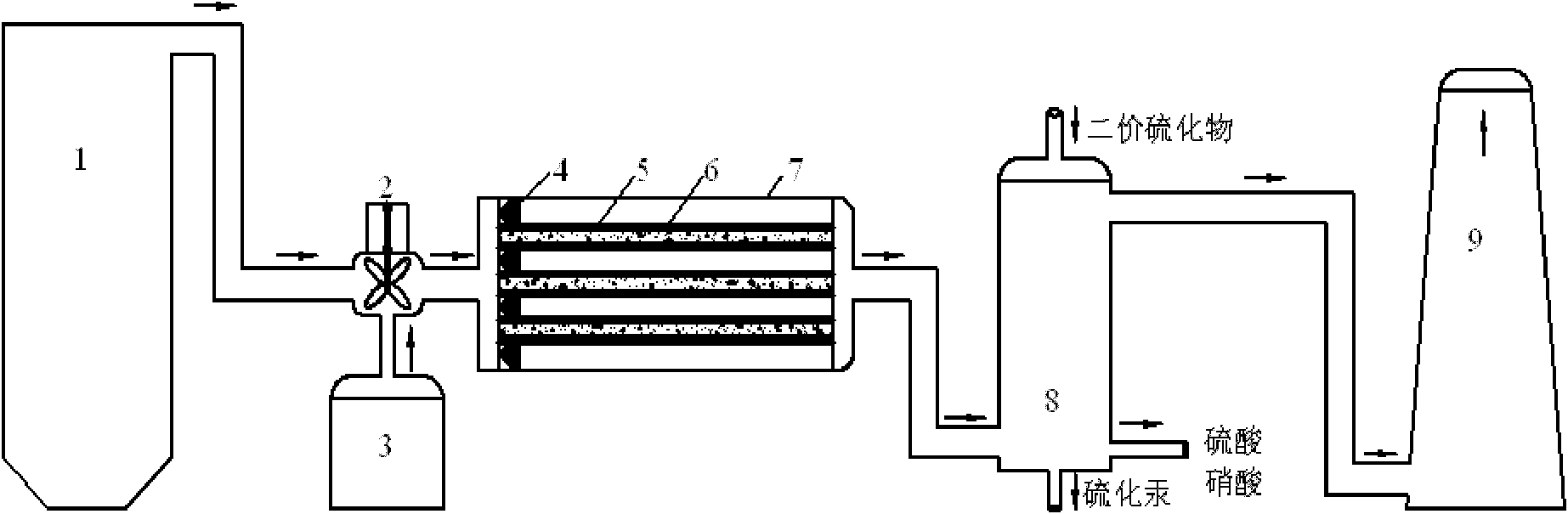

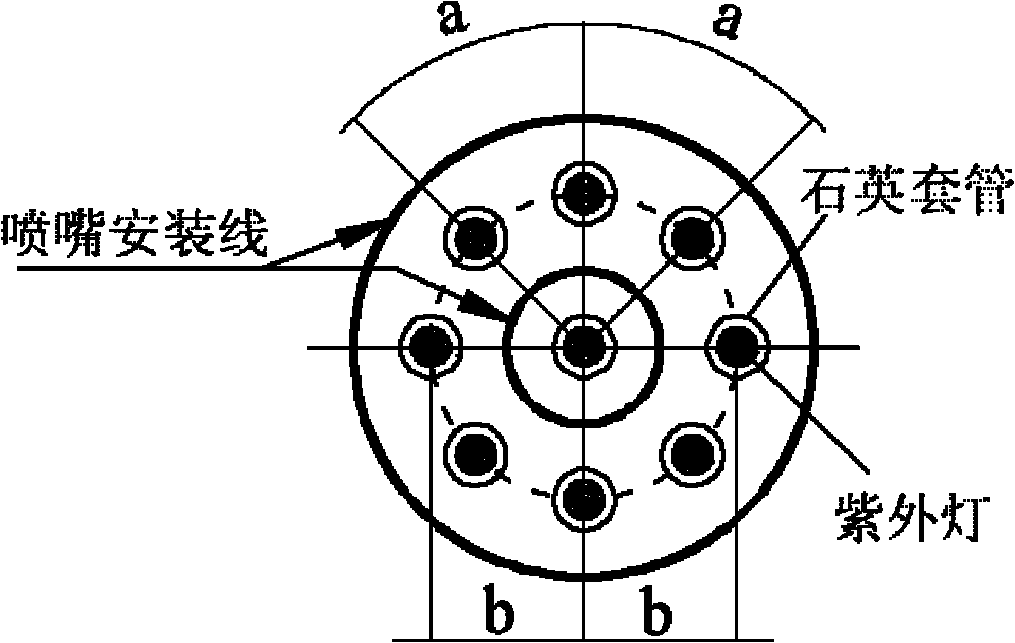

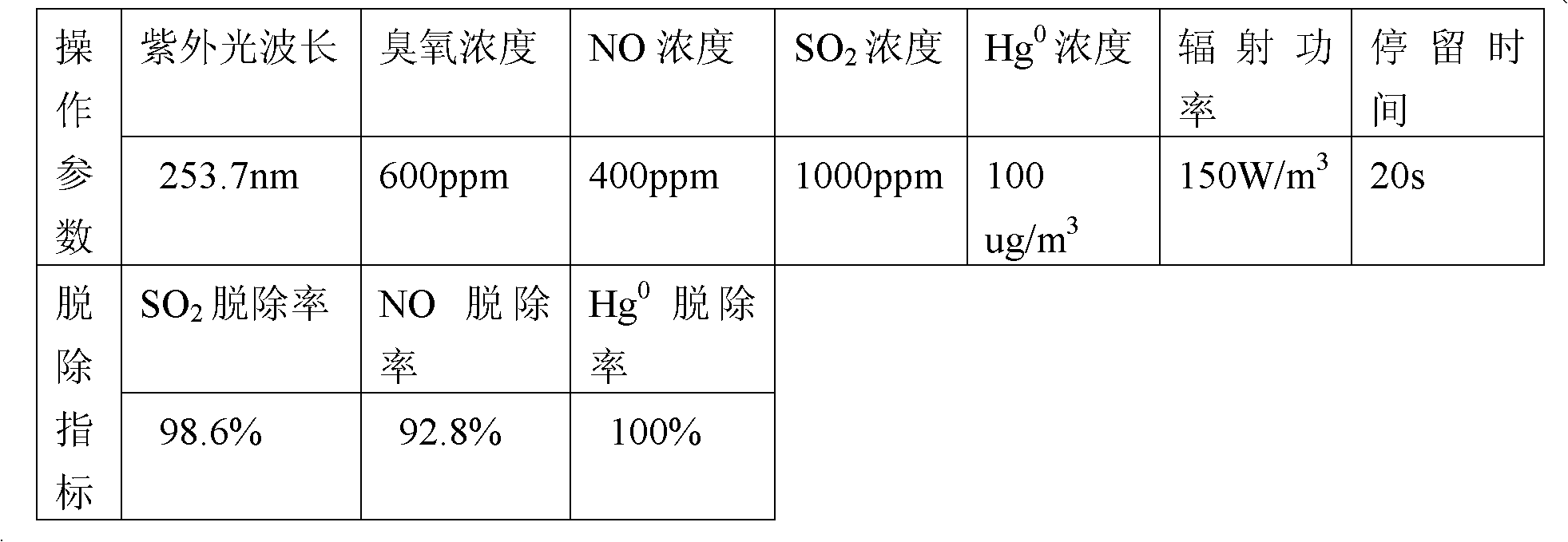

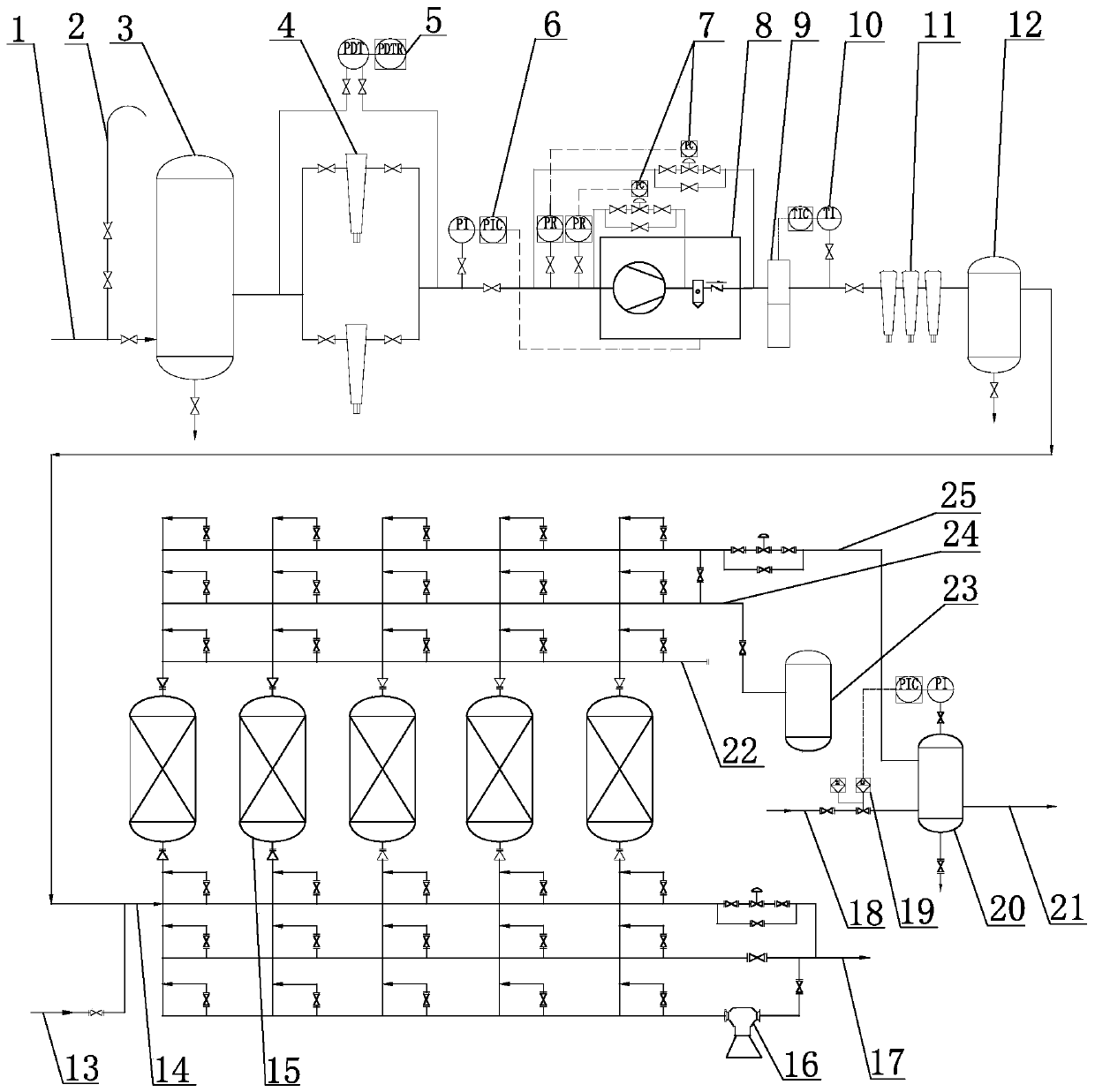

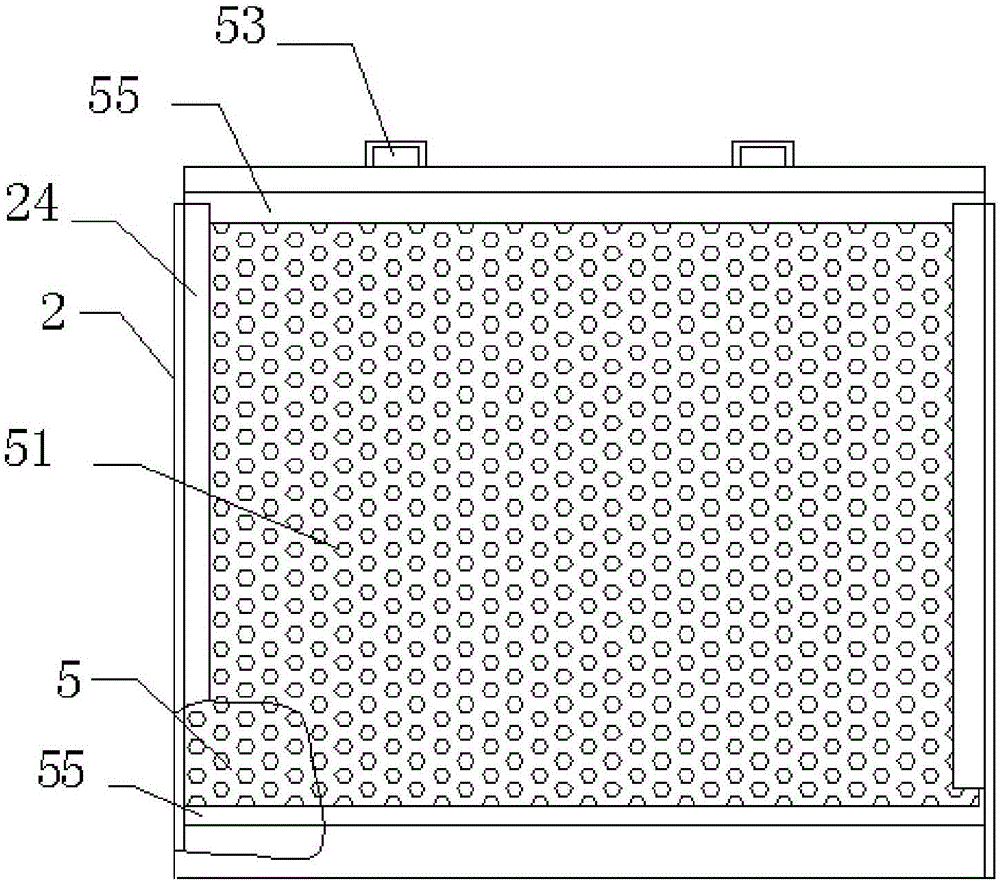

Fume purification system based on advanced oxygenation combining wet scrubbing

InactiveCN102160959AHigh reaction rate constantEasy attackDispersed particle separationSolubilityEngineering

The invention provides a fume purification system based on advanced oxygenation combining wet scrubbing. The system is a combustion and exhaust system formed by a boiler, an ozone generator, a stirrer, a swirl nozzle, a reactor, a gas-liquid absorption tower and a chimney, wherein fume containing sulfur oxide, nitric oxide and mercury generated by combustion of the boiler and O3 generated by the ozone generator enter the stirrer together, are mixed, flow through the swirl nozzle, and are sprayed into the reactor with an ultraviolet lamp tube; and hydroxyl radical (.OH) with strong oxidability generated under excitation of ultraviolet radiation, SO2 in the fume, indissoluble NO and HgO are oxidized into gaseous products with higher dissolubility and enter the gas-liquid absorption tower to be absorbed and removed by water; Hg<2+> generated in the gas-liquid absorption tower captures and retrieves mercuric sulfide by adding sulfidion S<2-> in equal molar ratio; and the residual sulfuric acid and nitric acid mixed solution is used as an industrial raw material for recycling, and the cleaned fume enters the chimney so as to be exhausted.

Owner:SOUTHEAST UNIV

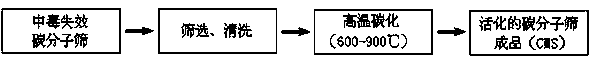

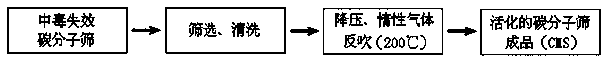

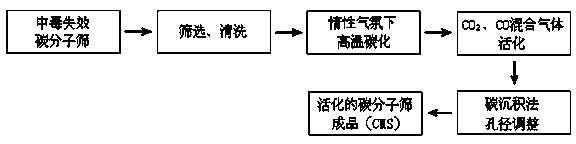

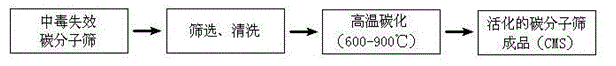

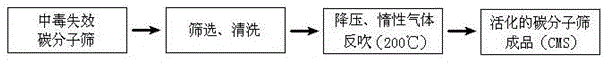

Regeneration method of nitrogen-preparation carbon molecular sieve

ActiveCN103349973ASmall apertureUniform pore sizeOther chemical processesCombustible gas purificationNitrogen gasBiological activation

The invention relates to the technical field of molecular sieve, and especially relates to a regeneration method of a nitrogen-preparation carbon molecular sieve. The method provided by the invention sequentially comprises the steps that: screening and washing are carried out, wherein poisoned carbon molecular sieve is screened by using a mesh, and the screened carbon molecular sieve is washed by using water, such that impurities are removed; nitrogen-based high-temperature charring is carried out, wherein the temperature is increased to 850-1000 DEG C under the protection of nitrogen gas, such that charring is carried out; mixed gas activation is carried out, wherein a mixed gas of CO2 and CO is delivered into a furnace cavity, wherein the proportion of CO2 is 85-90%, such that the charred carbon molecular sieve is activated, wherein the temperature in the furnace is 700-800 DEG C; carbon deposition is carried out, wherein activated carbon molecular sieve is placed in a furnace cavity of a converter; the temperature in the converter is 800-900 DEG C; xylene is delivered in under the protection of nitrogen gas; the temperature of the furnace is maintained at 300-500 DEG C, such that xylene is absorbed by the carbon molecular sieve; xylene is cracked under the temperature of 800-900 DEG C, such that pyrolytic carbon is deposited on the char material; the carbon molecular sieve is subjected to pore size adjustment, such that a regenerated finished product is obtained. With the method provided by the invention, deeply poisoned nitrogen-preparation carbon molecular sieve can be activated, and the pore sizes after activation is uniform.

Owner:HUZHOU XINAOLI ADSORPTION MATERIALS

Environmental protection material with insect expelling and purifying functions, and manufacturing method and application thereof

InactiveCN104693830AEasy to handleHas the function of repelling insects and purifyingCoatingsFiberEngineering

The invention relates to an environmental protection material with insect expelling and purifying functions, and a manufacturing method and an application thereof, and belongs to the field of the environmental protection material. The environmental protection material comprises the following components in percentage by mass: 10-15% of plant fiber, 30-40% of traditional Chinese medicine residue, 28-35% of glue and 18-25% of additive. The environmental protection material has the following beneficial effects: the raw materials of the environmental protection material are agricultural wastes and pharmaceutical wastes, the processing problem of the agricultural wastes is solved, and the processing problem of the pharmaceutical wastes is solved at the same time, the corruptible is transformed into mysterious life, the earth is protected and the environment is purified.

Owner:杨国桢 +2

Method for forming an embossed holographic pattern

ActiveUS20100000668A1Reduce tensionEasily woundDecorative surface effectsPretreated surfacesInformation layerLaser holography

A method for forming an embossed holographic pattern comprises the following steps: A. recording the required pattern onto a photo-sensitive plate by means of laser holography to produce an optical mask plate for the holographic pattern; B. duplicating the laser holographic information on the optical mask plate onto a metal plate, to produce a metal plate for the holographic pattern; C. transferring the laser holographic pattern on the metal plate onto an information layer on a water soluble film, to form an embossed holographic water transfer printing film; D. carrying out a cubic water transfer printing on the surface of a base material by using the embossed holographic water transfer printing film, to form the holographic pattern on the surface of the base material. With the method for forming the embossed holographic pattern according to the present invention, a holographic pattern can be formed on the surface of work-piece having a complex shape.

Owner:BYD CO LTD

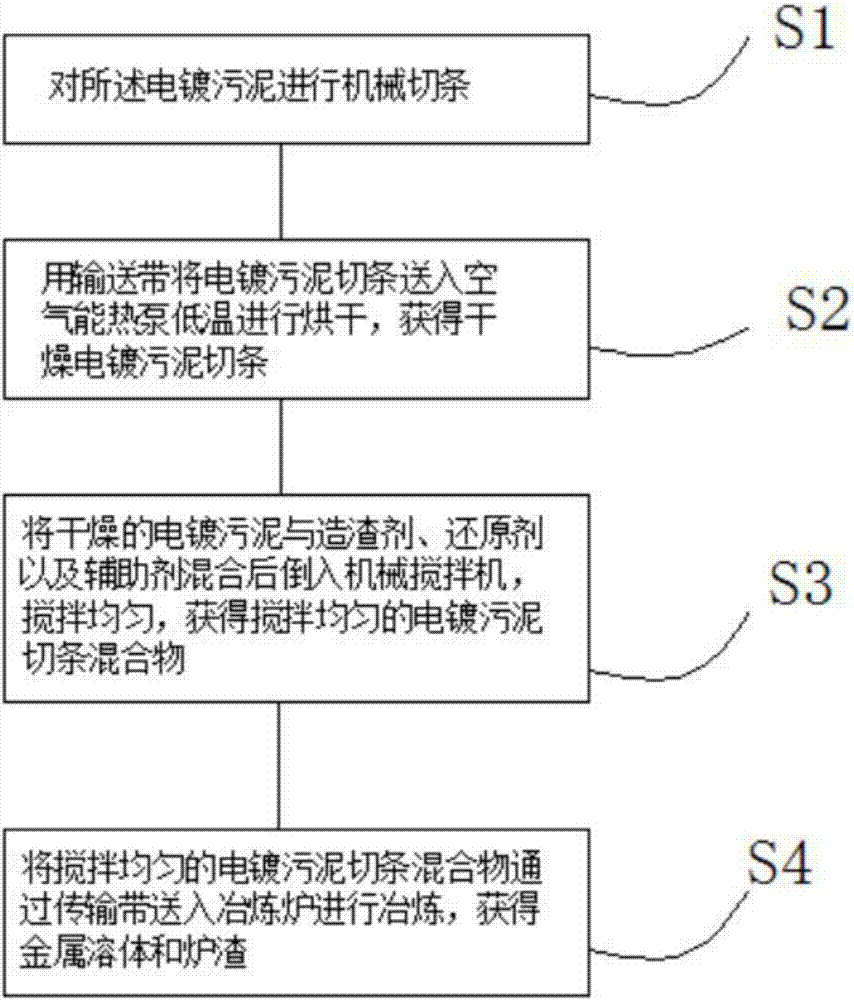

Processing method of electroplating sludge resource comprehensive utilization

InactiveCN107034357AReduce energy consumptionHigh recovery rateProcess efficiency improvementBrickSlag

The invention provides a processing method of electroplating sludge resource comprehensive utilization. The method comprises the following steps: S1, carrying out mechanical slitting on electroplating sludge; S2, feeding the electroplating sludge slice to an air energy heat pump to dry at a low temperature through a conveyer belt and obtaining a dried electroplating sludge slice; S3, after mixing the dried electroplating sludge with a fluxing medium, a reducing agent and a cosolvent, pouring into a machine mixer, uniformly stirring and obtaining a uniformly mixed electroplating sludge slice mixture; and S4, feeding the uniformly mixed electroplating sludge slice mixture to a smelting furnace to smelt through the conveyer belt, and obtaining metal solution and a furnace slag. The energy consumption needed for drying the electroplating sludge is reduced by adopting the heat pump to dry at low temperature, the metal solution and the furnace slag can be obtained by adopting the smelting furnace with the melting technology, metal recovery rate can be well increased, and the smelted furnace slag can be used for brickmaking recycling and reusing. The processing method effectively reduces the processing cost, is safe and hygienic, energy-saving and environmental friendly, and with wider adaptability.

Owner:郭聪

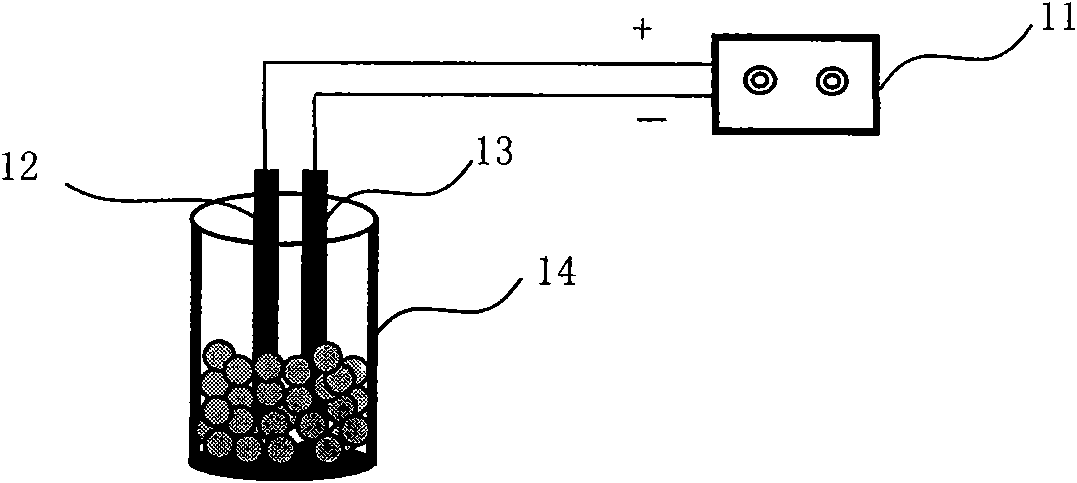

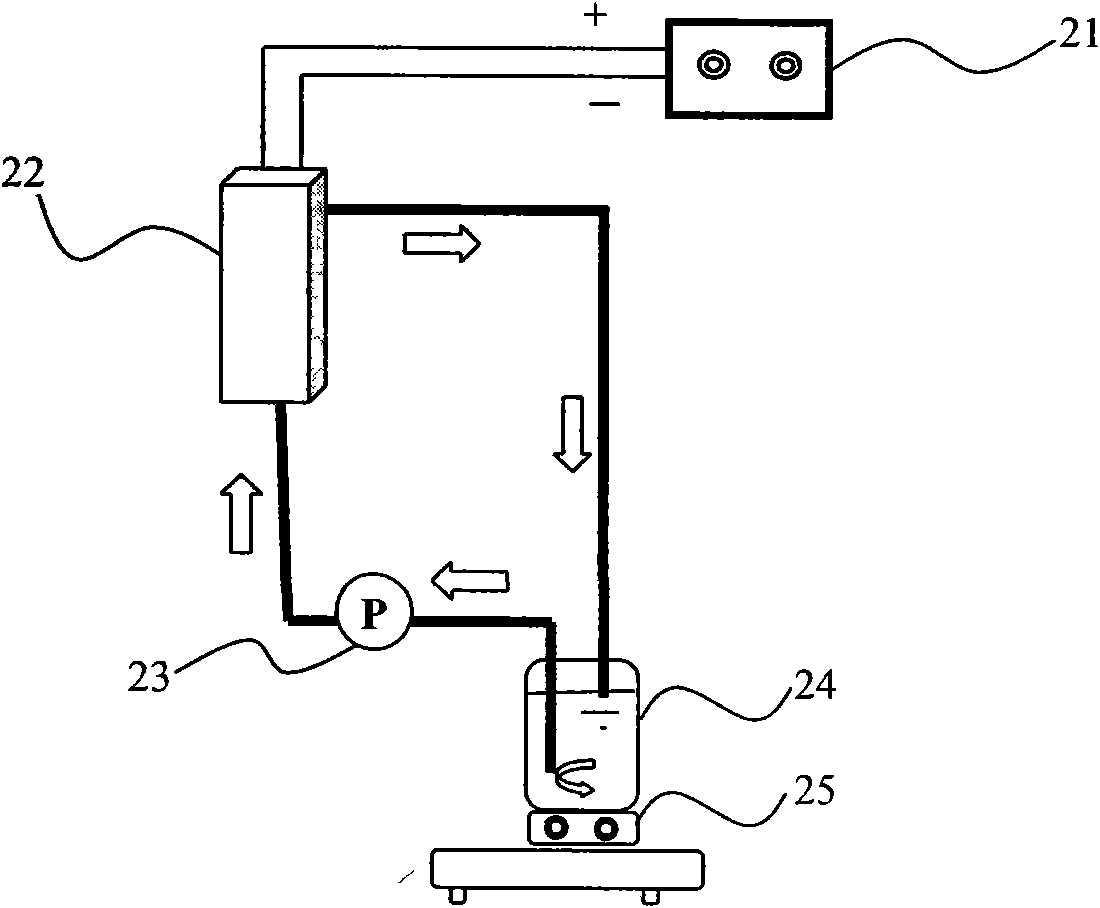

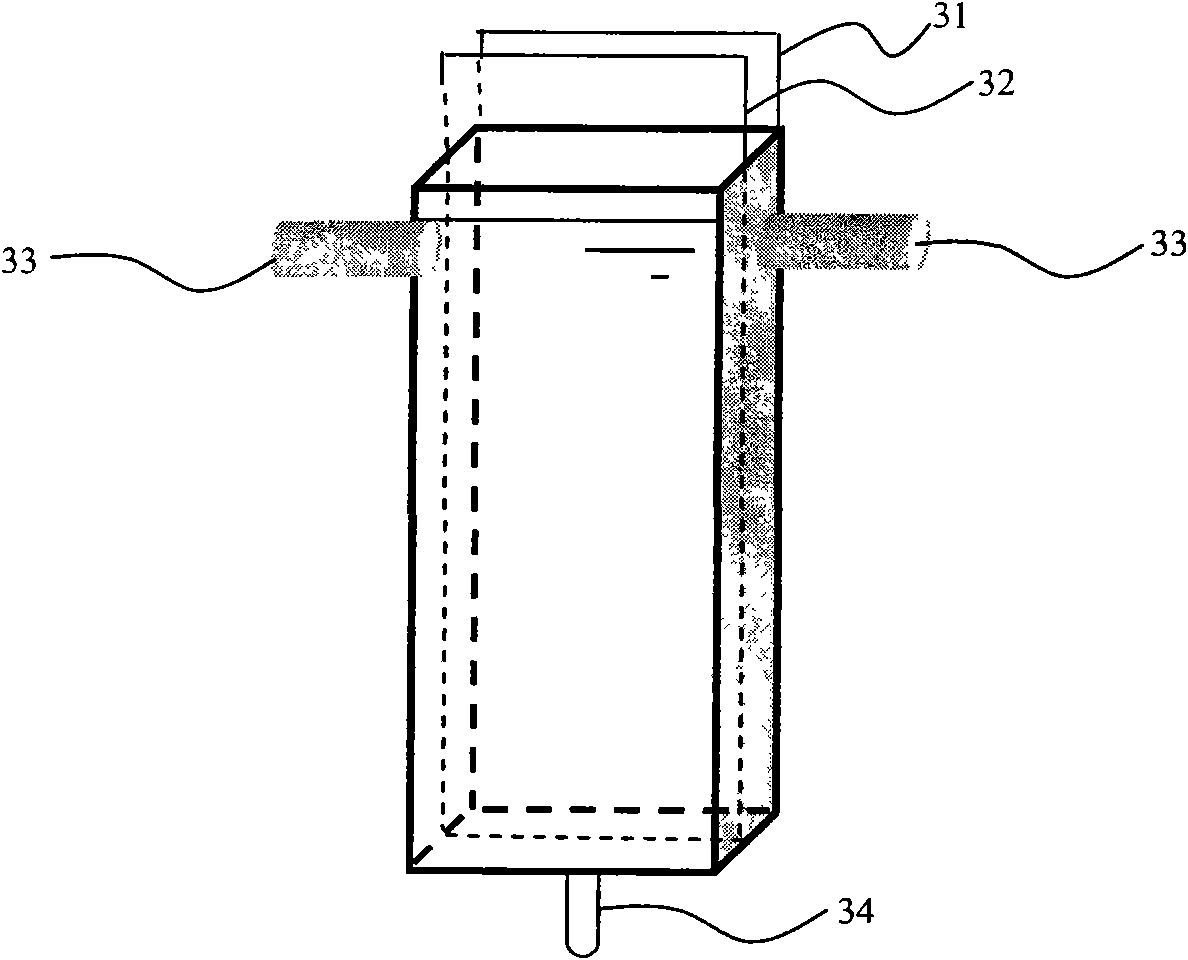

Ammonia adsorbent regeneration and regeneration liquid pollution-free disposal method and device

InactiveCN101862646AReduce secondary processing costsEasy to makeWater/sewage treatmentCombustible gas purificationElectrolysisSorbent

The invention discloses an ammonia adsorbent regeneration and regeneration liquid pollution-free disposal method and a device; the method comprises the following steps that: in an electrobath, using an electrode comprising Fe, Ti, Al, Pd, Cu, Zn, Sn, Cu / Zn, Cu / Pd or Ti / Pd as the cathode, using an insoluble electrode comprising Pt, Ir, Ru, Pd or Pb as the anode, using the solution containing a chloride ion compound as the electrolyte, putting ammonia adsorbent after ammonia adsorption saturation into the solution containing the chloride ion compound, and electrolyzing for 1 to 5h under the current density of 10 to 50mA / cm2. The invention carries out regeneration liquid pollution-free disposal while carrying out adsorbent regeneration, thereby reducing the regeneration cost of the ammonia absorbent, preventing secondary pollution and realizing the reuse of the regeneration liquid, and the device for implementing the ammonia adsorbent regeneration and regeneration liquid pollution-free disposal method has the advantages of simple manufacturing, convenient operation and easy automation realization; and in addition, the regeneration disposal can be fully completed in a single reaction device without other reactors.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

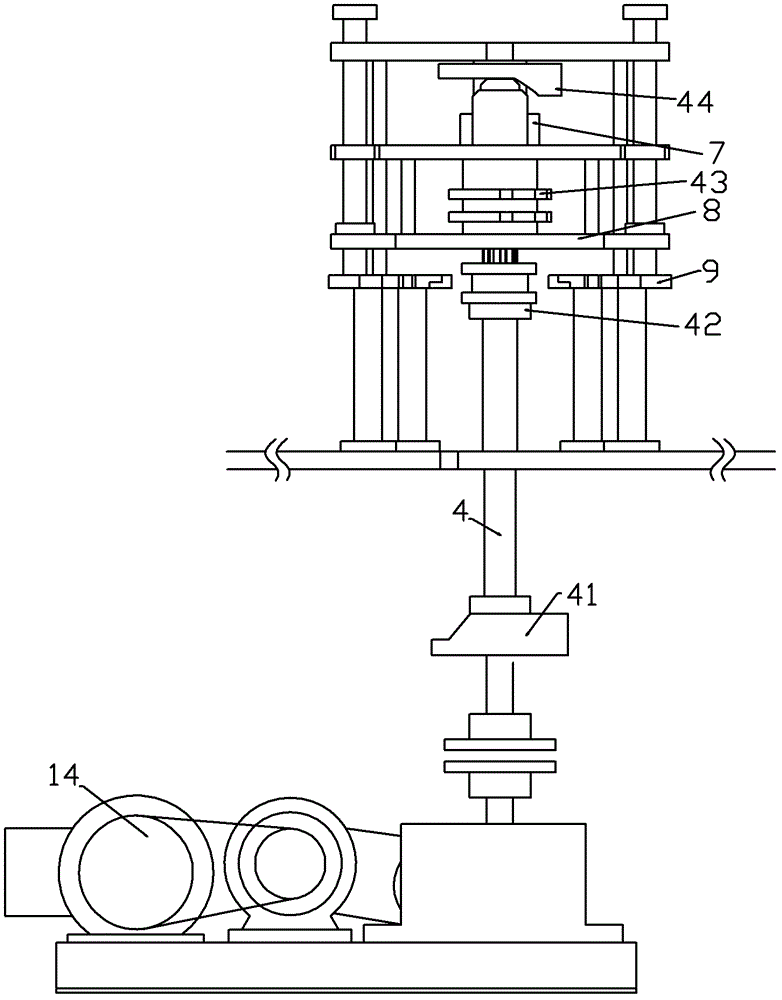

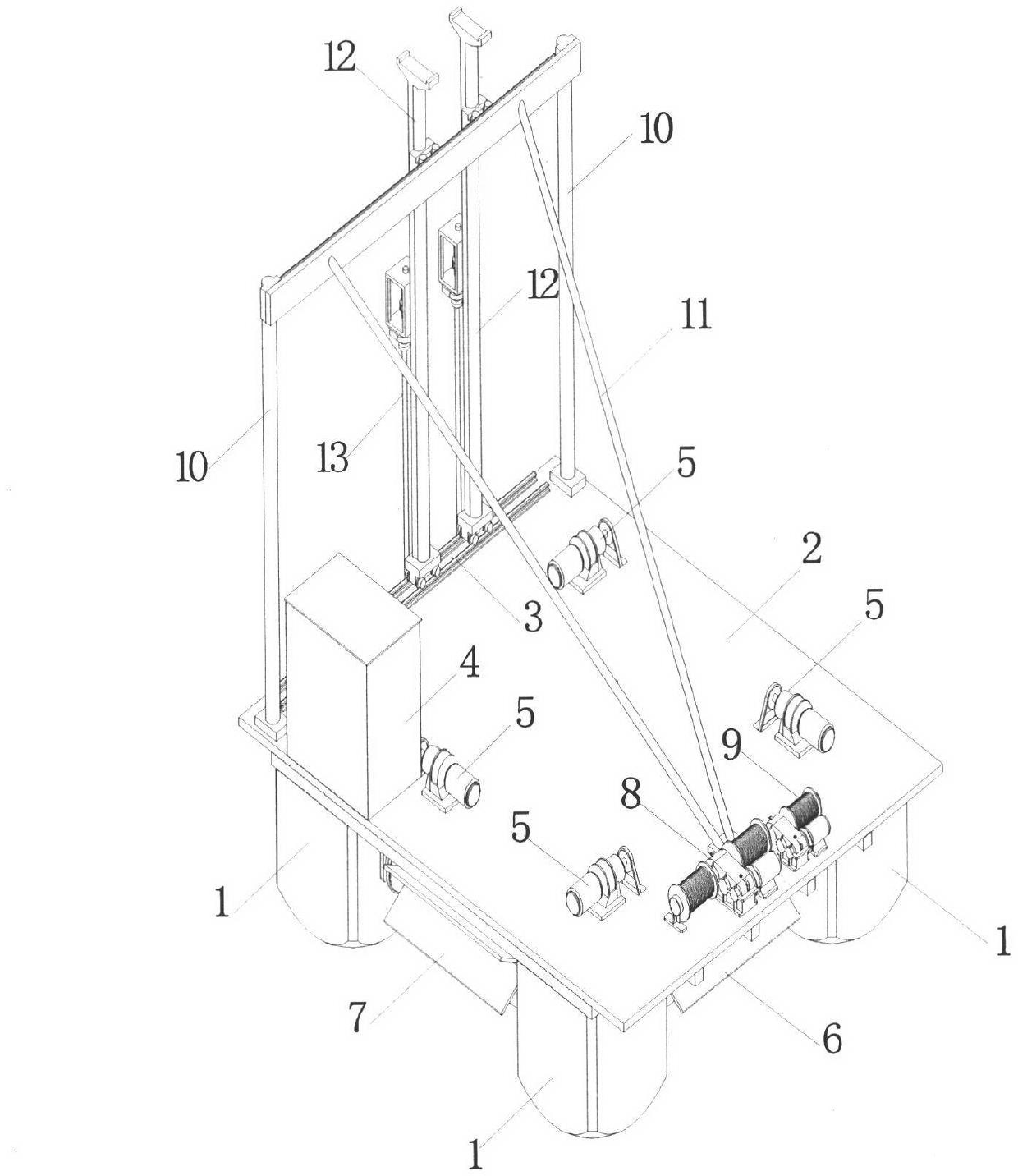

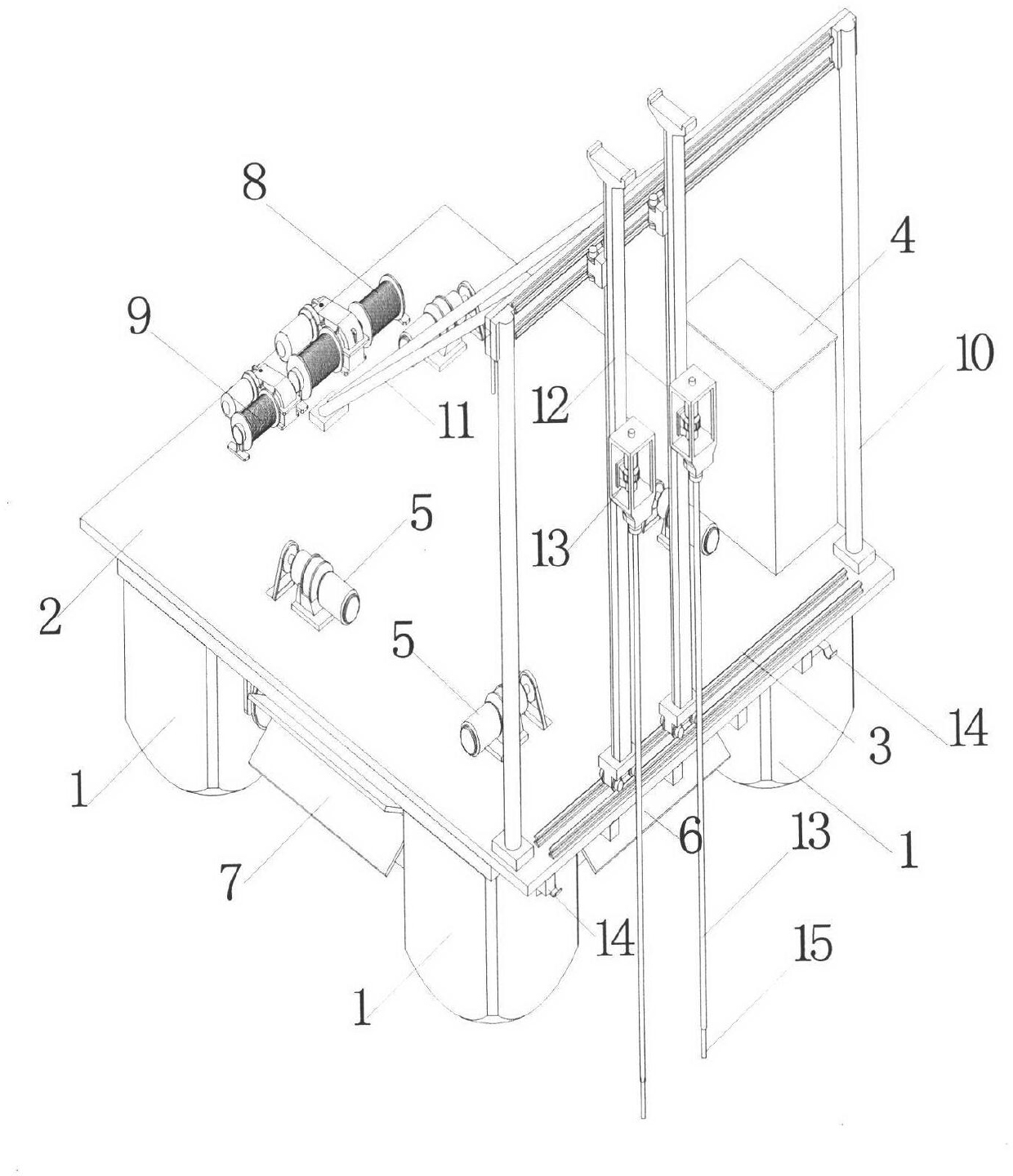

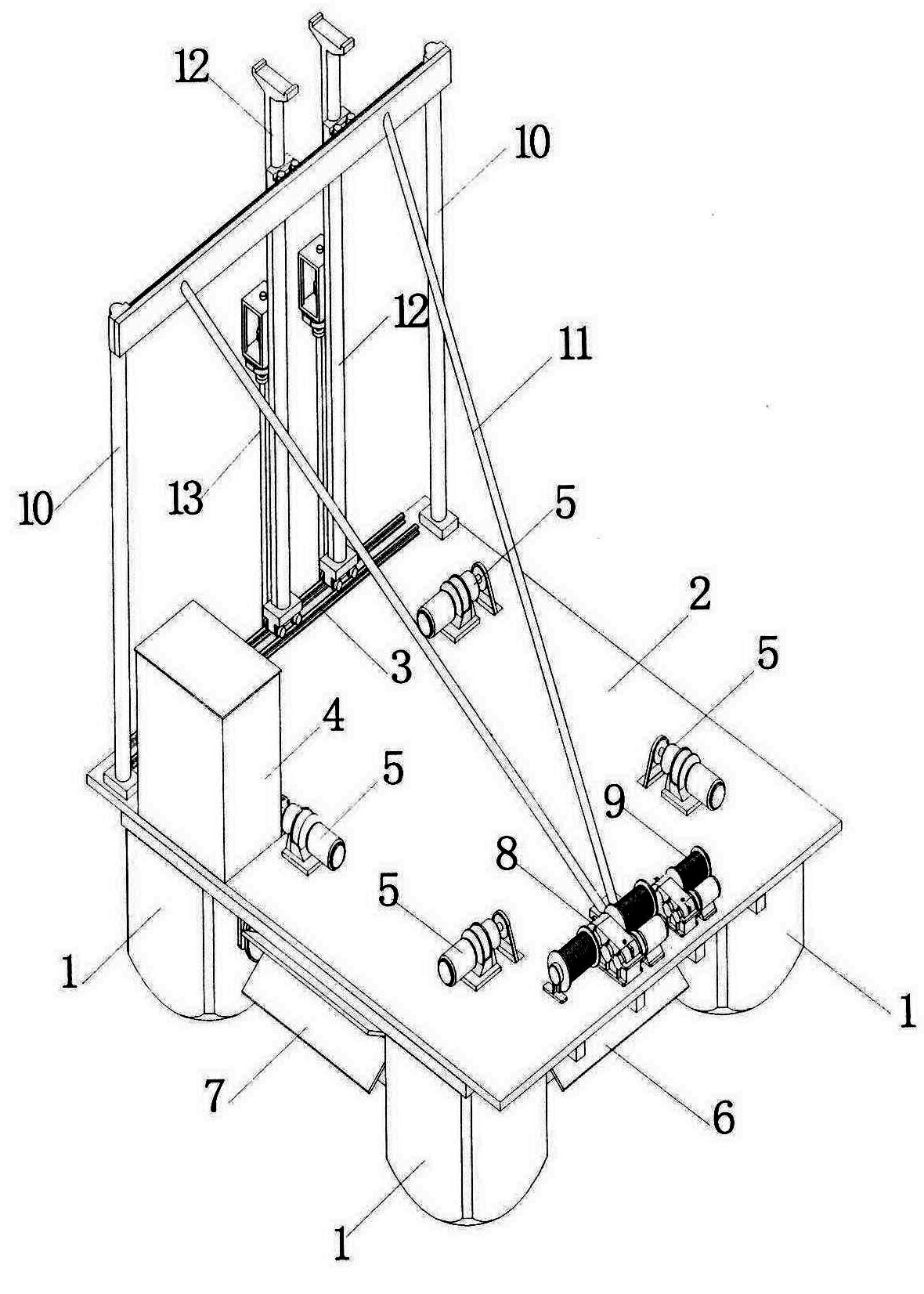

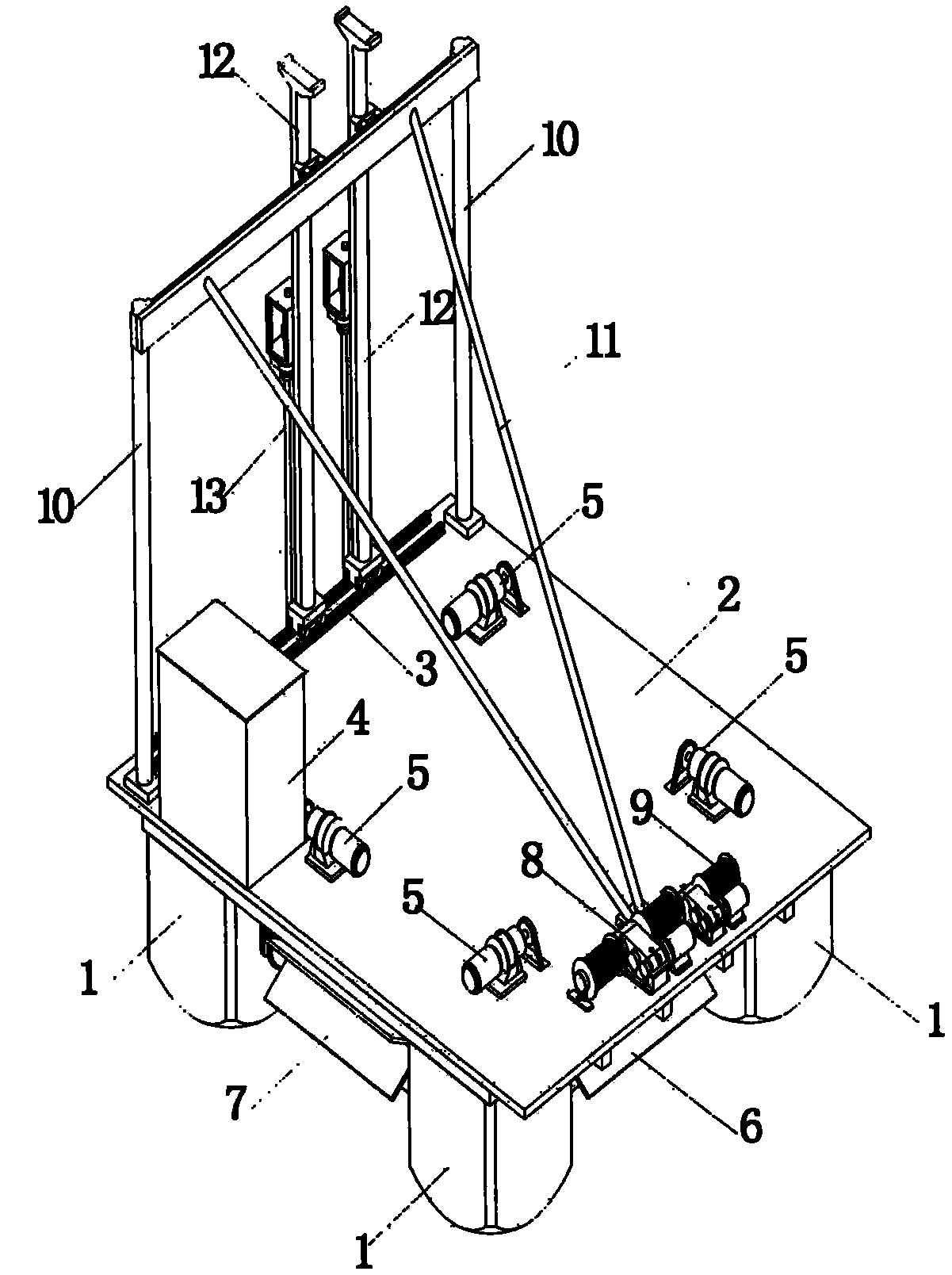

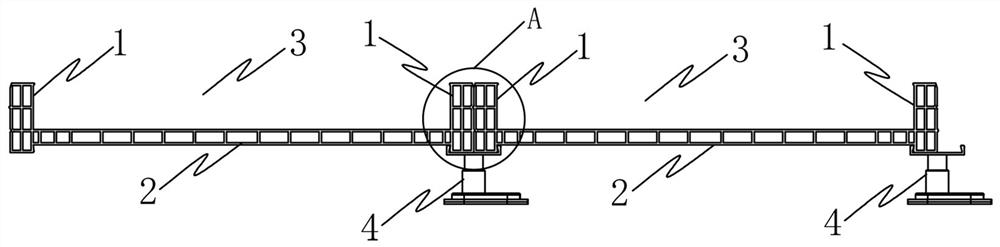

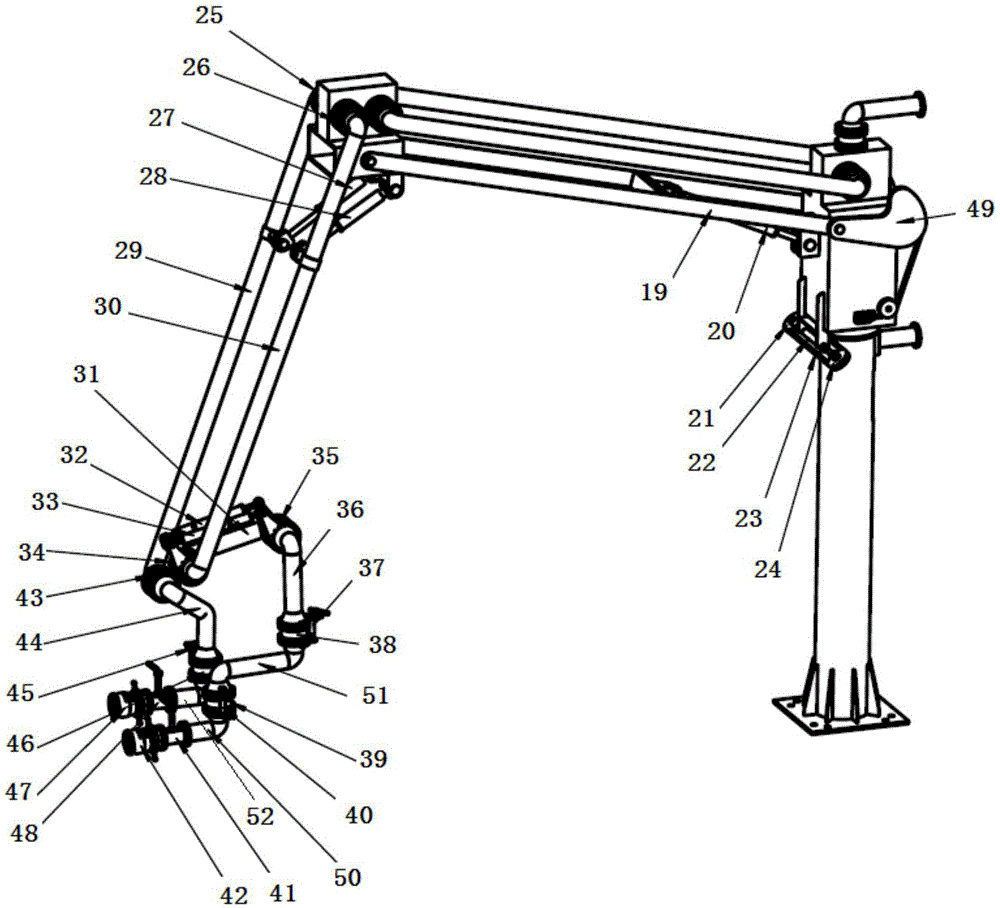

Insert plate device capable of walking on blown-filled mud soil

The invention relates to an insert plate device capable of walking on blown-filled mud soil. A horizontal-direction plate-type impeller and a vertical-direction plate-type impeller which are vertically arranged are installed between the lower part of a floating cabin connected with an operation platform and a floating cabin; one side of the operation platform is vertically provided with a gantry; the upper end of an inclined support is connected with a cross rod, and the lower end of the inclined support is connected with the other side of the operation platform; the upper end of an insert plate stand is connected on the cross rod of the gantry in a sliding way, and the lower end of the insert plate stand is connected on a guide rail of the insert plate stand in a sliding way; the other side of the operation platform is provided with an insert plate winch and a shifting winch; the insert plate winch is connected with an insert plate machine pipe by steel wires; and the shifting winch is connected with the insert plate stand by steel wires. The insert plate device overcomes the defects of slow speed, low construction efficiency, high potential safety hazard and the like in the process of manually inserting a plastic drainage plate. The insert plate device improves the depth and the effect of foundation treatment, and reduces the secondary treatment cost of foundation; and the insert plate device capable of walking on the blown-filled mud soil is capable of walking and inserting the plate on the blown-filled mud soil with low bearing capacity, so that the construction speed can be accelerated.

Owner:曾国海 +1

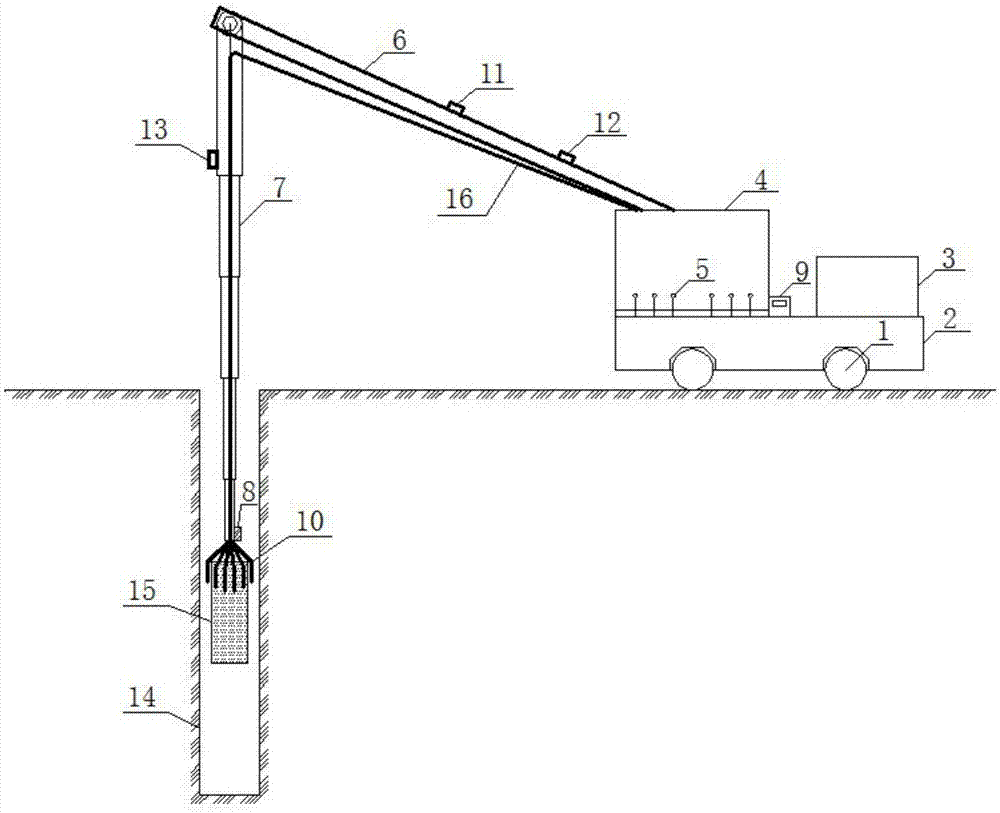

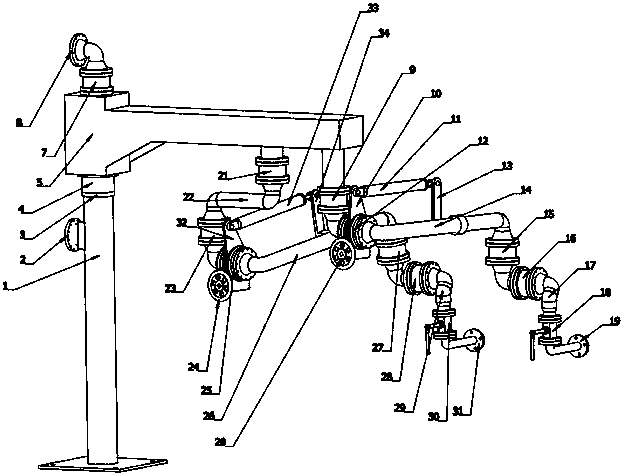

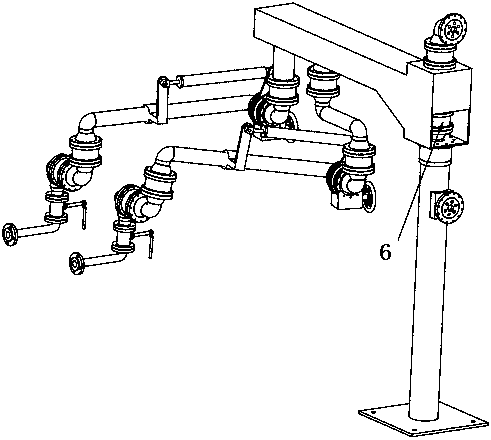

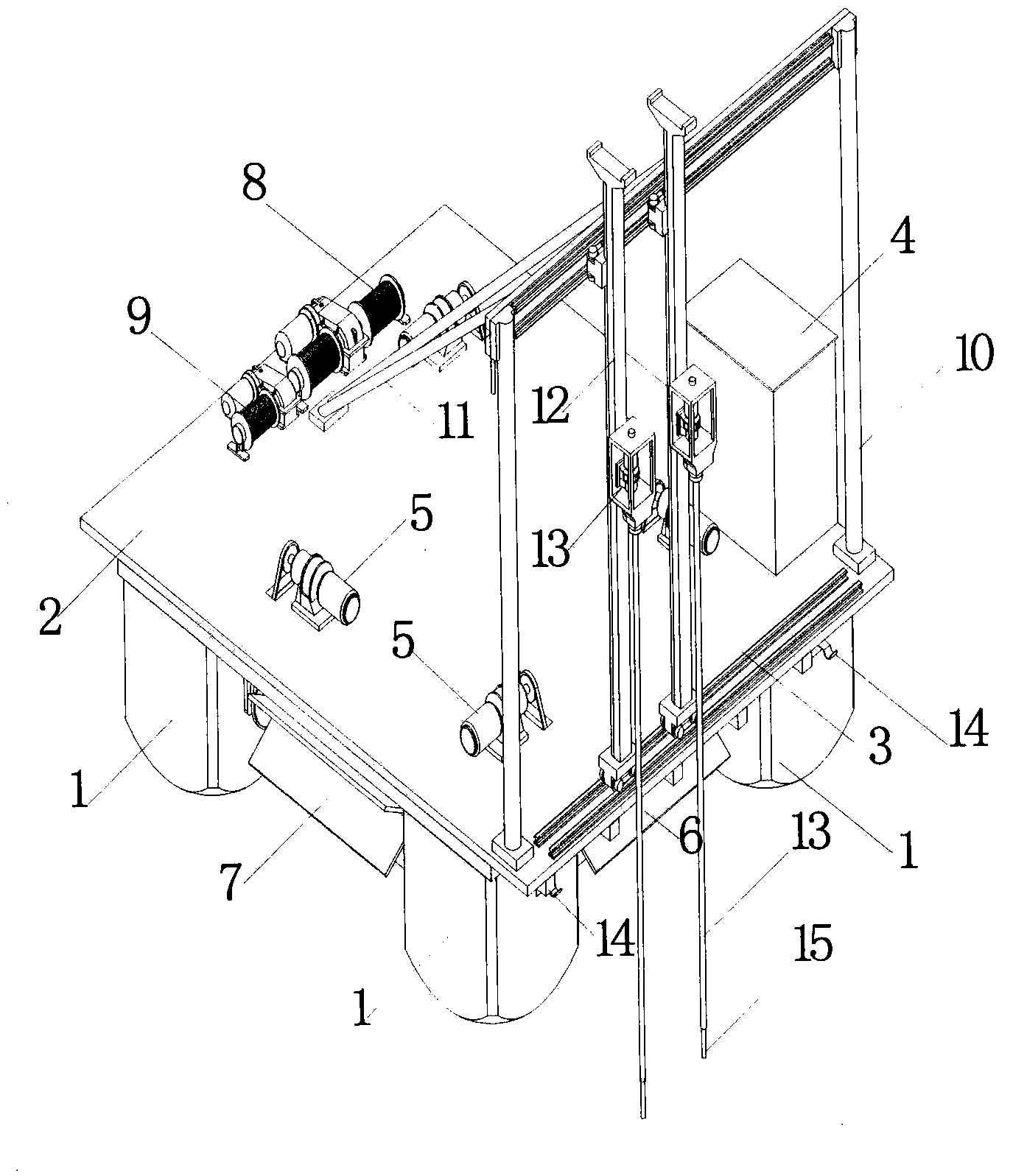

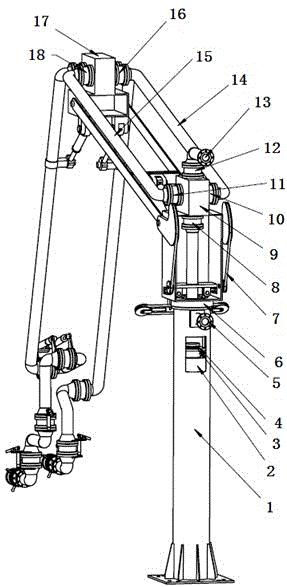

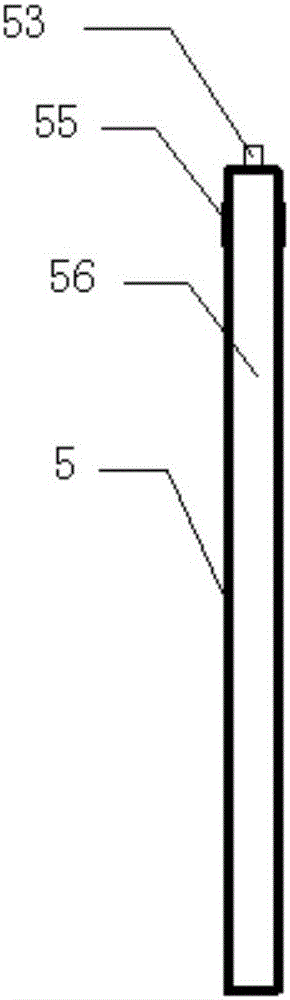

Surface blasting mechanization continuous powder charging system

ActiveCN107449333AEliminate premature explosion accidentsAvoid direct contactBlastingControl systemEngineering

The invention discloses a surface blasting mechanization continuous powder charging system. A rack (2) is supported on a travelling mechanism (1); a power system (3), a hydraulic system (4) and a control system (5) are mounted on the rack (2); one end of a support arm (6) is fixed on the travelling mechanism (1), and the other end of the support arm (6) is connected with a combined telescopic arm (7) downwards perpendicular; a hoisting oil cylinder (11) and a rotary oil cylinder (12) are arranged on the support arm (6); a telescopic oil cylinder (13) and a depth indicator (8) are arranged on the combined telescopic arm (7); the hydraulic system (4) communicates with the hoisting oil cylinder (11), the rotary oil cylinder (12) and the telescopic oil cylinder (13) through a hydraulic oil pipe (16); and the control system (5) controls operation of the support arm (6) and the combined telescopic arm (7) and controls open-close of a gripper (10) through the hydraulic system (4). The surface blasting mechanization continuous powder charging system can realize mechanization of the powder charging process, avoids the powder cut-off phenomenon, eliminates the misfire accident caused by discontinuous powder charging and improves the security of blasting operation.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

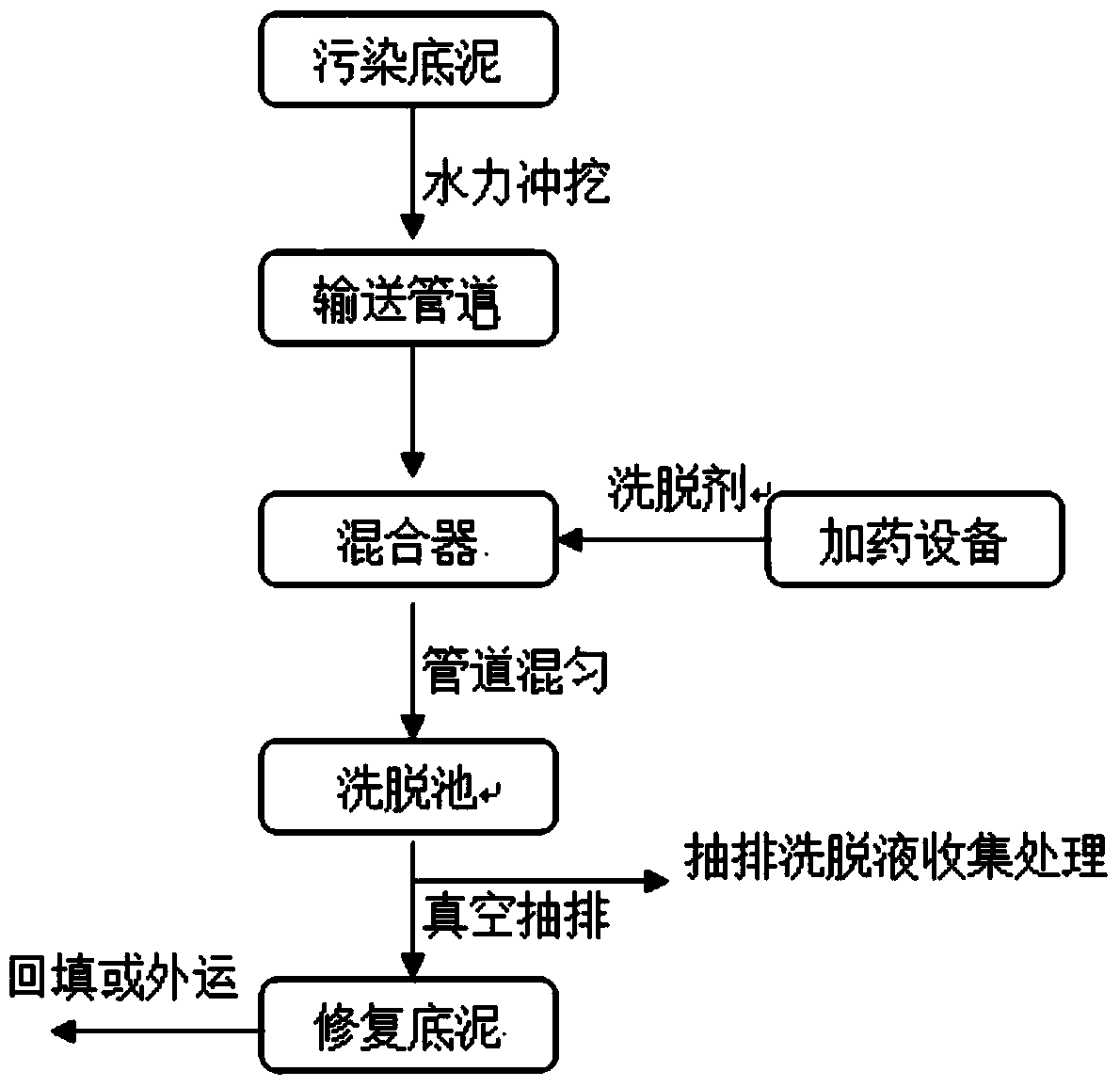

Repair technology for river and lake bottom mud site polluted by heavy metal

InactiveCN103526719AAvoid shippingAvoid the risk of secondary pollutionSludge treatmentStream regulationVacuum pumpingElution

The invention relates to a repair technology for a river and lake bottom mud site polluted by heavy metal. The technology comprises the following processing steps that (1) polluted bottom mud is conveyed to a pipeline by hydraulicking; (2) elution agents are added to the pipeline on line; (3) after blending, the mud is conveyed to an elution pool through the pipeline; (4) vacuum pumping and discharging are carried out on the static mud, eluant is separated; (5) when the heavy metal removal rate in the bottom mud reaches the designed value, work is stopped, and acceptance checking is carried out. According to the repair technology, on the basis that the effect of heavy metal elution repairing is guaranteed, on-site large-scale continuous operation is achieved, polluted bottom sample malposition repairing conveying cost and risks are lowered, the vacuum pumping mode accelerates heavy metal elution speed, and social and economical benefits are obvious.

Owner:JIANGSU JIANGDA ECOLOGICAL SCI & TECHCO

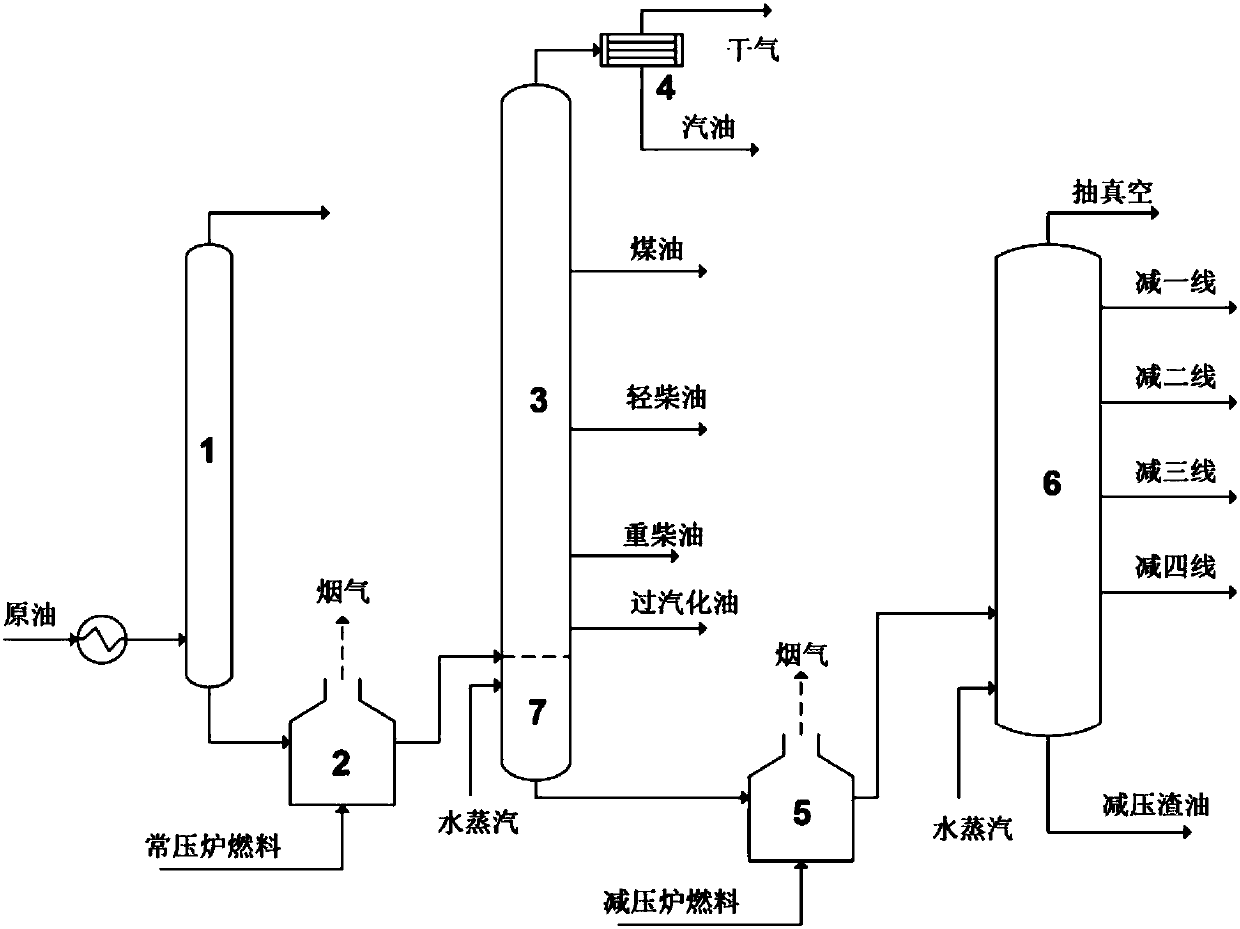

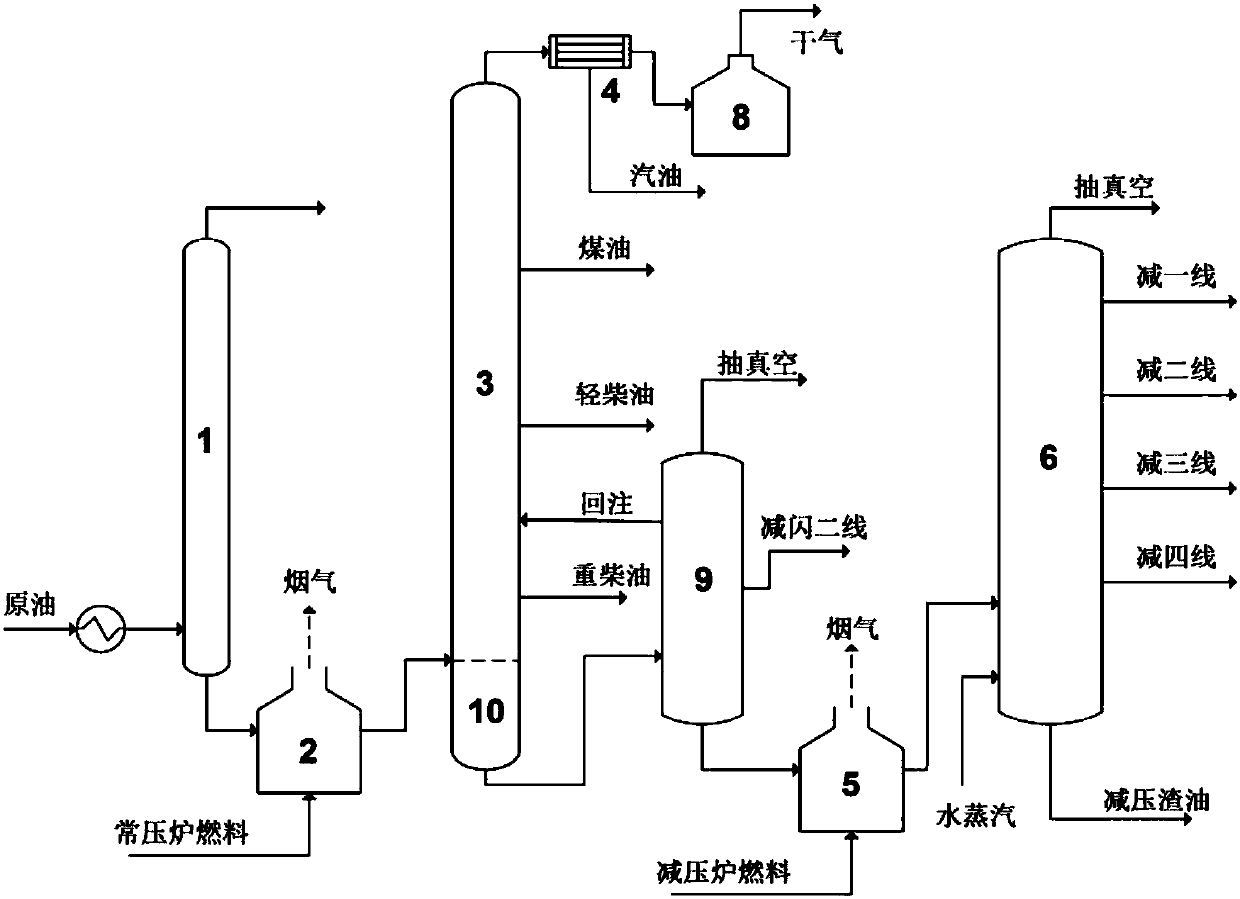

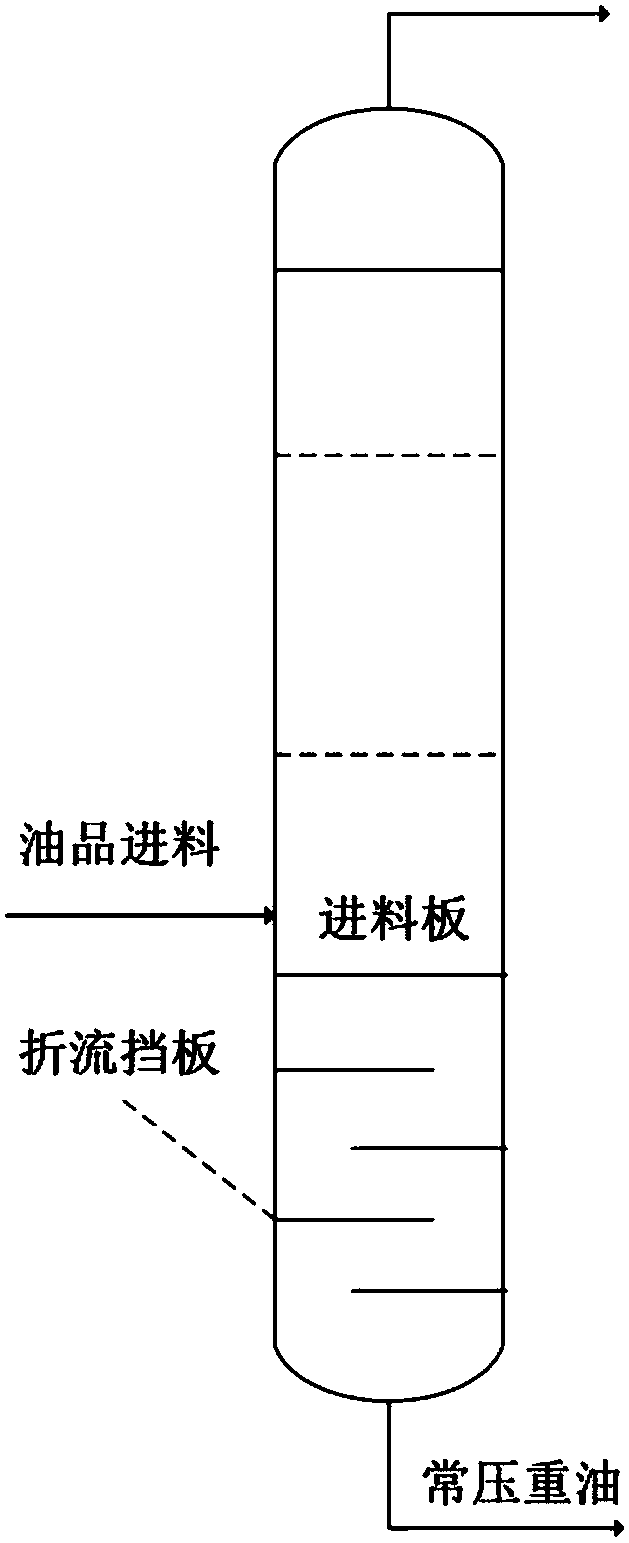

Water-free atmospheric vacuum distillation technology and device

ActiveCN107699273AEasy to separateSolve the problem of low temperature dew point corrosionHydrocarbon distillation control/regulationVacuum distillationReboilerFuel oil

The invention provides a water-free atmospheric vacuum distillation technology and device. The technology is characterized in that a normal-pressure tower and a vacuum tower adopt a four-time gasification and feeding manner; after crude oil is heated through a normal-pressure furnace, materials are fed from a tower kettle of the normal-pressure tower; water steam is not introduced into the tower kettle; each sideline product is heated by adopting a reboiler; alkali washing is carried out on tower top dry gas which is condensed and cooled at a tower top of the normal-pressure tower; a vacuum flashing tower is additionally arranged between the normal-pressure tower and a vacuum furnace; normal-pressure heavy oil from the tower kettle of the normal-pressure tower enters the vacuum flashing tower; the vacuum flashing tower is provided with a plurality of sidelines for drawing out products; the product drawn out from the first sideline is injected into the normal-pressure tower again; the heavy oil of the tower kettle enters the vacuum furnace and is further heated, and then enters the vacuum tower; pressure of the vacuum flashing tower is controlled between the pressure of the normal-pressure tower and the pressure of the vacuum tower. The invention further provides the water-free atmospheric vacuum distillation device. By adopting the device and the technology, provided by the invention, the low-temperature dew-point corrosion problem of the top of the normal-pressure tower can be solved, refinery wastewater is reduced and the diesel oil extraction rate of the normal-pressureheavy oil is improved; serious entrainment of the vacuum tower is alleviated and the decompression and deep drawing vacuum degree is reduced. The long-period, safe, stable and operation performance ofthe device is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

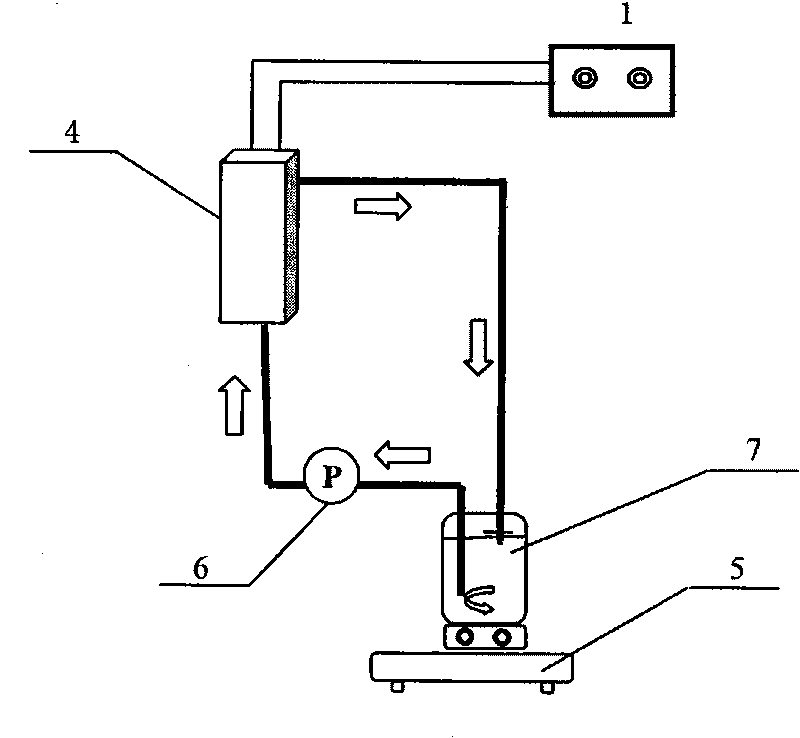

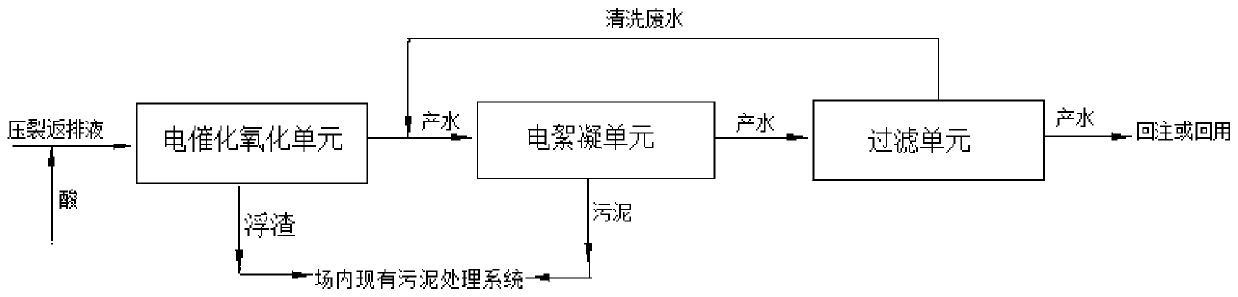

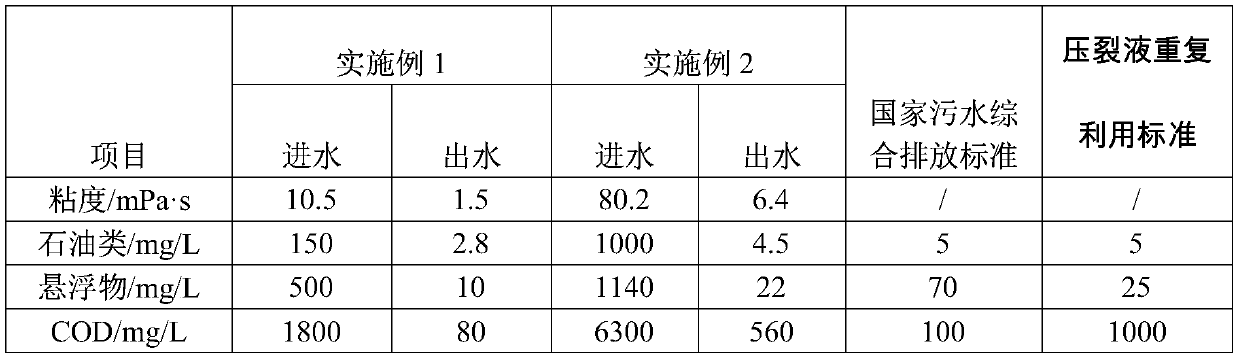

System and method for electrochemically treating high-viscosity fracturing flow-back fluid

InactiveCN110642334AReduce secondary processing costsHigh degree of automationWaste water treatment from quariesWater treatment parameter controlCatalytic oxidationElectro flocculation

The invention discloses a system for electrochemically treating a high-viscosity fracturing flow-back fluid. The system comprises a pH adjusting unit, an electrocatalytic oxidation unit and an electric flocculation unit which are arranged in sequence, wherein the pH adjusting unit is used for adjusting the pH value of the fracturing flow-back fluid to 4-7, the electrocatalytic oxidation unit comprises an electrocatalytic oxidation device, and the electric flocculation unit comprises an electric flocculation device connected with effluent of the electrocatalytic oxidation device. The inventionalso discloses a method for treating the fracturing flow-back fluid. The method comprises the following steps: 1) adjusting the pH value of the fracturing flow-back fluid to be treated to 4-7; 2) performing electrocatalytic oxidation treatment on the fracturing flow-back fluid obtained in step 1); and 3) performing electric flocculation treatment on effluent in step 2). The treatment system and the method mainly adopt electric energy to achieve the treatment of the fracturing flow-back fluid, so the system and the method accord with the clean production category; and a large amount of an organic or inorganic polymer agent is not needed in the treatment process, so the system and the method have the advantages of no secondary pollution, stable effluent quality, and saving of resources and cost.

Owner:BEIJING DILI WEIYE TECH DEV

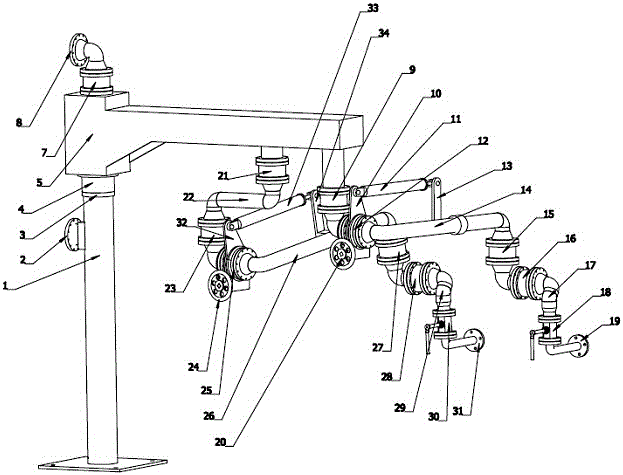

Vacuum insulation ultralow-temperature medium land conveying device

ActiveCN103672405APrevent leakagePrevent freezingLiquid transferring devicesPipeline systemsGas phaseNitrogen

The invention relates to a vacuum insulation ultralow-temperature medium land conveying device. The upper face of the back end of a rotating inner pipe is connected with a liquid-phase connector through a liquid-phase rotating connecting head. A gas-phase connector is fixedly connected to a stand column. The gas-phase connector is connected with a gas-phase channel in the rotating inner pipe. A gas-phase outlet and a liquid-phase outlet are formed in the lower face of the front end of the rotating inner pipe. The gas-phase outlet is connected with a gas-phase valve through a gas-phase rotating connecting head, a gas-phase rotating pipe, a gas-phase worm and gear device, a gas-phase vacuum outer pipe and a gas-phase connector gravity center adjusting pipe. The liquid-phase outlet is connected with a liquid-phase valve through the liquid-phase rotating connecting head, the liquid-phase worm and gear device, a liquid-phase vacuum outer pipe, two liquid-phase rotating connecting heads and a liquid-phase connector gravity center adjusting pipe. The phenomenon of cold loss caused by original assembling and disassembling arm frosting and freezing is avoided, BOG generated by gasifying can be lowered, system circulating processing pressure can be relieved, leakage caused by rotating part low-temperature deforming can be overcome, connector freezing is prevented, connecting speed is improved, disassembling and assembling time is shortened, nitrogen protection is of no need, and operation cost is saved.

Owner:大连中工策控科技有限公司

Construction method of wire seam wall for pseudo-classic architecture

The invention discloses a construction method of a wire seam wall for pseudo-classic architecture. The construction method includes the following steps of (1), scheme optimization; (2), construction preparation; (3), surveying and setting out; (4) arrangement of tie bars and constructional columns; (5), block arranging, bottom laying and ridge table pouring; (6), wire retractor arrangement; (7), poling, wire hanging and wall laying; (8), arrangement of the constructional columns, a ring beam and lintel pouring concrete; (9), calking ending; (10), plate layout of the wire seam wall; (11), arrangement of bottoming pieces; (12), laying of the silk seam wall; (13), arranging and pouring of a hidden beam; and (14), dot repairing. A composite wall is divided into a structural wall and the wire seam wall, two methods of wall separation construction highlight the professional advantages of two kinds of wall workers, the quality of each wall is guaranteed, the construction progress is accelerated, the labor cost is saved, the problem that cross contamination is prone to occurring due to simultaneous laying is solved, and meanwhile, the construction technical difficulties caused by compositewalls with different specifications and modules are eliminated.

Owner:SHANDONG JIAOTONG UNIV

Insert plate device capable of walking on blown-filled mud soil

InactiveCN102433868BEasy to handleReduce secondary processing costsSoil preservationImpellerEngineering

The invention relates to an insert plate device capable of walking on blown-filled mud soil. A horizontal-direction plate-type impeller and a vertical-direction plate-type impeller which are vertically arranged are installed between the lower part of a floating cabin connected with an operation platform and a floating cabin; one side of the operation platform is vertically provided with a gantry; the upper end of an inclined support is connected with a cross rod, and the lower end of the inclined support is connected with the other side of the operation platform; the upper end of an insert plate stand is connected on the cross rod of the gantry in a sliding way, and the lower end of the insert plate stand is connected on a guide rail of the insert plate stand in a sliding way; the other side of the operation platform is provided with an insert plate winch and a shifting winch; the insert plate winch is connected with an insert plate machine pipe by steel wires; and the shifting winch is connected with the insert plate stand by steel wires. The insert plate device overcomes the defects of slow speed, low construction efficiency, high potential safety hazard and the like in the process of manually inserting a plastic drainage plate. The insert plate device improves the depth and the effect of foundation treatment, and reduces the secondary treatment cost of foundation; and the insert plate device capable of walking on the blown-filled mud soil is capable of walking and inserting the plate on the blown-filled mud soil with low bearing capacity, so that the construction speed can be accelerated.

Owner:曾国海 +1

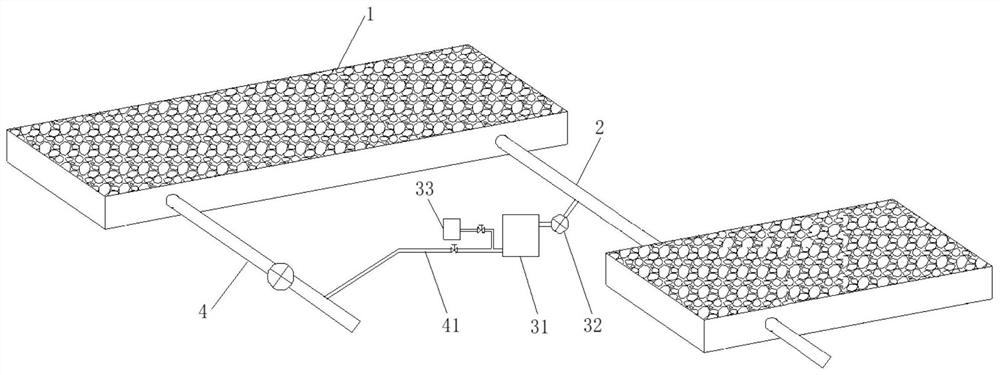

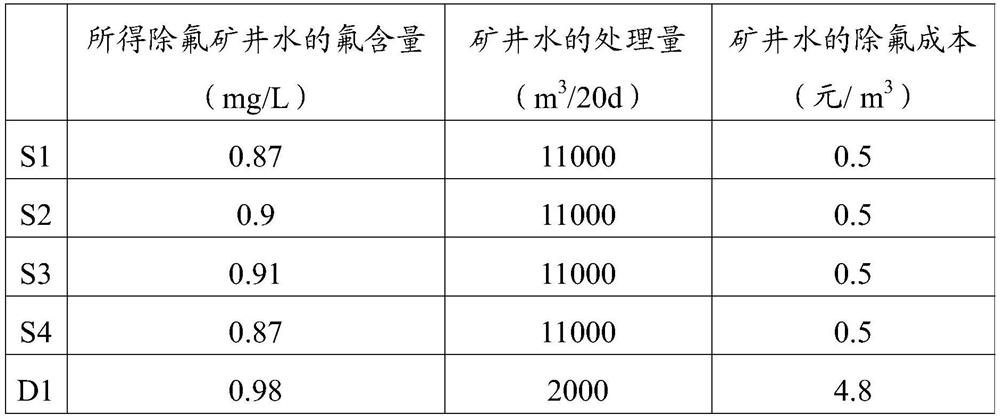

Method and system for defluorinating mine water

PendingCN113072125AImprove resource utilization valueImprove adsorption capacityWater contaminantsWater/sewage treatment by ion-exchangeWater dischargeEnvironmental engineering

A method for defluorinating mine water removes fluorine in the mine water through a fluorine removal agent, the fluorine removal agent comprises a main fluorine removal agent, and the main fluorine removal agent is fly ash. The invention also provides a system for defluorinating the mine water by using the method. The system comprises a first underground reservoir, a mine water injection pipeline, a fly ash adding device and a mine water discharge pipeline; the fly ash adding device comprises a stirring pool and a grouting pump; the stirring pool is used for stirring the added fluorine removal agent and water to obtain a mixture; the feeding end of the grouting pump is connected to the discharging port of the stirring pool, and the discharging end of the grouting pump is connected to the mine water injection pipeline and used for pumping the mixture to the mine water injection pipeline; the mine water injection pipeline is connected to the water injection port of the first underground reservoir and is used for injecting mine water and the mixture into the first underground reservoir; and the mine water discharge pipeline is connected to the water intake of the first underground reservoir and is used for discharging the fluorine-removed mine water. According to the method and the system, the treatment capacity of the mine water is large, the fluorine removal cost is low, and fluorine can be effectively removed, so that the fluorine content of the mine water is reduced to 1 mg / L or below.

Owner:SHENHUA SHENDONG COAL GRP

Ammonia recovery system for wastewater with high content of ammonia and nitrogen

InactiveCN108341418AImprove recycling efficiencyHigh puritySolidificationLiquefactionHigh concentrationAmmonia storage

The invention provides an ammonia recovery system for wastewater with high content of ammonia and nitrogen. The system comprises the following process steps the wastewater with high content of ammoniaand nitrogen is introduced into a stripping tower for stripping to generate high-concentration ammonia gas, the ammonia gas with moisture is introduced into a water washing tower, after water washingand impurity removal are conducted through the water washing tower, the moisture in the ammonia gas is removed through a mist eliminator, a pressure regulating tube and a filter in sequence, then theammonia gas is conveyed to an ammonia compressor for compression and pressurization, and finally the ammonia gas is condensed by a condenser to obtain liquid ammonia; liquid ammonia flows into an ammonia reflux tank serving as a transfer station and partially flows back into the water washing tower for secondary recycling, and other liquid ammonia is conveyed to an ammonia storage tank to obtainpure liquid ammonia. Through reasonable process improvement and parameter setting, the efficiency of recovering the high ammonia nitrogen wastewater is effectively improved, the purity of recovered liquid ammonia is high, the problems of secondary pollution and high energy consumption during ammonia recycling are solved, the ammonia recovery cost is reduced, and the environmental pollution is reduced.

Owner:ANHUI COSTAR BIOCHEM CO LTD

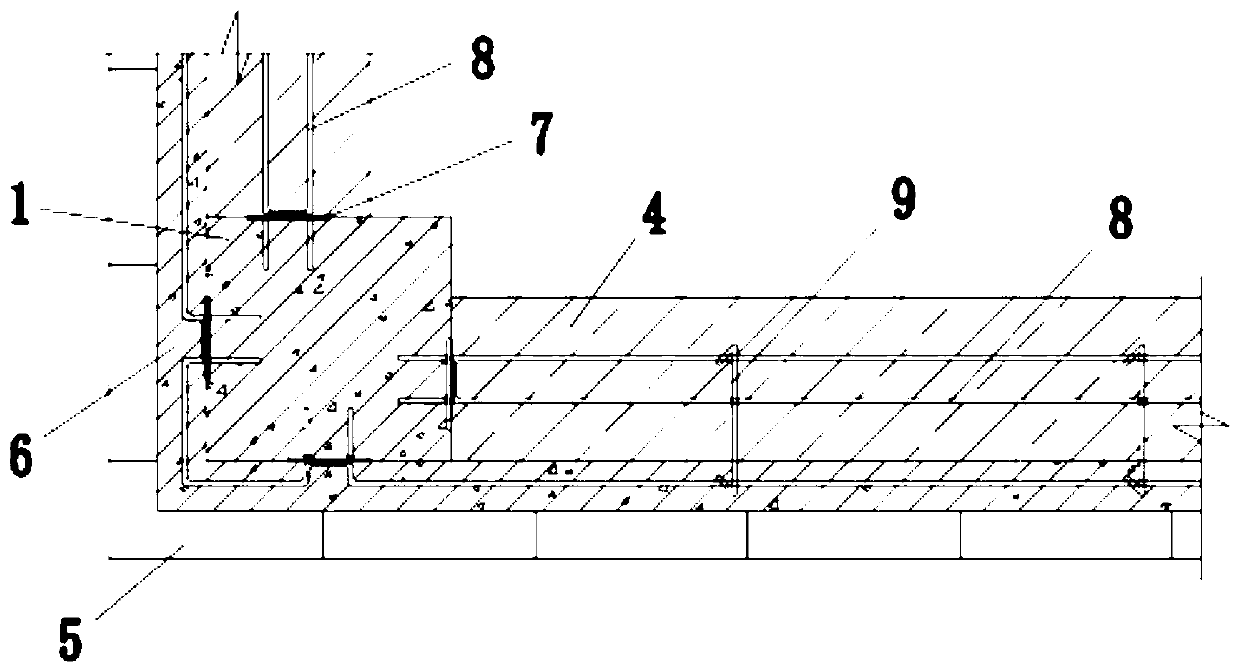

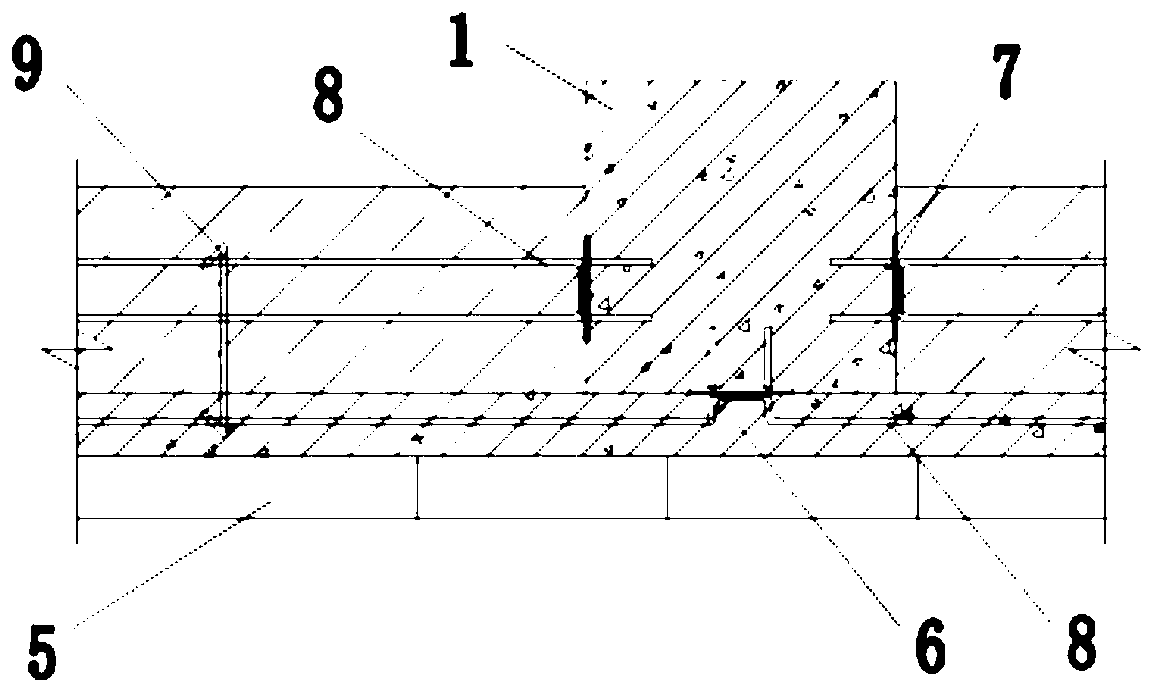

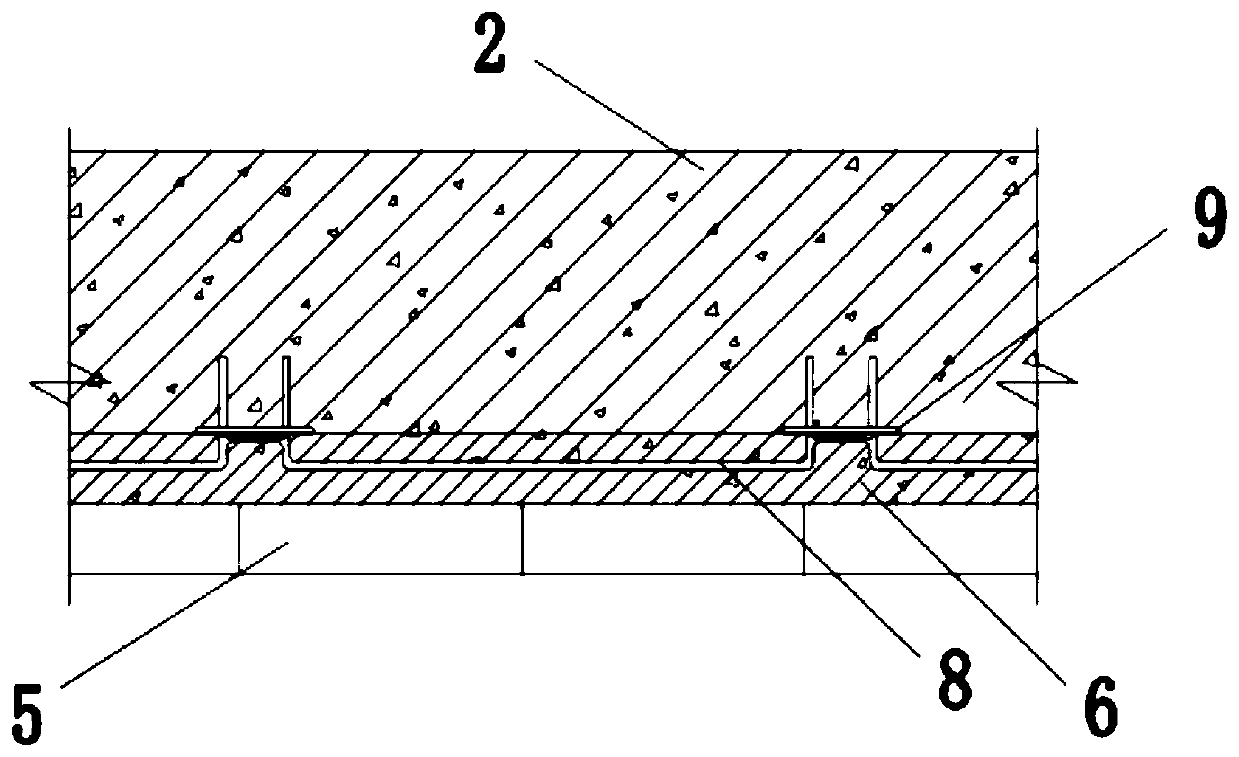

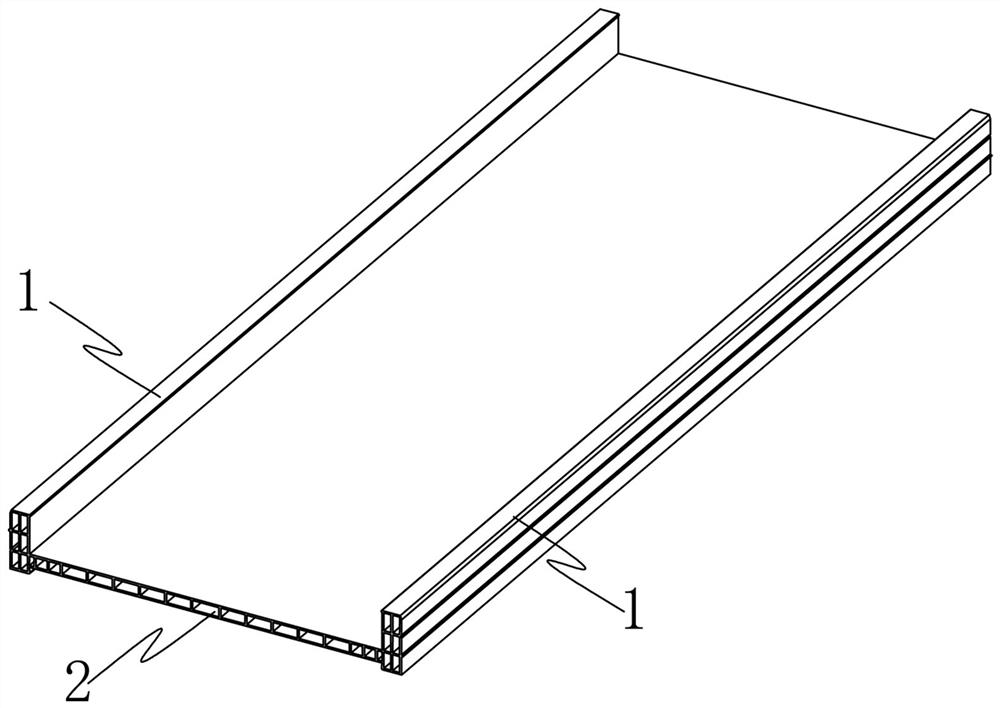

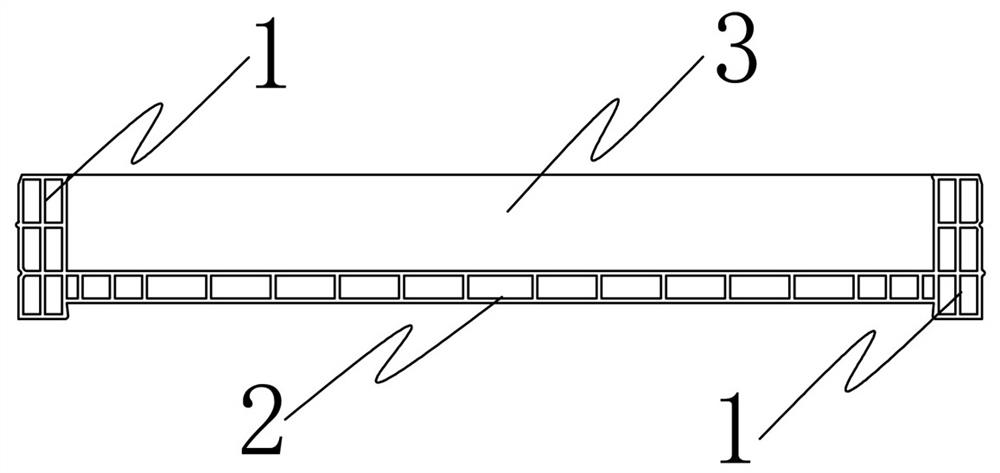

Floor heating bearing base plate structure

PendingCN112443123AEasy to installStable docking combined useCovering/liningsFlooring insulationsEngineeringStructural engineering

The invention discloses a floor heating bearing base plate structure. A base plate is mainly composed of reinforcing ribs and a plate face, the two sides of the long edge of the plate face are each provided with one reinforcing rib, the two reinforcing ribs and the plate face form an installation space used for installing a heat preservation plate, a limiting groove and a limiting table are sequentially arranged on the outer side of the reinforcing rib on one side of the long edge of the plate face from top to bottom, a limiting table and a limiting groove are sequentially arranged on the outer side of the reinforcing rib on the other side of the long edge of the plate face from top to bottom, the limiting grooves are matched with the limiting tables to be buckled, the reinforcing ribs ofthe base plate are sequentially arranged, and therefore when the outer sides of the reinforcing ribs are perpendicularly attached, the reinforcing ribs of any two adjacent base plates can be buckled with each other. According to the floor heating bearing base plate structure, the heat preservation plate can be stably installed, the heat preservation plate is buckled in the middle vacant position of the two reinforcing ribs, butt joint buckle structures are arranged between the reinforcing ribs, the combined structures at the bottoms of the reinforcing ribs of a base plate module are used as awhole to be fixed and buckled together through buckle pieces of adjusting feet, and the overall stability of a floor heating plate can be improved.

Owner:ZHEJIANG YASHA DECORATION

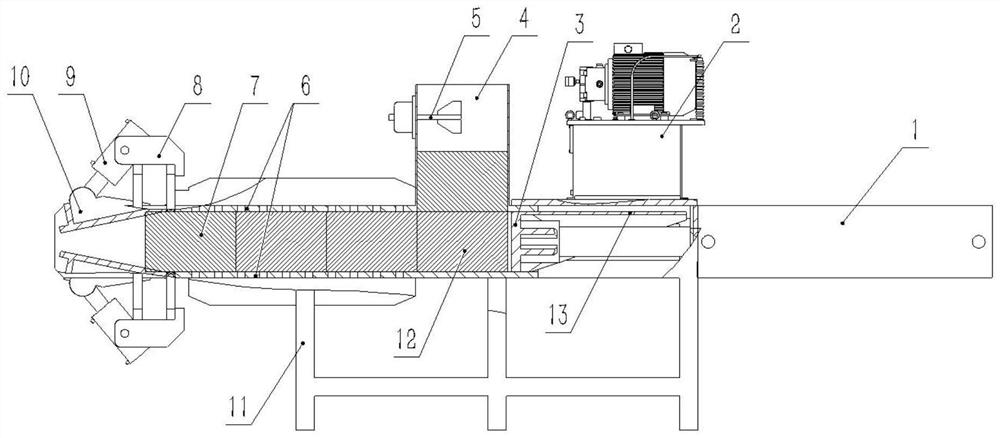

Horizontal hydraulic secondary solid-liquid separator

PendingCN114228224AIntegrity guaranteedReduce wearSludge treatmentPressesThermodynamicsProcess engineering

The invention provides a horizontal hydraulic secondary solid-liquid separator which comprises a compression cavity, a feeding hopper, a hydraulic device, a compression cavity filter plate and a discharge port adjusting device, the feeding hopper is mounted above the compression cavity, the hydraulic device is mounted behind the compression cavity, the compression cavity filter plate is mounted in the compression cavity, and the discharge port adjusting device is mounted in front of the compression cavity. The spiral extrusion type secondary solid-liquid separator solves the technical problems of high solid content of liquid separated by a spiral extrusion type secondary solid-liquid separator in the prior art, serious equipment abrasion, high processing cost, high failure rate and high maintenance cost, adopts a hydraulic extrusion mode, can ensure the integrity of materials, is small in equipment abrasion, greatly reduces the secondary treatment cost of the liquid, and improves the working efficiency of the spiral extrusion type secondary solid-liquid separator. Compared with a screw extruder, the screw extruder has the biggest advantages of small abrasion of equipment parts, long service life of equipment and low maintenance cost.

Owner:HARBIN HUAMEI YIFENG COMPOUND MATERIALS

Impurity Removal Process of Southern Ionic Rare Earth Mine Leaching Solution

Owner:赣州稀土开采技术服务有限公司

Fully automatic pin insertion machine for pcb board

The invention discloses an automatic pin machine of a PCB board. The automatic pin machine of the PCB board comprises a frame, a power system, a main shaft transmission system, a wire rod clamping relaxing module, a cutting needle module, a plate putting warehouse, a numerical control division plate system, a numerical control shift plate positioning system and an automatic material returning system. The automatic pin machine of the PCB board possesses a completely automatic production function which comprises that: the automatic division plate, the automatic shift plate, the automatic positioning and automatic plate returning can be achieved; a main shaft transmission mechanism drives the machine to automatically clamp a wire, send the wire and be cut off after automatic insertion. A plurality of pins are simultaneously inserted at once. A speed is fast, an output is high, cost is low and pin efficiency is high. In addition, the pins have a same length during a pin process. Verticality of the pins is good and pin quality is high, which provides a solid foundation for a subsequent automatic production technology. The wire rod used by the pin machine is a whole roll of steel wire which is automatically cut into the pins through the machine so that secondary processing cost of processing the wire rod into the pins can be saved. The raw material cost can be substantially reduced.

Owner:颍上县祥盛建设管理有限公司

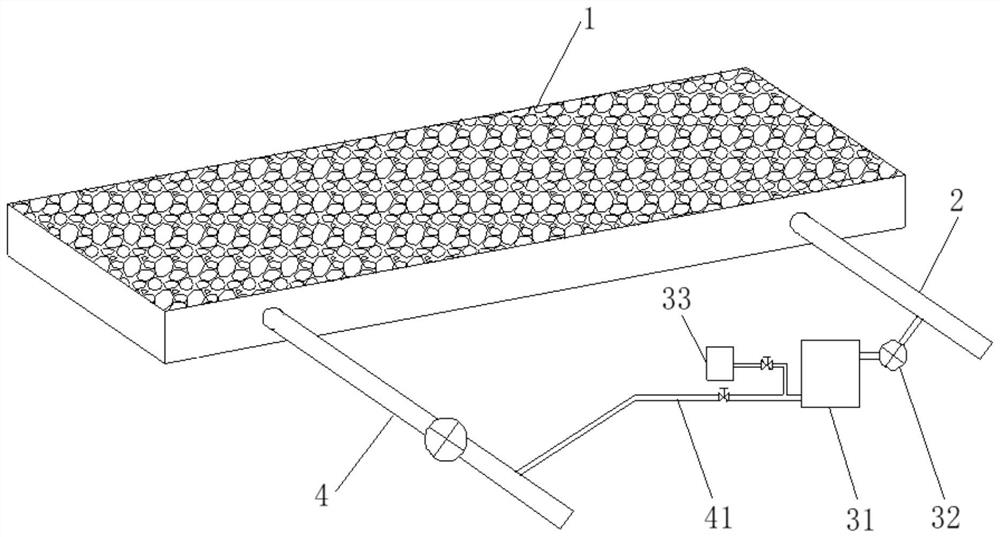

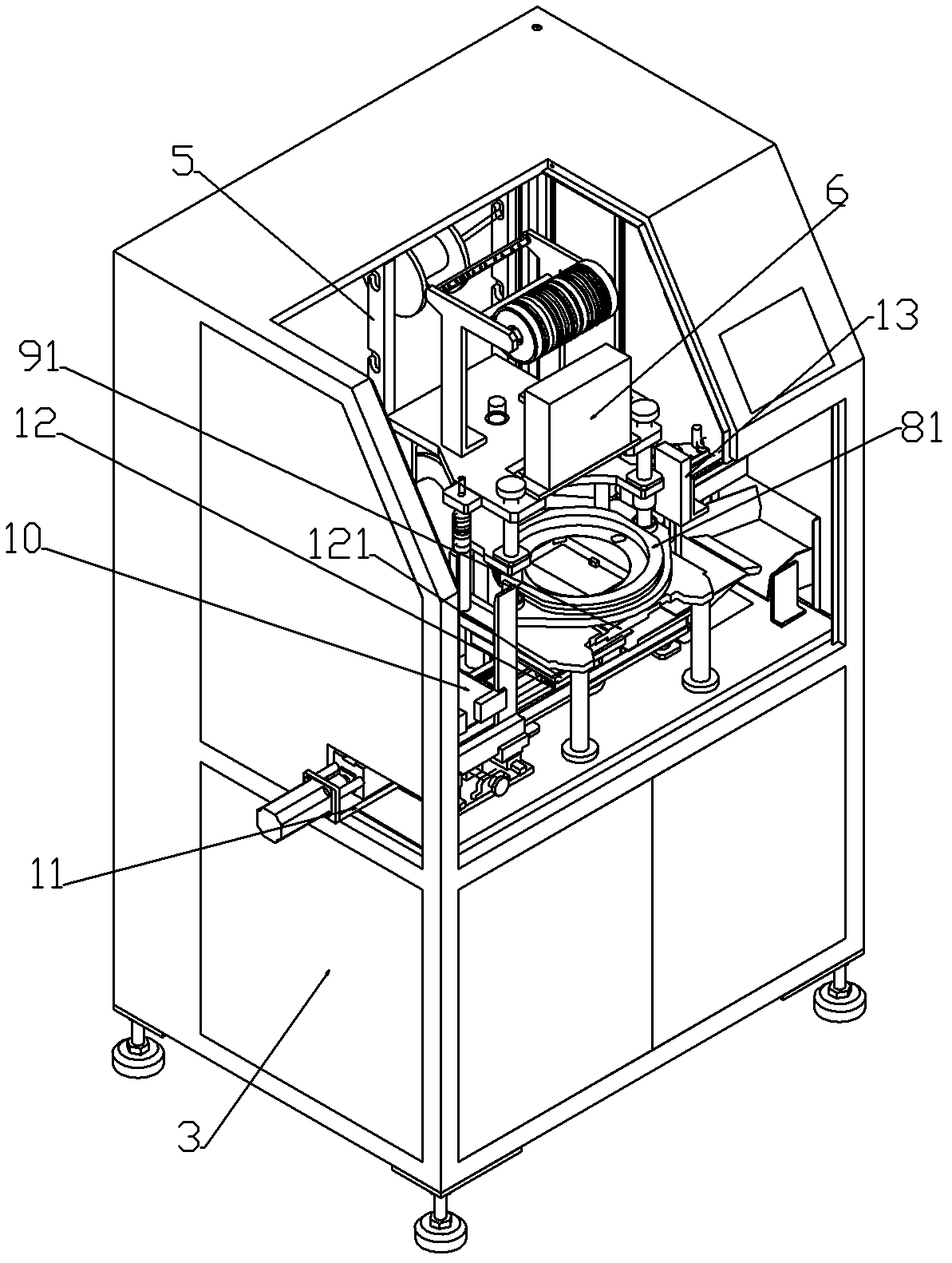

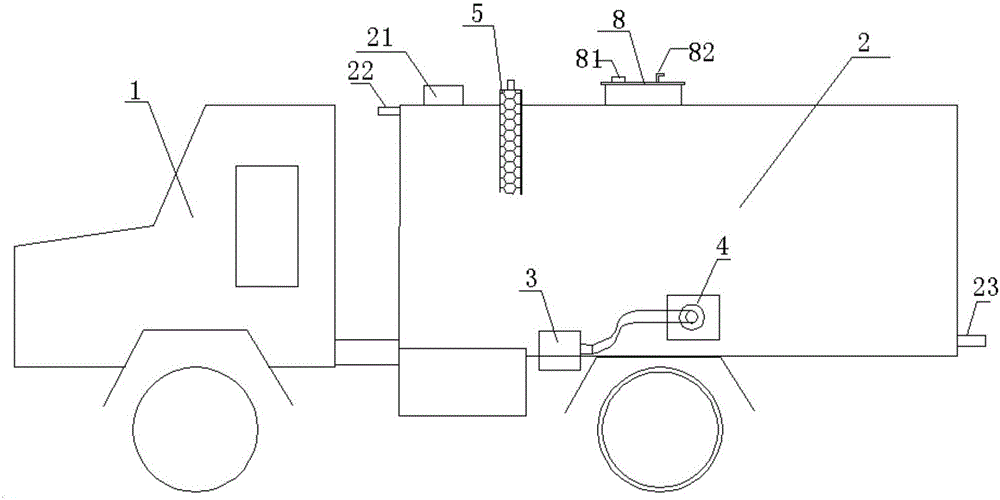

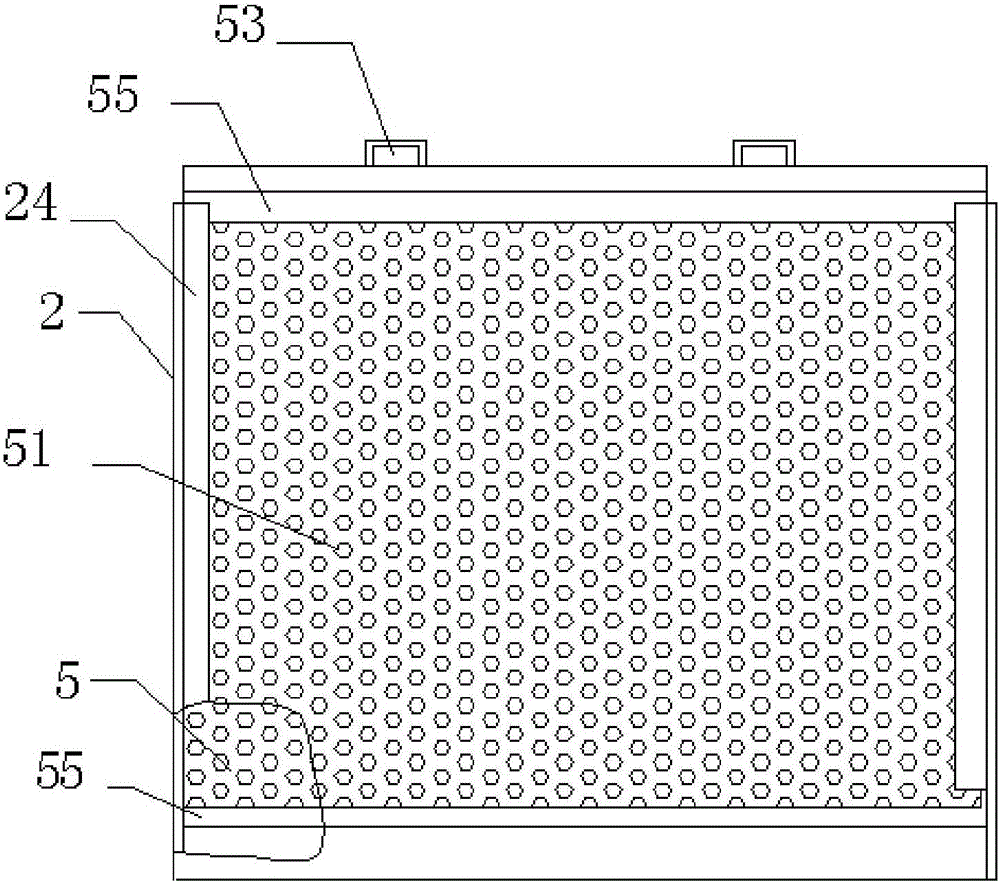

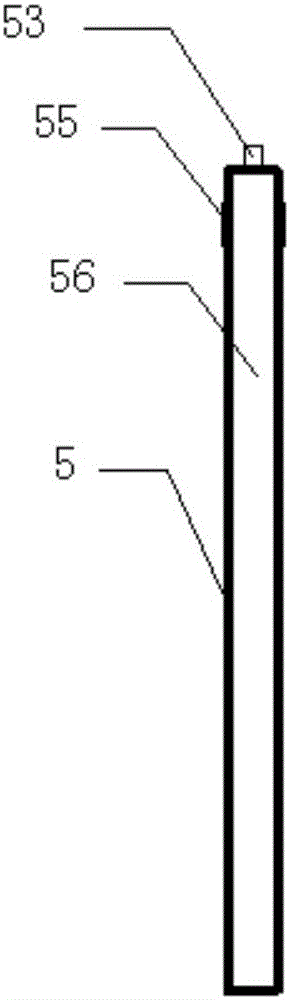

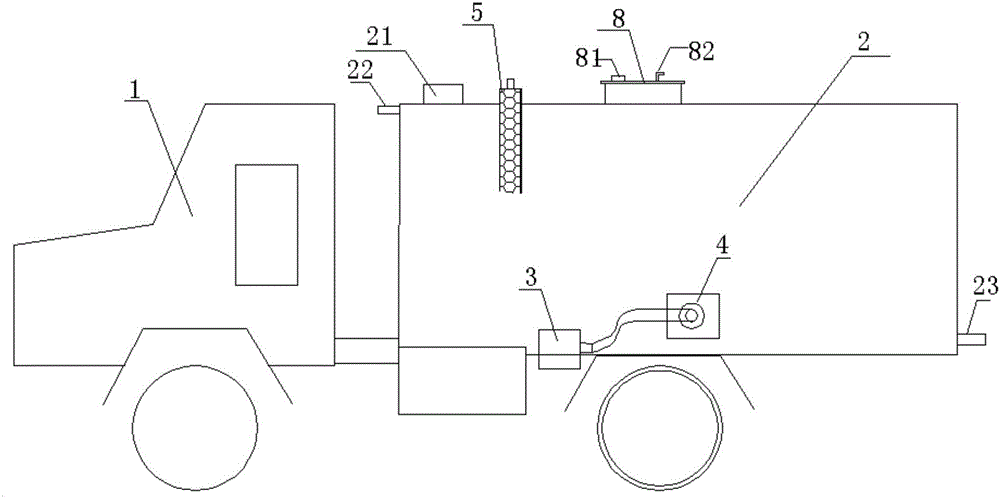

Mining pumping and spraying integrated vehicle

ActiveCN105908662AReduce secondary processing costsSimple structureRoad cleaningWater pipeFloating platform

The invention discloses a mining pumping and spraying integrated vehicle. The mining pumping and spraying integrated vehicle includes a vehicle body, a water tank, a filtering plate and a pumping and spraying device; the water tank is arranged on the vehicle body; the filtering plate is arranged in the water tank; the inner space of the water tank is divided into a muddy water chamber and a clean water chamber by the filtering plate; a water inlet of the water tank is formed in the top of the muddy water chamber; the pumping and spraying device is positioned under the clean water chamber; the pumping and spraying device includes a water pump, a water intake pipe, a floating platform and a nozzle, wherein the water pump is arranged on the bottom of the clean water chamber, the water pump is connected to the floating platform through the water intake pipe, and the floating platform includes a suspensible material for allowing an opening of the water intake pipe to be in a preset depth under water surface of the clean water chamber; the water pump pumps water in the clean water chamber, and then water is sprayed through the nozzle; the water pump is connected to the water inlet through a pipeline; and a sediment deposition pool is arranged on the bottom of the muddy water chamber. The mining pumping and spraying integrated vehicle can pump water on a stope working face into the water tank and spray a road with water to remove dust; the process is simple; and the cost is low.

Owner:CHINA SHENHUA ENERGY CO LTD +1

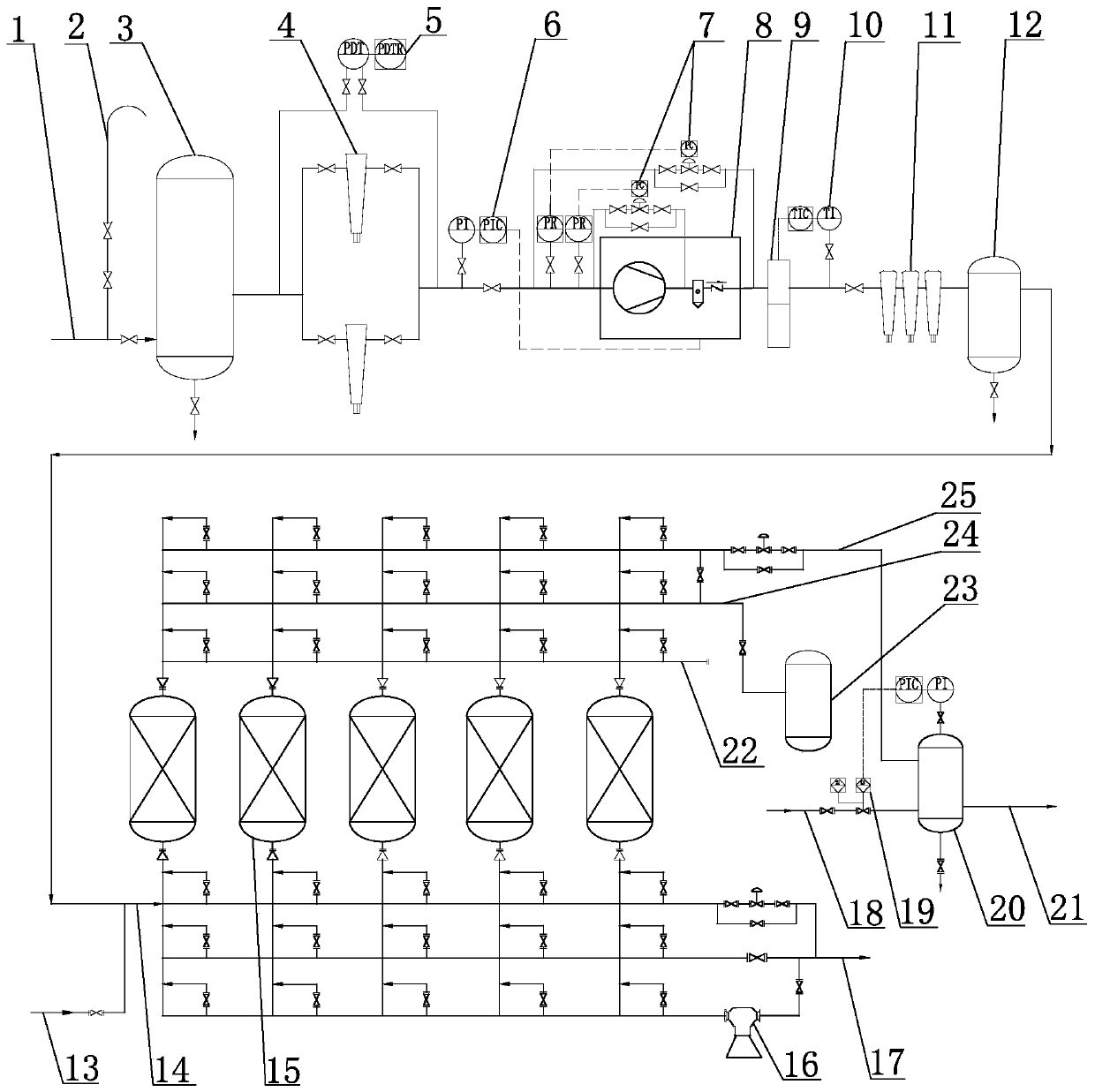

Pressure swing adsorption purification and recovery device and process for polypropylene SPG process tail gas

InactiveCN111151097AHigh degree of automationEasy to operateNitrogen purification/separationGas treatmentBuffer tankProcess engineering

The invention relates to the technical field of tail gas treatment, in particular to a pressure swing adsorption purification and recovery device and process for polypropylene SPG process tail gas. The pressure swing adsorption purification and recovery device for polypropylene SPG process tail gas comprises a recovered gas buffer tank, a folded wave filter, a compressor, a refrigeration dryer, athree-stage precision filter, a separator and a pressure swing adsorption tower which are connected in sequence. The recovered gas buffer tank is connected with a polypropylene SPG process tail gas pipeline. The top of the pressure swing adsorption tower is connected with a nitrogen buffer tank through a nitrogen discharge pipeline and is also connected with a flushing gas buffer tank through a sequential discharge pipeline. The bottom of the pressure swing adsorption tower is connected with a gas inlet pipeline and a reverse discharge pipeline. According to the device and process, the pressure swing adsorption technology is adopted for purifying the polypropylene SPG process tail gas, nitrogen in the tail gas is recycled while organic gas such as propylene and propane is removed, the emission environmental protection problem is solved, and benefits are increased for enterprises.

Owner:胡啸

Vacuum insulation type ultra-low temperature medium land transportation device

ActiveCN103672405BPrevent leakagePrevent freezingLiquid transferring devicesPipeline systemsDielectricGas phase

The invention relates to a vacuum insulation type ultra-low temperature medium land transportation device. The rear end of the rotating inner tube is connected to the liquid phase interface through the liquid phase rotary joint, and the gas phase interface is fixedly connected to the column, and the gas phase interface is connected to the gas phase channel in the rotating inner tube. The gas phase and liquid phase outlets are arranged under the front end of the rotating inner tube. The gas phase outlet is connected to the gas phase valve through the gas phase rotary joint, the gas phase rotary tube, the gas phase turbine worm device, the gas phase vacuum outer tube, and the gas phase interface center of gravity adjustment tube; the liquid phase outlet The liquid phase valve is connected through a liquid phase rotary joint, a liquid phase turbine scroll device, a liquid phase vacuum outer tube, two liquid phase rotary joints, and a liquid phase interface gravity center adjustment tube. The invention solves the phenomenon of cold loss caused by the frosting and icing of the original loading and unloading arm, can reduce the BOG generated by gasification, and reduce the pressure of the system cycle treatment; overcome the leakage caused by the low temperature deformation of the rotating parts; prevent the interface from freezing, improve the connection speed and Loading and unloading time, without nitrogen protection, saving operating costs.

Owner:大连中工策控科技有限公司

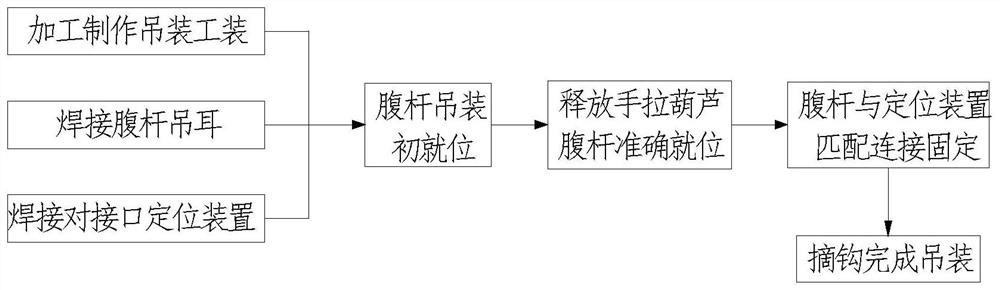

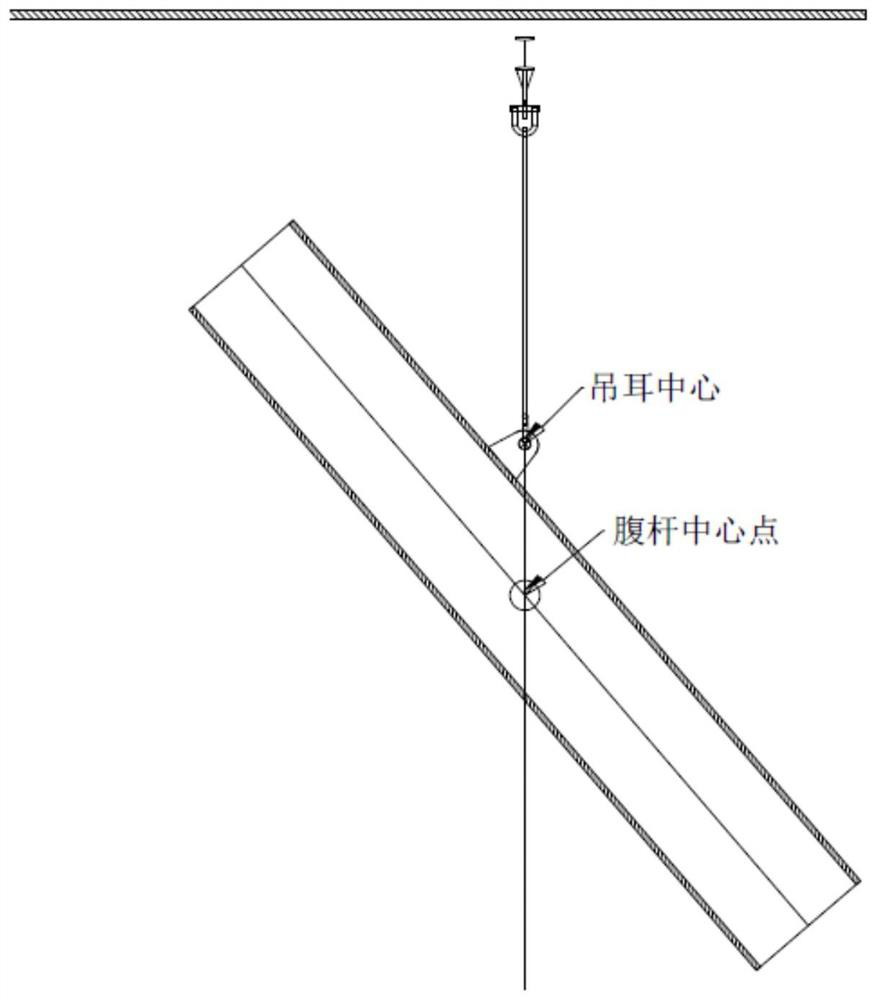

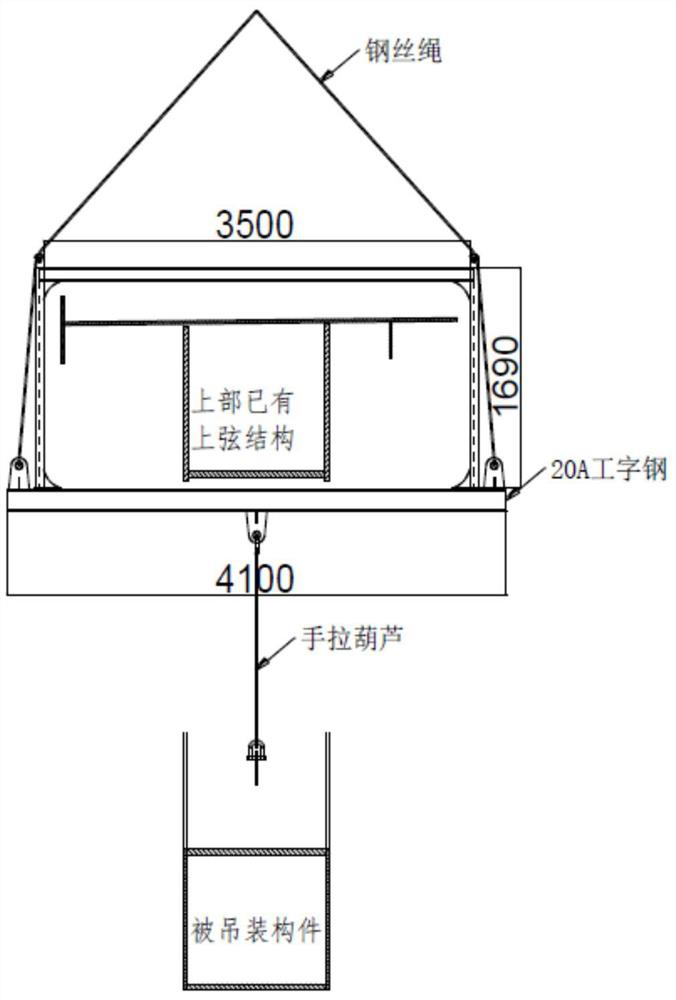

Hoisting method for installation of reversely inserted part

ActiveCN113774864AAvoid WeldingImprove protectionArtificial water canalsBuilding material handlingButt jointWeld seam

The invention discloses a hoisting method for installation of a reversely inserted part. The hoisting method comprises the following steps that a hoisting tool is machined and manufactured; machining and blanking are carried out according to a design drawing, assembly welding is carried out, it is guaranteed that welding seams are fully welded during welding, and wrap angle welding is carried out on the ends; web member lifting lugs are welded, specifically, the web member lifting lugs are welded on web member parts, and accurate lofting is carried out on the web member lifting lugs according to the mounting angles of the web member parts to ensure that the web member lifting lugs are on plumb lines of the centers of the web member parts; butt joint port positioning devices are welded, specifically, the positioning devices are welded when the web member parts are pre-assembled; the web members are hoisted in place initially; and the web members are matched and connected with the positioning devices. According to the hoisting method for installation of the reversely inserted part, the workload of site construction is greatly saved, a plurality of lifting points are prevented from being welded on the main part, and the finished product of the part is well protected.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

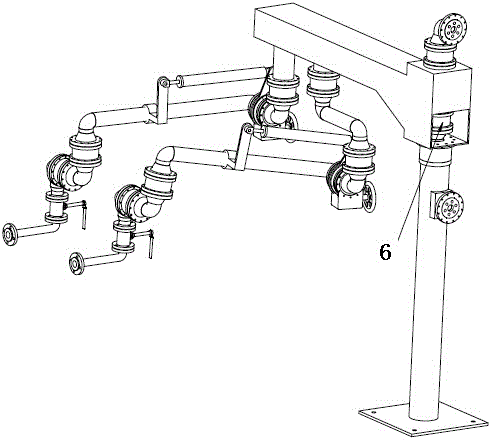

Vacuum adiabatic ultra-low temperature medium marine conveying device

ActiveCN103613060BSolve the load problemPrevent freezingLiquid transferring devicesGas phaseNitrogen atmosphere

The invention relates to a vacuum insulation type ultra-low temperature medium marine conveying device. The gas phase port and the liquid phase port of the rear vacuum box are respectively connected to the gas phase interface and the liquid phase interface through the gas phase rotary joint and the liquid phase rotary joint. The gas phase flow channel is formed by connecting the gas phase rotary joint with the vacuum gas phase inner tube, and the liquid phase flow channel is formed by connecting the liquid phase rotary joint with the vacuum liquid phase inner tube; One end of the tube and the liquid phase outer tube, and the other end of the gas phase outer tube and the liquid phase outer tube are respectively connected to the gas phase valve and the liquid phase valve through the gas phase rotary joint and the liquid phase rotary joint. The invention solves the phenomenon of cold loss caused by the frosting and icing of the original loading and unloading arm; it can reduce the BOG produced by gasification, reduce the pressure of the system circulation process, overcome the leakage caused by the low temperature deformation of the rotating parts, prevent the interface from freezing, and improve the connection efficiency. Speed and loading and unloading time, no need for nitrogen protection, saving operating costs.

Owner:大连中工策控科技有限公司

Mining pumping and sprinkler integrated vehicle

Owner:CHINA SHENHUA ENERGY CO LTD +1

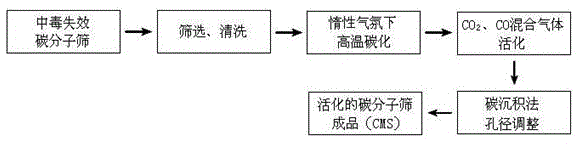

Regeneration method of nitrogen-preparation carbon molecular sieve

ActiveCN103349973BUniform pore sizeIncrease production costOther chemical processesCombustible gas purificationNitrogen gasBiological activation

The invention relates to the technical field of molecular sieve, and especially relates to a regeneration method of a nitrogen-preparation carbon molecular sieve. The method provided by the invention sequentially comprises the steps that: screening and washing are carried out, wherein poisoned carbon molecular sieve is screened by using a mesh, and the screened carbon molecular sieve is washed by using water, such that impurities are removed; nitrogen-based high-temperature charring is carried out, wherein the temperature is increased to 850-1000 DEG C under the protection of nitrogen gas, such that charring is carried out; mixed gas activation is carried out, wherein a mixed gas of CO2 and CO is delivered into a furnace cavity, wherein the proportion of CO2 is 85-90%, such that the charred carbon molecular sieve is activated, wherein the temperature in the furnace is 700-800 DEG C; carbon deposition is carried out, wherein activated carbon molecular sieve is placed in a furnace cavity of a converter; the temperature in the converter is 800-900 DEG C; xylene is delivered in under the protection of nitrogen gas; the temperature of the furnace is maintained at 300-500 DEG C, such that xylene is absorbed by the carbon molecular sieve; xylene is cracked under the temperature of 800-900 DEG C, such that pyrolytic carbon is deposited on the char material; the carbon molecular sieve is subjected to pore size adjustment, such that a regenerated finished product is obtained. With the method provided by the invention, deeply poisoned nitrogen-preparation carbon molecular sieve can be activated, and the pore sizes after activation is uniform.

Owner:HUZHOU XINAOLI ADSORPTION MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com