Concentration controllable ultrasonic soybean milk machine device and working method thereof

A soymilk machine and ultrasonic technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of inability to adjust the concentration of soymilk, low grinding efficiency, and insufficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings, but the implementation and protection of the present invention are not limited thereto.

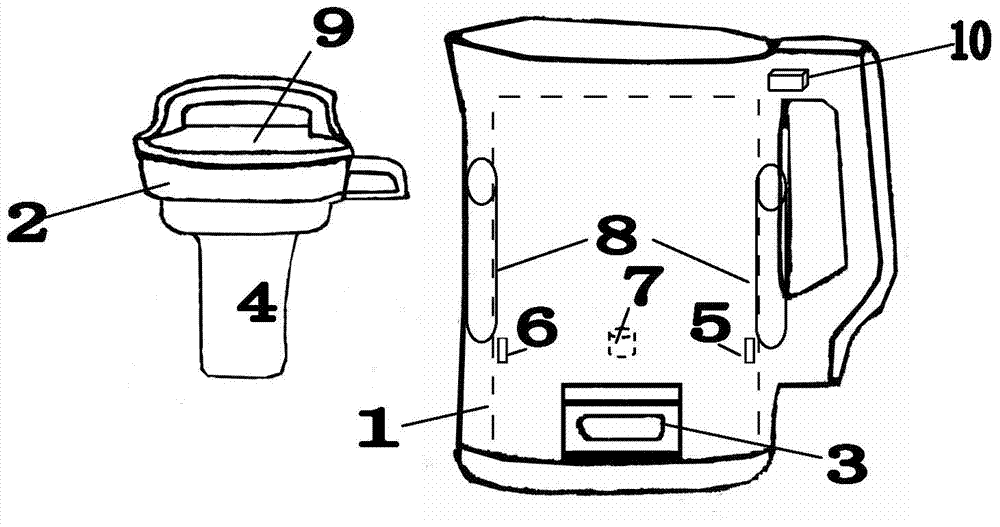

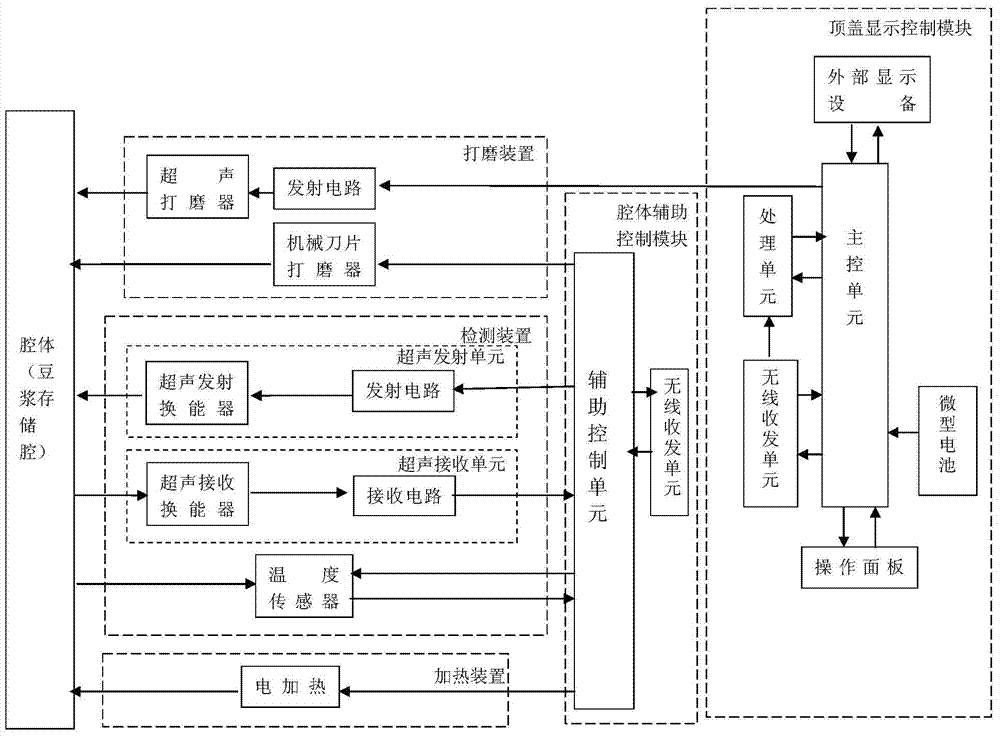

[0098] Such as figure 1 As shown, the soybean milk machine mainly includes a cavity 1, a top cover 2, a mechanical blade grinder 3 and an ultrasonic grinder 4 in the grinding device, a group detection device, a heating device 8, a top cover display control module 9 and an auxiliary cavity control module 10. The top cover and the cavity are separated structures (that is, when the top cover is opened, the top cover can be completely separated from the cavity) and can be closed with each other.

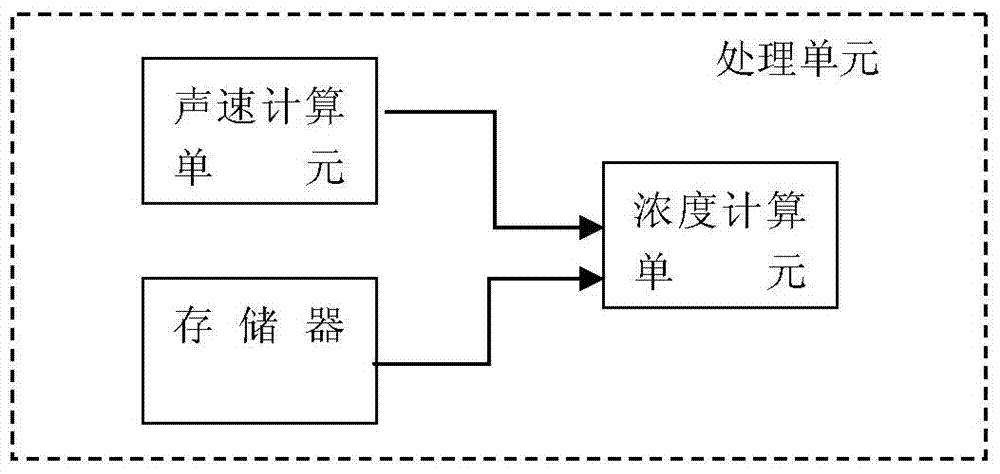

[0099] The cavity 1 is composed of an outer shell and an inner cavity, both of which are cylinders, and an interlayer is formed between the outer shell and the inner cavity. The inner cavity is used for making and storing soybean milk, the detection dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com