An end-supported threaded soil-squeezing pile-forming equipment and a pile-forming construction method

A construction method and a threaded technology are applied in the field of end-bearing threaded soil extruding pile forming equipment and pile construction, which can solve the problems of large distribution thickness, poor pile quality, and difficulty in removing ballast at the bottom of the pile. Achieve the effect of increasing resistance and bearing capacity, increasing the vertical bearing capacity of a single pile, and being beneficial to long-term action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

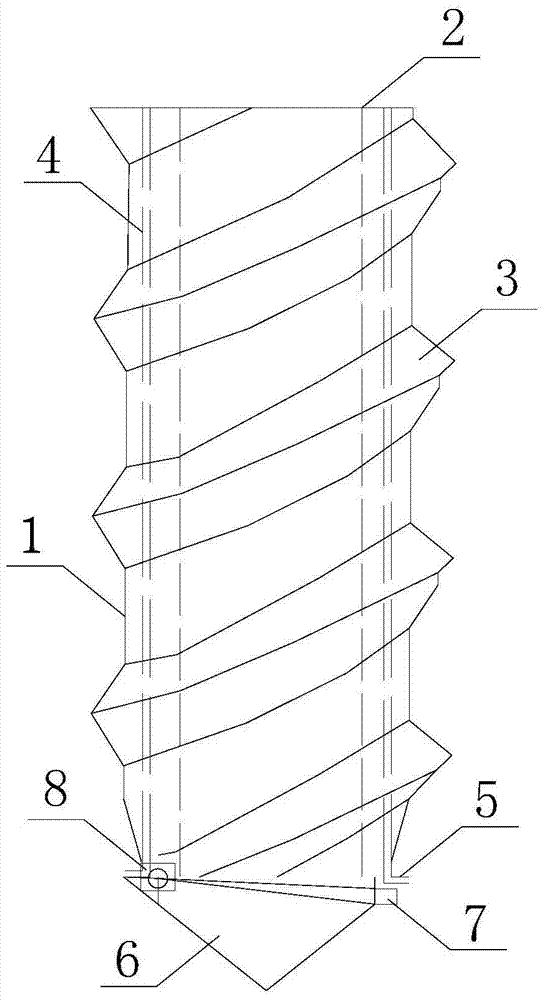

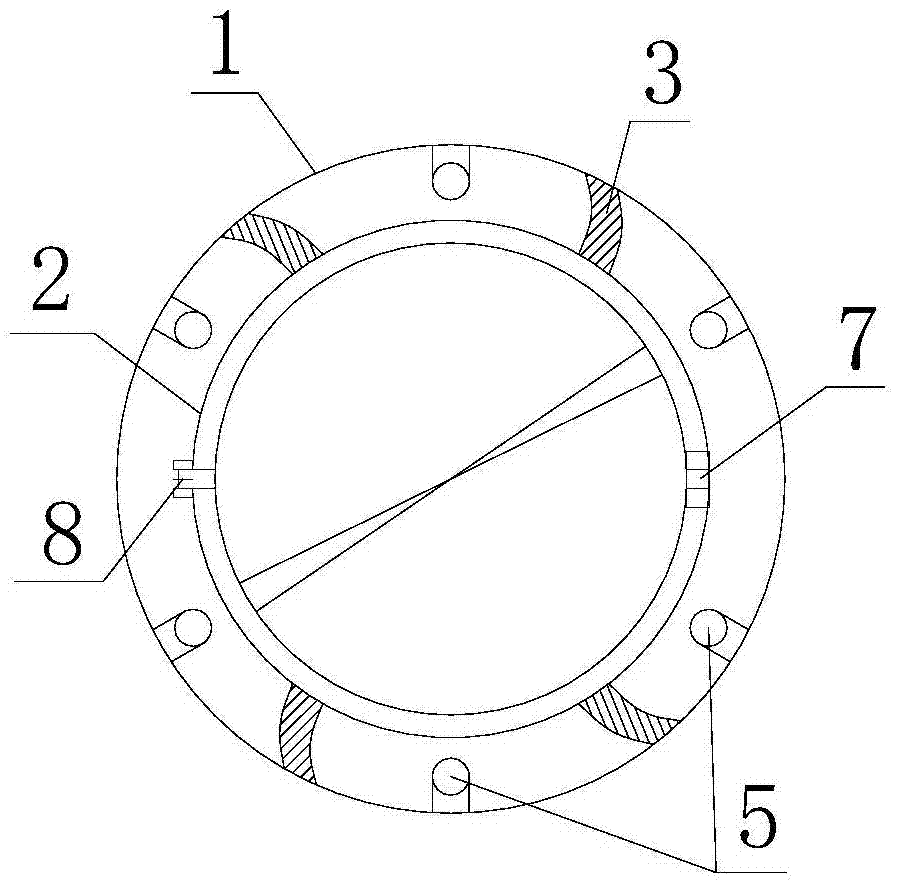

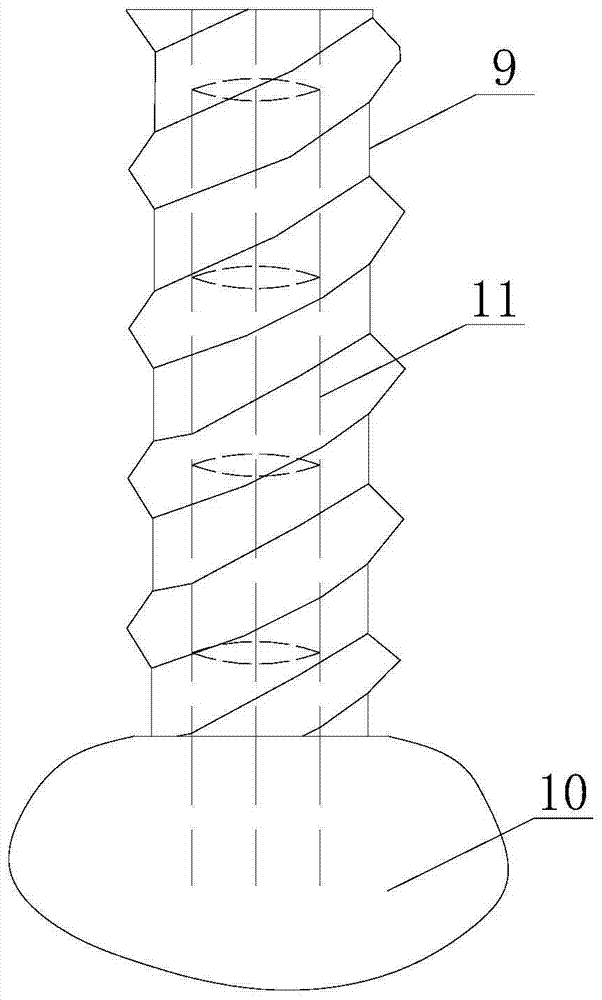

[0027] refer to figure 1 , figure 2 and image 3 , a kind of end-supporting threaded soil-extruding pile forming equipment of the present embodiment mainly includes drilling tools and grouting equipment, and the drilling tools are tools for drilling holes in deep soft soil or soft soil foundation, and it includes drill pipe 1 The drill pipe 1 is provided with a through grouting channel 2 along the axis. The diameter of the grouting channel 2 is 150 mm to 200 mm. The grouting channel 2 is mainly used to transport concrete slurry to form a pile 9. The upper end of the grouting channel 2 is The grouting port of the grouting equipment is connected, the lower end of the grouting channel 2 is hinged with the drill bit, and the drill bit 6 has the function of opening and closing. When drilling, the drill bit 6 is in a closed state. At thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com