Ammonia adsorbent regeneration and regeneration liquid pollution-free disposal method and device

A harmless treatment and ammonia adsorption technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve secondary pollution and other problems, and achieve the effects of automation, easy automation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

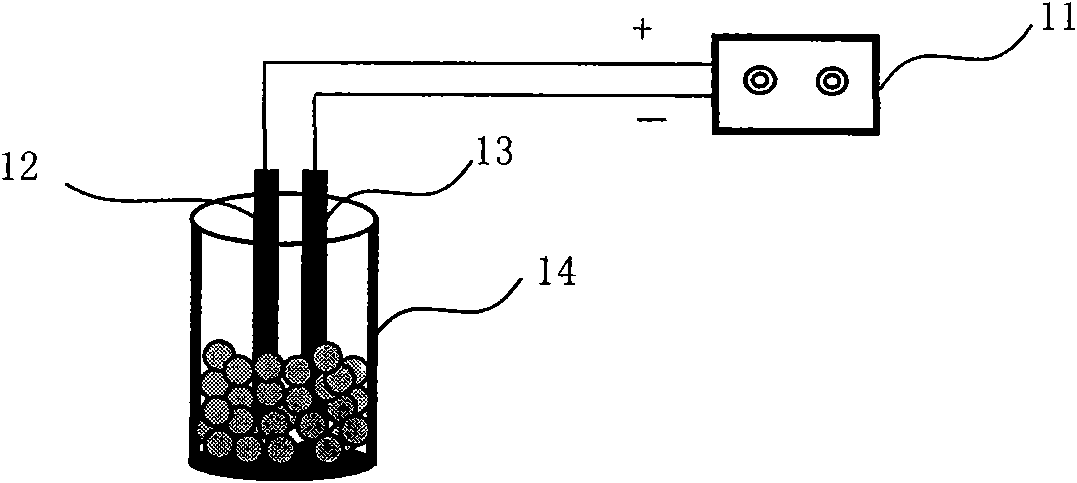

[0062] Electrolyzer as attached figure 1 As shown, the electrolytic cell 14 is a cylindrical water tank with a volume of 400 mL, which is made of polyethylene, the cathode 13 is a Cu / Zn (Cu: 62.2 wt. %; Zn: 37.8 wt. %) electrode, and the anode 12 is a Ti / Zn electrode. Pt-IrO 2 Electrode, a DC voltage stabilizer is used as power supply 11, its effective voltage is 0-50V, and its effective current is 0-5A. The volume of the regeneration solution for each electrolysis is 300mL, and the effective use area of the electrode is 50cm 2 .

[0063] In the experiment, 100g zeolite was first put into ammonia solution (100mg NH 4 + Ammonia was adsorbed in -N), after 30 minutes of adsorption, the total amount of ammonia adsorbed by the zeolite was measured, and the zeolite (64 mg NH) containing ammonia was 4 + -N / 100g zeolite) 100g is put into 300mL regeneration solution (Na 2 SO 4 0.5g / L, NaCl; 1.0g / L) in the electrolytic cell 14, turn on the power supply 11, regulate the current...

Embodiment 2

[0065] The method and device for removing ammonium salt in the regeneration solution are as in Example 1, but the concentration of NaCl in the regeneration solution is increased to 1.5g / L, and after 2 hours of reaction, no ammonia is detected in the regeneration solution, and the nitrate nitrogen concentration in the regeneration solution is less than At 10.0 mg / L, the conversion ratio of ammonia in zeolite to nitrogen is greater than 96%. After the zeolite was regenerated, its adsorption capacity was tested, and the adsorption capacity completely reached the level before use. The zeolite can be fully recovered by reusing the regeneration solution for 5 times of regeneration.

Embodiment 3

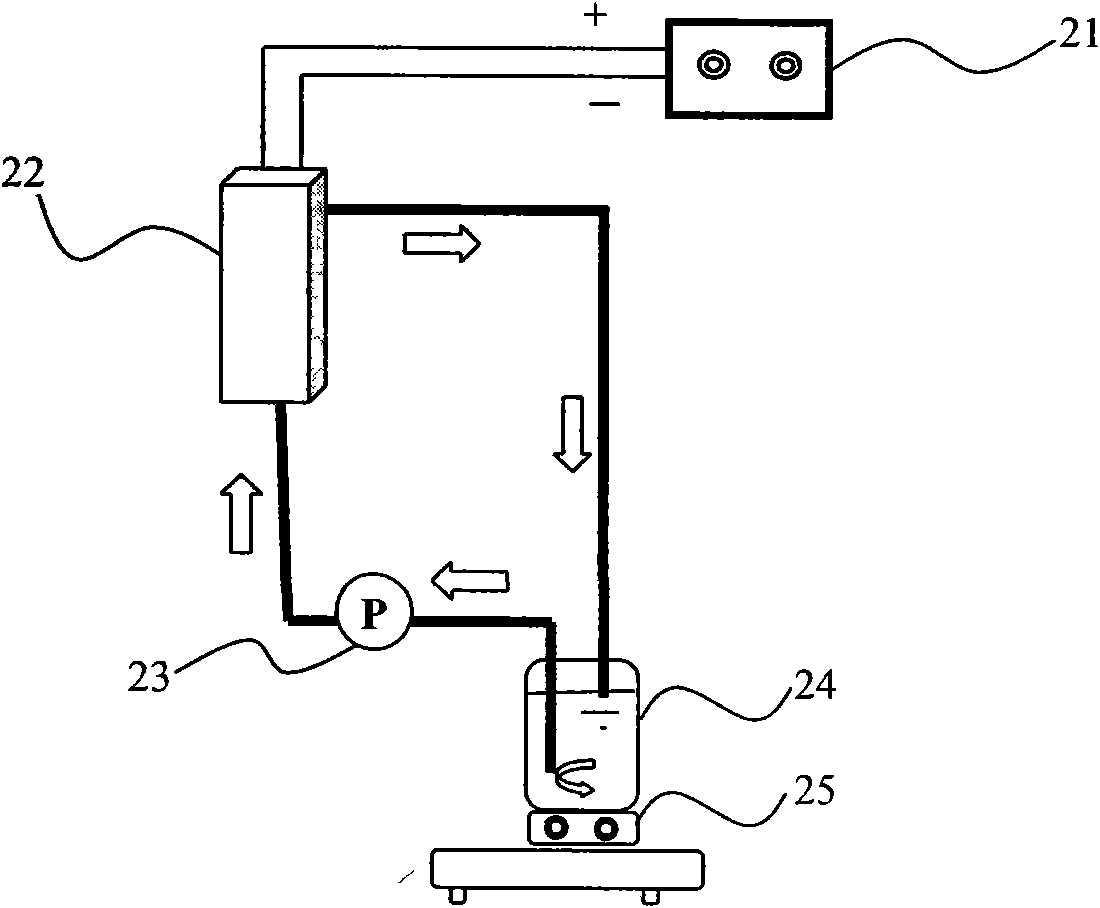

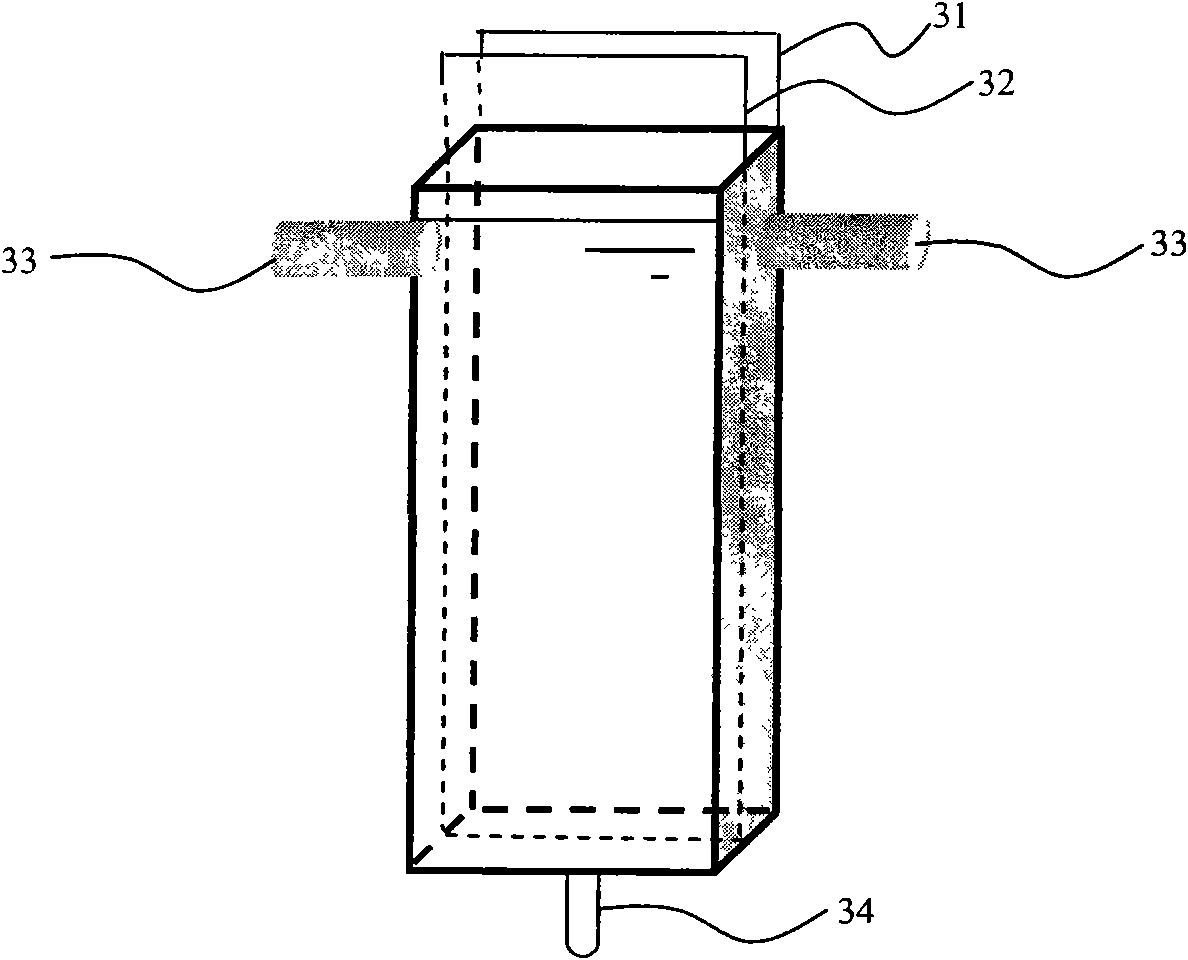

[0067] Electrolyzer as attached figure 2 , as shown in 3, the electrolytic cell 22 (reactor) is a 5cmx5cmx15cm=375cm 3 The cuboid water tank, the actual volume used in electrolysis is 200cm 3 . Made of polyethylene, the cathode 32 is a Cu / Zn (Cu: 62.2 wt.%; Zn: 37.8 wt.%) electrode, and the anode 31 is Ti / Pt-IrO 2 Electrode, cathode 32 is placed in the center of electrolytic cell 22. A DC voltage stabilizer is used as the power supply 21, and its effective voltage is 0-50V, and its effective current is 0-5A. The zeolite containing a certain amount of ammonia (64 mg NH 4 + -N / 100g zeolite) 100g is put into the electrolytic cell 22, and 300mL regeneration solution is passed from the water inlet 34 (Na 2 SO 4 0.5g / L, NaCl; 1.0g / L) is put into the circulation tank 24, the power supply 21, the circulation pump 23 and the magnetic stirrer 25 are turned on, and the current density is adjusted to 40mA / cm 2 . After 2 hours of reaction, no ammonia was detected in the regenerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com