Patents

Literature

115 results about "Cutting needle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Suture needle, triangular in cross-section, with the apex of triangle on inner circumference of needle (contrast with reverse cutting needle) Want to thank TFD for its existence? Tell a friend about us , add a link to this page, or visit the webmaster's page for free fun content .

Method and apparatus for tissue sampling

Owner:THE CLEVELAND CLINIC FOUND

Method and apparatus for tissue sampling

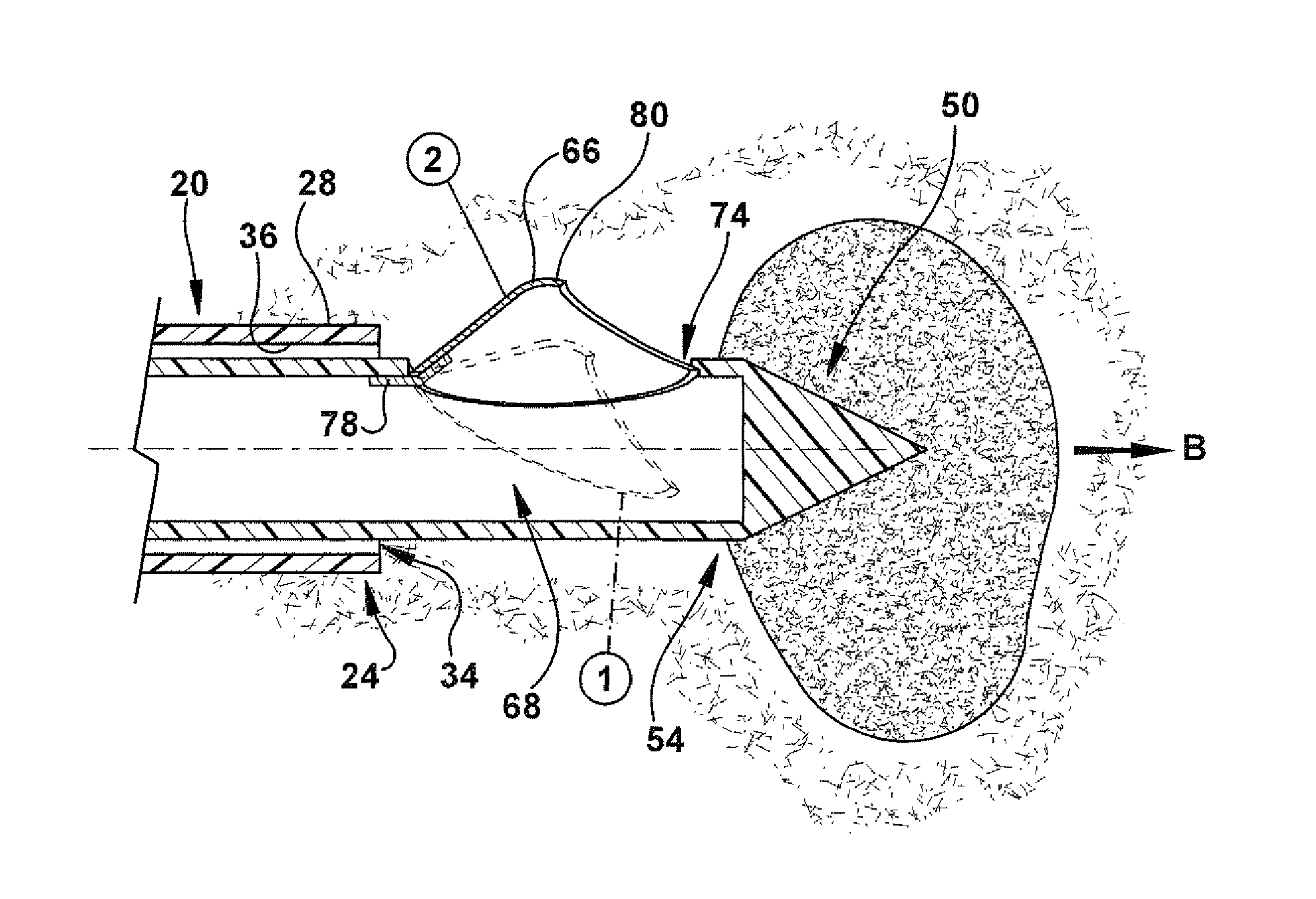

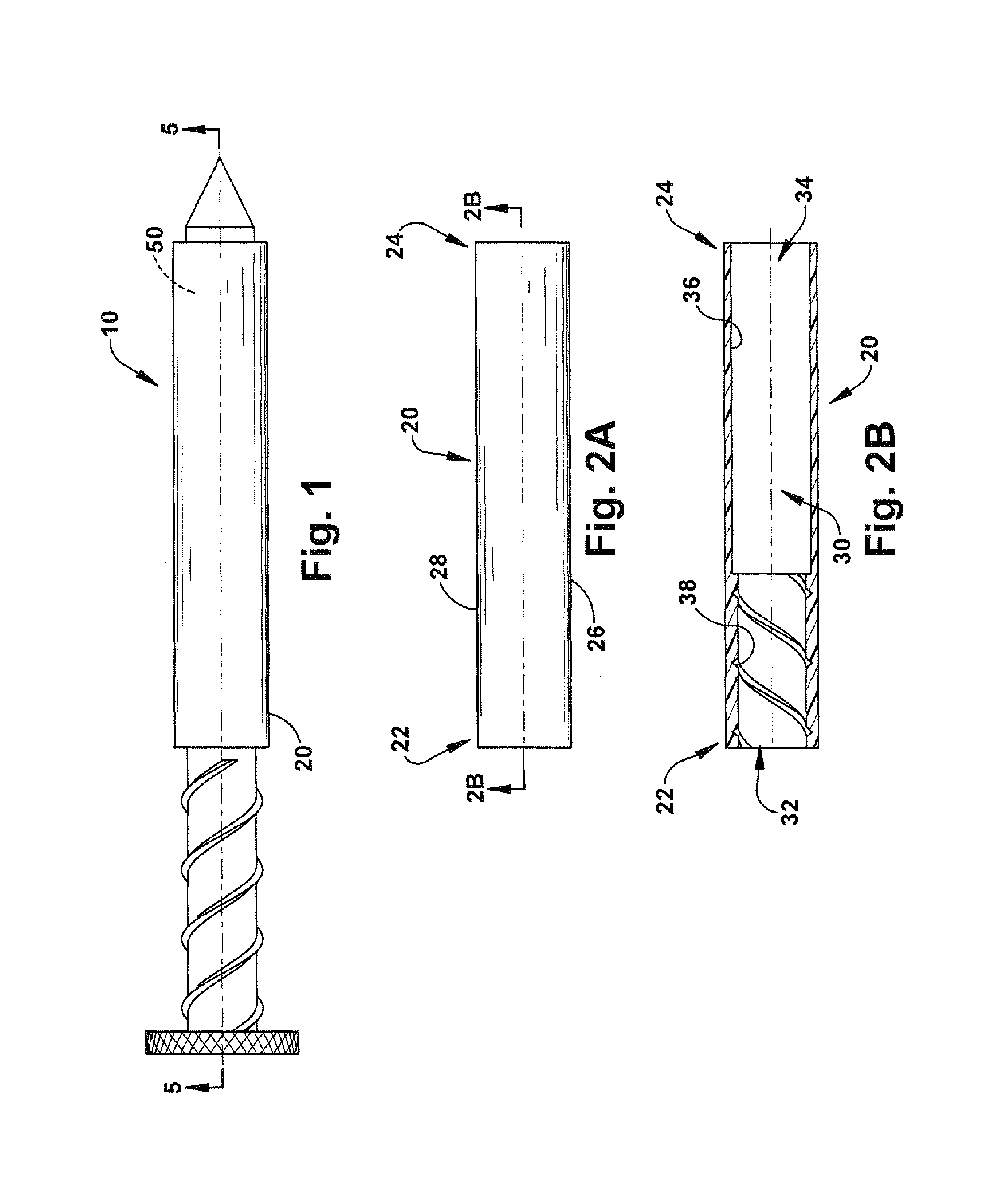

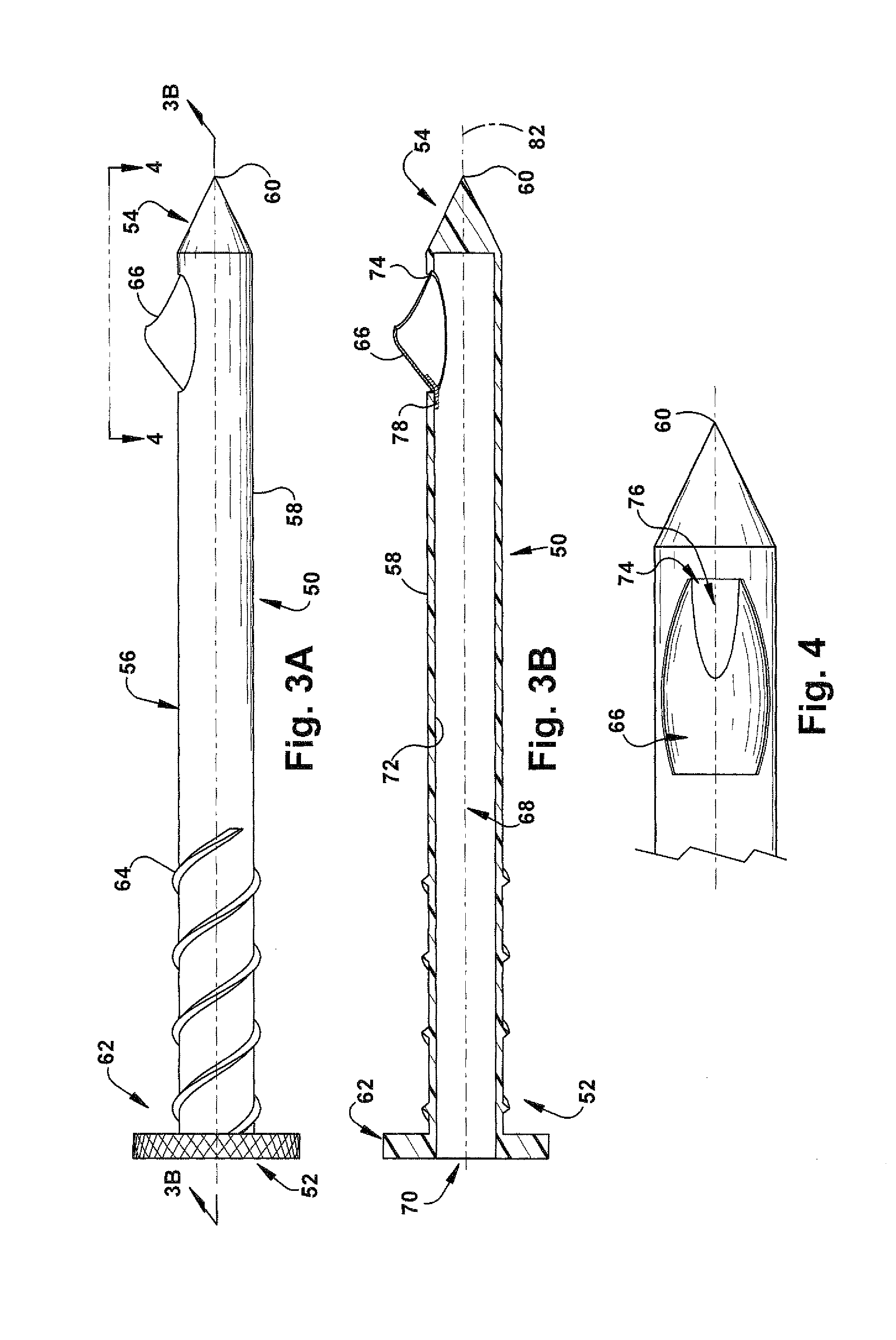

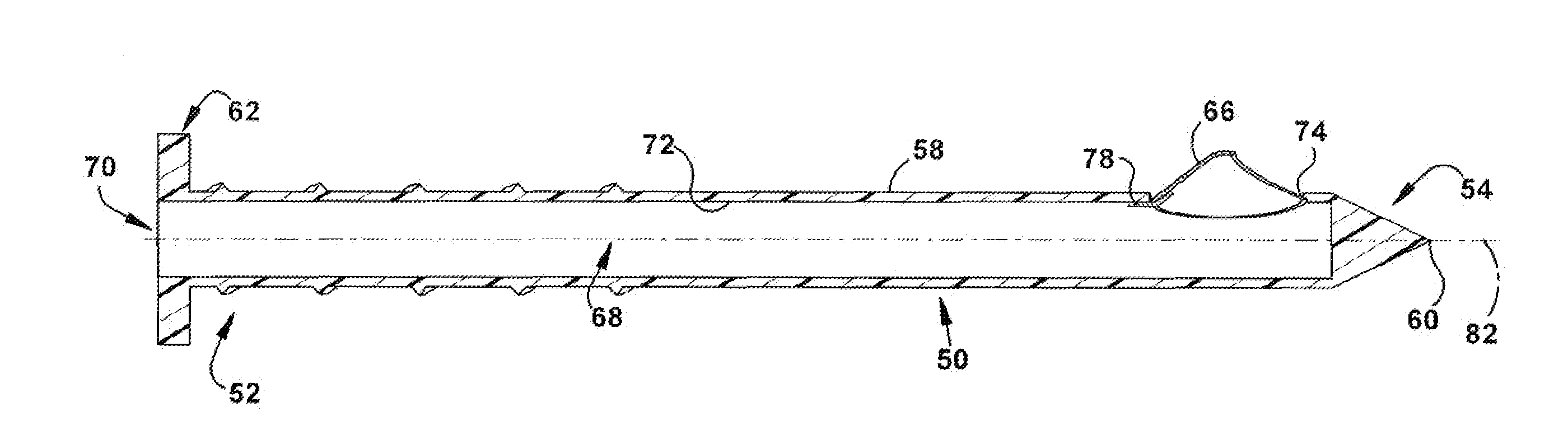

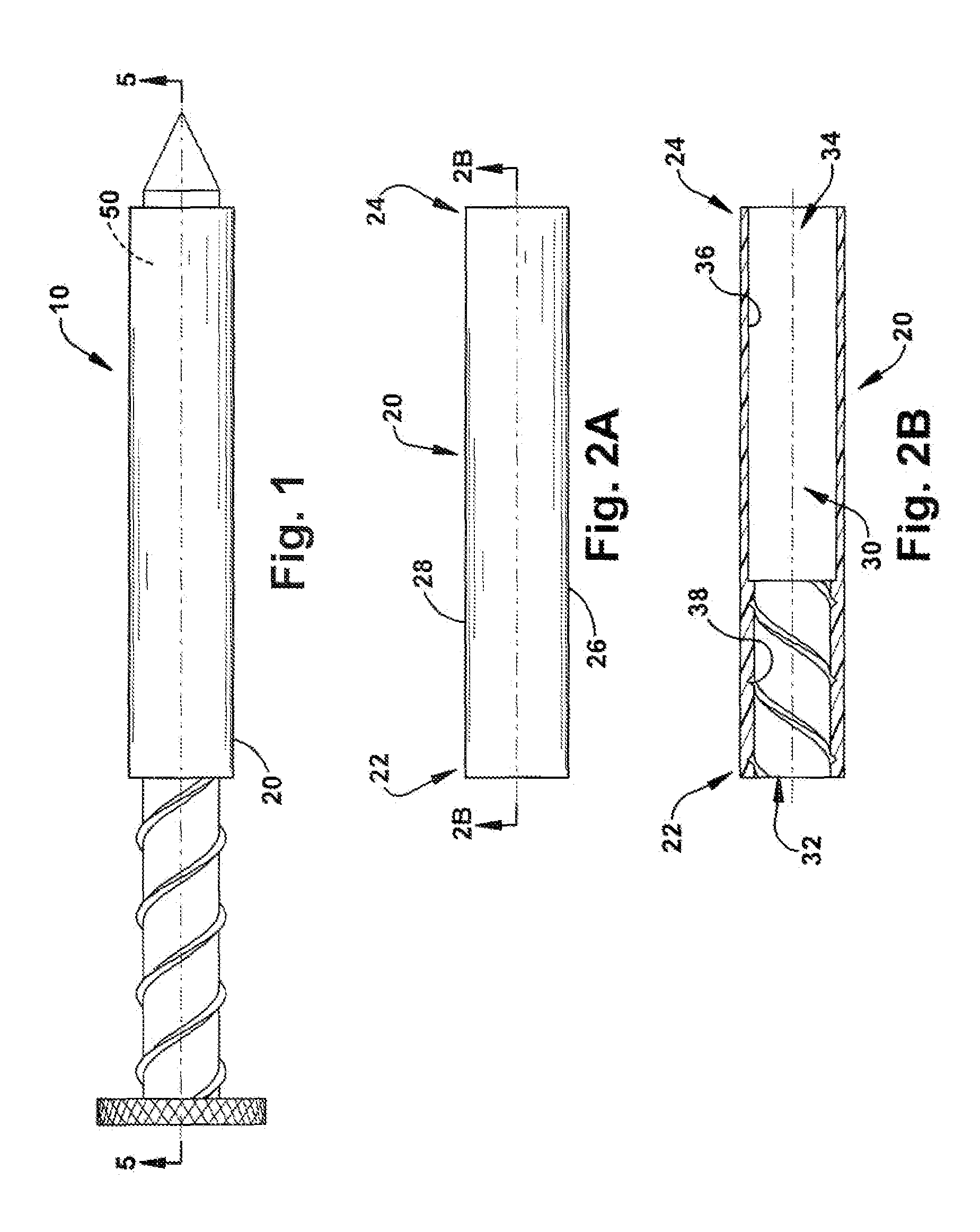

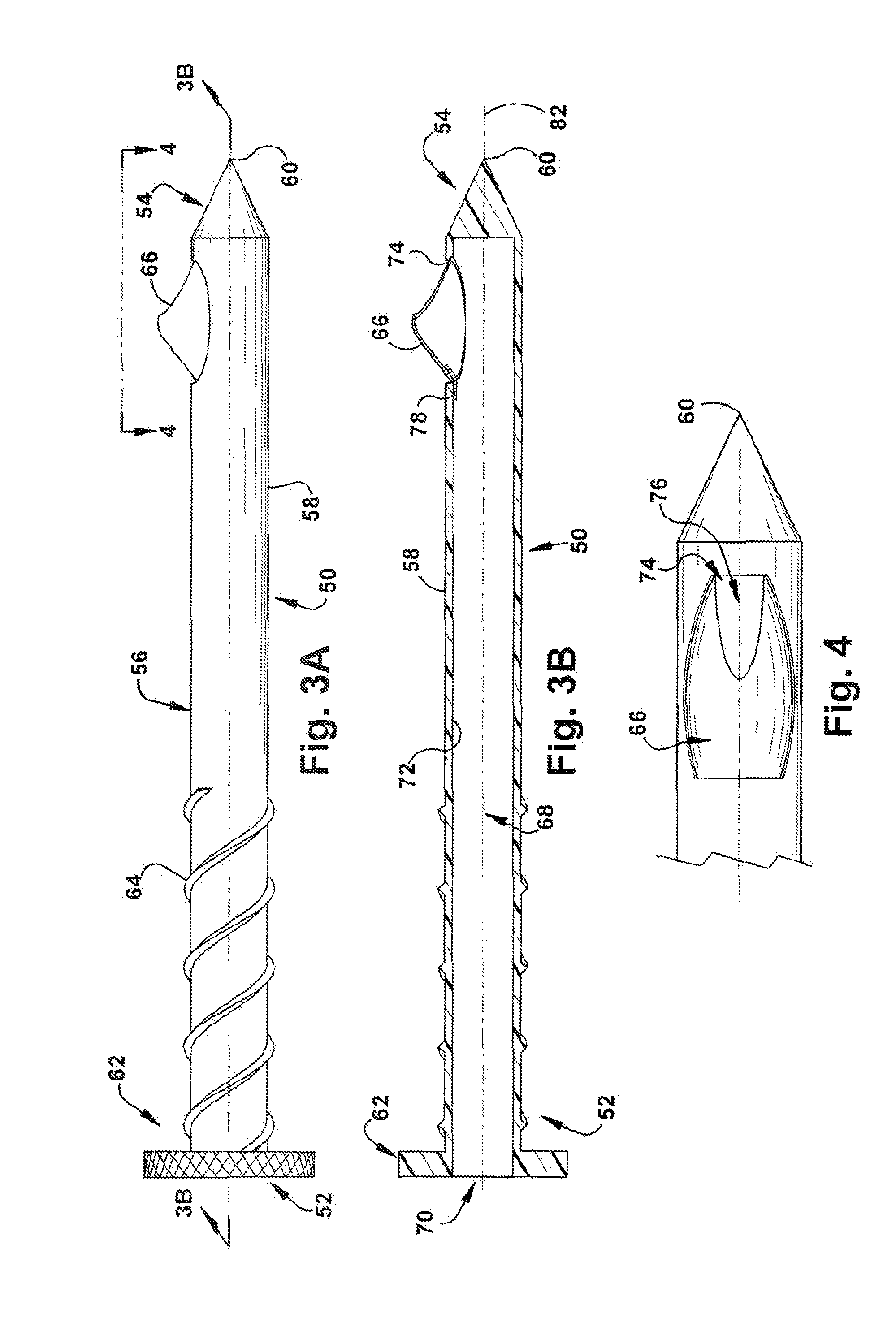

A tissue sampling device (10) includes a sheath (20) having an inner surface having a proximal end and a distal end, and an inner surface defining a passage. An inner tube (50) is disposed within the passage. The inner tube has an inner surface defining a passage, and an outer surface radially spaced outward from the inner surface. A cutting needle is pivotally mounted to the inner tube and pivots between a first position radially inward of the inner surface of the sheath and a second position substantially radially outward of the outer surface of the inner tube. Relative movement between the inner tube and the sheath causes the cutting needle to move between the first position and the second position. Rotation of the inner tube relative to the sheath when the cutting needle is in the second position causes the cutting needle to remove tissue in a helical path.

Owner:THE CLEVELAND CLINIC FOUND

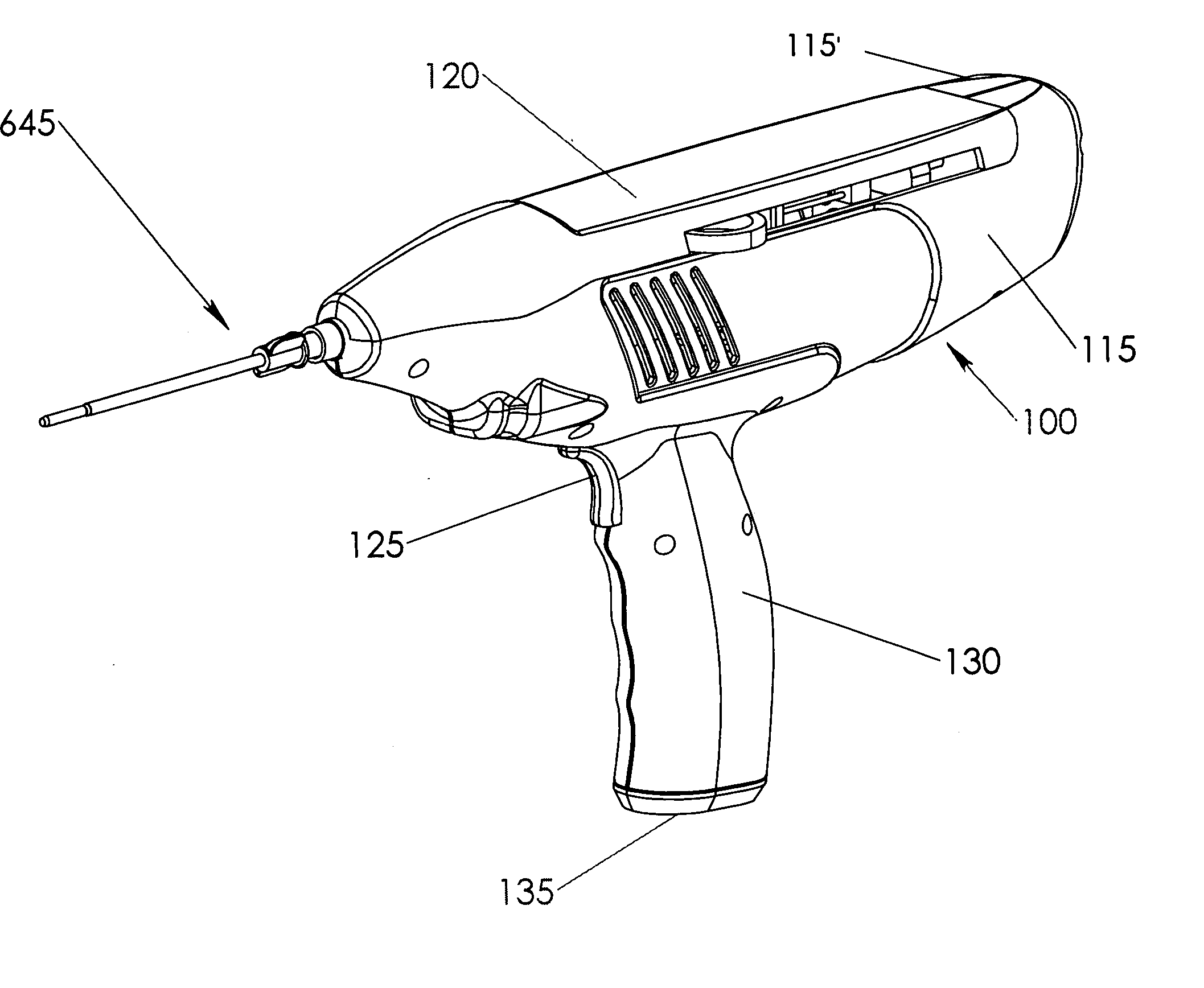

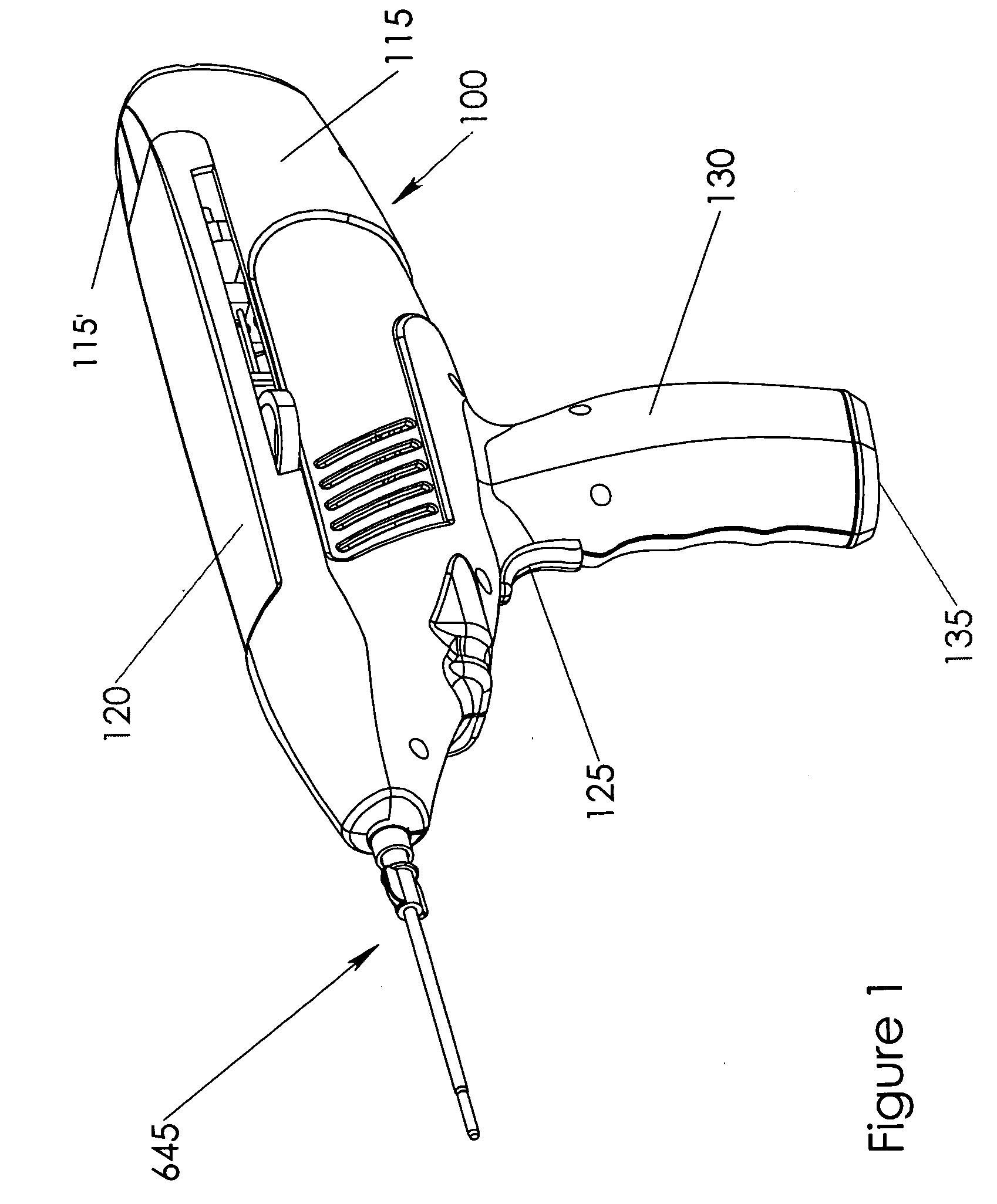

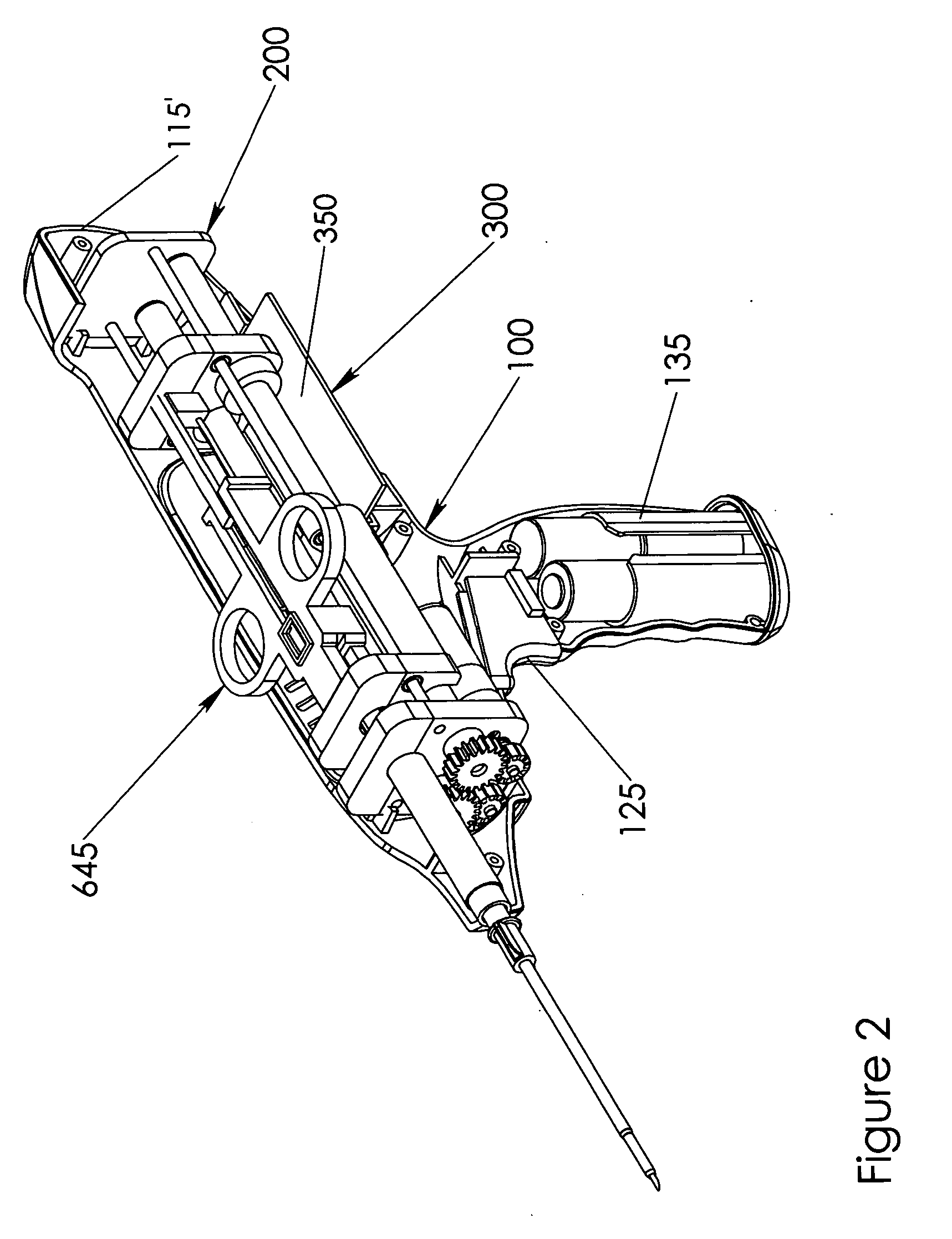

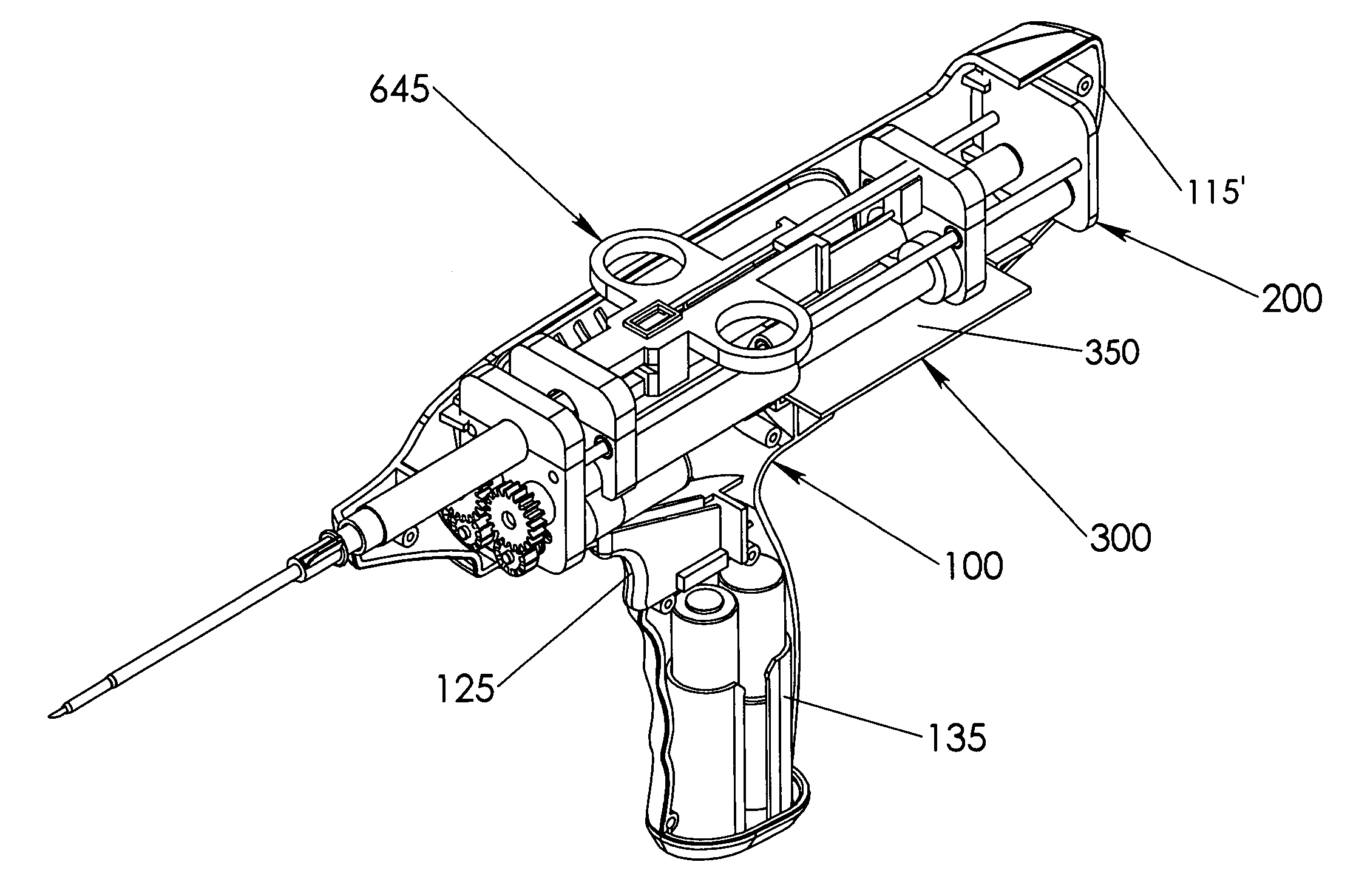

Automated biopsy and delivery device

An automated device and method for obtaining a tissue biopsy and the delivery of a material to provide hemostatis, therapeutic agents or marker material is described that can be used in conjunction with a cutting needle biopsy device. The device has an outer casing, a power source, a drive mechanism, an application chamber through which the biopsy mechanism, typically a cutting needle device, passes through and an application channel. The cutting biopsy mechanism has a mechanical or electromechanical mechanism to rapidly fire a stylet with a biopsy trough into the intended tissue and then rapidly propel a biopsy cannula over the stylet to sever and retain tissue that has protruded into the biopsy trough. At least one application channel is formed by a tube centrically slipped over the biopsy cannula wall. To enable the collection of tissue specimens, the distal segment of the application channel forms a close fitting and concentric sheath around the biopsy cannula. The biopsy cannula wall projects out of the tube with its acute-angularly designed cutting edge and the tube end encloses an obtuse angle with the biopsy cannula. The proximal end of the application channel has a larger diameter than the distal end allowing for unobstructed flow of the application material past the biopsy cannula wall upon retraction of the biopsy cannula from the distal segment of the application channel. The drive mechanism contains holders for placement of the application chamber and the biopsy mechanism and a method to manipulate the proper sequence and movement of the two.

Owner:BIOENG CONSULTANTS LTD

Phacoemulsification device having rounded edges

A phacoemulsification needle is disclosed having a hollow member with an inner surface, an outer surface, and a distal end tip. The distal end tip has an outer edge portion and an inner edge portion both of which are rounded to eliminate any sharp edges. The needle can be used to deliver ultrasonic energy to a surgical site, such as a cataract, to emulsify unwanted tissue and to aspirate the tissue through the lumen of the hollow member without using any sharp surfaces for cutting. The rounded outer and inner edge portions of the distal end tip of the needle increase the safety of the surgical procedure by reducing the risk of damage to the capsule or other intraocular structures or tissues near the surgical site. This improvement in safety has allowed the development of new needle configurations to improve the efficiency of phacoemulsification, several of which are disclosed herein.

Owner:DRT VENTURES

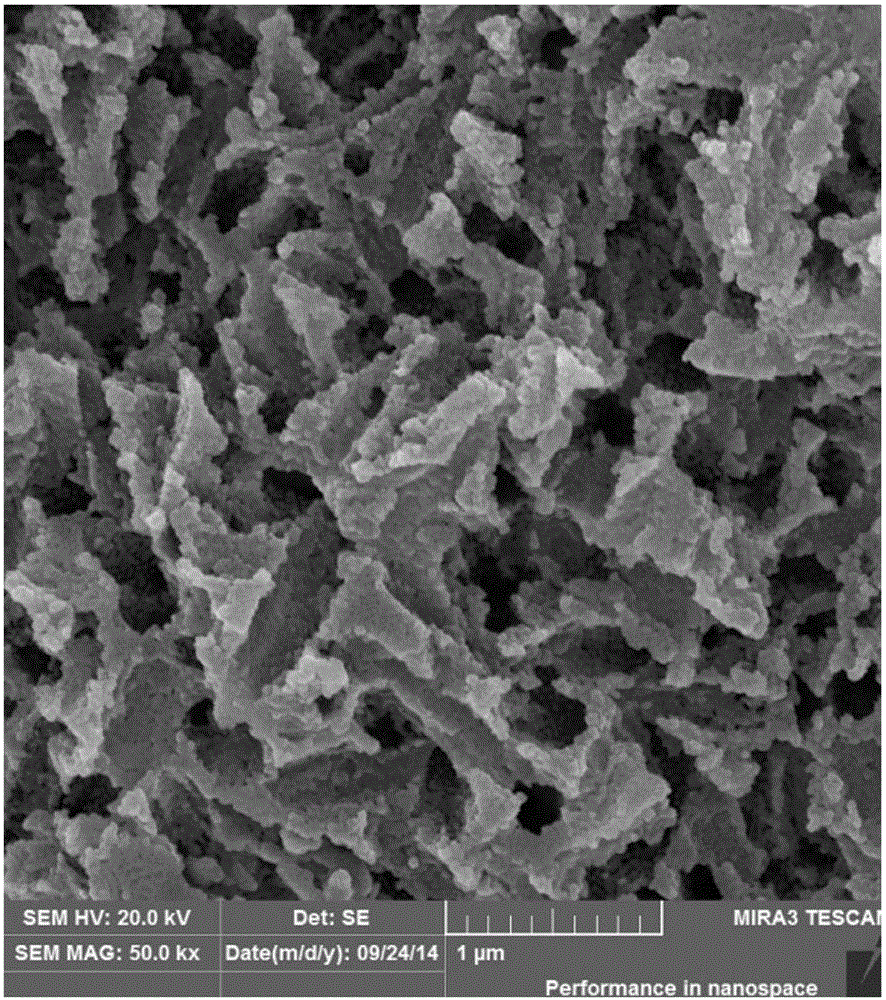

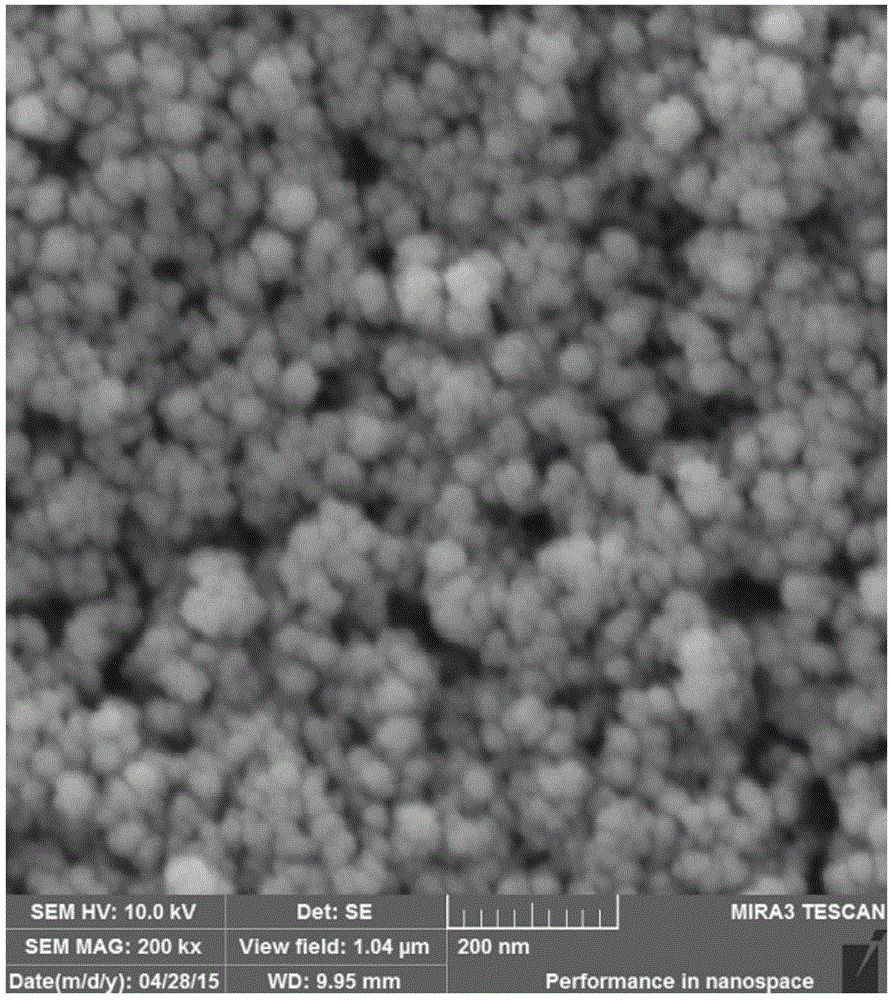

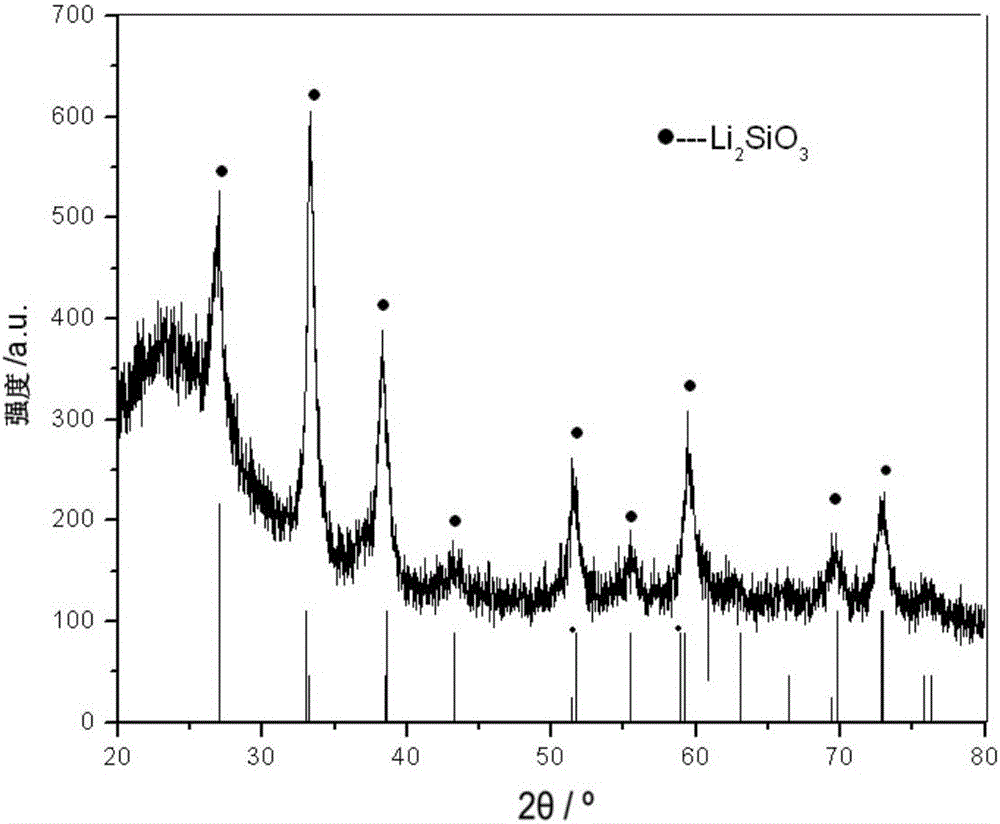

Lithium metasilicate glass ceramic and preparation method thereof

ActiveCN106277798ASimple production processLow requirements for production equipmentCrystal morphologyThermal insulation

Owner:SHENZHEN UPCERA DENTAL TECH

Automated biopsy and delivery device

An automated device for obtaining a tissue biopsy and delivering material to provide hemostatis, therapeutic agents or marker material is described. The device has an outer casing, a power source, a drive mechanism, an application chamber through which the biopsy mechanism, typically a cutting needle, passes through and an application channel. The cutting biopsy mechanism has a mechanical or electromechanical mechanism to rapidly fire a stylet with a biopsy trough into the intended tissue and then rapidly propel a biopsy cannula over the stylet to sever and retain tissue that has protruded into the biopsy trough. At least one application channel is formed by a tube centrically slipped over the biopsy cannula wall. To enable the collection of tissue specimens, the distal segment of the application channel forms a close fitting and concentric sheath around the biopsy cannula.

Owner:BIOENG CONSULTANTS LTD

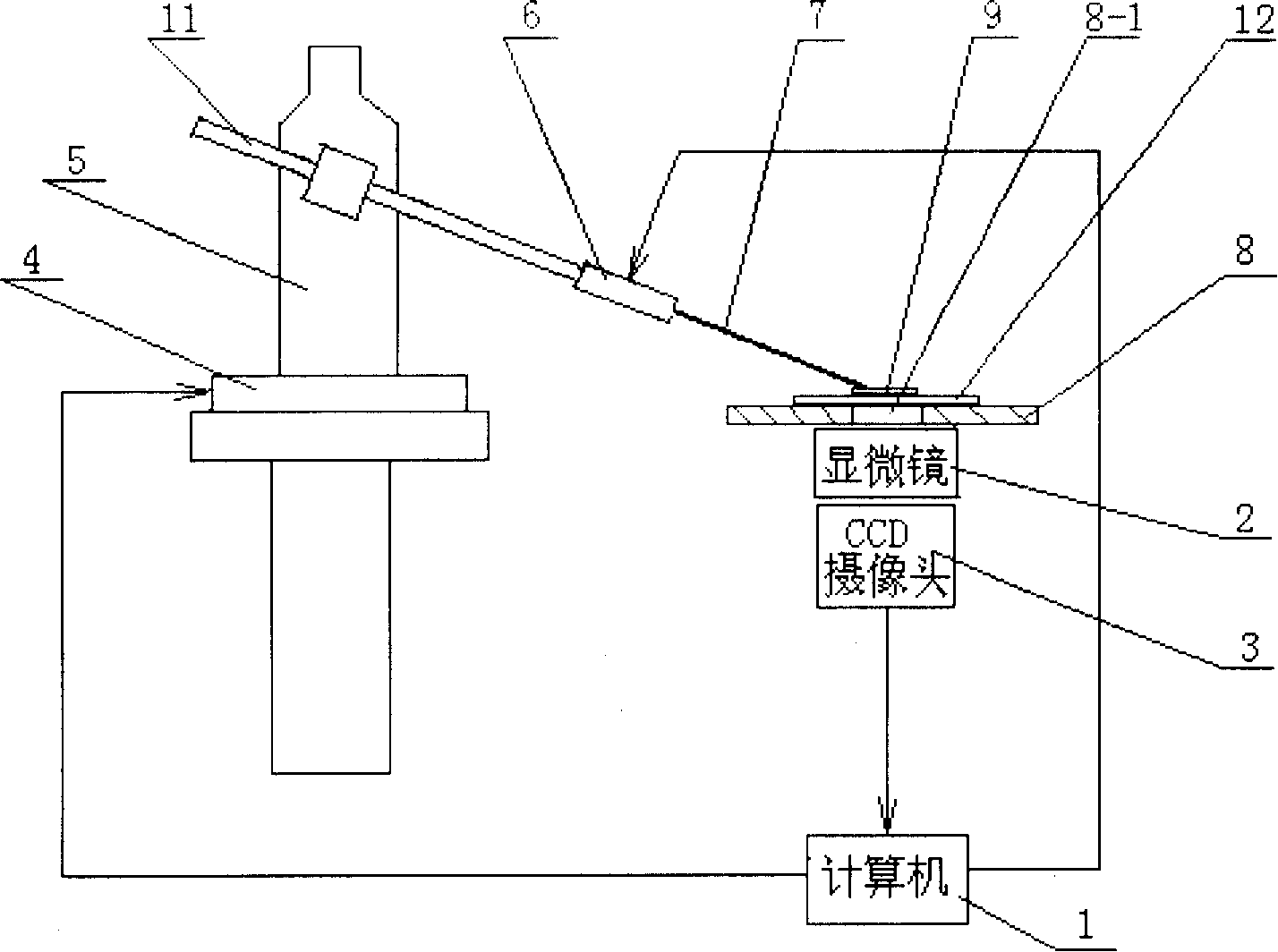

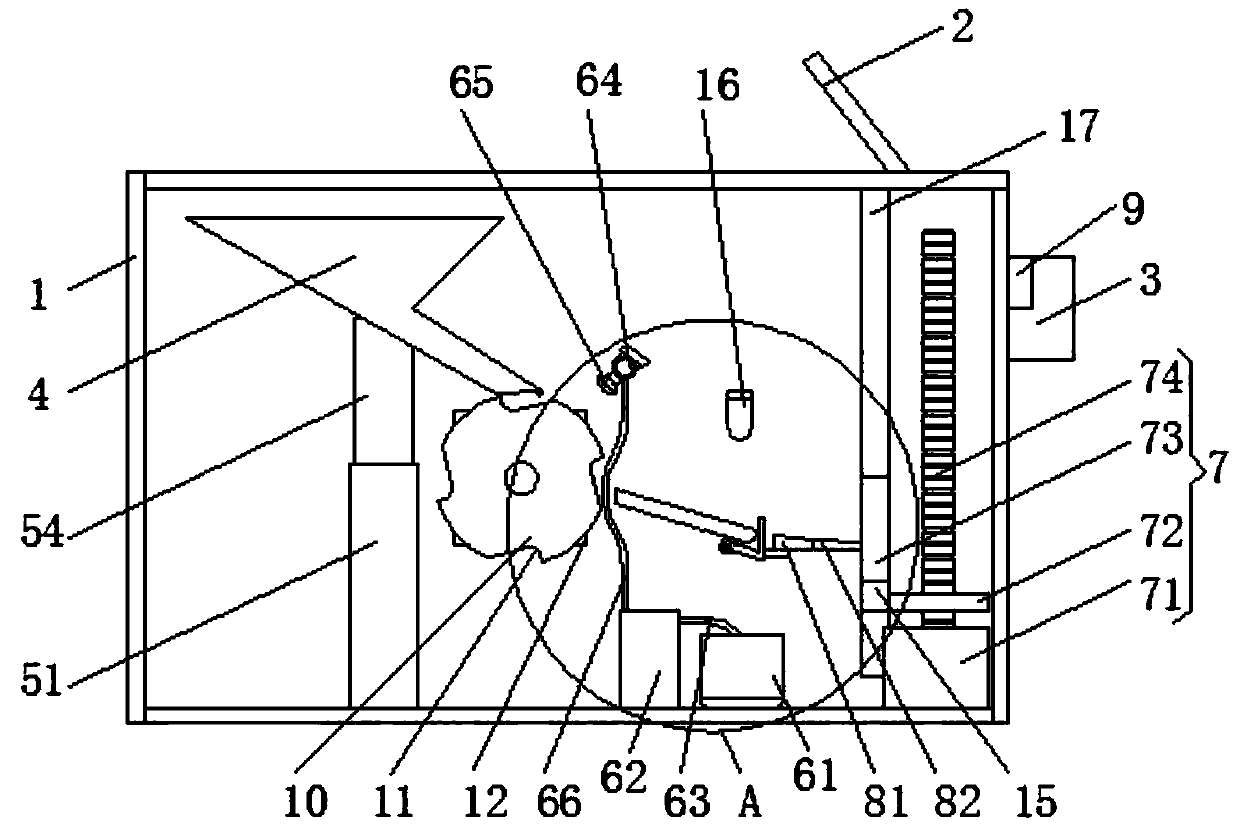

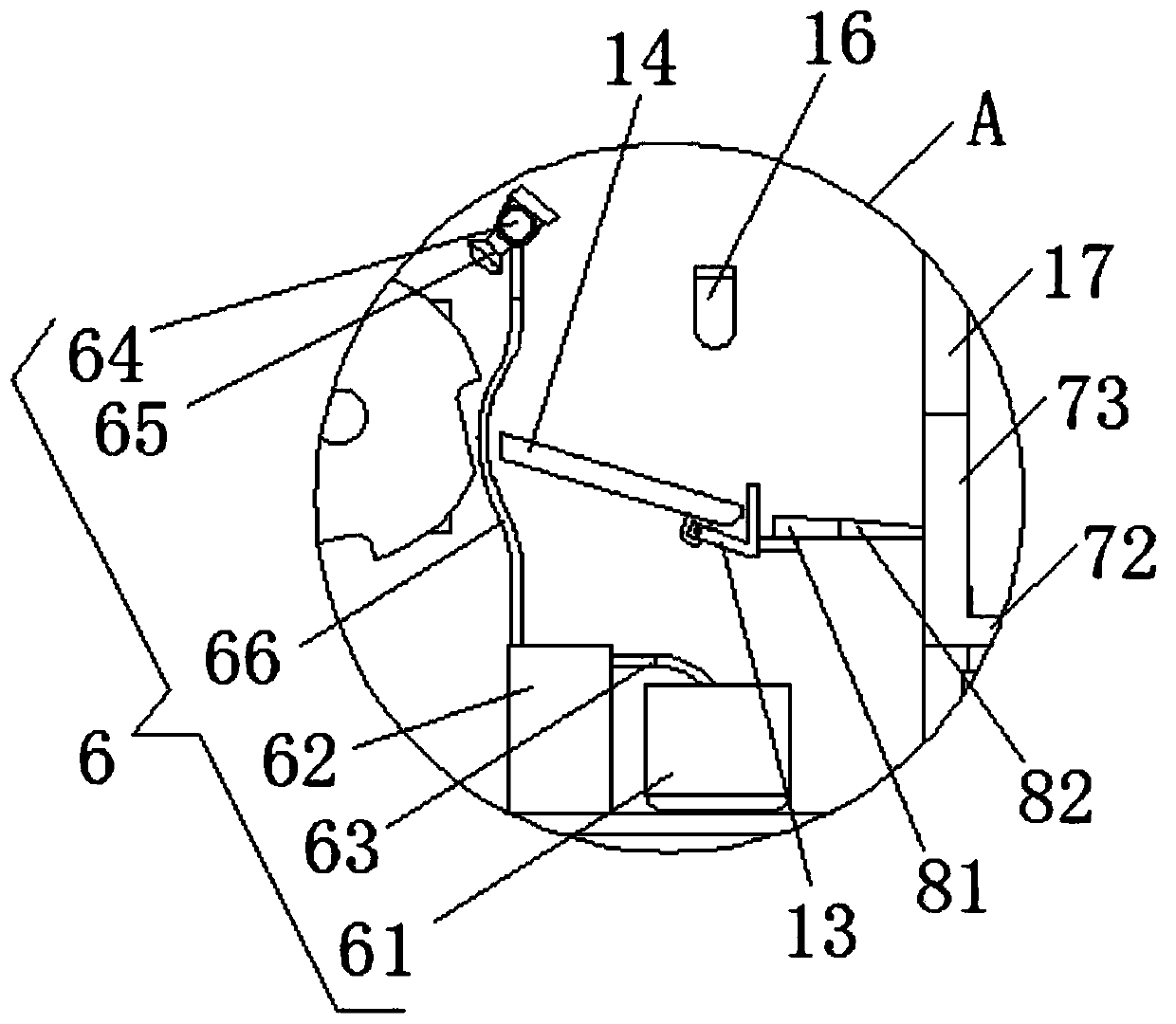

Microdissection device based on piezoelectric ultrasonic vibration

InactiveCN1875893ARealize the cutting operationMeet the vibration state requirementsWithdrawing sample devicesSurgeryCut needleEngineering

The invention relates the microscopic cutting device. The invention overcomes the defects of strong working strength, fatigability and big personal error. The device comprises computer 1, microscope 2, CCD cam 3, free mechanical micro motion desk 4, clamp 5, ultrasonic vibration emitter 6, cutting needle 7, biological section stage 8 and cutter bar. 2 is installed under 8, 3 is connected with 2 to collect the object magnified by 2, the signal output terminal of 3 is connected with signal input terminal of 1, 4 is installed at the side of 8, the signal output terminal of 1 is connected with controlling terminal of 4, 5 is fixed on the 4, 11 is fixed on the 5, one end of 11 is connected with one end of 6, the other end of 6 is connected with the butt of 7, the tip of 7 extends to the upper surface of 8, and the other signal output terminal of 1 is connected with the input terminal of 6.

Owner:HARBIN INST OF TECH

Cut pile fabric and method of making same

A knit fabric may be formed by providing a plurality of cylinder needles and a plurality of cutting needles having a cutting surface. A first yarn may be fed to the plurality of cylinder and the plurality of cutting needles to form loops during a knitting cycle. A second yarn may be fed to the plurality of cylinder needles during the knitting cycle so that the first yarn and the second yarn having a plated relationship on the plurality of cylinder needles. A pile may be formed on the knit fabric by cutting the loops on the cutting needles with the cutting surface.

Owner:HBI BRANDED APPAREL ENTERPRISES

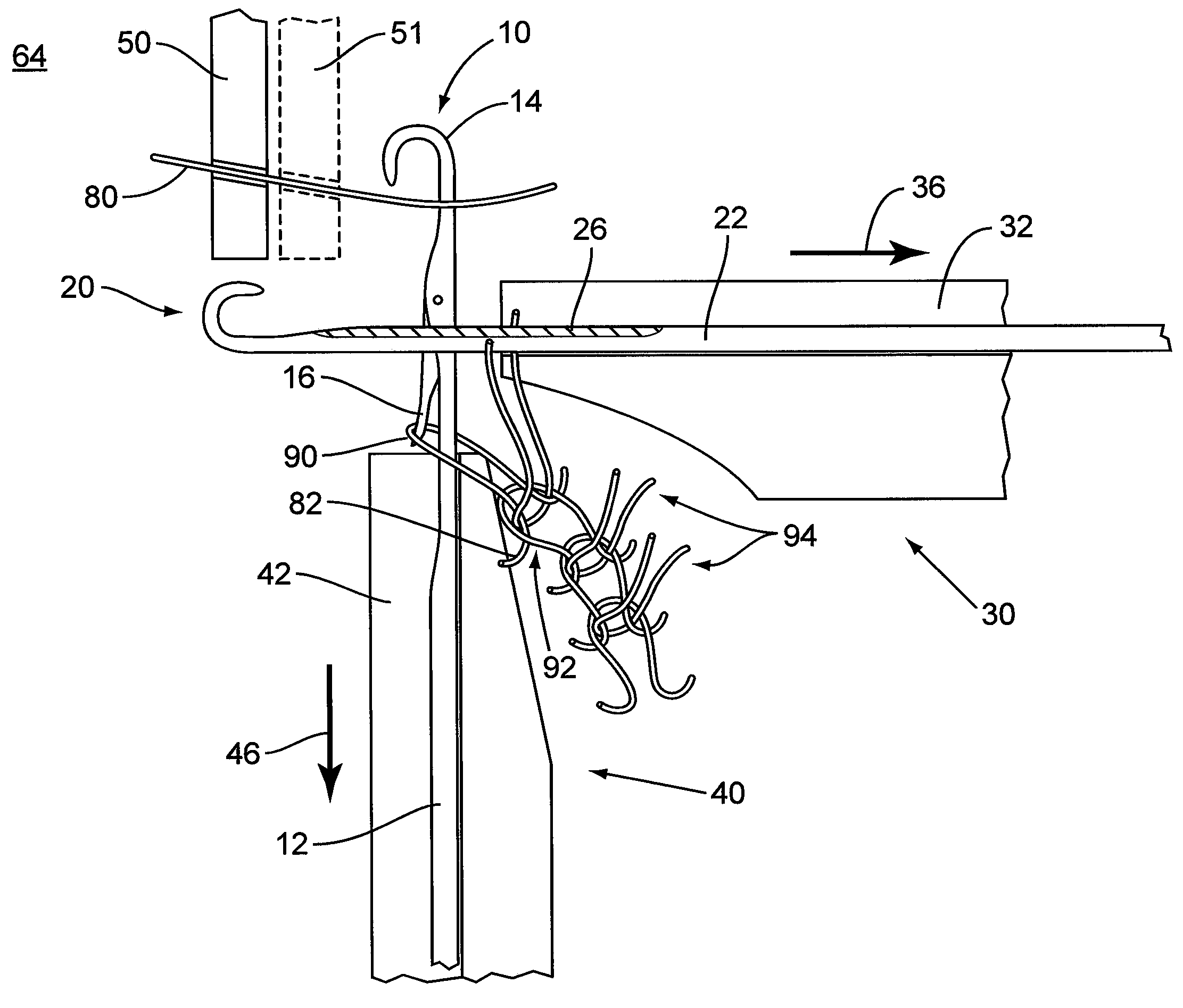

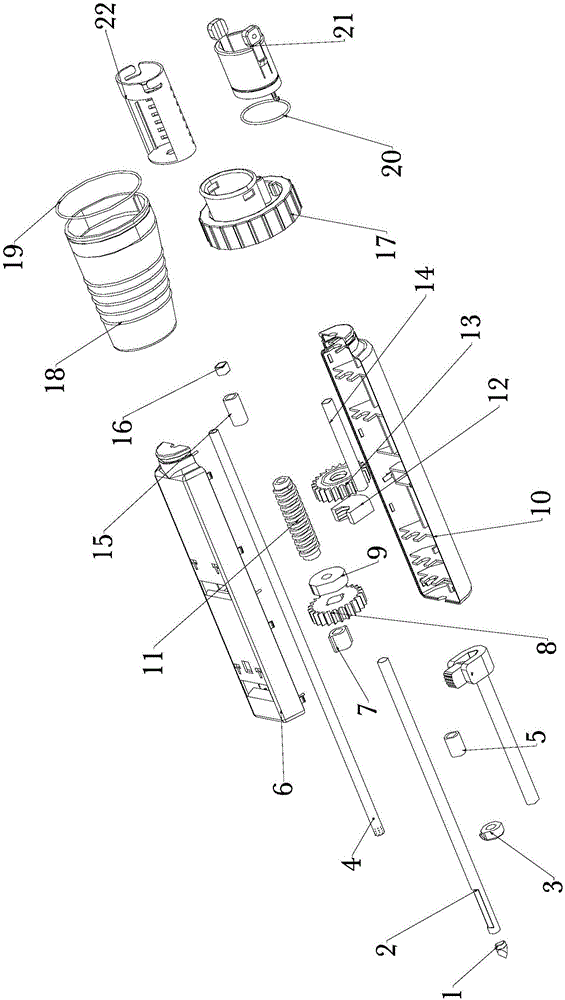

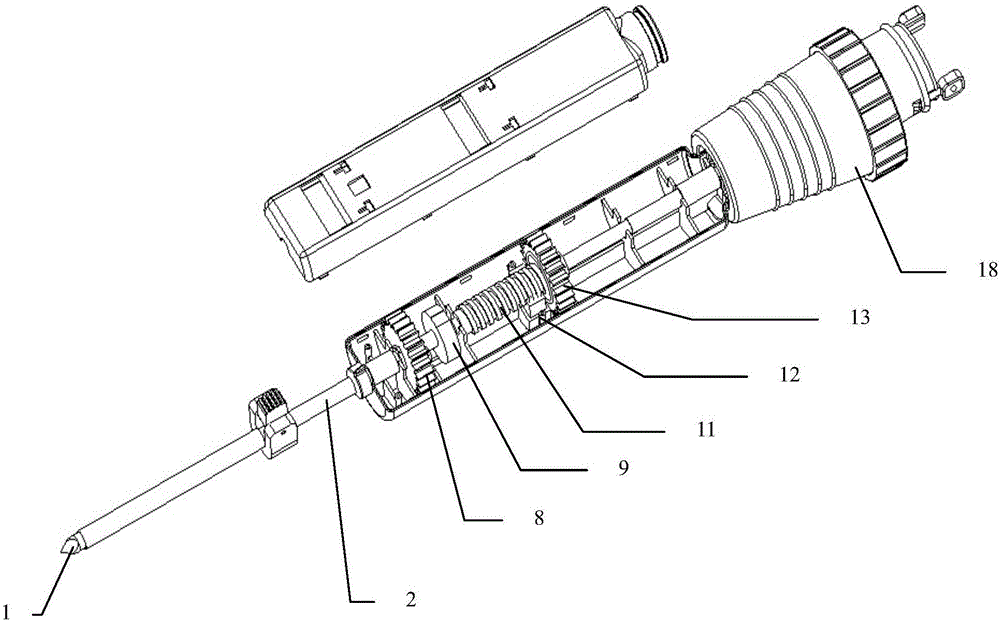

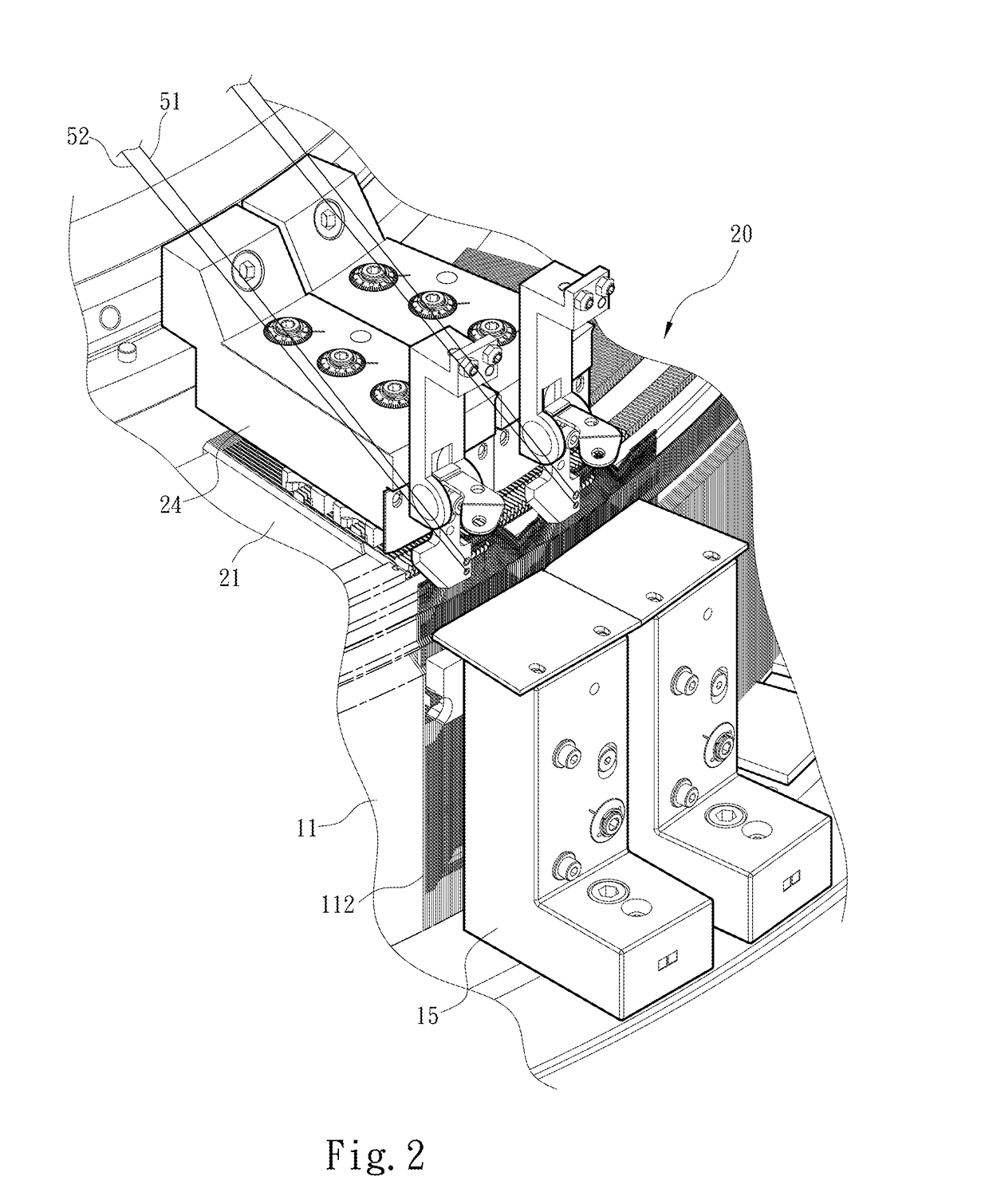

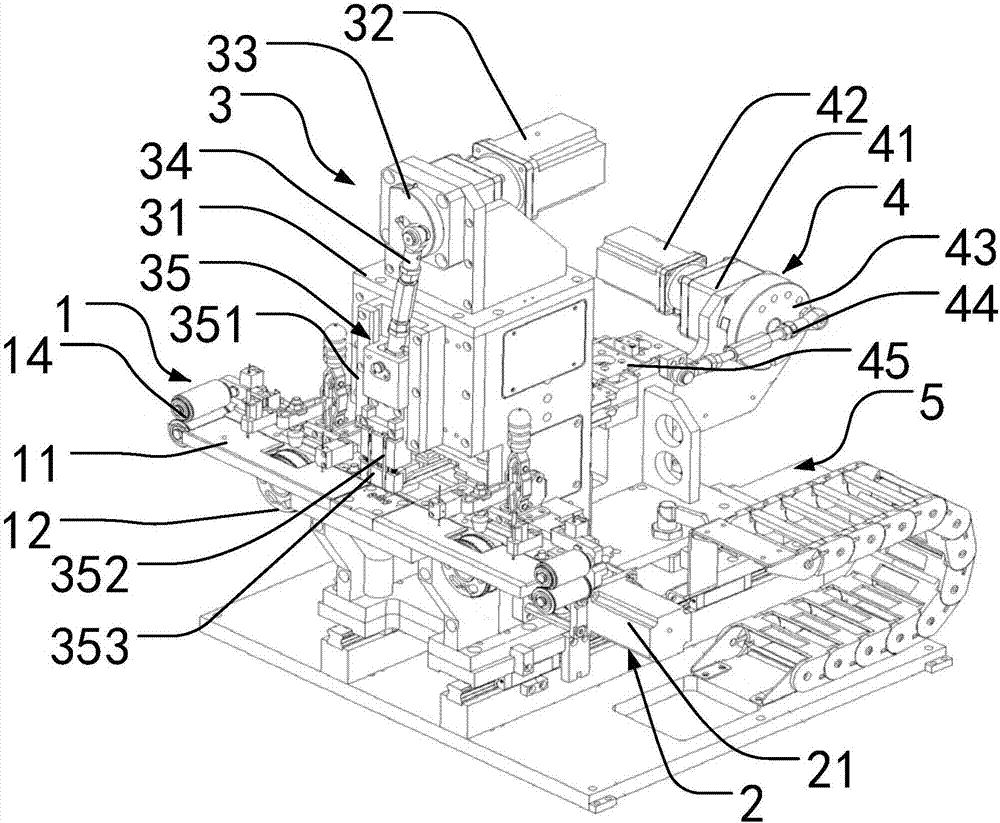

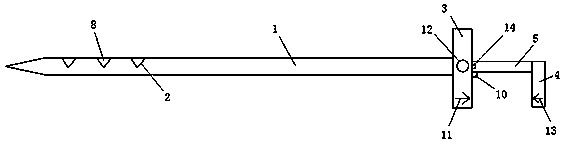

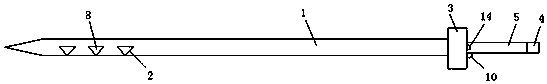

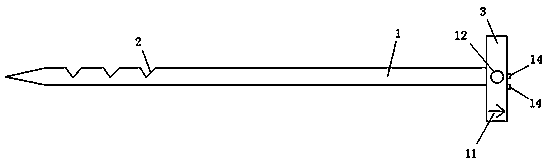

Cutting needle advancing and retreating structure of rotary-cut needle and rotary-cut needle with same

PendingCN106166079ARealize forward and backwardImplement rotary cuttingSurgical needlesVaccination/ovulation diagnosticsCut needleStructural engineering

The invention relates to a cutting needle advancing and retreating structure of a rotary-cut needle and the rotary-cut needle with the same. The cutting needle advancing and retreating structure of the rotary-cut needle comprises a shell, a needle point part and a cutting part. The needle point part comprises a needle point, a needle sleeve and a gear a. The needle point is welded to one end of the needle sleeve, the other end of the needle sleeve is located in the shell, the gear a is fixed to the other end of the needle sleeve through a gear fixing block, and the side wall of the end, close to the needle point, of the needle sleeve is provided with a cutting through hole. A cutting part comprises an inner sleeve, a worm, a worm fixing block and a gear b, the worm and the gear b are arranged in the shell, one end of the inner sleeve is arranged in the needle sleeve, sawteeth are arranged at one end of the inner sleeve, and a bevel chamfer is arranged. A round hole is formed beside the sawteeth, the other end of the inner sleeve is in close fit with the worm, the gear b is also in close fit with the inner sleeve, and the worm fixing block is fixed to a lower shell and in screw fit with the worm. The rotary-cut needle can fill in the domestic blank through the simple structure and the sharp puncture cutting capacity.

Owner:杭州思客医学科技有限公司

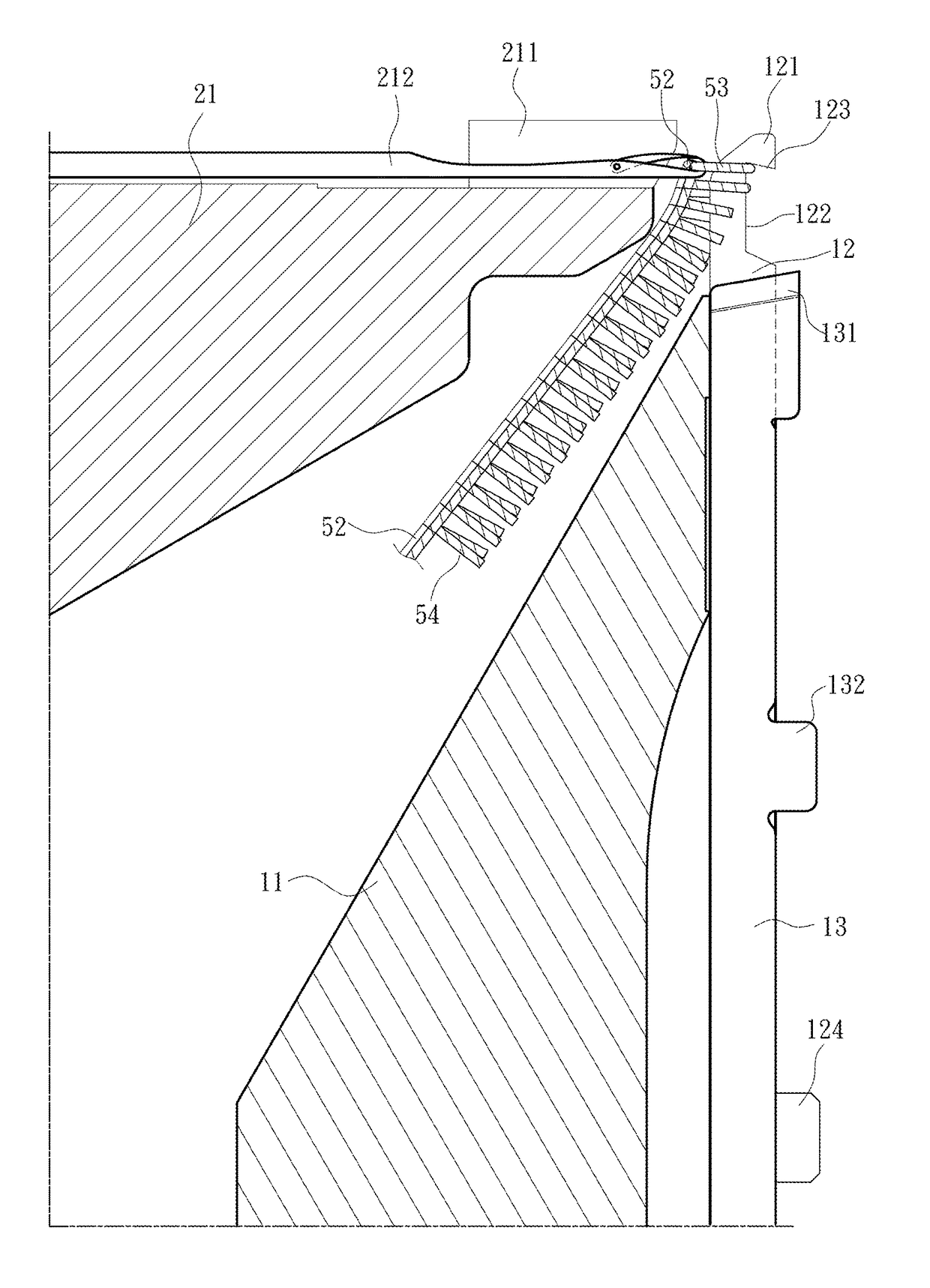

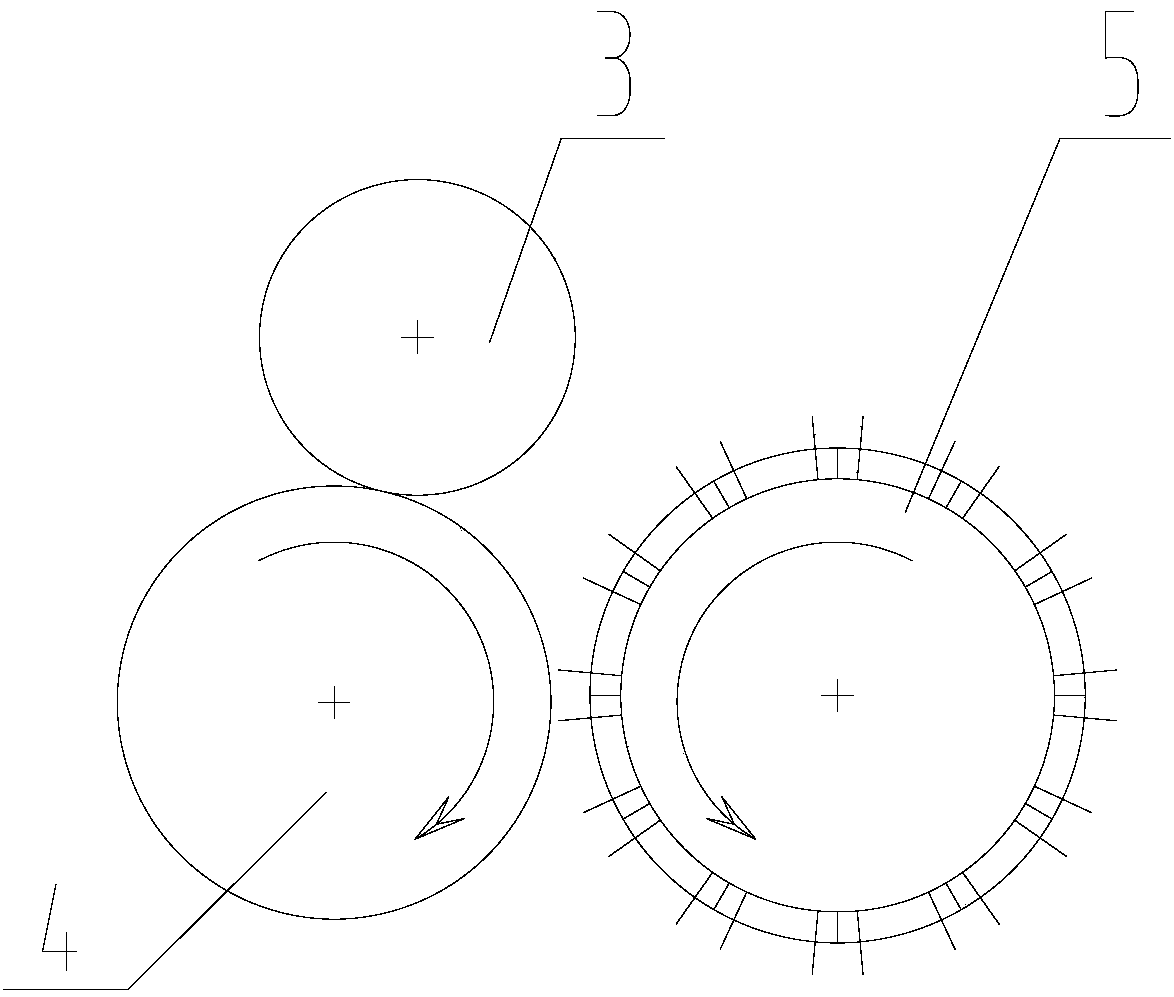

Loop cutting apparatus for circular knitting machines

A loop cutting apparatus for a circular knitting machine which has a circular cylinder including a plurality of knitting needles movable independently includes an upper needle dial located on the circular cylinder and a plurality of yarn cutting needle sets radially centered about the axis of the circular cylinder. Each yarn cutting needle set includes a first cutter needle and a second cutter needle movable against the first cutter needle in a first yarn cutting displacement thereof. The first cutter needle has a yarn holding section leaned by a yarn and collaborated with the two abutting knitting needles at two sides to pick up and draw the yarn to form a pile loop and a first cutter section connected to the yarn holding section. The second cutter needle has a second cutter section staggered against the first cutter section in the first yarn cutting displacement to cut the pile loop.

Owner:PAI LUNG MACHINERY MILL CO LTD

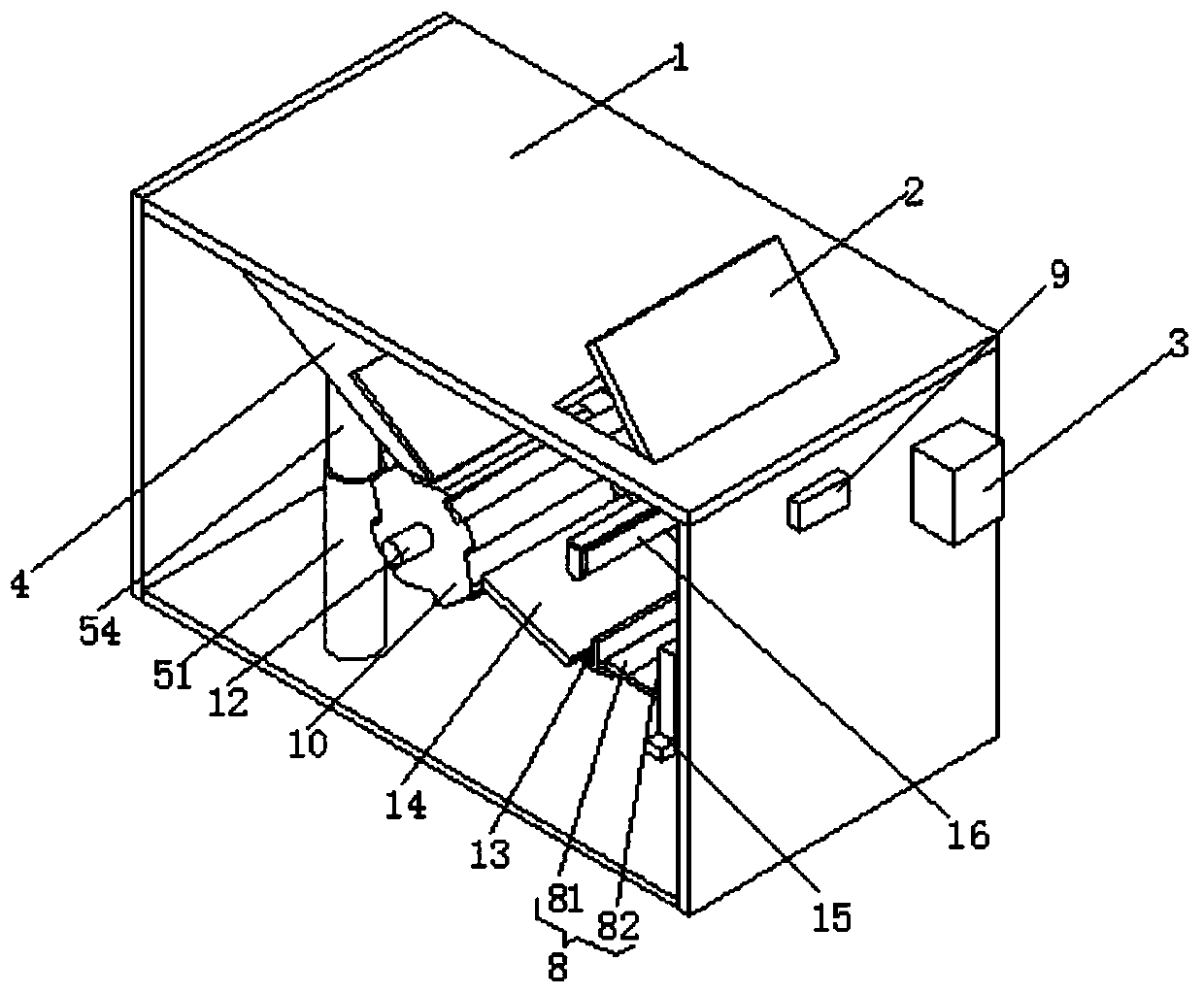

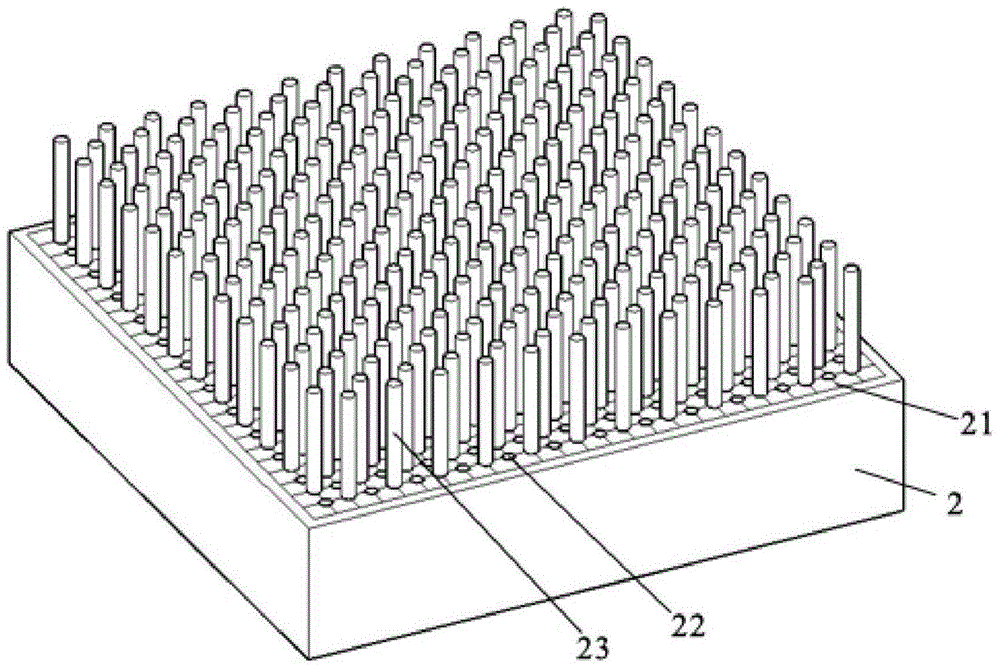

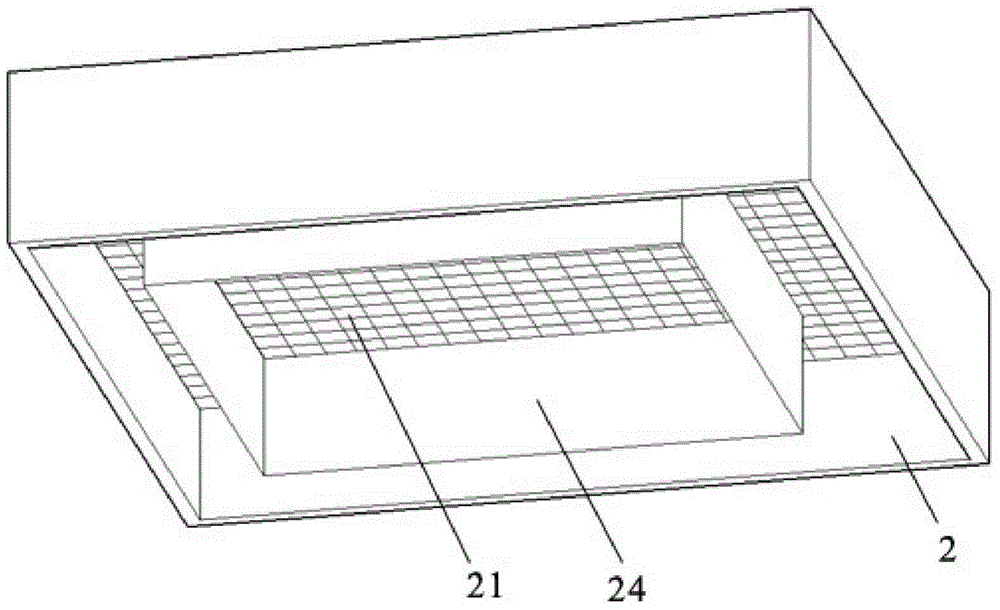

Sterile take-and-place box for orthopedic cutting needles

InactiveCN111407423AEasy to observeFill in timeSurgical furnitureChemicalsOrthopedic departmentCut needle

The invention discloses a sterile take-and-place box for orthopedic cutting needles. The box comprises a box body, a weighing unit, a spray disinfection unit, a lifting unit and a needle taking unit;a rear side plate of the box body is fixedly connected with a rotating motor, the outer arc surface of the output shaft of the rotating motor is fixedly connected with a needle taking cylinder, and the outer end of the arc surface of the needle taking cylinder is provided with four uniformly arrayed needle grooves; and the lower end of the rear side plate of the box body is fixedly connected witha transition plate, the front end of the transition plate is fixedly connected with the inner surface of a front side plate of the box body, the transition plate is arranged corresponding to the needle taking cylinder, the right end of the lower surface of the transition plate is connected with an L-shaped baffle through an elastic hinge, and the lower end of the right side surface of the verticalpart of the L-shaped baffle is fixedly connected with a pressing the plate. The sterile take-and-place box for the orthopedic cutting needles can visually display the number of the orthopedic cuttingneedles in the box body, adopts a double sterilization manner, realize thorough sterilization, automatically takes the needles, can close a needle taking opening in time to prevent external bacteriafrom entering the box, and is convenient to use.

Owner:孙慧琴

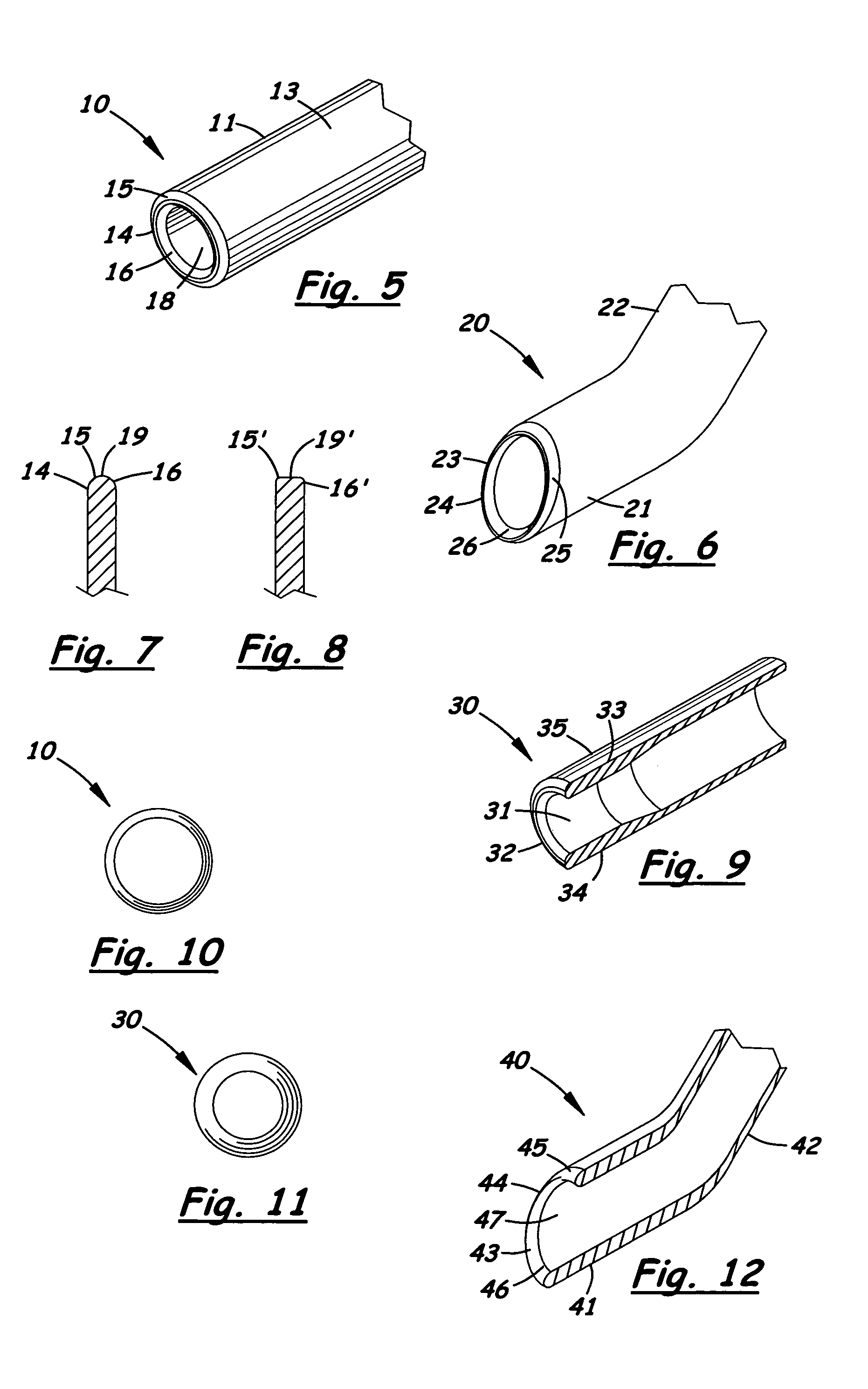

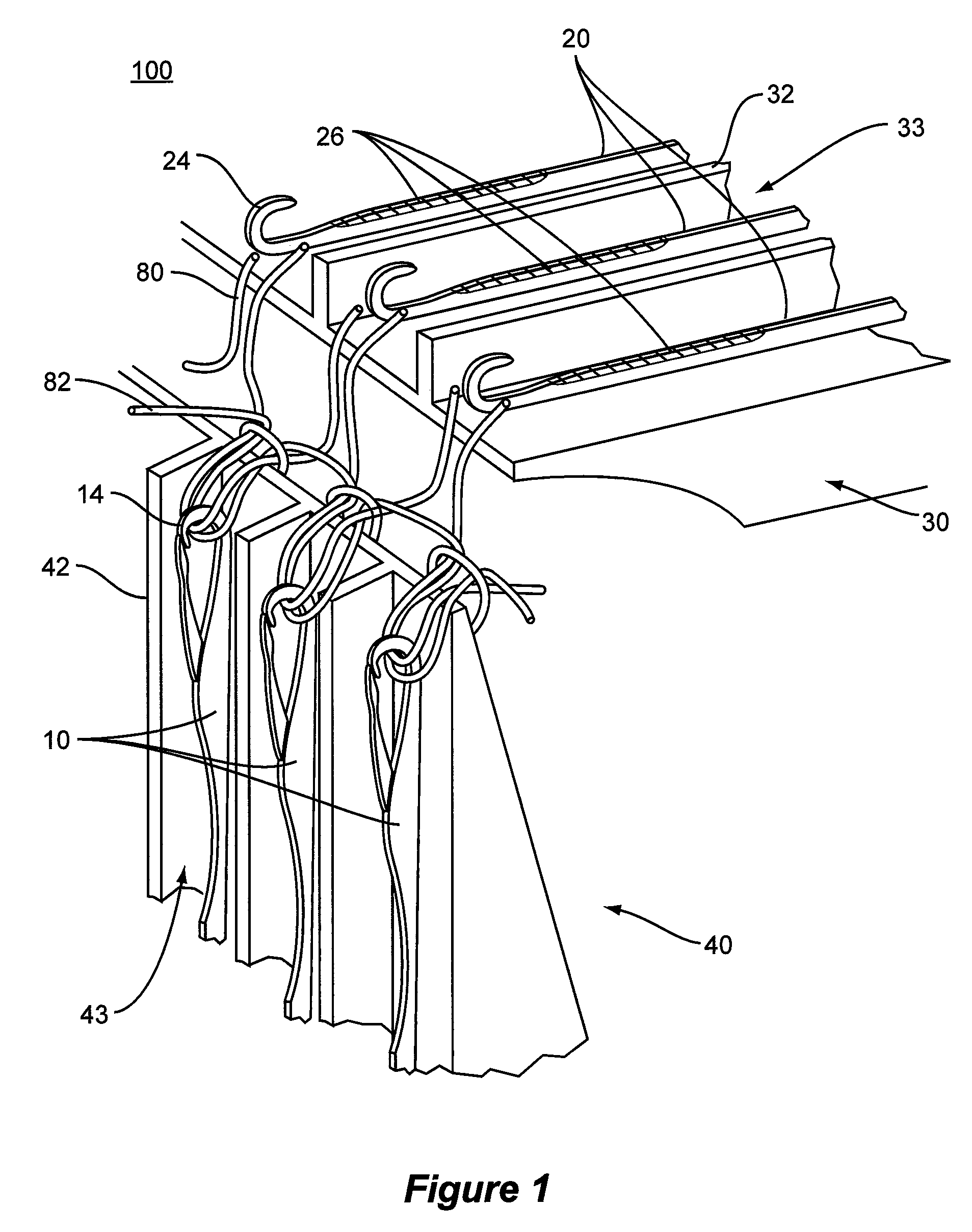

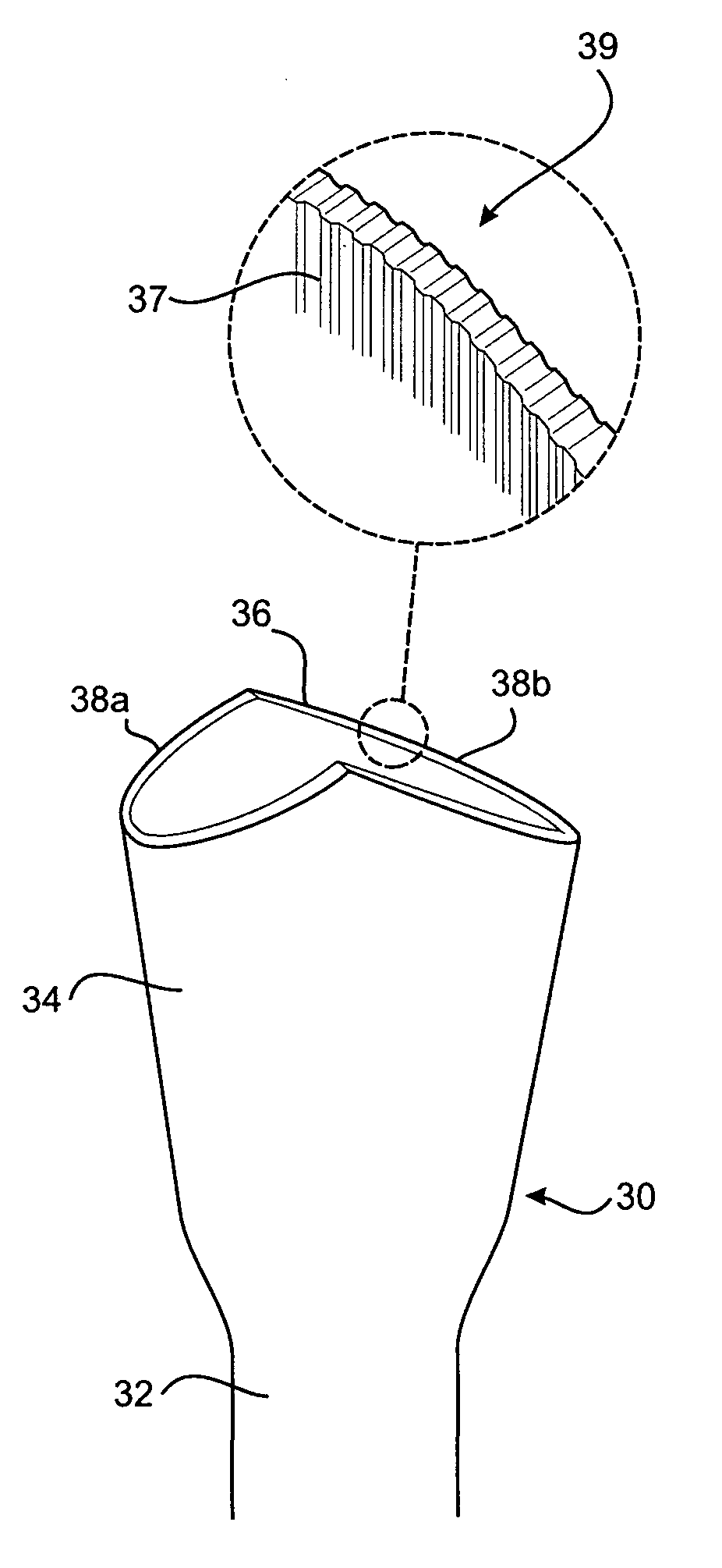

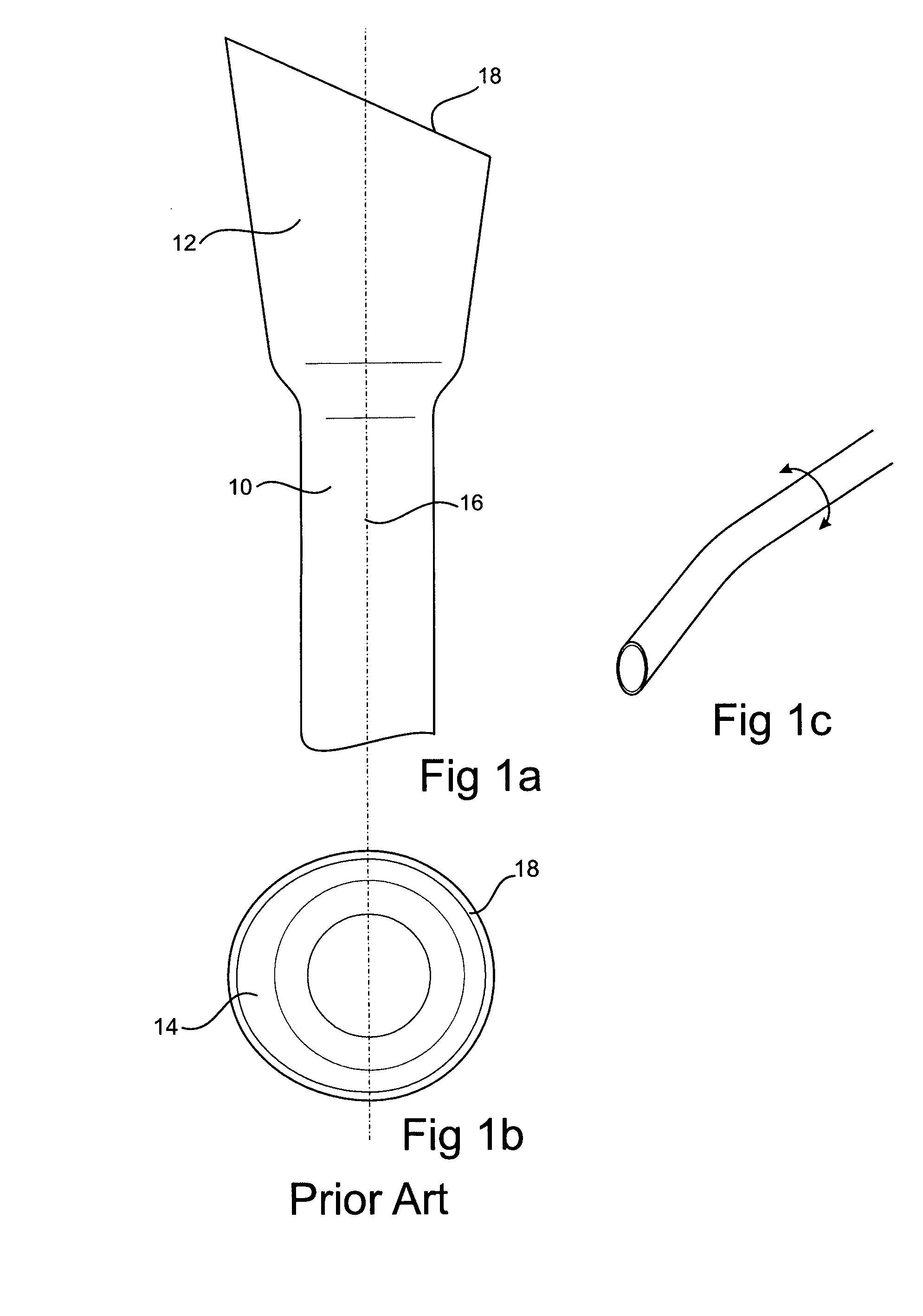

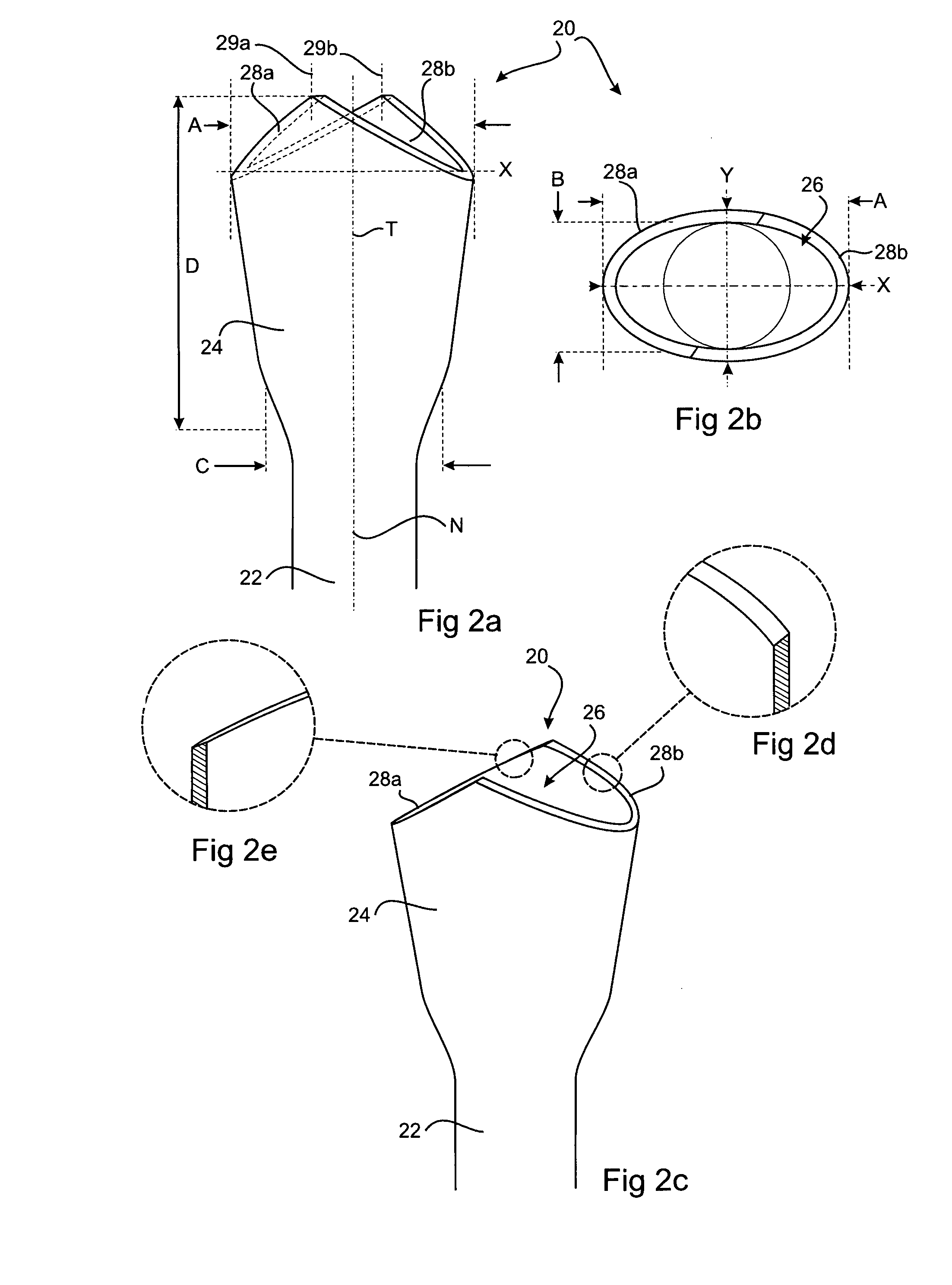

Cutting needle tip for surgical instrument

A needle 20 for use with a torsional or transverse ultrasound surgical phacoemulsification instrument comprises a hollow elongated needle body 22 having a needle tip 24 at a distal end for cutting lens material. The needle tip 24 is flared in one plane to produce a substantially elliptical tip mouth 26. The elliptical tip mouth 26 has a major axis ‘X’ larger than an outer diameter of the needle body and a minor axis ‘Y’ smaller than the major axis so as to form a spade-shaped tip. The eccentricity of the elliptical tip mouth 26 can be varied, however for practical purposes it is preferred that the major axis of the tip mouth is about 1.5 to 2.5 times longer than the minor axis. The spade-shaped tip 24 provides an improved cutting action, particularly with torsional ultrasonic vibration, the cutting action being analogous to that of a spade drill bit used in woodworking.

Owner:MORLET NIGEL

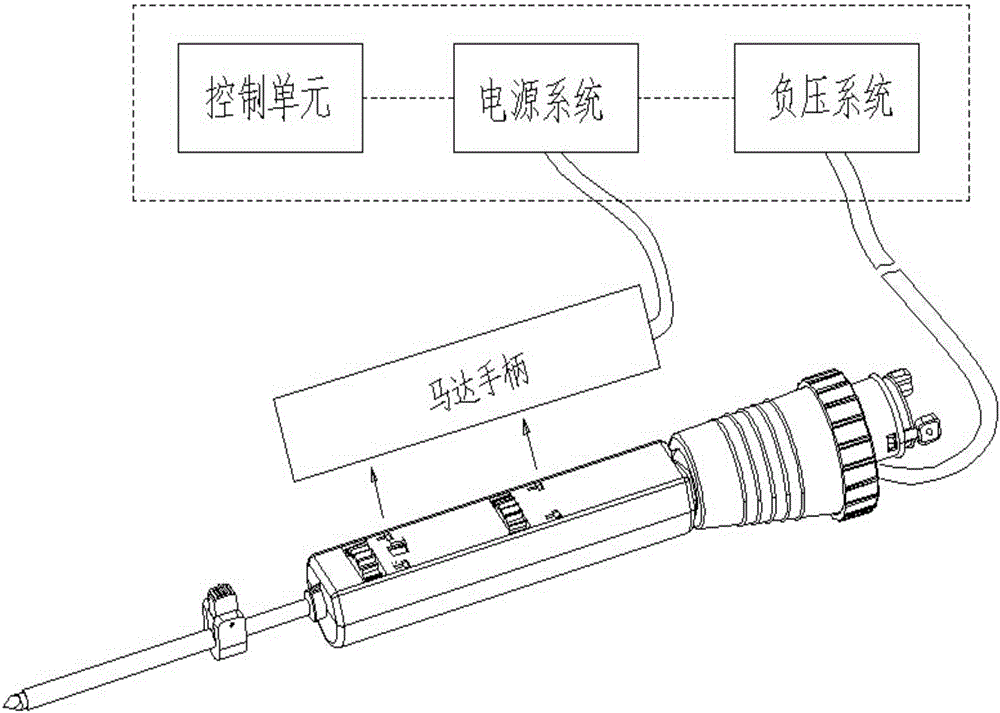

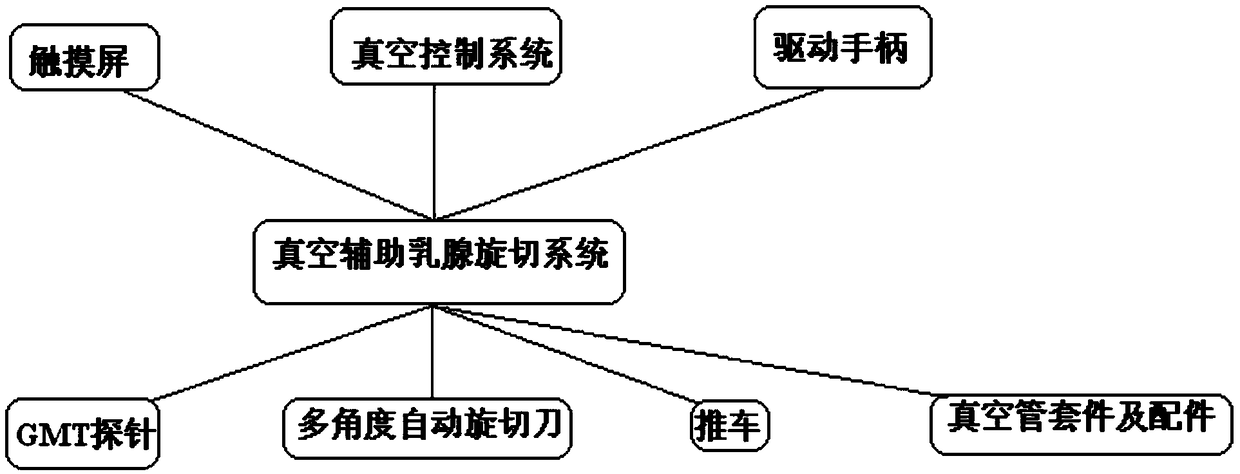

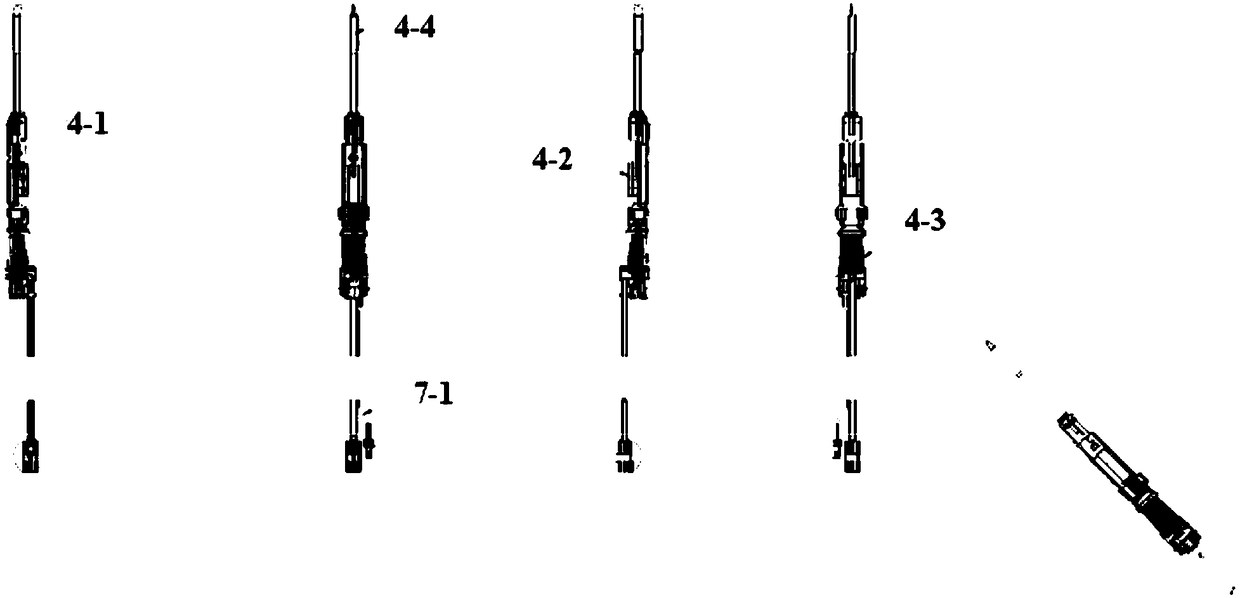

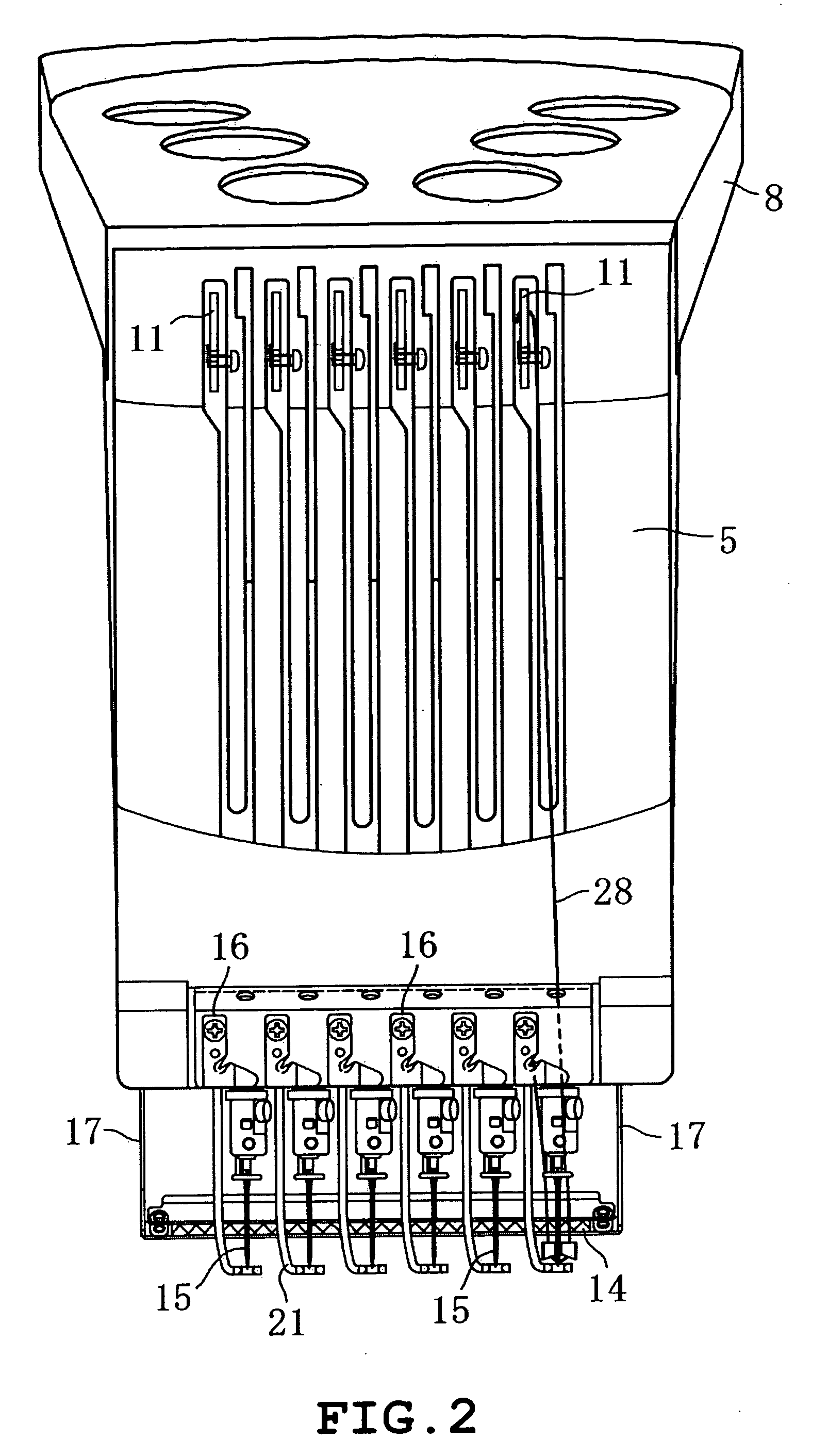

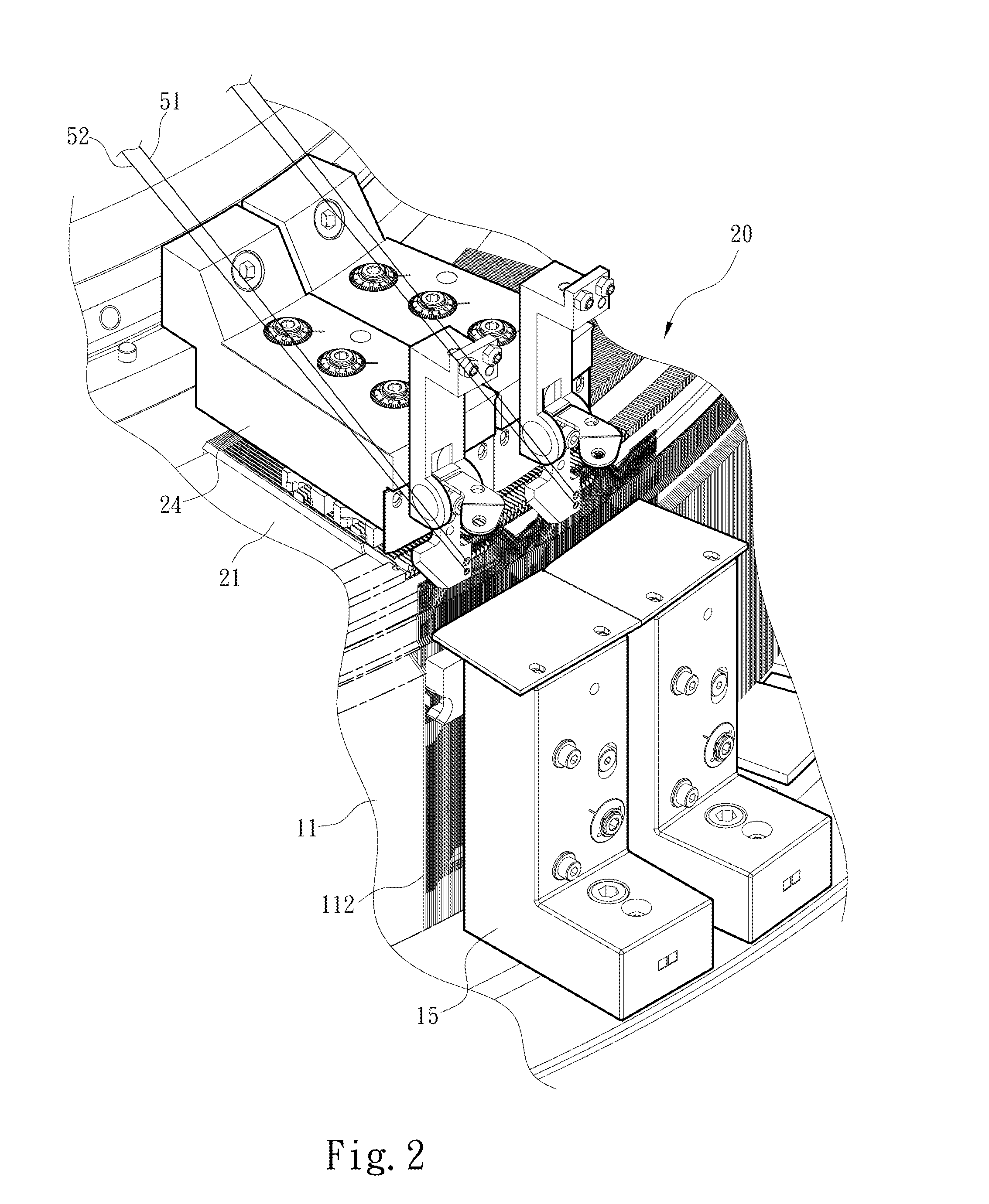

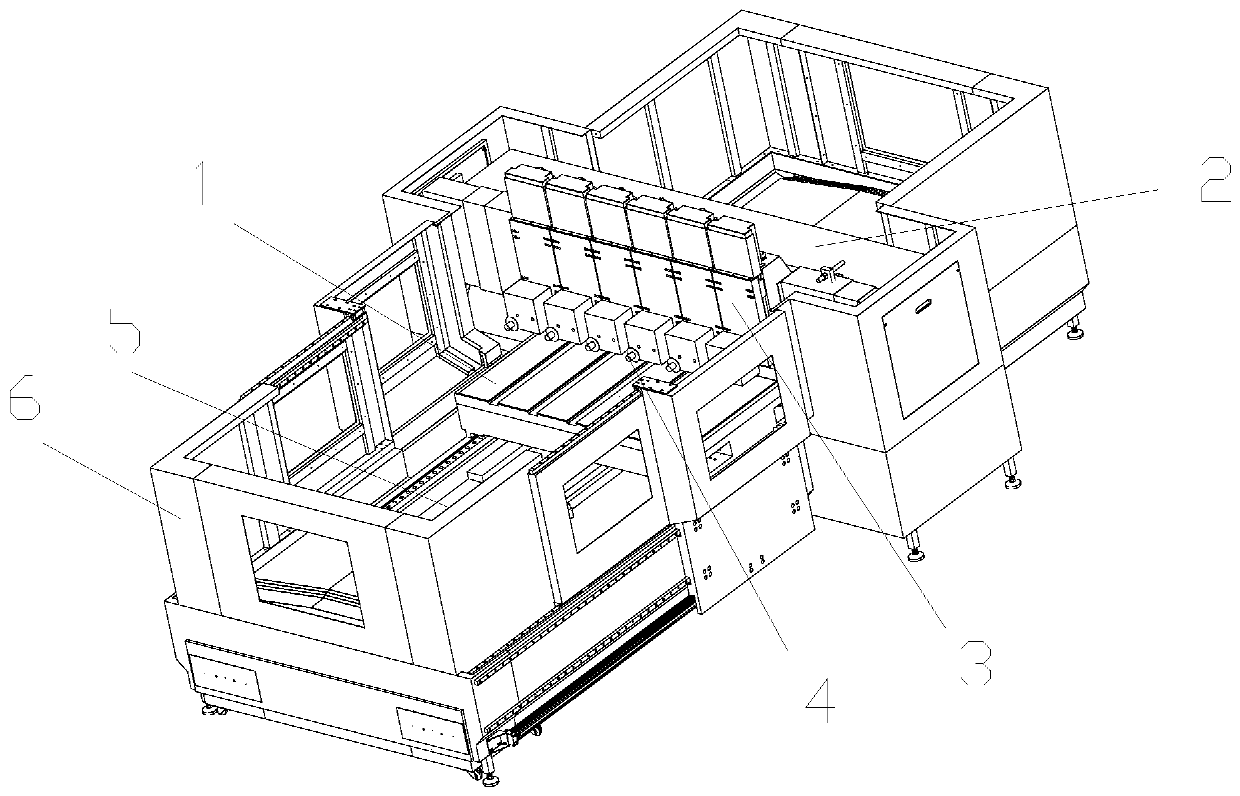

Vacuum-assisted mammary gland rotary cutting system and using method thereof

PendingCN108852424AReduce labor costsAvoid missed cutsSurgical needlesVaccination/ovulation diagnosticsVacuum assistedX-ray

The invention provides a vacuum-assisted mammary gland rotary cutting system. The system comprises a touch screen (1), a vacuum control system (2), a driving handle (3), GMT probes (4) and a multi-angle automatic rotary cutter (5), a trolley and vacuum tube kits and accessories; the touch screen (1) is provided with a touch screen data transmission port (1-1); the vacuum control system (2) provides vacuum pressure required for the entire system, drives a handle interface, controls the rotary cutting speed and identifies the probes, and tissue is sucked into a cutter groove through downward vacuum and sucked and conveyed through backward vacuum; the driving handle (3) comprises a handle driving connecting line (3-1), and a biopsy stent guided under X rays is arranged; the GMT probes (4) comprise the 7G puncture rotary cutting needle, the 10G puncture rotary cutting needle and the 12G puncture rotary cutting needle, and each GMT probe comprises a probe assembly (4-1), a rotary cutting puncture needle shell (4-2), a sample collection box assembly (4-3) and a probe protection sleeve (4-4), and the GMT probes (4) are compatible with various images; the multi-angle automatic rotary cutter (5) has 60-degree, 180-degree, 240-degree and 360-degree automatic rotary cutting modes preset by a program. The invention further provides a corresponding use method.

Owner:GERMAN MEDICAL TECH BEIJING

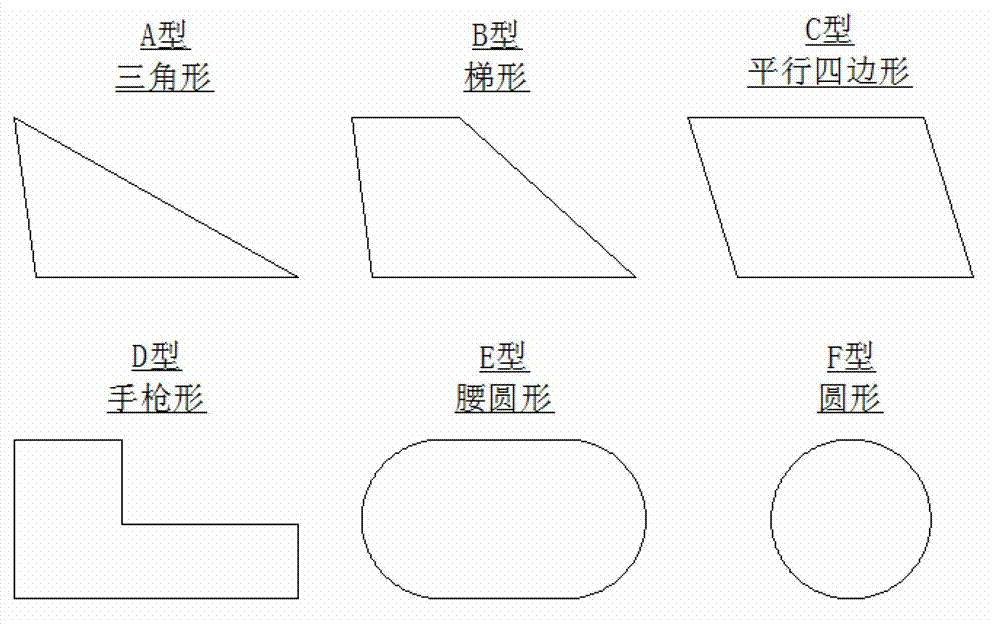

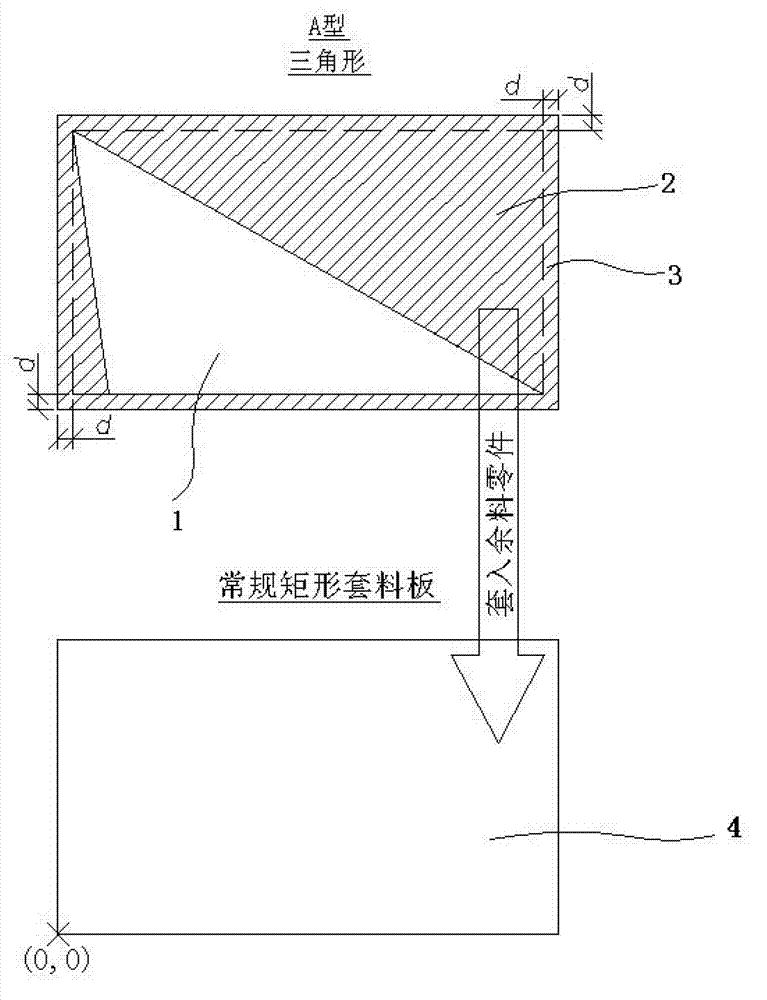

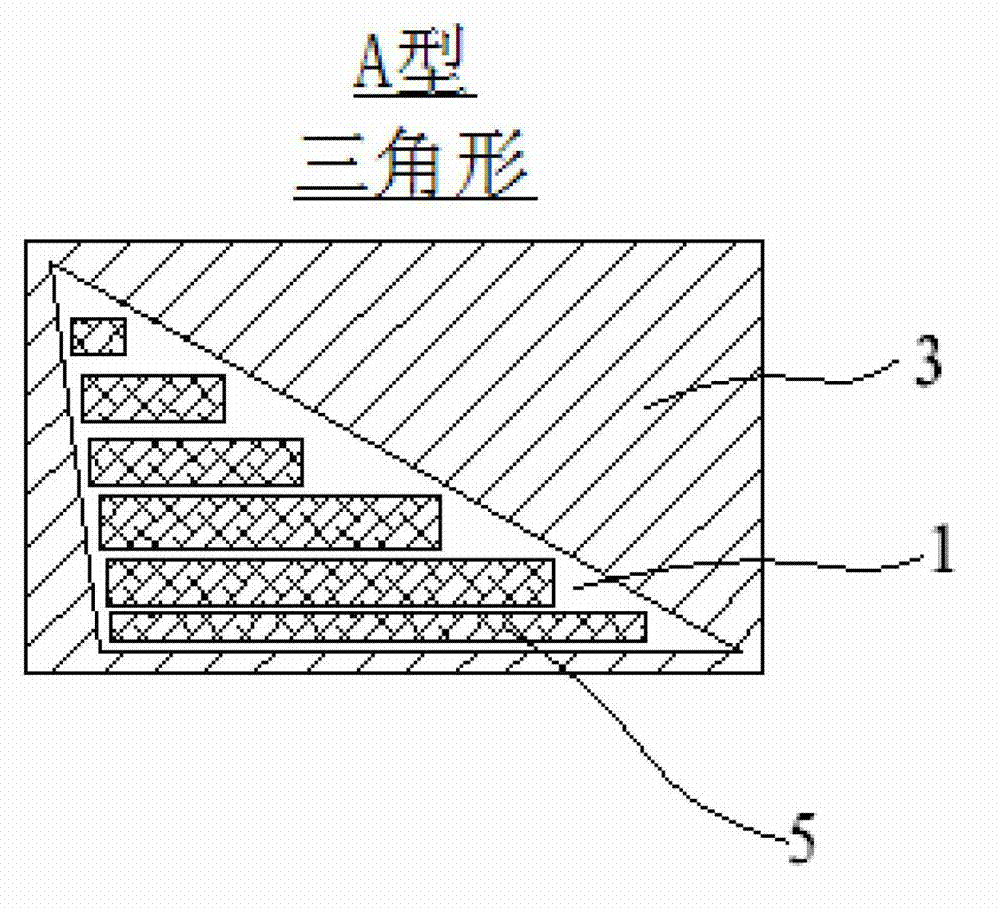

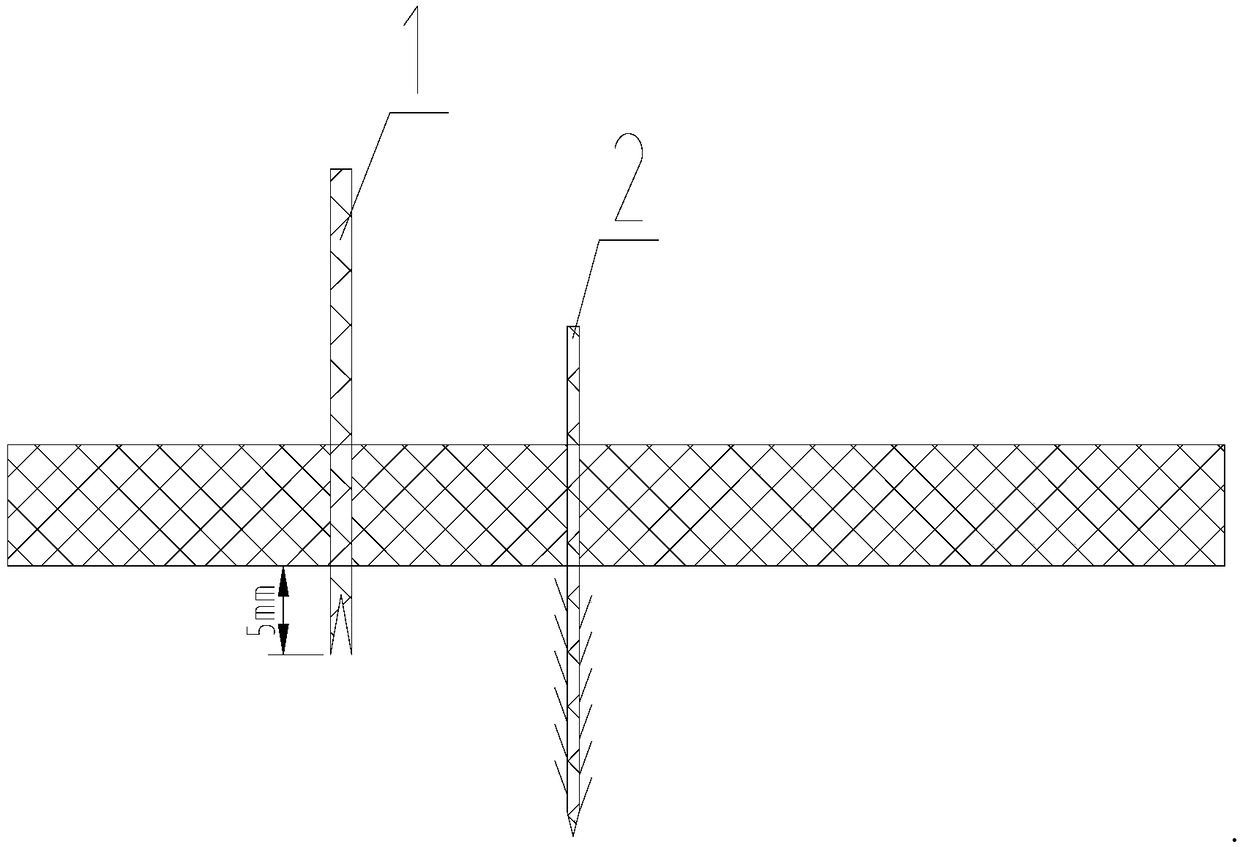

Nesting method of irregular residual material

The invention discloses a nesting method of irregular residual material. The method includes: firstly, selecting irregular residual material, setting a smallest rectangle fully covering the irregular residual material according to the irregular residual material, and allowing the periphery of the smallest rectangular to cover the irregular residual material; secondly, nesting the irregular residual material into a conventional rectangular nesting board, nesting profiles of other actual parts to the body of the irregular residual material; and thirdly, guiding a cutting needle to cut the profiles of the other actual profiles. The residual parts include perforated rectangular parts in the same shape as the irregular residual material. The irregular residual material is fully applied, utilization rate of materials is high, operation is convenient, defining and using are convenient for various pieces of software, and the method is adaptable to various encoding systems.

Owner:BESTWAY MARINE & ENERGY TECH CO LTD

Electronic cam needle insertion system

PendingCN107332096AImprove efficiencyMeet pin requirementsContact member assembly/disassemblyControl systemCut needle

The invention discloses an electronic cam needle insertion system, comprising a needle feeding mechanism arranged along the X-axis direction, defining the X-axis direction as a horizontal direction, the needle sending mechanism is used to transport the insertion needles; the needle taking mechanism is assembled on the The needle sending mechanism is used to obtain the insertion needles on the needle sending mechanism; the needle cutting mechanism is assembled above the needle sending mechanism, and the needle cutting mechanism is used to cut the insertion needles on the needle taking mechanism into shape The pin insertion mechanism is assembled with the needle cutting mechanism, and the pin insertion mechanism is used to insert the sheared and formed pins on the connector; the pin depth adjustment mechanism is assembled with the pin insertion mechanism, The needle insertion depth adjustment mechanism is used to adjust the needle insertion depth; the control system is used to integrally control the needle feeding mechanism, needle removal mechanism, needle cutting mechanism, needle insertion mechanism, and needle insertion depth adjustment mechanism to simulate the cam to insert The pins are plugged into the connector.

Owner:KUNSHAN LEAGUE AUTOMECHANISM

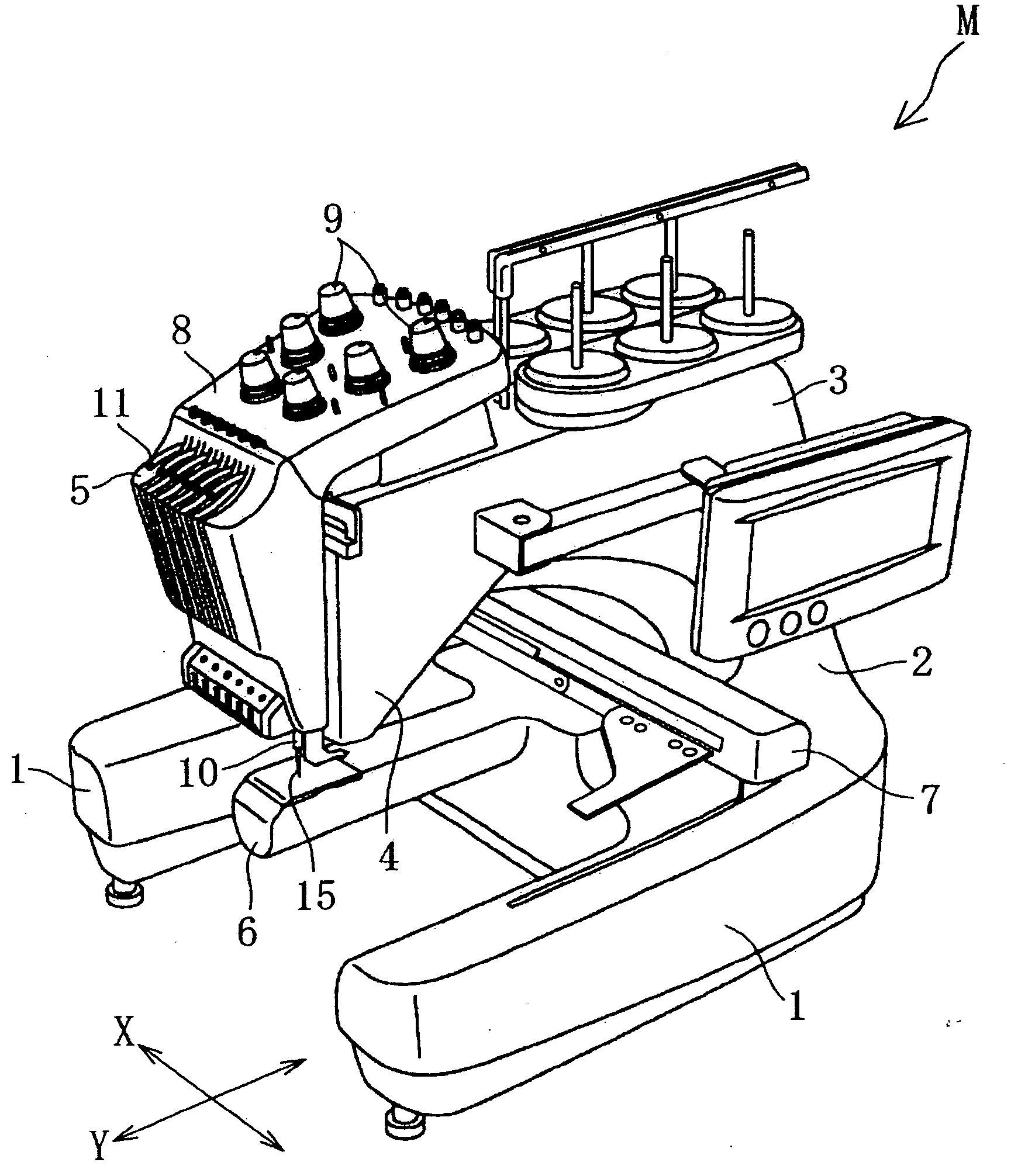

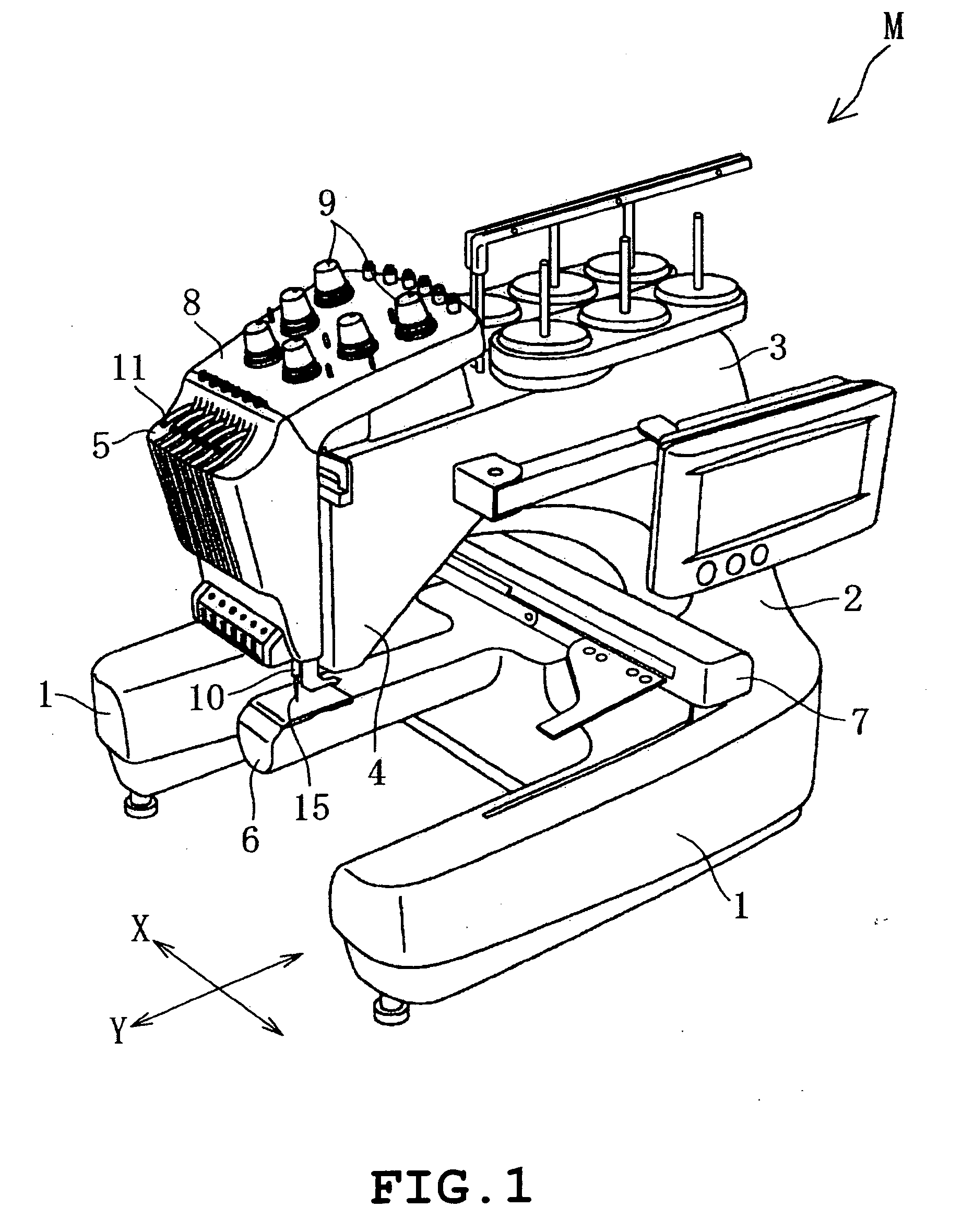

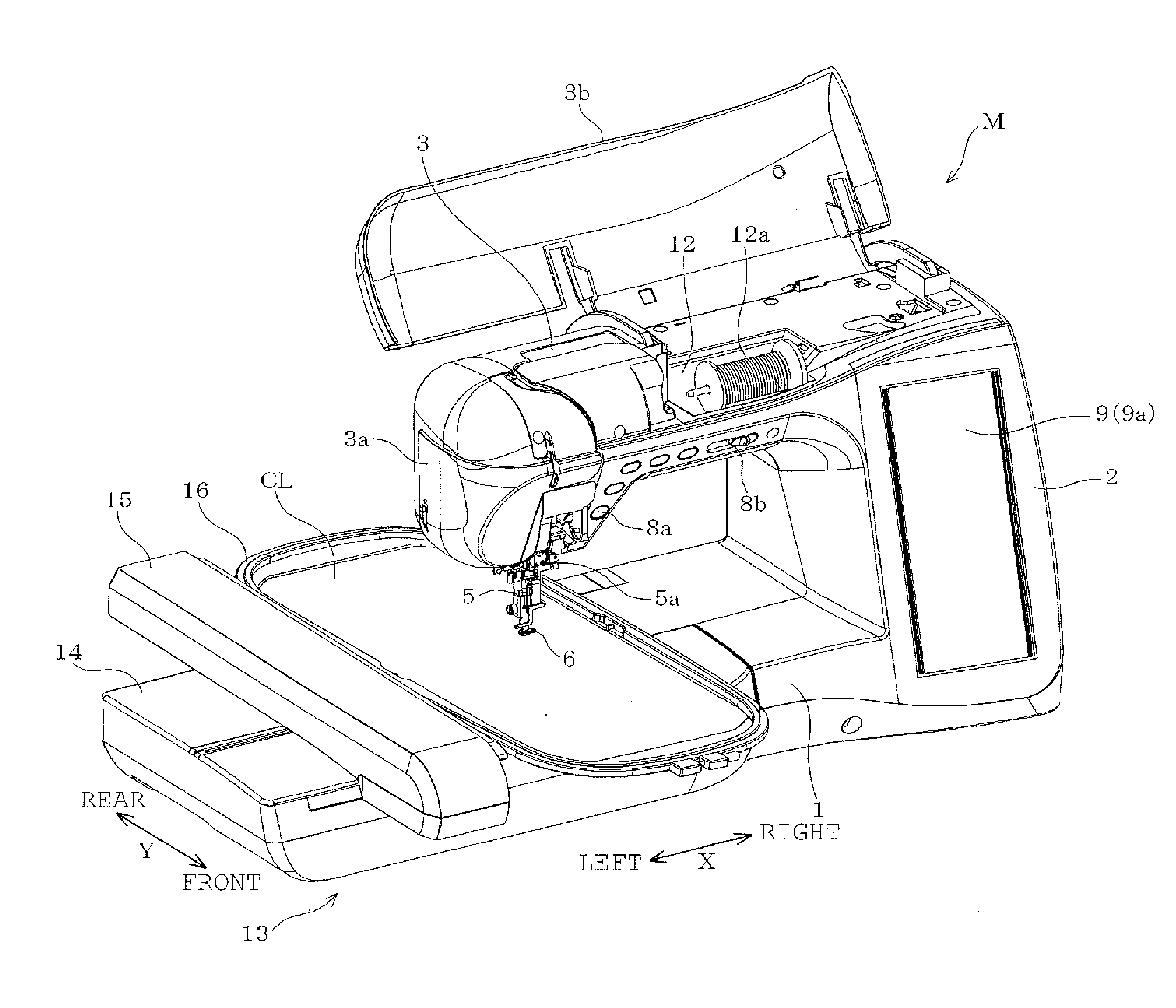

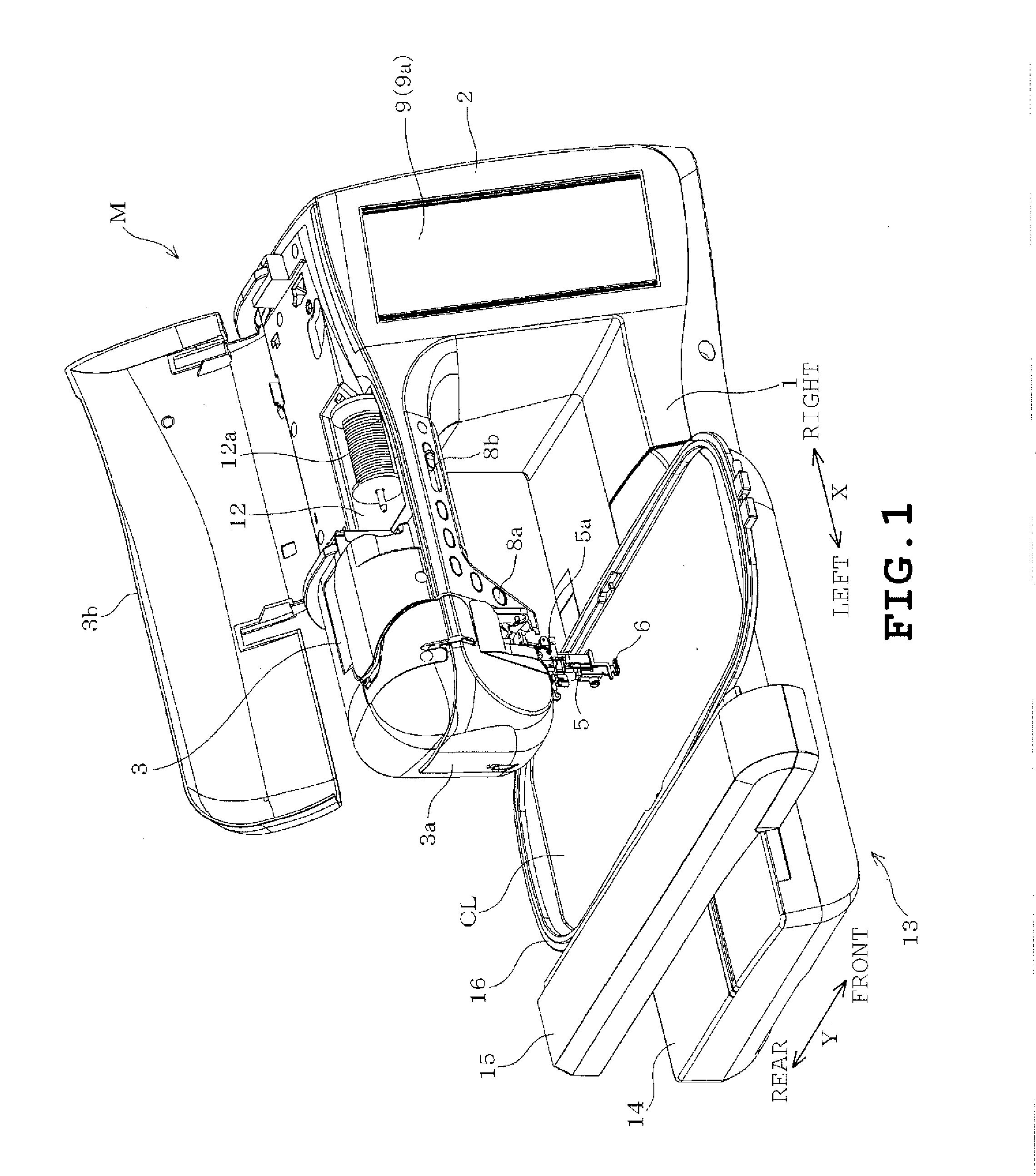

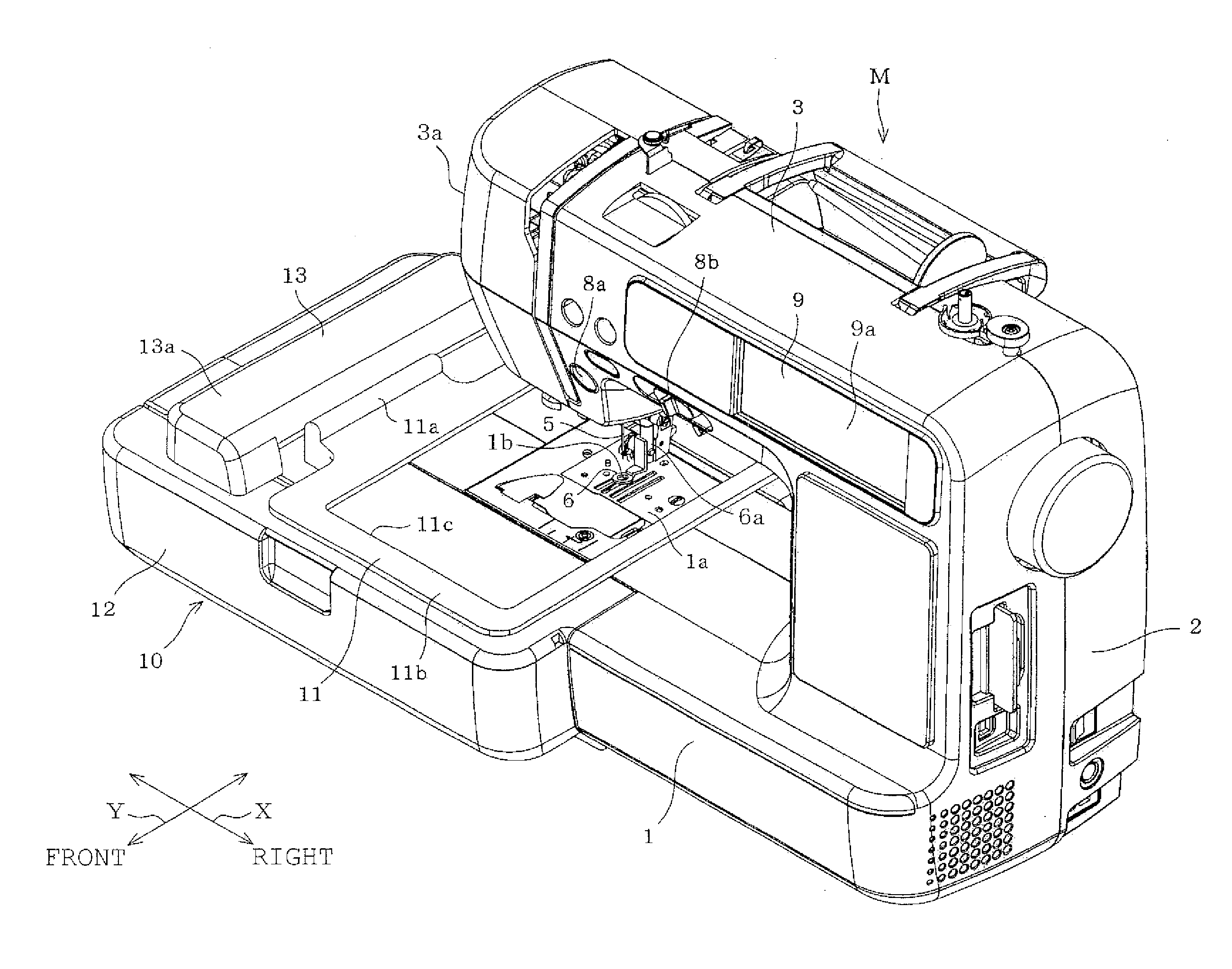

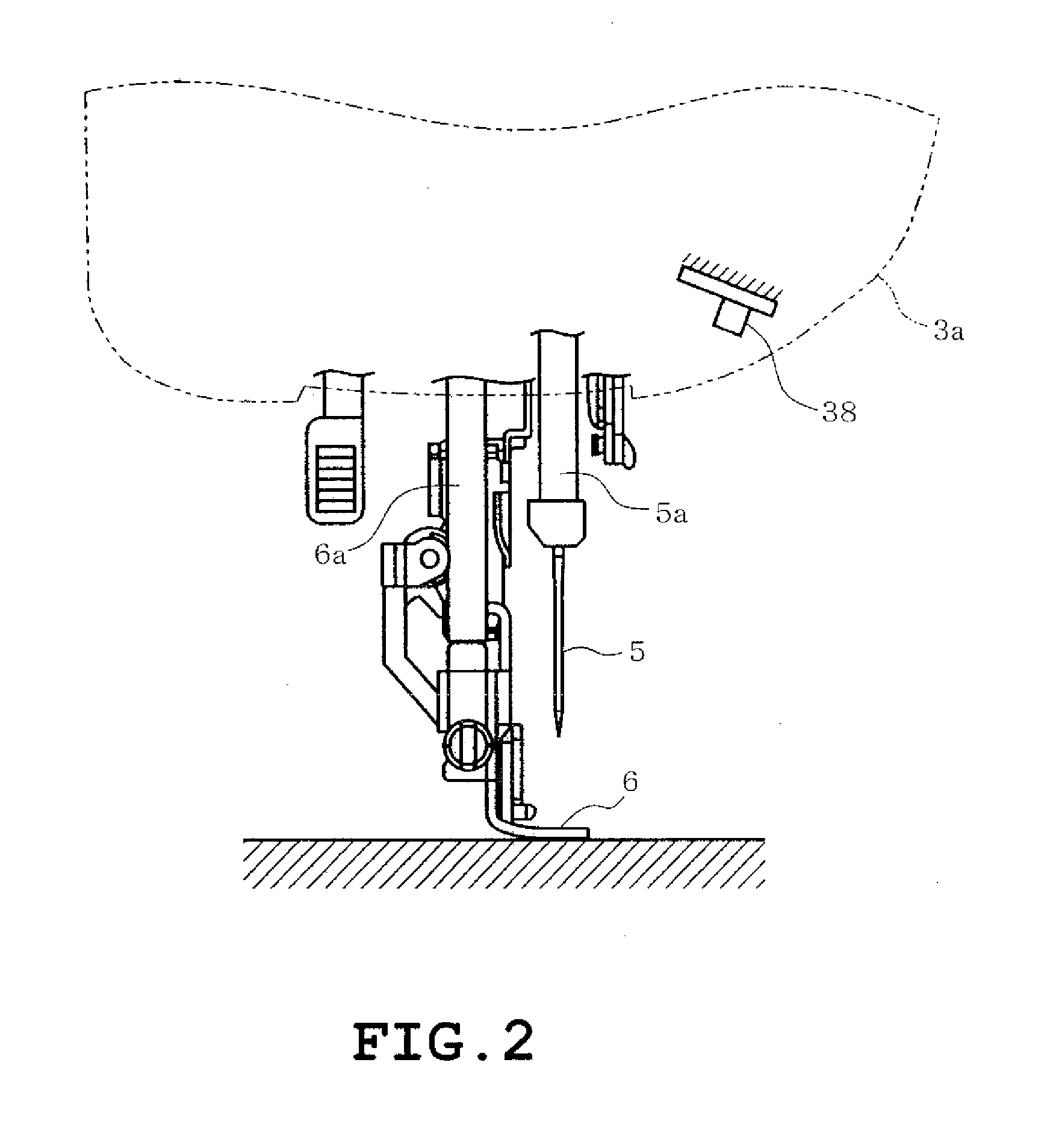

Sewing machine

A sewing machine includes a thread take-up, a thread take-up driving mechanism driving the thread take-up, a thread cutting mechanism including a fixed cutting blade and a movable cutting blade both cutting the needle thread and a movable cutting blade driving mechanism driving the movable cutting blade, a thread wiper wiping the cut needle thread away over workpiece cloth, a wiper driving mechanism driving the thread wiper, and a control device which, upon receipt of a needle thread cutting command to actuate the thread cutting mechanism, controls the movable cutting blade driving mechanism and the wiper driving mechanism so that the thread wiper carries out a thread amount securing operation to secure a predetermined amount of needle thread located downstream relative to a needle eye of a sewing needle in a state previous to cutting of the needle thread where the needle thread is seized by the movable cutting blade.

Owner:BROTHER KOGYO KK

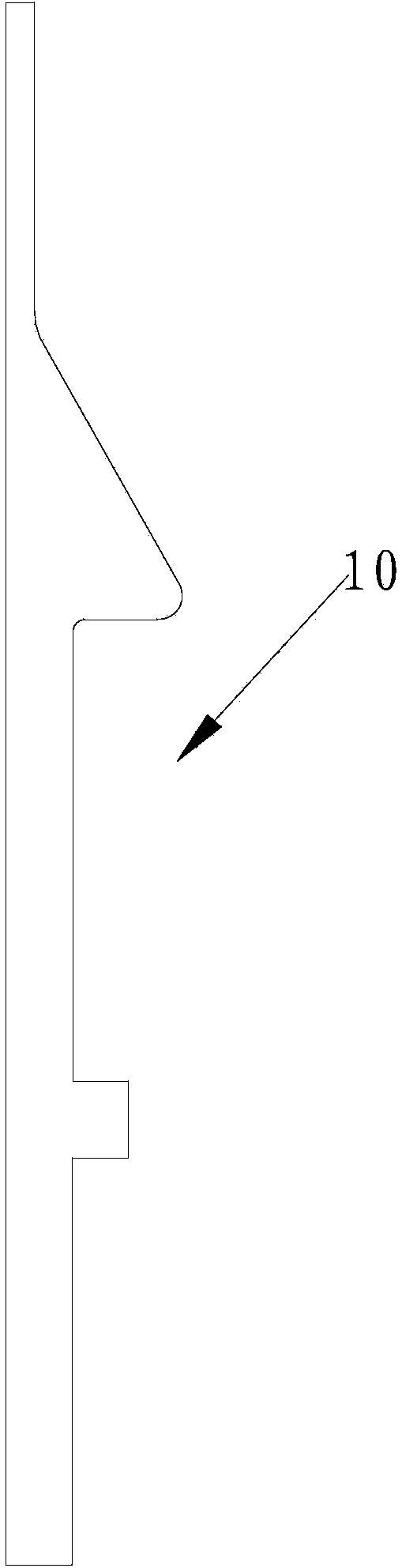

Production process of Boa-plush cutting needle for circular knitting machine

The invention relates to a production process of a Boa-plush cutting needle for a circular knitting machine. The cutting needle is of a sheet body and mainly comprises a hook, a blade and a needle body. Barbs are formed on two opposite sides of the hook; cutting edges are formed on two opposite sides of the blade. The barbs of the hook and the cutting edges of the blade of the cutting needle are formed at one step by a punch and then subjected to heat treatment. Since the cutting needle is formed by punching directly, the individual bending process is omitted; since the barbs of the hook and the cutting edges of the blade are subjected to the punching process directly, metal density of the corresponding positions of the cutting needle is high, and service life of the cutting needle is prolonged. The conventional process of bending to form barbs at hooks through needle making equipment by multiple steps is changed, basic processing of the cutting needle is completed by the punch at one step, only the heat treatment is needed, and multiple manual operation steps are omitted, so that labor force is saved, production efficiency is increased greatly and product quality is guaranteed further.

Owner:常熟市白莲制针有限公司

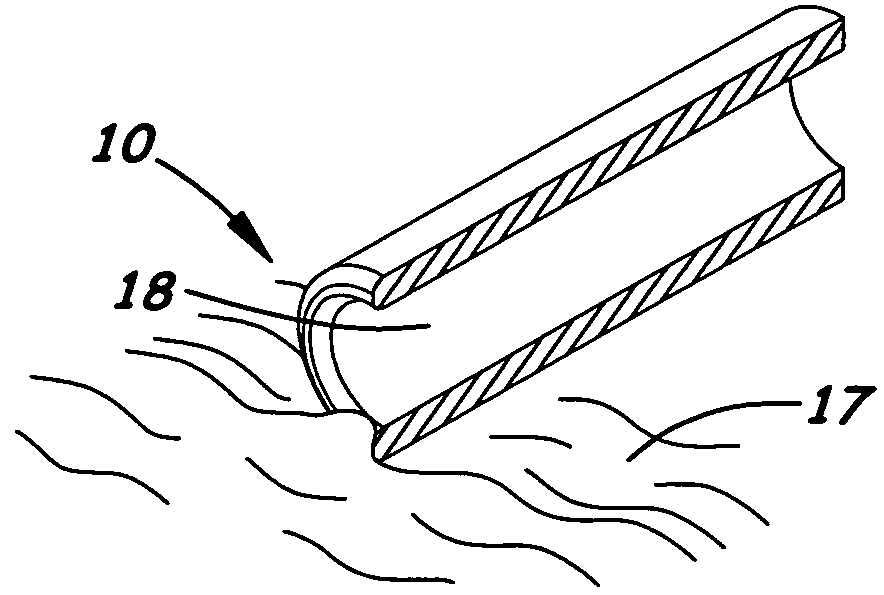

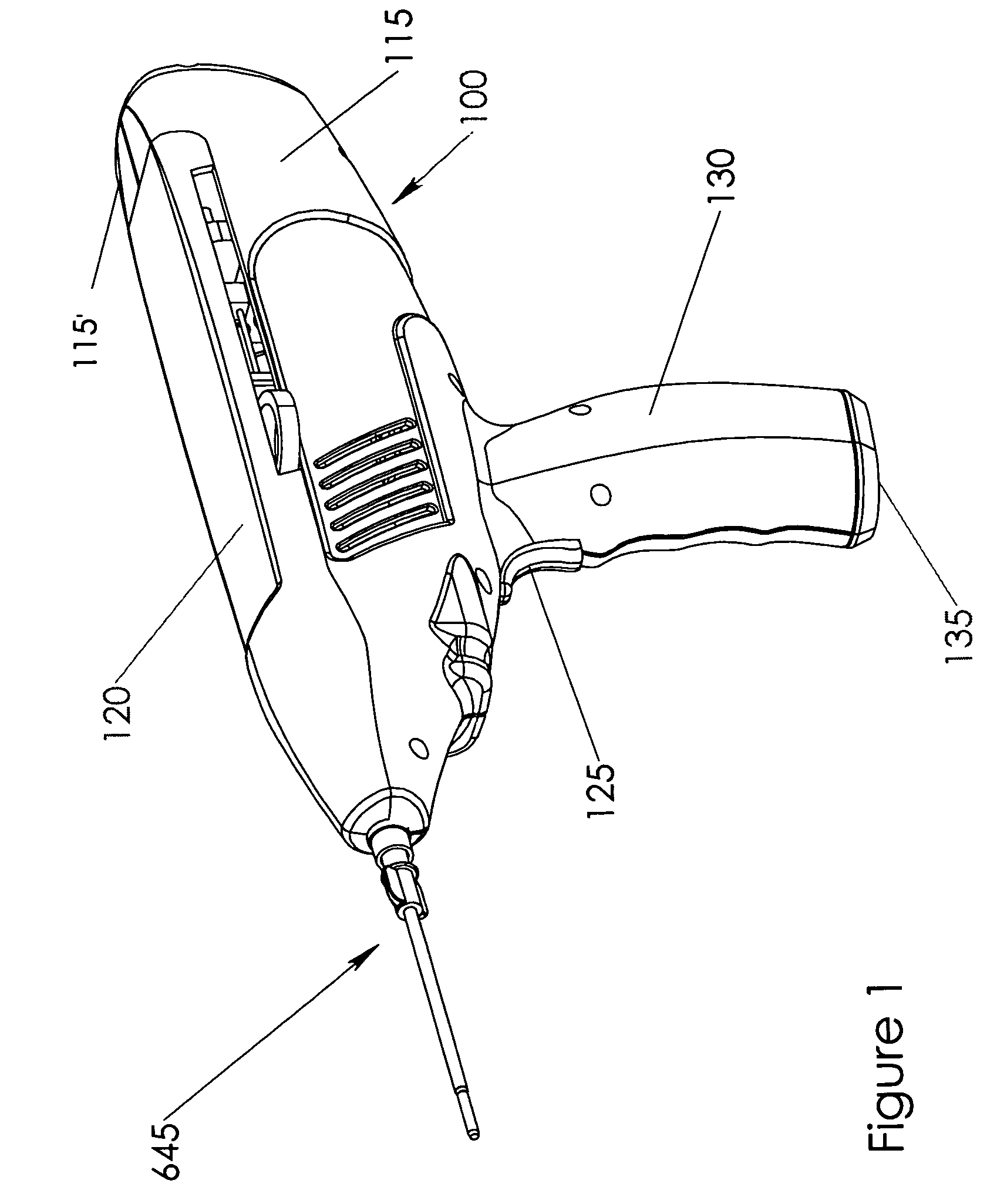

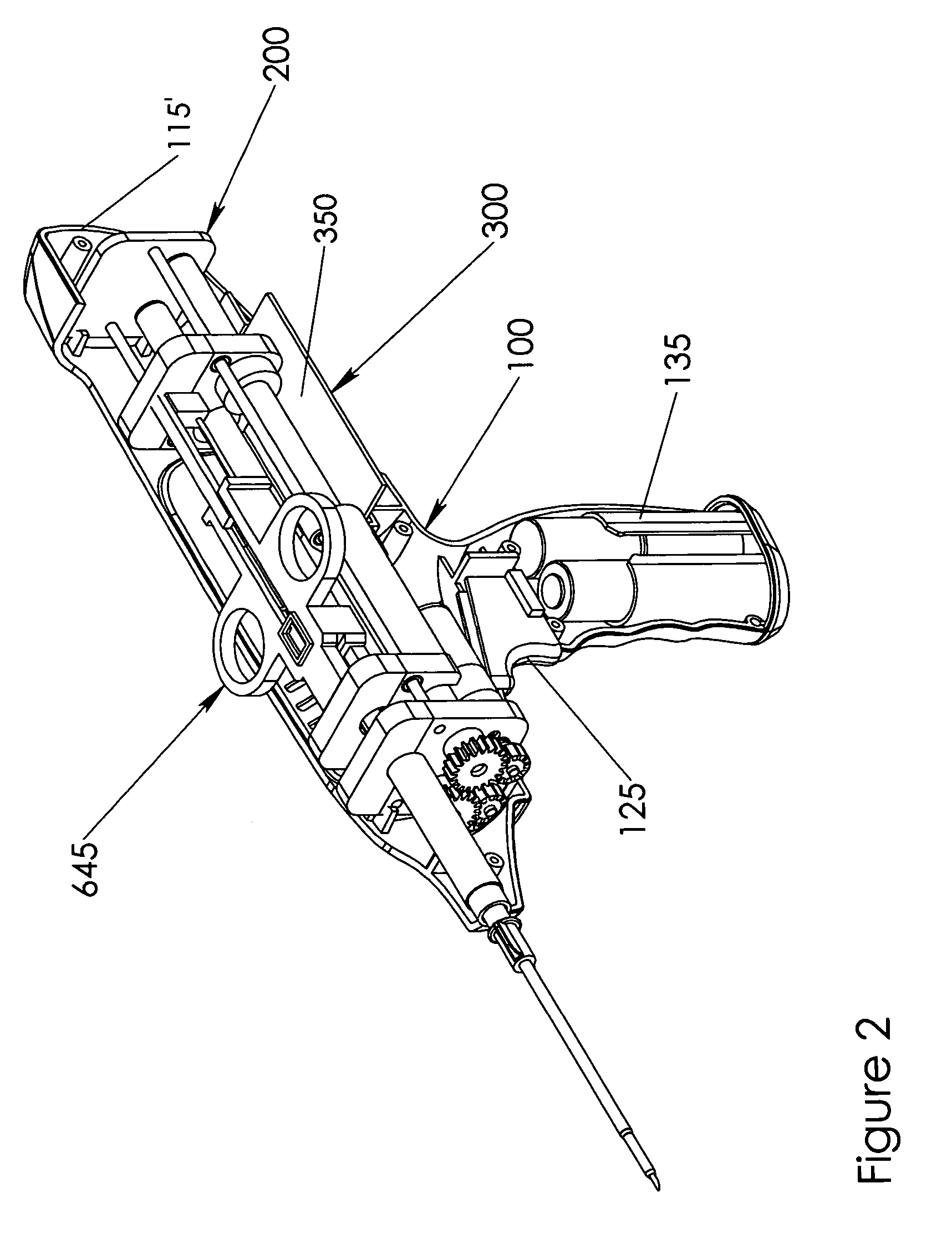

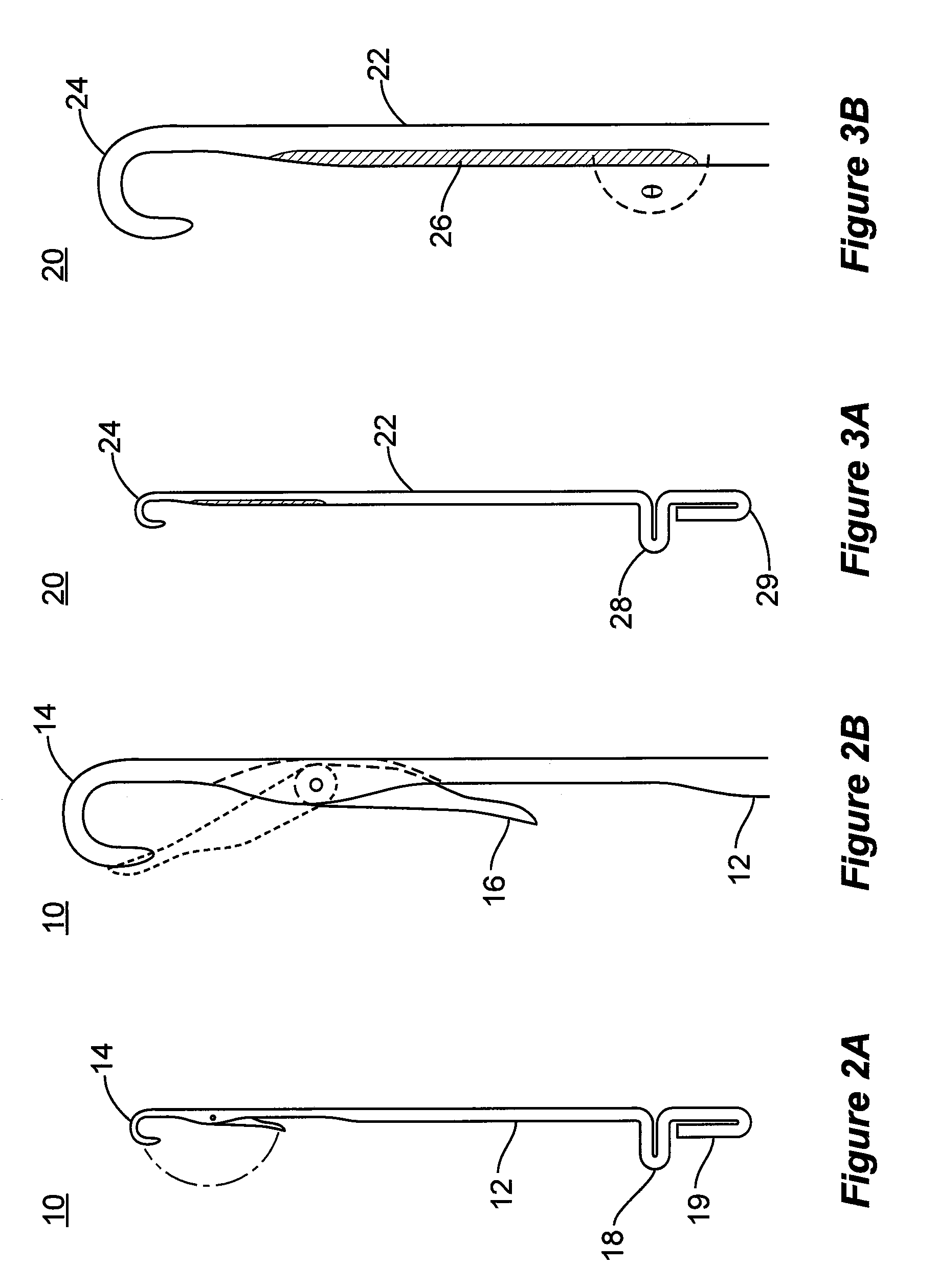

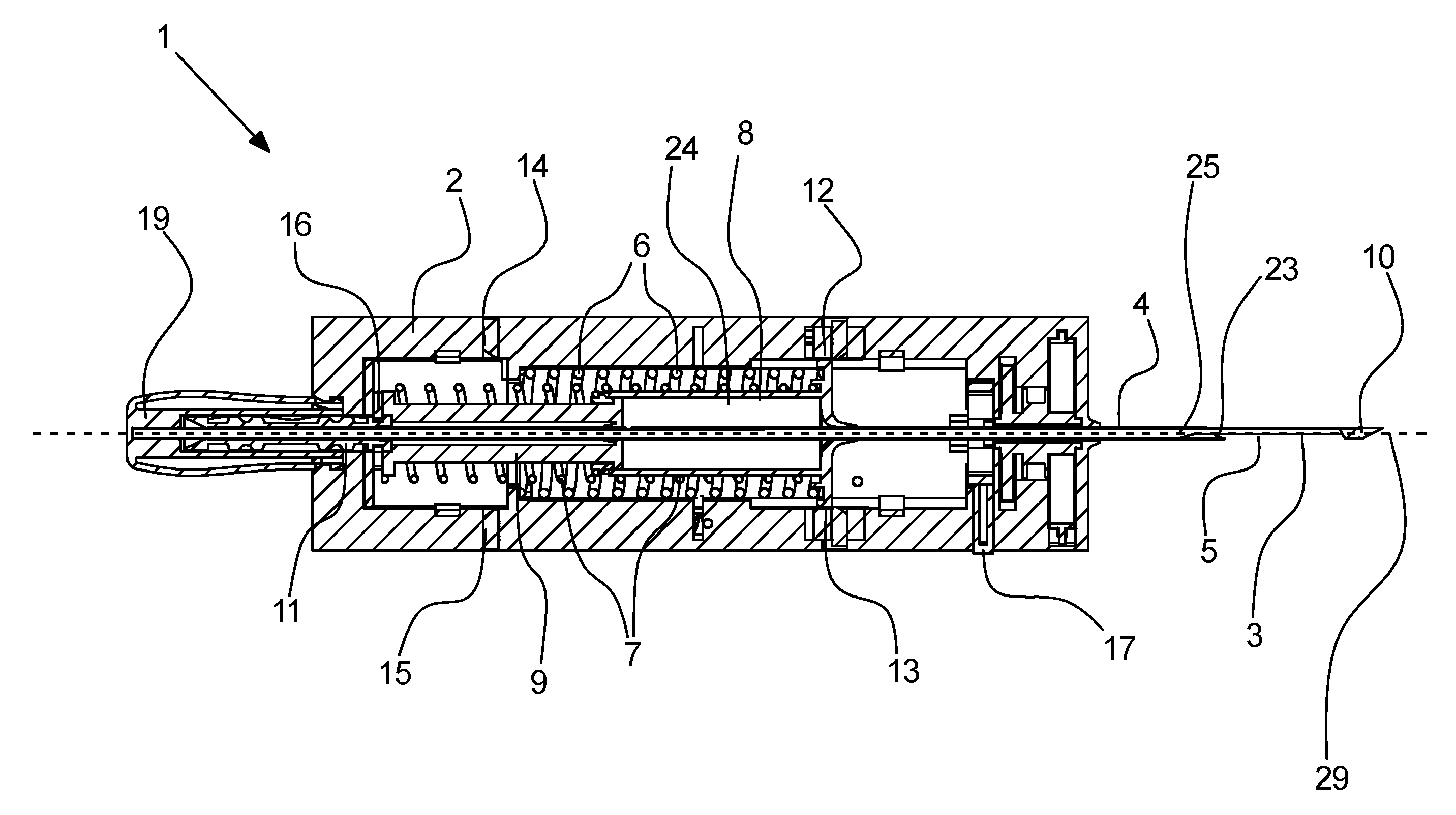

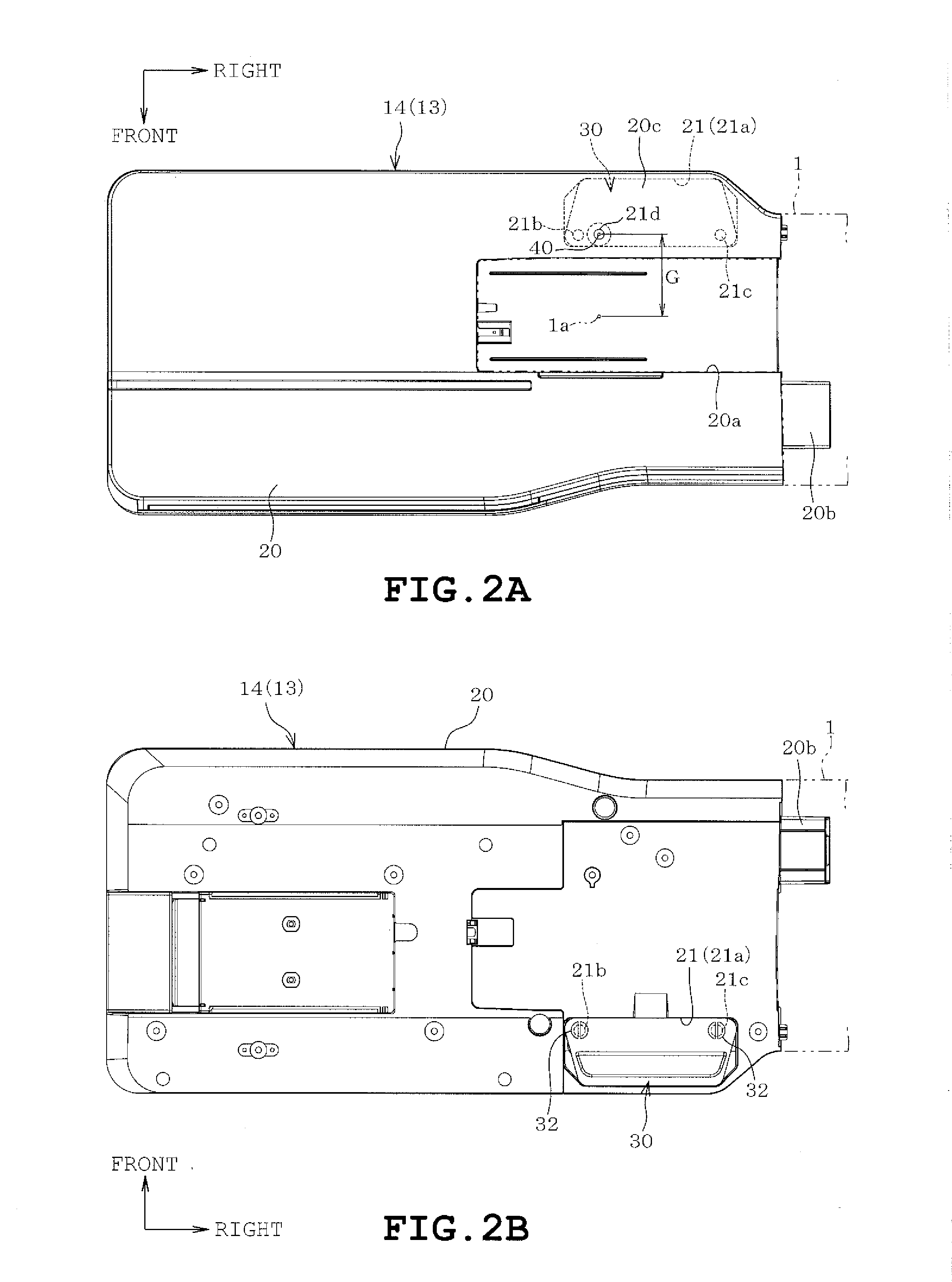

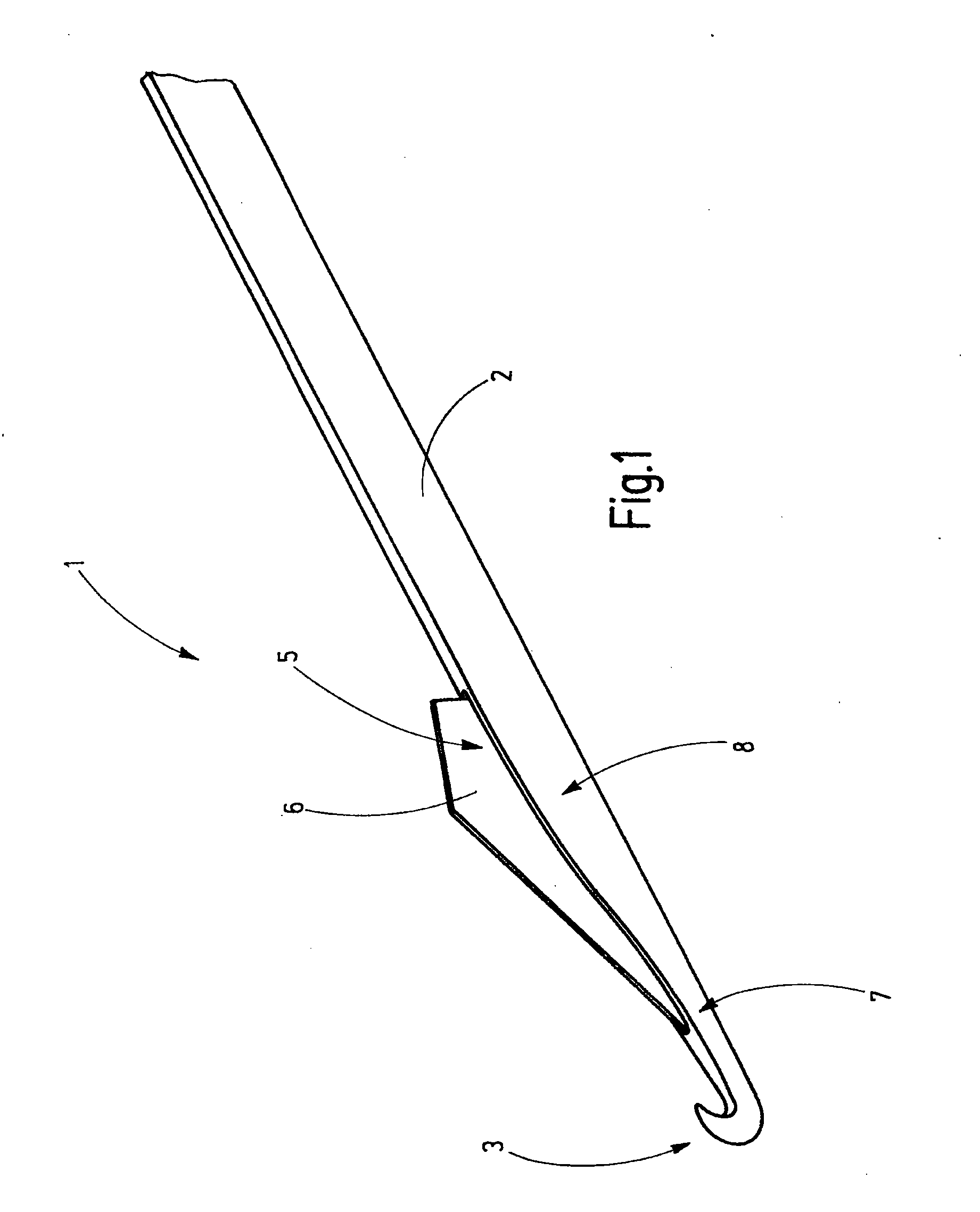

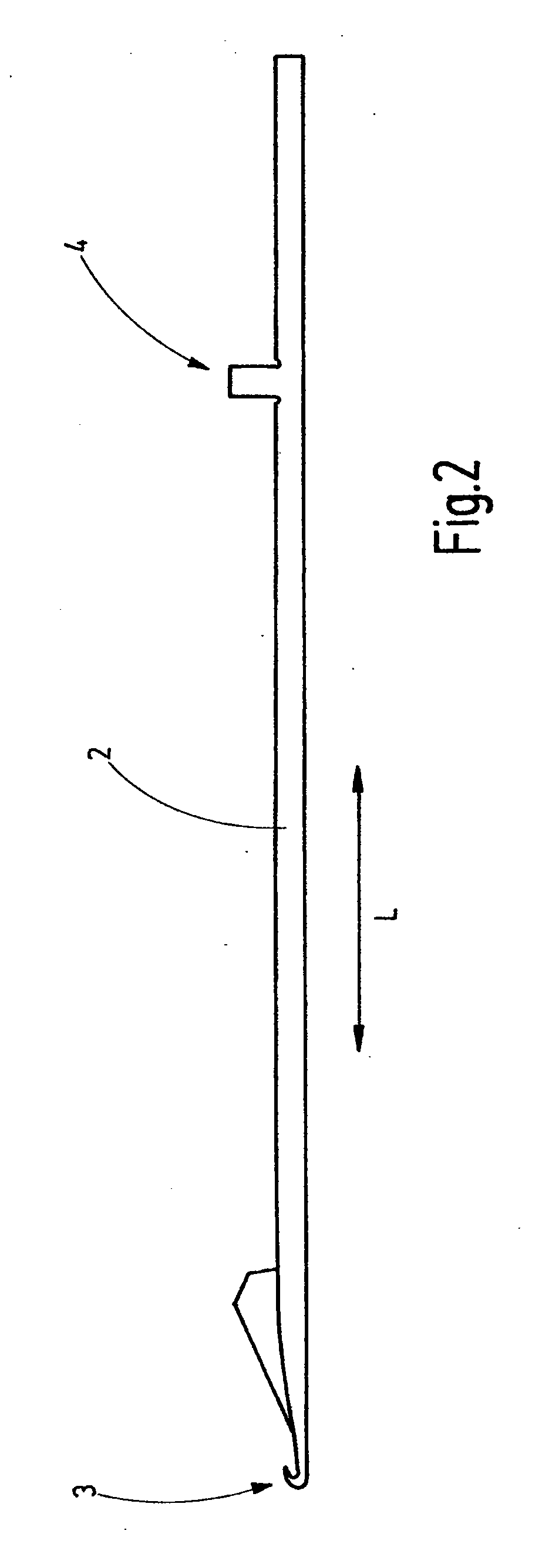

Handheld tissue sample extraction device

ActiveUS20150057571A1Reduce cutting efficiencyImprove cutting efficiencySurgical needlesVaccination/ovulation diagnosticsTissue sampleHand held

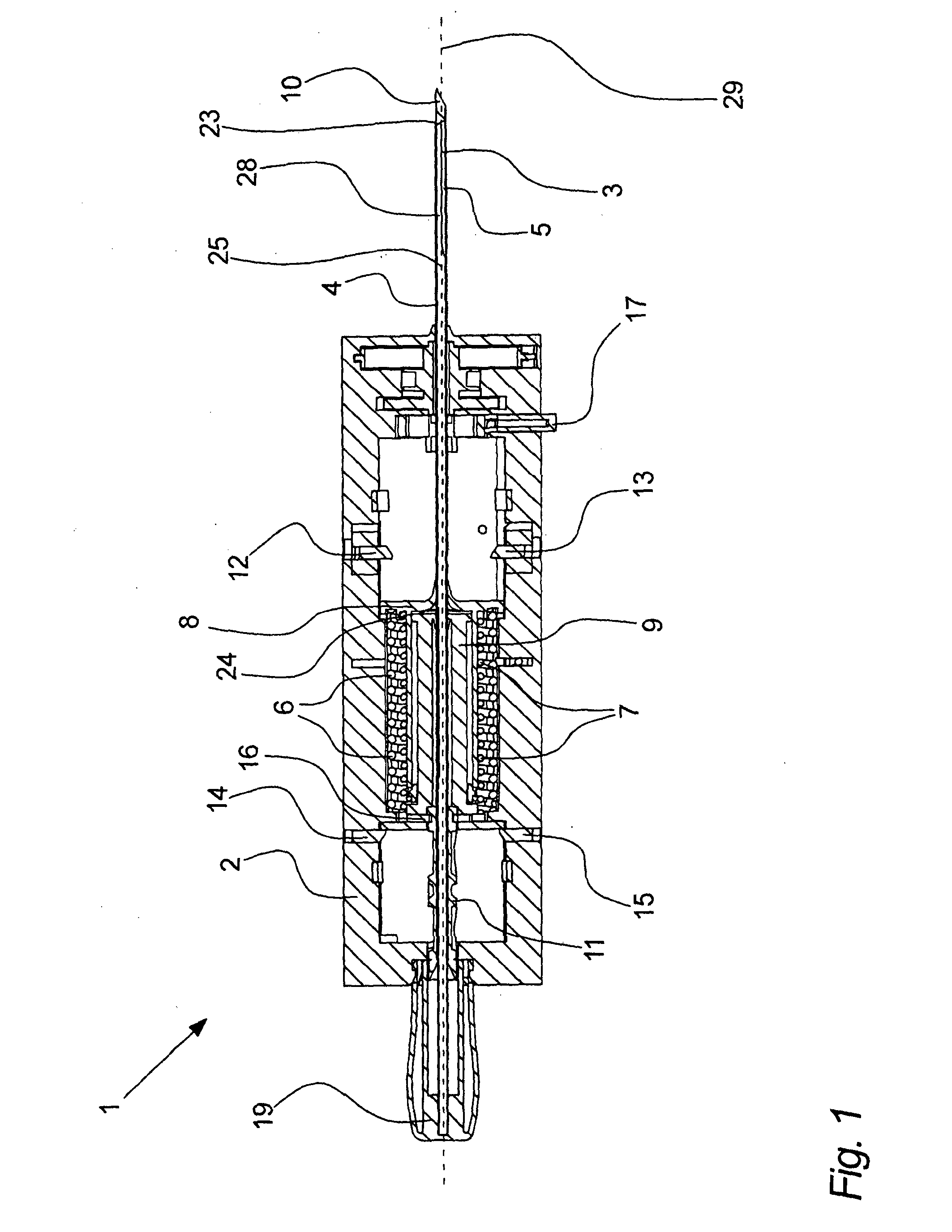

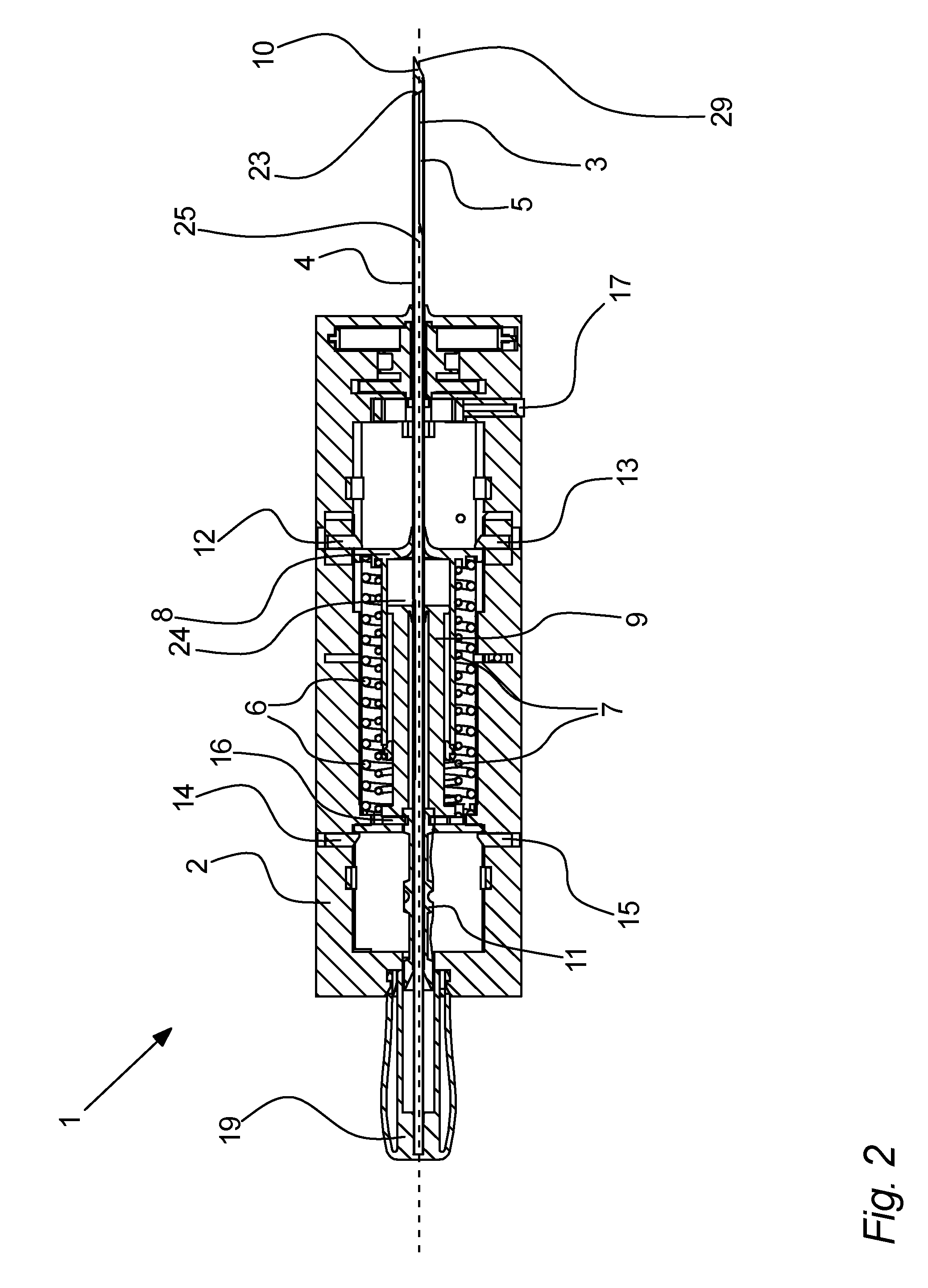

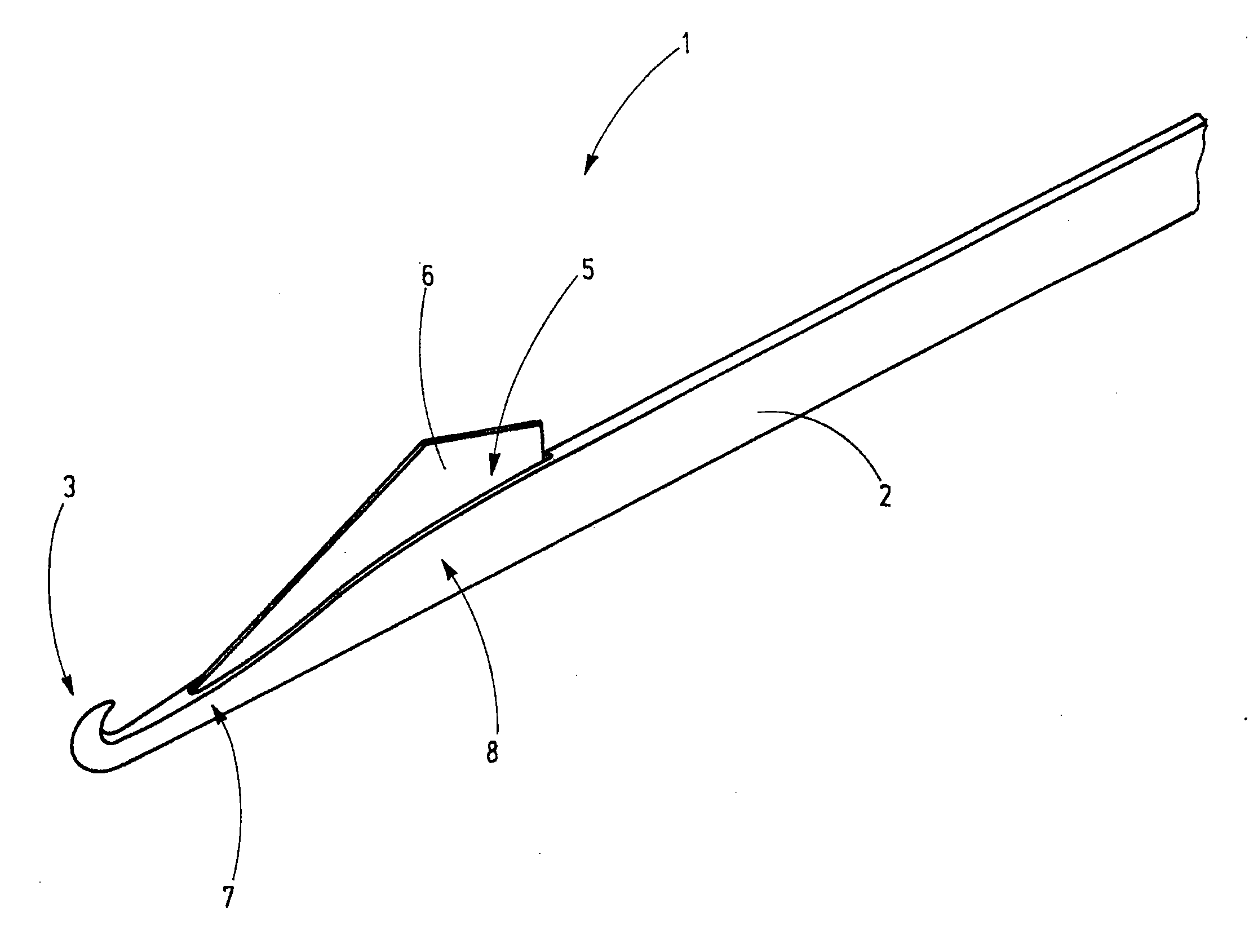

A handheld device (1) for extraction of tissue samples (27) is disclosed, comprising a needle arrangement (25) and control arrangement (2), said needle arrangement (25) comprising a cutting needle (4) and a sample extraction needle (3), said needle arrangement (25) having a first end (28) for inserting into tissue (30),—said cutting needle (4) comprising a cutting edge (23) for cutting said tissue sample (27) from said tissue (30),—said sample extraction needle (3) comprising a side opening (5) for receiving said tissue (30), said control arrangement (2) comprising a vacuum chamber (24) in fluid communication with said sample extraction needle (3), the vacuum chamber (24) comprising a first member (8) and a second member (9), said first and second members (8, 9) being adapted to move relative to each other, wherein said first member is mechanically connected to said cutting needle (4), and wherein said handheld device (1) is configured so that—a movement between said first member and said second member to increase the volume of said vacuum chamber (24) and thereby reduce the pressure in said sample extraction needle induces—a movement between said cutting needle (4) and said sample extraction needle (3) to expose said side opening (5) of said sample extraction needle (3).

Owner:TEESUVAC APS

Loop cutting apparatus for circular knitting machines

InactiveUS20150329999A1Effective spaceEfficiency of knittingCircular knitting machinesYarnCut needle

A loop cutting apparatus for a circular knitting machine which has a circular cylinder including a plurality of knitting needles movable independently includes an upper needle dial located on the circular cylinder and a plurality of yarn cutting needle sets radially centered about the axis of the circular cylinder. Each yarn cutting needle set includes a first cutter needle and a second cutter needle movable against the first cutter needle in a first yarn cutting displacement thereof. The first cutter needle has a yarn holding section leaned by a yarn and collaborated with the two abutting knitting needles at two sides to pick up and draw the yarn to form a pile loop and a first cutter section connected to the yarn holding section. The second cutter needle has a second cutter section staggered against the first cutter section in the first yarn cutting displacement to cut the pile loop.

Owner:PAI LUNG MACHINERY MILL CO LTD

Liver biopsy puncture needle and use method thereof

InactiveCN109171824AReduce manufacturing costEfficient identificationSurgical needlesVaccination/ovulation diagnosticsMedicineCut needle

A liver biopsy puncture needle includes a needle cannula, wherein a cutting window is arranged at a position close to the needle head of the puncture needle cannula; the needle tail position of the puncture needle cannula is provided with a handgrip; a cut needle core is pierced in the cannula of the puncture needle; a cut needle core includes a positioning block; the cutting section is a fixing piece adapted to the inner wall of the puncture needle cannula; the fixing piece is provided with a cutting blade; the outer structure of the cutting blade is adapted to the outer structure of the cutting window; the side of the cutting blade is provided with a tissue fixing piece; and the needle body of the cutting needle core is provided with a positioning block. The invention discloses a liveerbiopsy puncture needle and a use method thereof. The puncture needle has simple structure, and only needs the cooperation of a puncture needle cannula and a cutting needle core to complete the puncture operation. One or more tissues can be punctured at the pathological part at one time, and one or more tissue can be punctured at different positions at the pathological part at one time.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

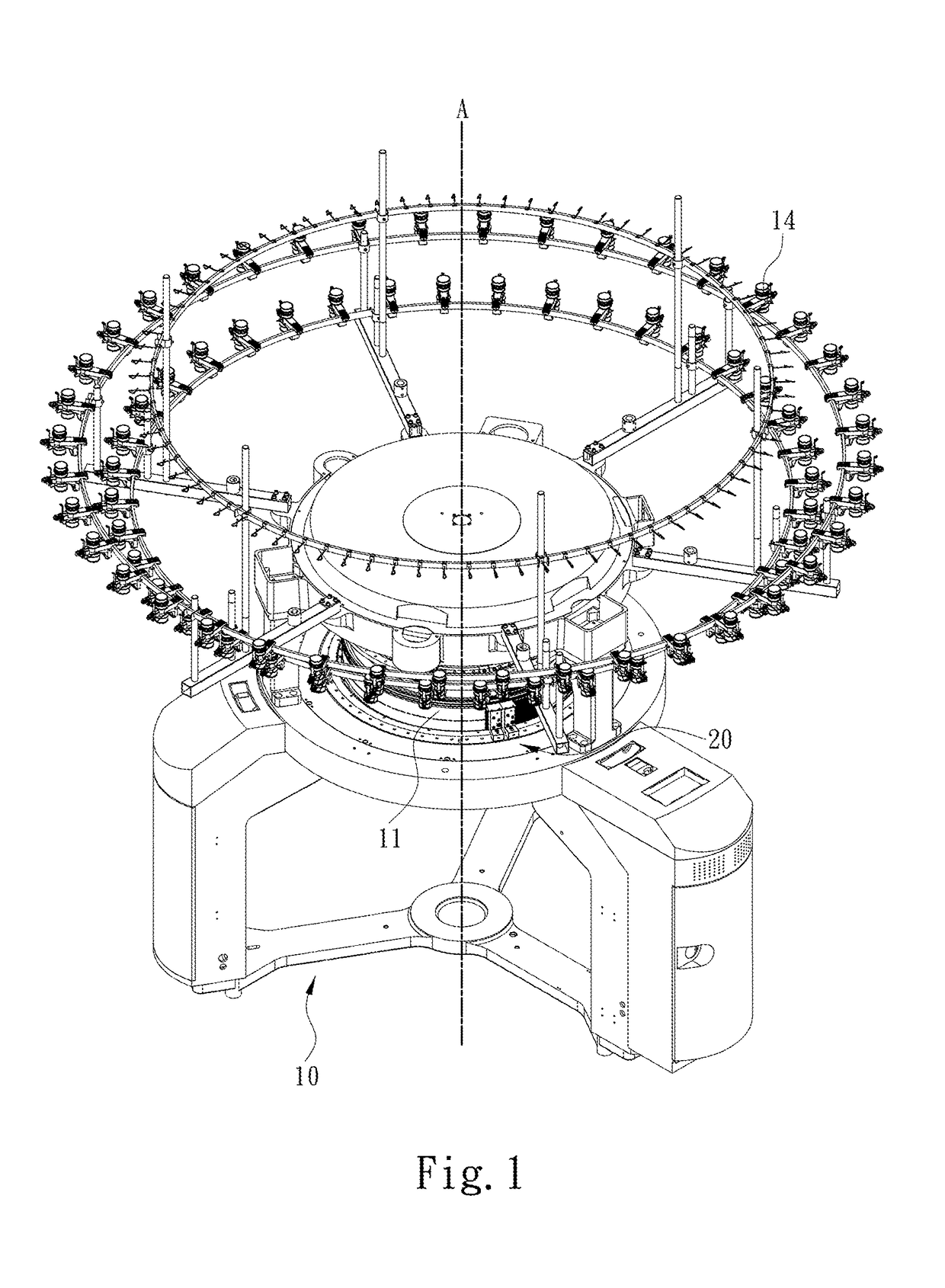

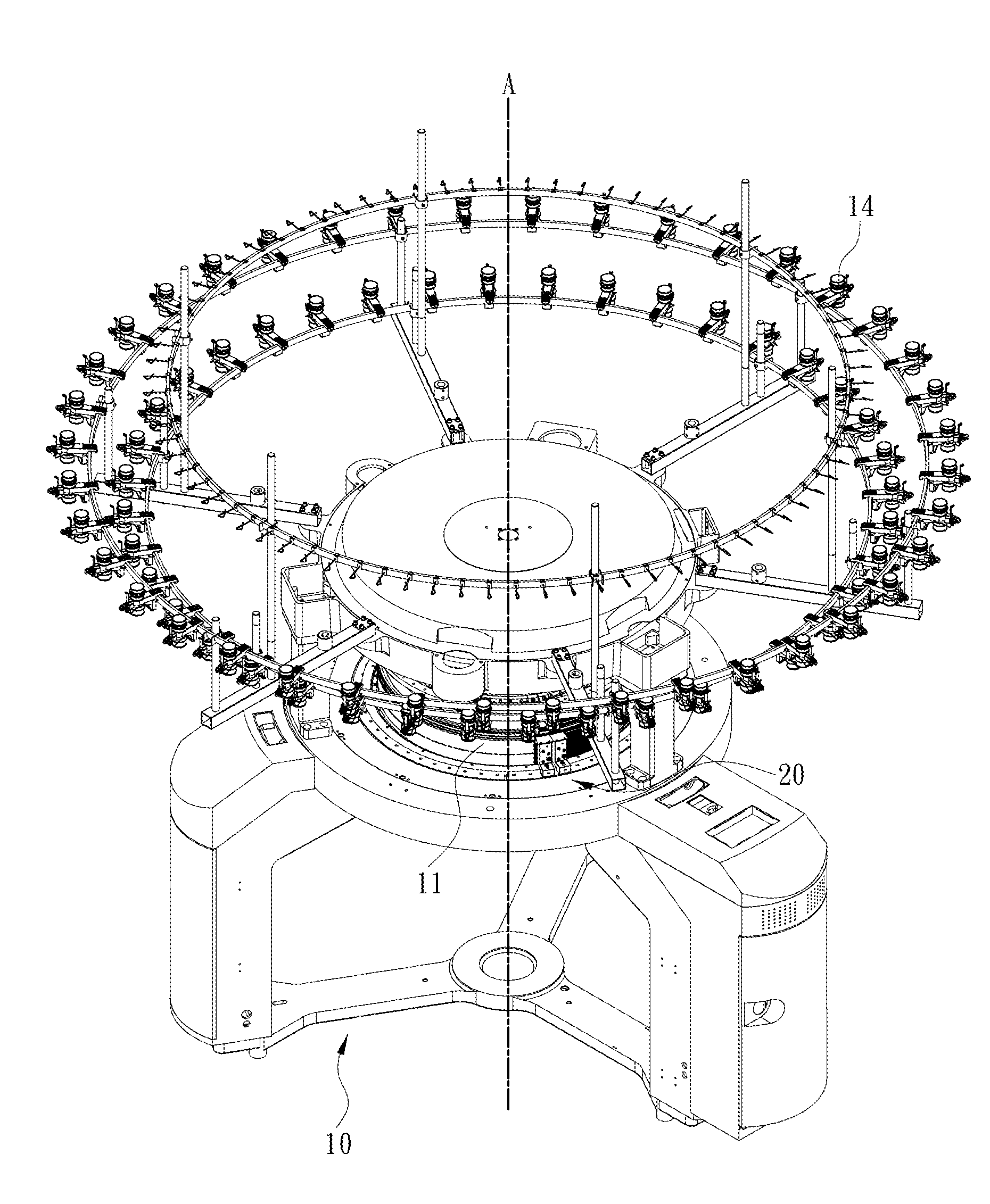

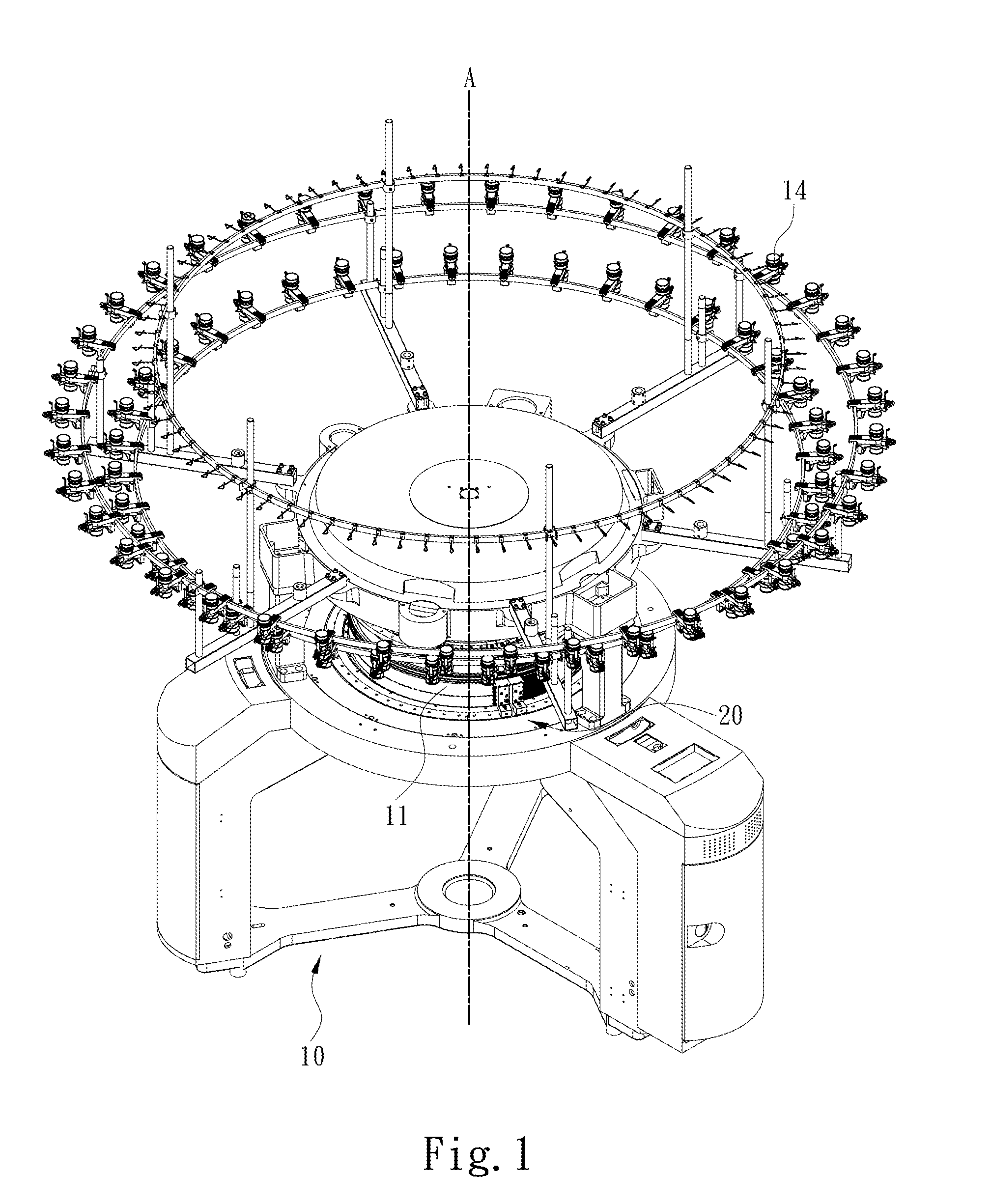

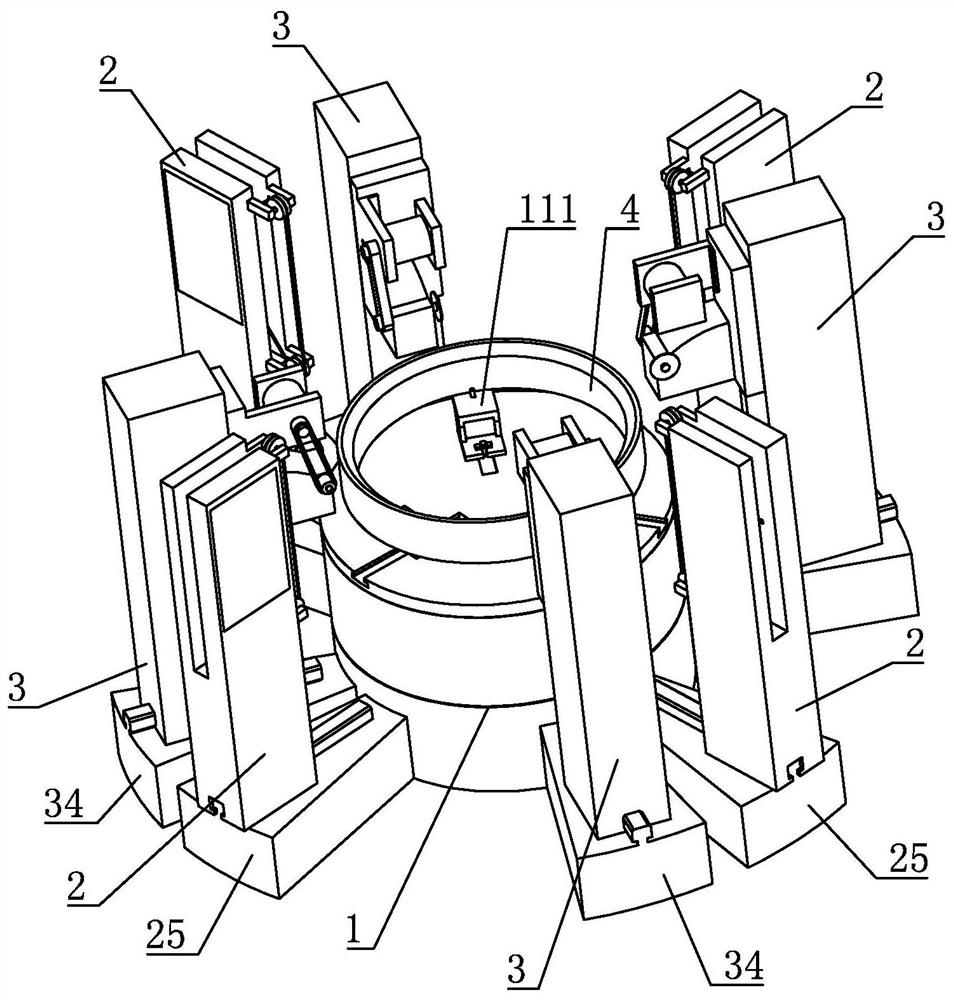

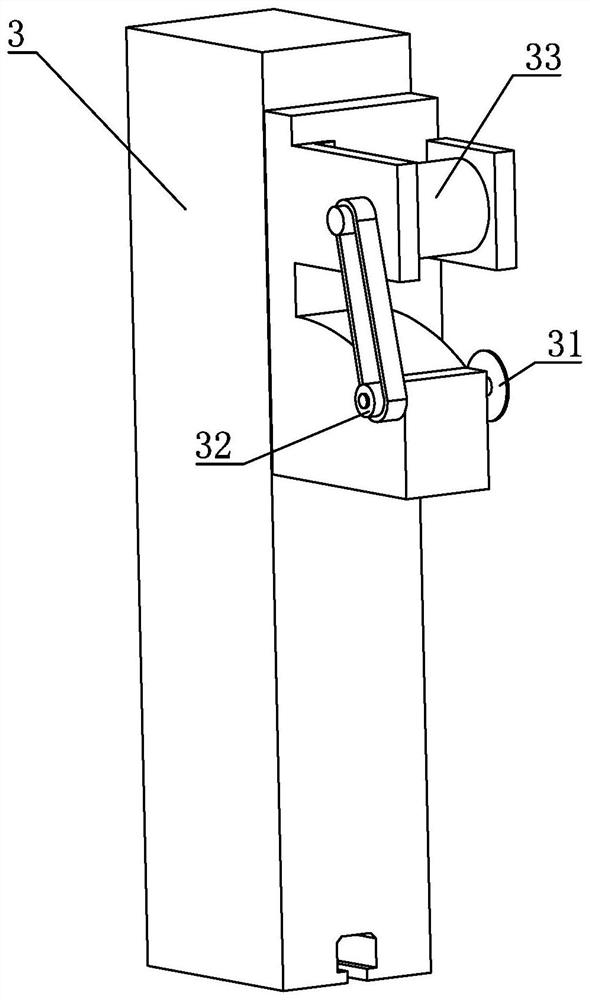

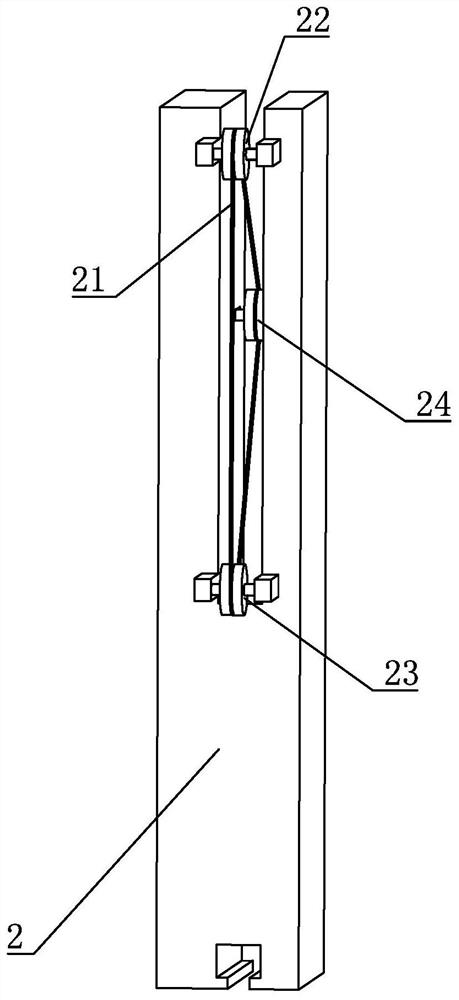

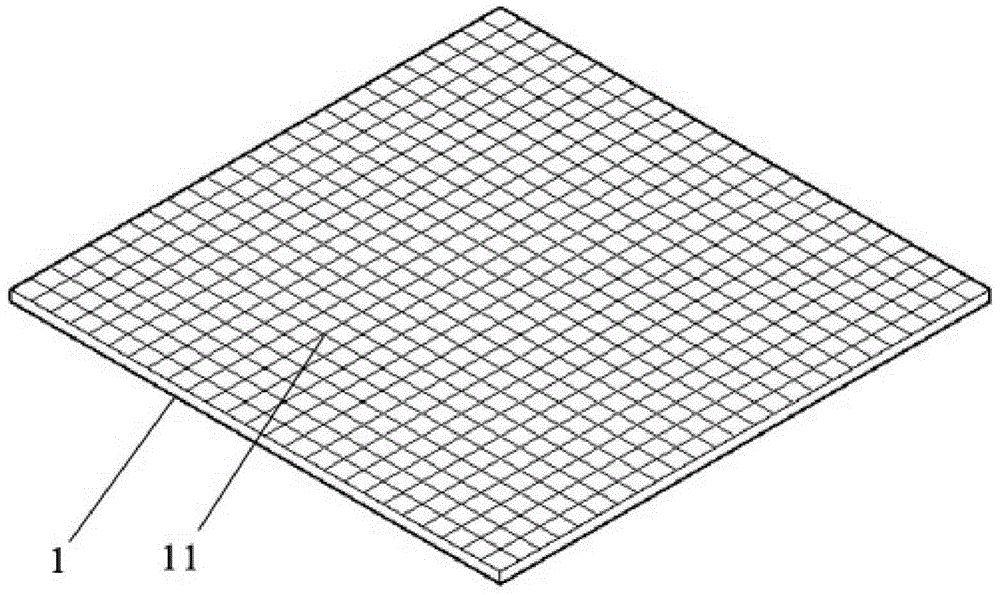

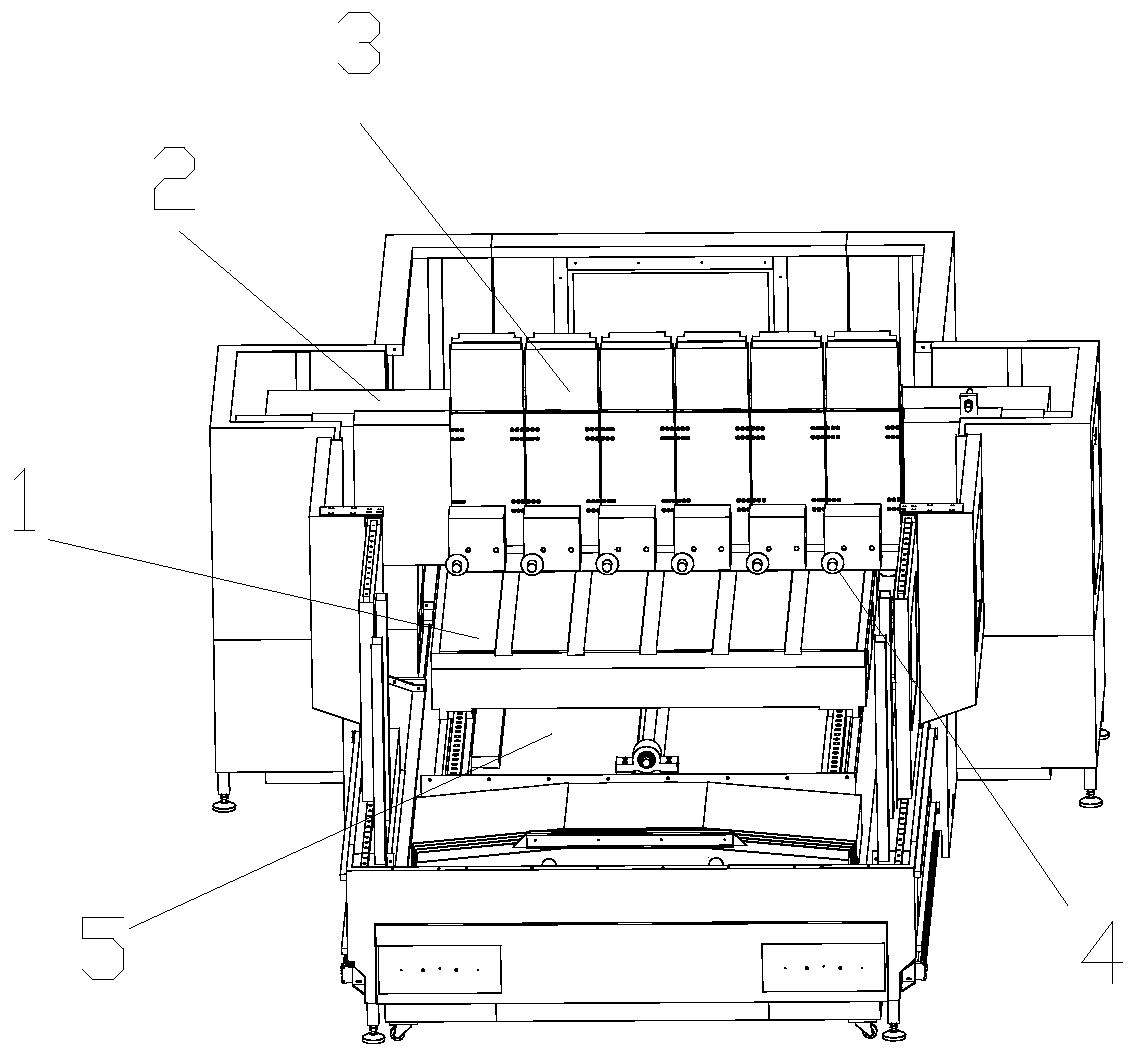

Manufacturing process and equipment for circular knitting machine work drum

ActiveCN111644812AImprove production efficiencyQuick cutWeft knittingOther manufacturing equipments/toolsManufacturing technologyIndustrial engineering

The invention discloses a manufacturing process for a circular knitting machine work drum. The manufacturing process comprises the following steps: a blank work drum is roughly turned through a roughturning device; a finish turning device conducts finish turning on the roughly-turned blank work drum to form a needle-groove-free work drum; grooving devices groove the surface of the needle-groove-free work drum to form a work drum with a needle groove; when grooving is still conducted, polishing devices polish the cut needle groove; and the needle groove in the surface of the polished work drumis tested to judge whether the needle groove is qualified or not. The manufacturing process is short in manufacturing time and high in automation degree. The invention further discloses manufacturingequipment for the circular knitting machine work drum. The manufacturing equipment for the circular knitting machine work drum comprises a rotatable and lifting base; the multiple grooving devices and the multiple polishing devices are arranged surrounding the base; and the polishing devices are located at the downstream of the grooving devices. Through adjacent arrangement of the cutting devicesand the polishing devices, after the needle groove is cut in the surface of the work drum, the polishing devices can polish the cut needle groove, the time of cutting-before-polishing is shortened, and the production efficiency is improved.

Owner:福建省永宏针纺机械有限公司

Automatic anti-toxin gel cutting machine, imager and gel cutting method of anti-toxin automatic gel cutting machine

The invention relates to an automatic anti-toxin gel cutting machine and an imager. The automatic anti-toxin gel cutting machine comprises a base plate and a cold cutter. The base plate is square and is provided with a first grid. The cold cutter is a cover lid. A second grid is arranged on the top of the cover lid. The first grid is the same with the second grid. Cutting needles or cutting pieces are arranged on the cover lid. The base plate is matched with the cover lid. The anti-toxin gel cutting machine is arranged in the imager. The invention further provides a cutting method of the anti-toxin gel cutting machine. The automatic anti-toxin gel cutting machine, the imager and the cutting method of the anti-toxin automatic gel cutting machine have the advantages that the shape and the position of gel to be cut can be determined through the grid on the base plate, gel cutting is completed in the imager under the coordination of the cover lid, a human body is prevented from making contact with ultraviolet rays and ED colorants during gel cutting, and therefore the harm of the ultraviolet rays and the ED colorants to the human body is avoided.

Owner:SHANGHAI OCEAN UNIV

Sewing machine

A sewing machine includes a needle bar to which a sewing needle is attached, a needle bar up-and-down motion mechanism moving the needle bar up and down and a cutting unit including a cutting needle having a distal end formed with a blade and a cutting needle up-and-down motion mechanism which is independent of the needle bar up-and-down motion mechanism and moves the cutting needle up and down. The cutting unit is located on a sewing machine bed with the blade being directed upward.

Owner:BROTHER KOGYO KK

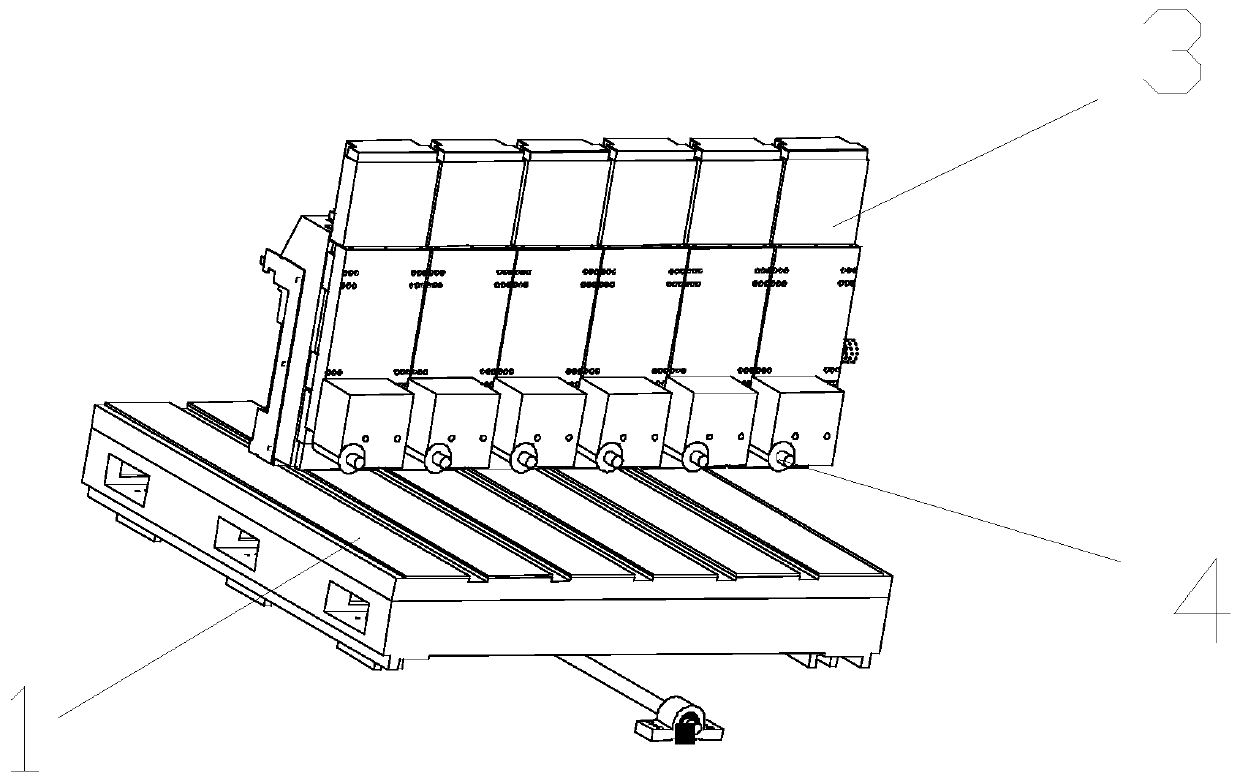

Numerical control gantry needle groove milling machine

InactiveCN109940208AEasy to replaceEasy maintenanceMilling equipment detailsNumerical controlMilling cutter

The invention discloses a numerical control gantry needle groove milling machine. The numerical control gantry needle groove milling machine comprises a milling machine body and milling heads, whereinthe plurality of milling heads capable of carrying out tool setting independently are arranged on the milling machine body, and each milling head is provided with a milling tool. The numerical control gantry needle groove milling machine has the advantages that the scale division is accurate, the replacement and the maintenance of a single blade are convenient, the cost is low, the width of needle grooves of a cutting needle plate can be consistent, the milling tool of each milling head is capable of undergoing fine tool setting independently, and the problem that the machining depth is different due to different milling tool radiuses can be effectively solved

Owner:ZHEJIANG BAIXIN KNITTING MACHINERY

Processing method of glass fiber short-cutting needled felt

InactiveCN108162436AUniform weightMeet strength requirementsNon-woven fabricsGlass fiberUltimate tensile strength

The invention relates to a processing method of a glass fiber short-cutting needled felt. The method comprises the following steps that thermoplastic resin in a flowing state is poured on a glass fiber needled felt, and the thermoplastic resin fully mixed and soaked the glass fiber needled felt; and the glass fiber needled felt is the short-cutting needled felt for GMT, and the thickness is 10-15cm. The processing method of the glass fiber short-cutting needled felt method has the advantages that the short-cutting needled felt for the GMT is developed, and the product single weight is uniform;and through repeated tests, a produced product can meet requirement of different clients and different glass fiber reinforced plastic products on the needled felt, the requirement of the glass fiberreinforced plastic production process for fluidity and expansion height is met, and meanwhile, the requirement for strength of the product is met.

Owner:TAISHAN FIBERGLASS INC

Sewing machine

ActiveUS20150233032A1Well formedProgramme-controlled sewing machinesWorkpiece carriersReciprocating motionCut needle

A sewing machine includes a detection unit configured to detect a moving direction of an object to be processed when the object placed on a sewing machine bed is moved in any direction, a cutting needle having a distal end formed with a blade edge and configured to form a cut in the object, an up-down drive mechanism configured to reciprocate the cutting needle in an up-down direction, a rotational drive mechanism configured to rotate the cutting needle about a rotation axis line of the cutting needle, and a control device configured to control the up-down drive mechanism and the rotational drive mechanism based on a result of detection by the detection unit so that the cutting needle forms the cut in the object while changing an orientation of the blade edge according to the moving direction of the object.

Owner:BROTHER KOGYO KK

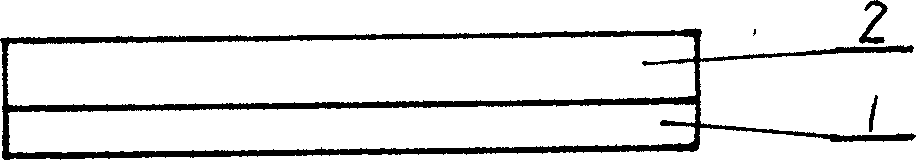

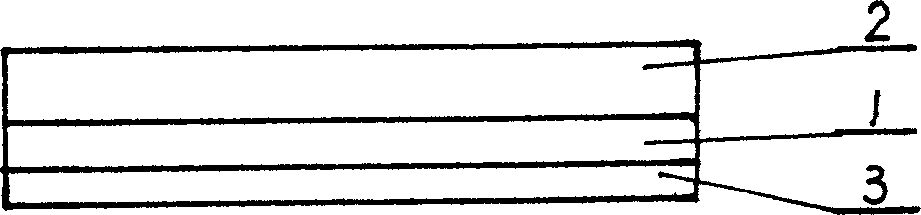

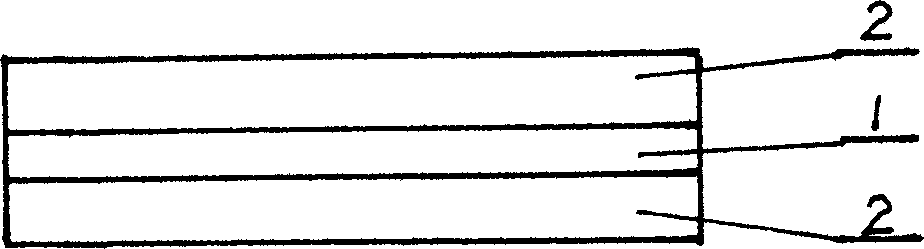

Composite foaming geomembrane

InactiveCN1736699ASoftElasticSynthetic resin layered productsProtective foundationPolyesterPolyvinyl chloride

The invention discloses a foamed composite geomembrane for water control and seepage control in the project of reservoir, river, road, culverts, dam and the trash treating factory, which is prepared by welding or sticking at least one layer impervious layer (1) and at least one layer foaming layer (2). The connection side-face of impervious layer (1) with the foaming layer (2) can be equipped with a reinforcing layer (3), the impervious layer (1) being made up of high-density polyethylene film or polychloroethylene film, the foaming layer (2) made up of continuous foaming material such as polyphenylacetylene and polyethylene, the reinforcing layer (3) being a braided fabric or net of the glass fibre / polyester / polypropylene. It can avoid the problem of infiltration conduced by that the cutting needle pierces the geomembrane in the construction and usage process, and avoid the problem of stabbing working people. It is soft and elastic, and is facile to use or transport.

Owner:范吉廷

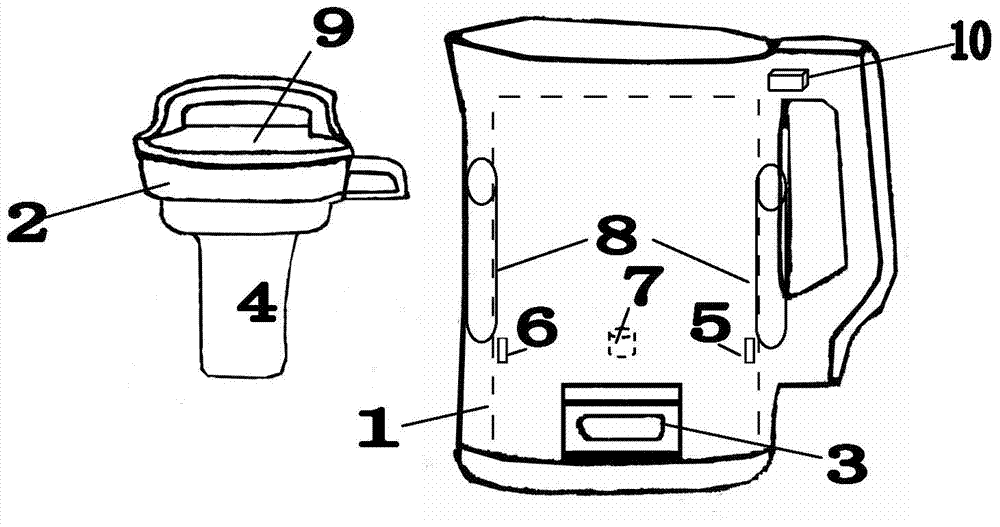

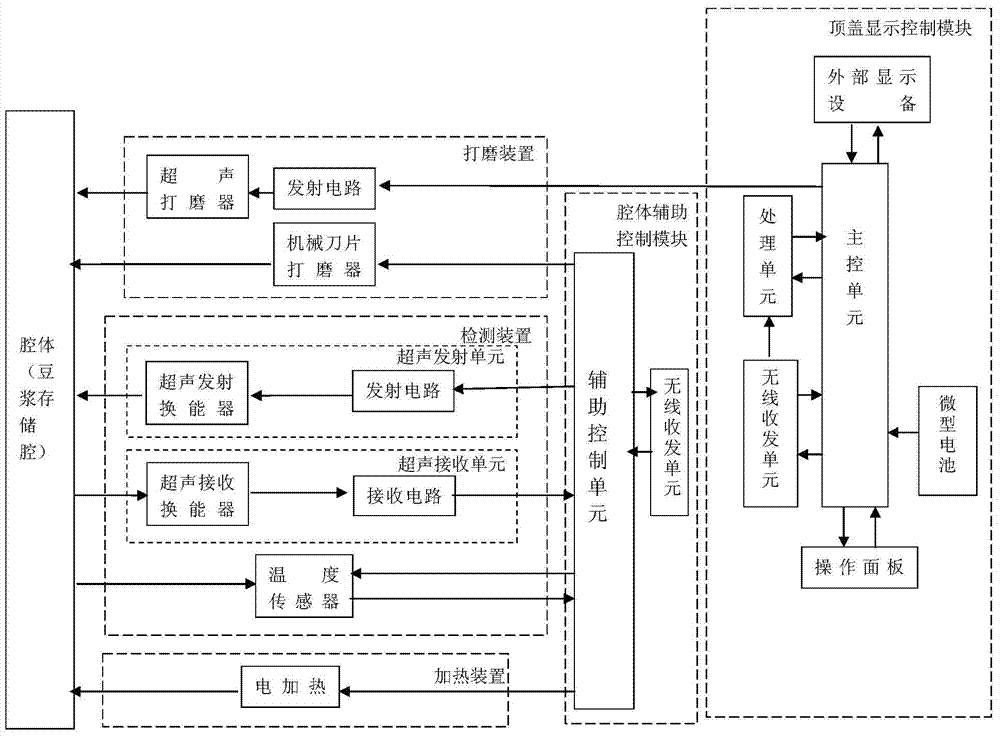

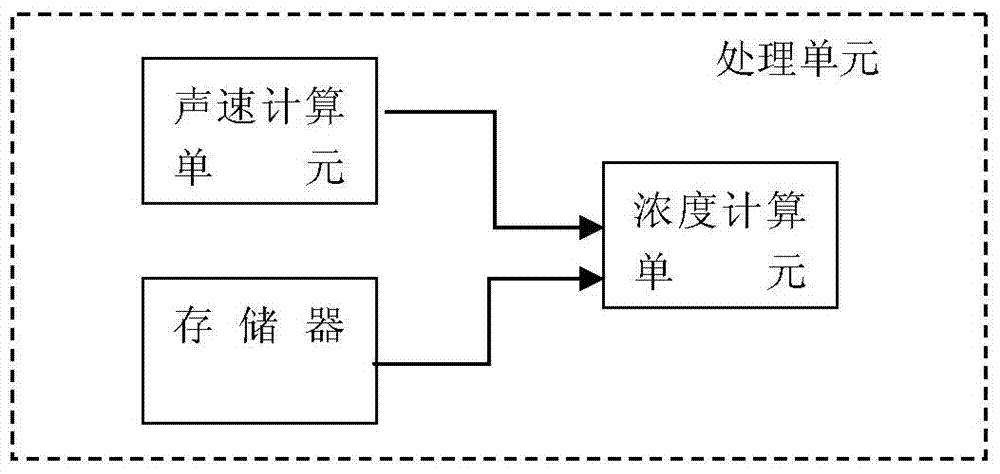

Concentration controllable ultrasonic soybean milk machine device and working method thereof

The invention discloses a concentration controllable ultrasonic soybean milk machine device and a working method thereof. The device comprises a cavity body, a top cover, a base, a grinding device, a heating device, a testing device, a top cover display control module and a cavity body assisting control module; the grinding device comprises a mechanical blade grinding device and an ultrasound grinding device; the testing device comprises an ultrasound transmitting transducer, an ultrasound receiving transducer and a temperature sensor. In the controlling method, mechanical cutting needles are used for conducting grinding on large particulate matters, and then the further refining of small particulate matters can be achieved through ultrasonic grinding. According to the concentration controllable ultrasonic soybean milk machine device, the advantages of the mechanical cutting and the ultrasound grinding are combined, and mutual complementation is conducted, the grinding time is shortened, the grinding quality is improved, further more, soybean milk is ground more sufficiently, the taste is finer and smoother, the device not only can use the mechanical effect of ultrasonic waves to achieve the fine grinding and stirring but also obtain the information of the soybean milk concentration through the measurement of the propagation velocity of the ultrasonic waves in the soybean milk, and therefore the controllability of the soybean milk concentration is achieved.

Owner:SOUTH CHINA UNIV OF TECH

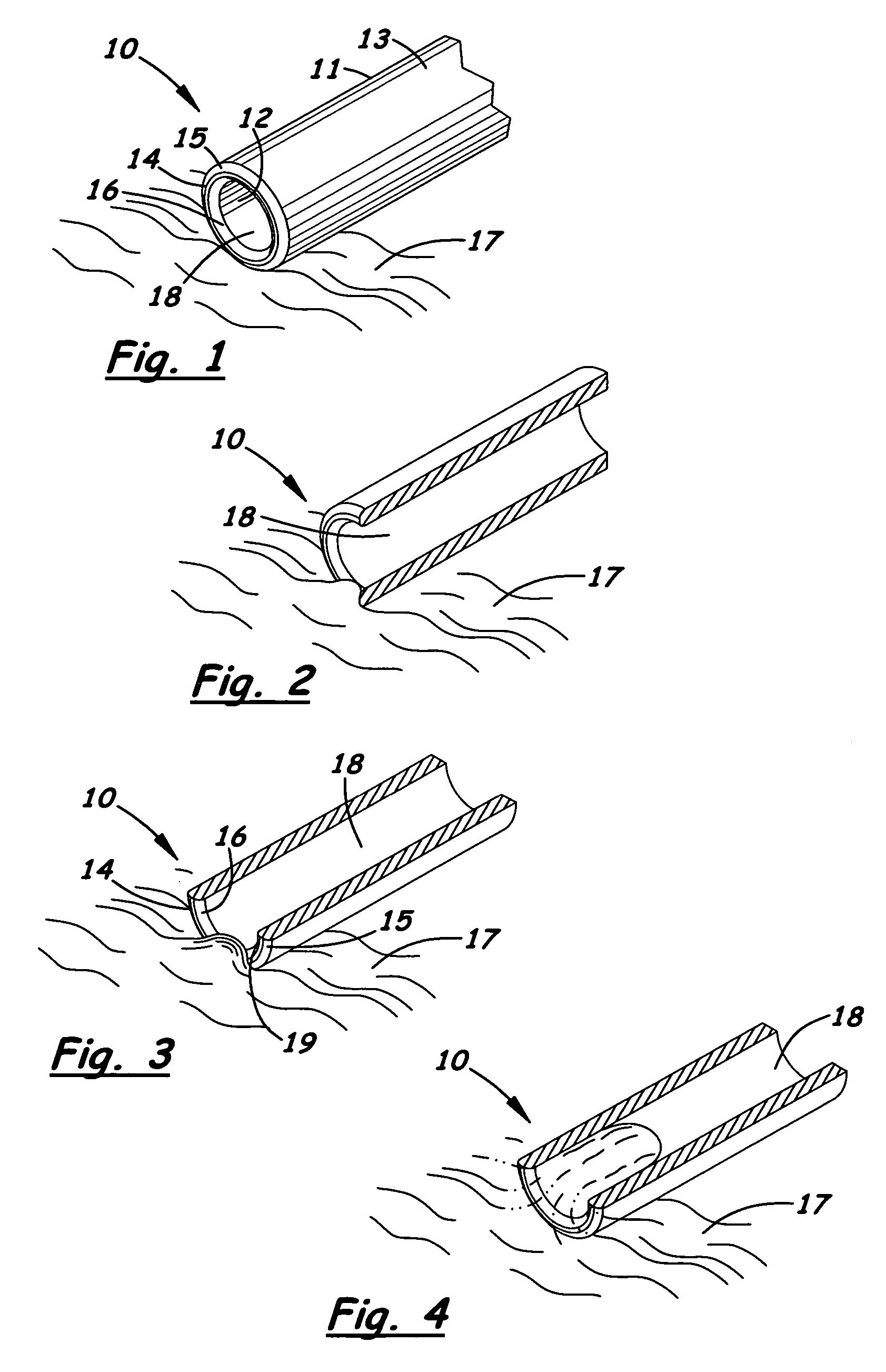

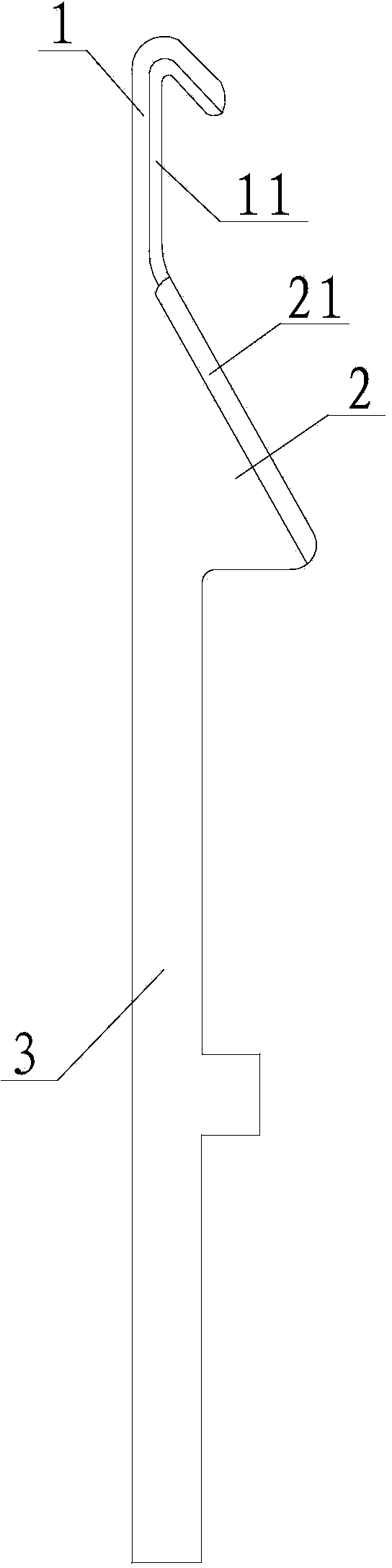

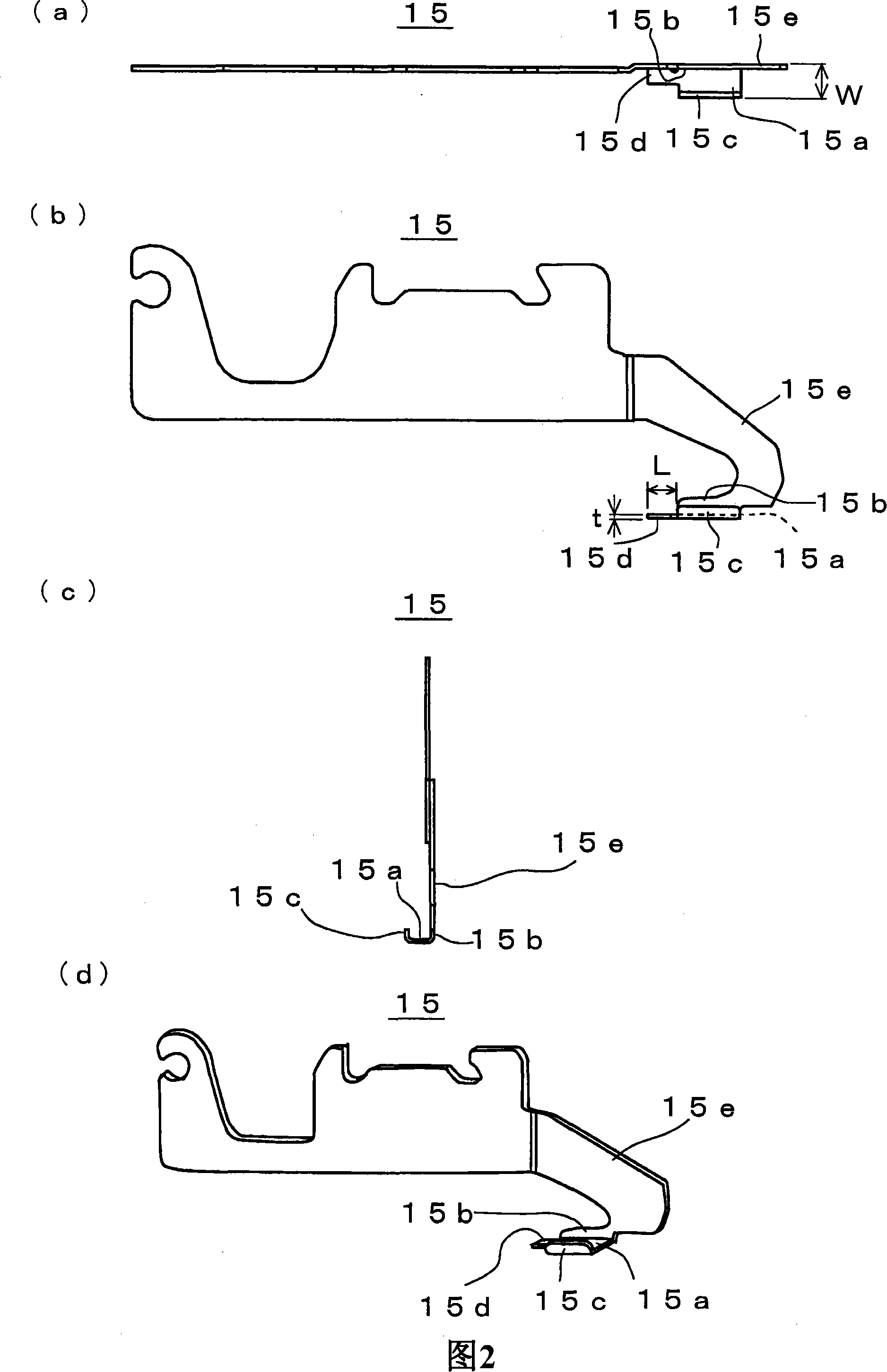

Cutting needle with interchangeable knife

ActiveUS20090000338A1Easy maintenanceFast and simple to changeWeft knittingManufacturing technologyDetent

A cutting needle (1) for knitting machines and similar applications has been provided, said cutting needle having a needle body (2) on which a knife (6) is detachably held, preferably by means of a detent device (19). Such a cutting needle (1) reduces the maintenance costs of knitting machines and discloses ways for optimizing needle bodies (2) and knives (6) in view of manufacturing technology and materials.

Owner:GROZ BECKERT KG

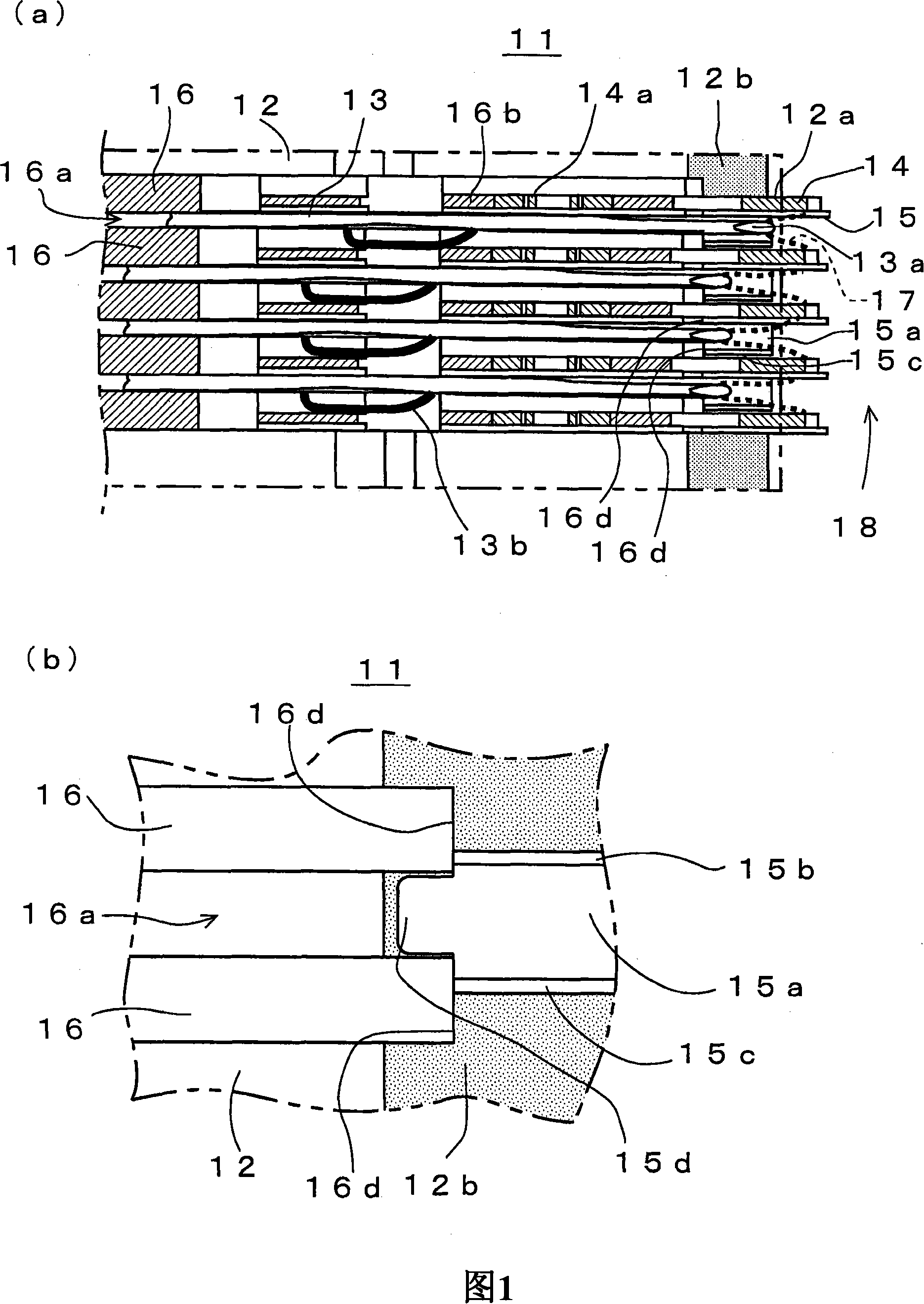

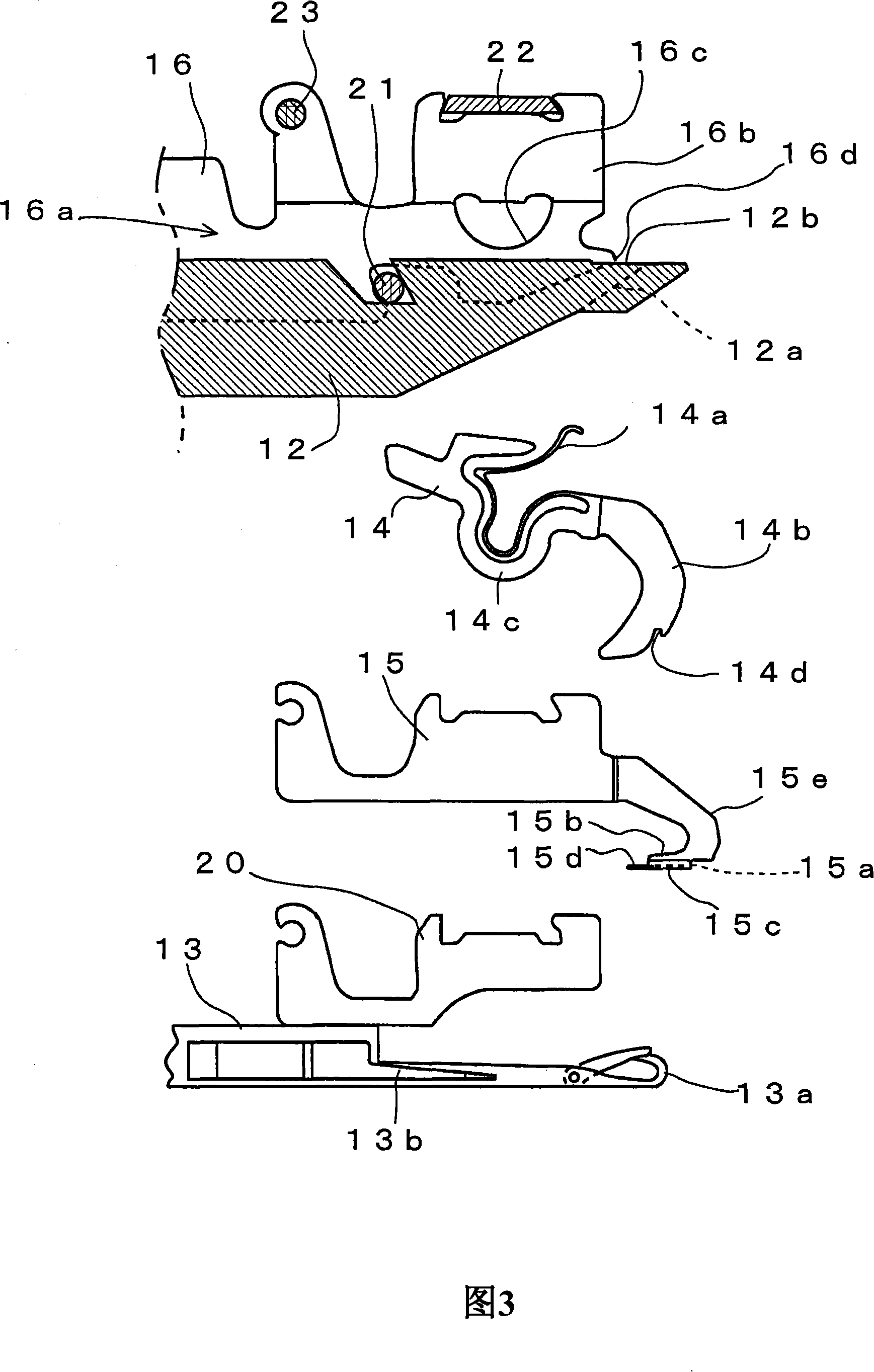

Flat-bed machine sinker and feed distance clip

A horizontal machine sinker device capable of preventing the feed distance clip from vibrating and a feed distance clip are provided in the present invention. It has an extending part (15a), a knitting yarn fall-preventing parts (15b, 15c), and an entering part (15d) for preventing the feed distance clip from vibrating. The entering part (15d) enters from the middle of the extending part (15a) to a needle slot (16a) direction that is apart from gear open (18) direction, tow sides are clamped by a needle plate (16). On the upper surface of the needle bed (12), at the part arranged with the extending part (15a) and the entering part (15d), forming step part (12b). It can easily form step part (12b) by processing such as cutting needle bed (12) along the gear open (18) longitude direction. To lead the extending part (15a) to reliably prevent from vibration, when the entering part (15d) two sides end edges connects with the needle plate (16) end part (16d).

Owner:SHIMA SEIKI MFG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com