Repair technology for river and lake bottom mud site polluted by heavy metal

A heavy metal and sediment technology, applied in sludge treatment, water/sludge/sewage treatment, river regulation, etc., can solve problems such as high cost, difficulty in turning river sediment, and difficult large-scale application on site, so as to avoid Outward transportation, avoiding the risk of secondary pollution, and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

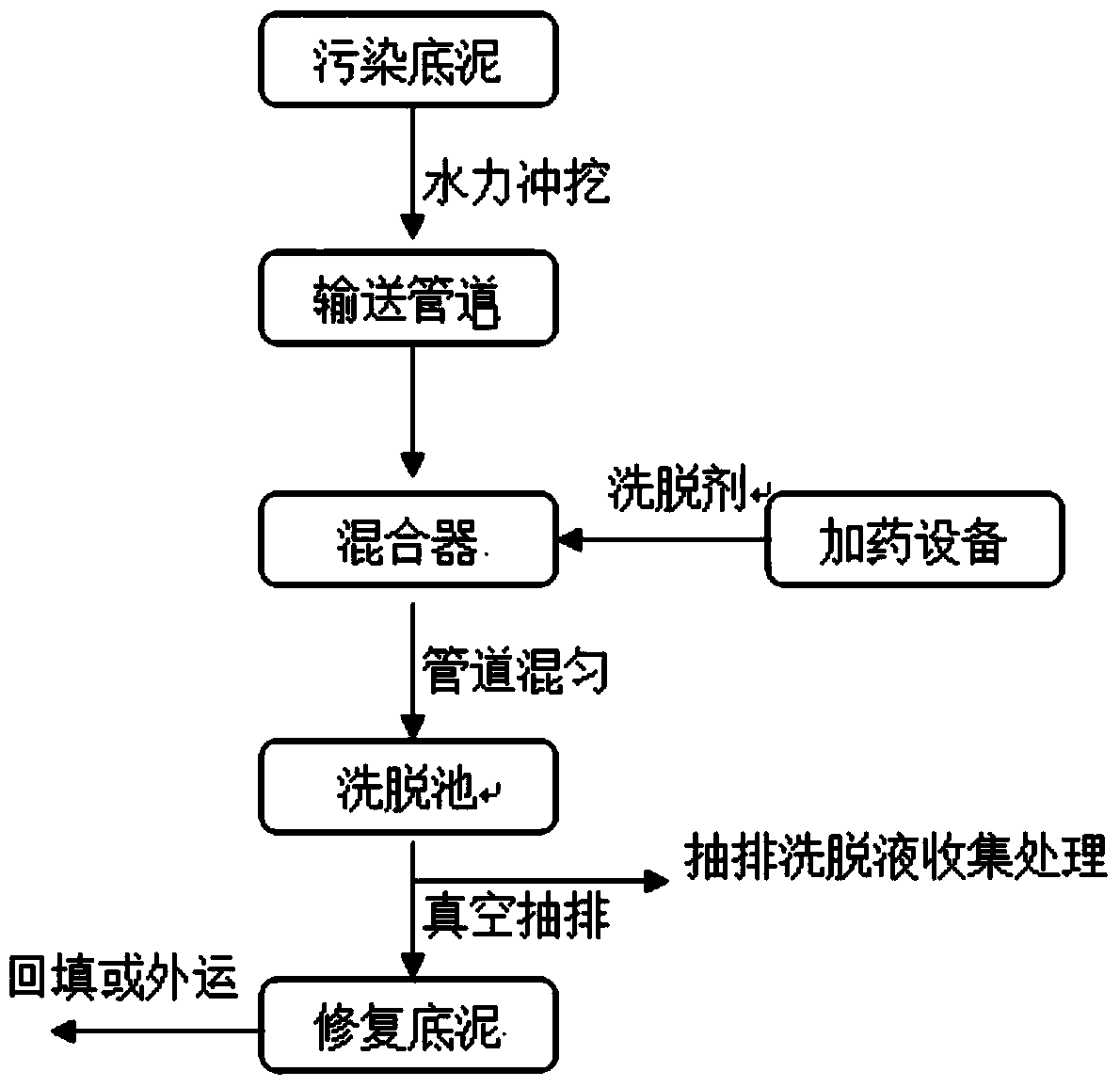

[0022] Such as figure 1 Shown: in order to illustrate the present invention better, be convenient to understand technological process of the present invention, typical but non-limiting embodiment of the present invention is as follows:

[0023] In this example, the volume of the elution pool is 10000m 3 , the specific process is:

[0024] (1) Mud transportation: transport the contaminated bottom mud to the mud pipeline through the cutter suction dredger or mud pump hydraulic excavation unit, and control the solid content of the mud at 35-40%;

[0025] (2) Elution agent: Add the eluent agent online in the pipeline. The composition of the eluent agent is citric acid. When feeding, the mass ratio of agent:slurry solids is 3:1000;

[0026] (3) Transportation: The agent and mud solids in step (2) are mixed and transported to the elution tank through the mud pipeline, and the middle end of the mud pipeline is connected to the dosing and mixing device;

[0027] (4) Elution and sep...

Embodiment 2

[0033] Embodiment 2 A kind of on-site restoration process of heavy metal polluted river and lake mud

[0034] (1) Mud transportation: transport the contaminated bottom mud to the mud pipeline through cutter suction dredgers or mud pump hydraulic excavation units, and control the solid content of the mud between 35% and 40%;

[0035] (2) Elution agent: Add the eluent agent online in the pipeline. The composition of the eluent agent is citric acid. When feeding, the mass ratio of agent:slurry solids is 5:1000;

[0036] (3) Transportation: The agent and mud solids in step (2) are mixed and transported to the elution tank through the mud pipeline, and the middle end of the mud pipeline is connected to the dosing and mixing device;

[0037] (4) Elution and separation: the mixed mud obtained in step (3) was left to stand for 120 hours; the mud after standing was vacuum pumped to separate the eluent, and the vacuum degree was controlled to 0.06MPa, and the eluent was discharged and c...

Embodiment 3

[0039] Embodiment 3 A kind of on-site restoration process of heavy metal polluted river and lake mud

[0040] (1) Mud transportation: transport the contaminated bottom mud to the mud pipeline through cutter suction dredgers or mud pump hydraulic excavation units, and control the solid content of the mud between 35% and 40%;

[0041] (2) Elution agent: Add the eluent agent online in the pipeline. The composition of the eluent agent is citric acid. When feeding, the mass ratio of agent:mud solids is 4:1000;

[0042] (3) Transportation: The agent and mud solids in step (2) are mixed and transported to the elution tank through the mud pipeline, and the middle end of the mud pipeline is connected to the dosing and mixing device;

[0043] (4) Elution and separation: the mixed mud obtained in step (3) was left to stand for 110 hours; the mud after standing was vacuum pumped to separate the eluent, and the vacuum degree was controlled to 0.07MPa, and the eluent was discharged and coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com