Flat-bed machine sinker and feed distance clip

A sinker and spacer technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of poor movement and the effect of knitted fabric completion, and achieve the effect of preventing gaps and vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

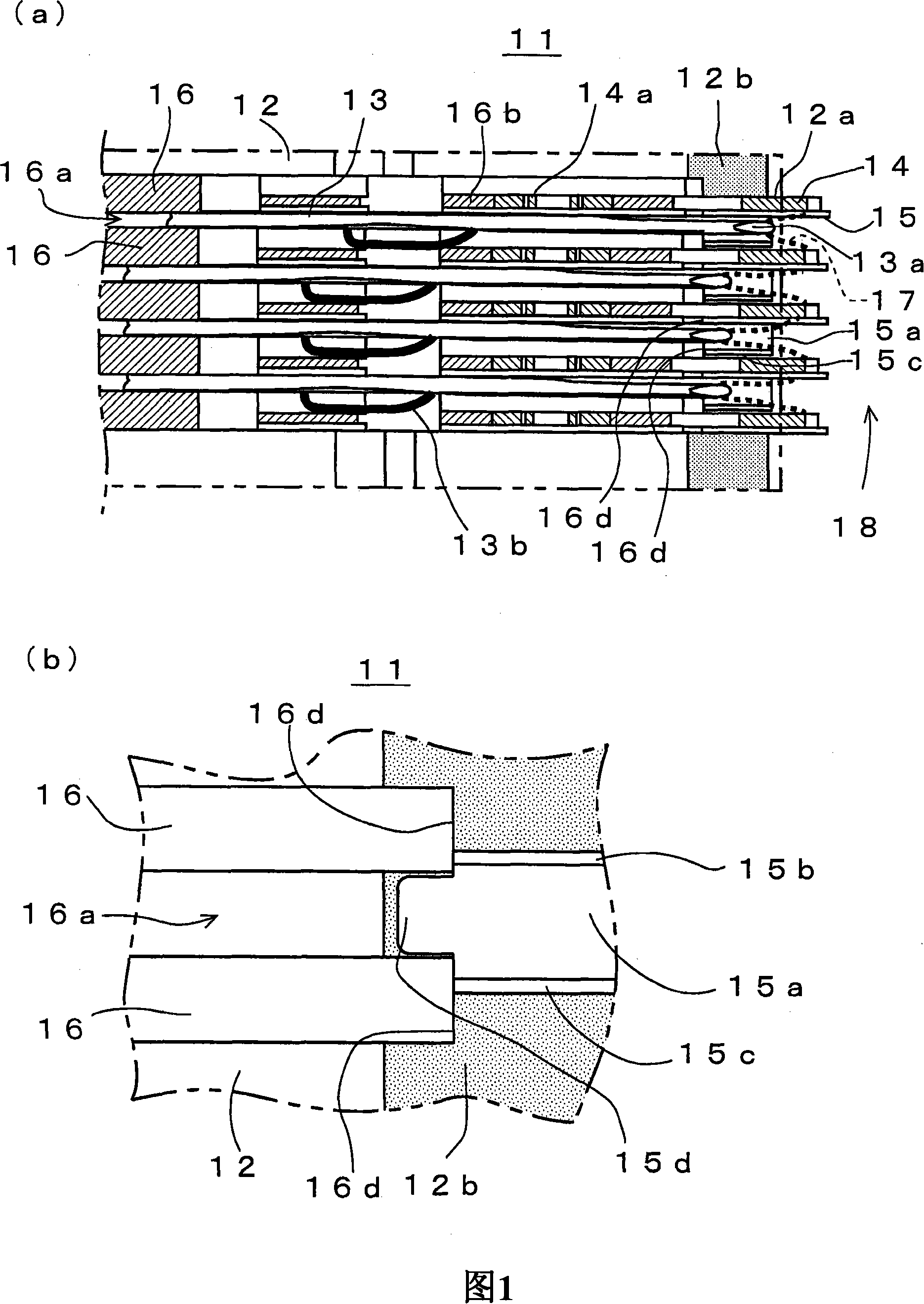

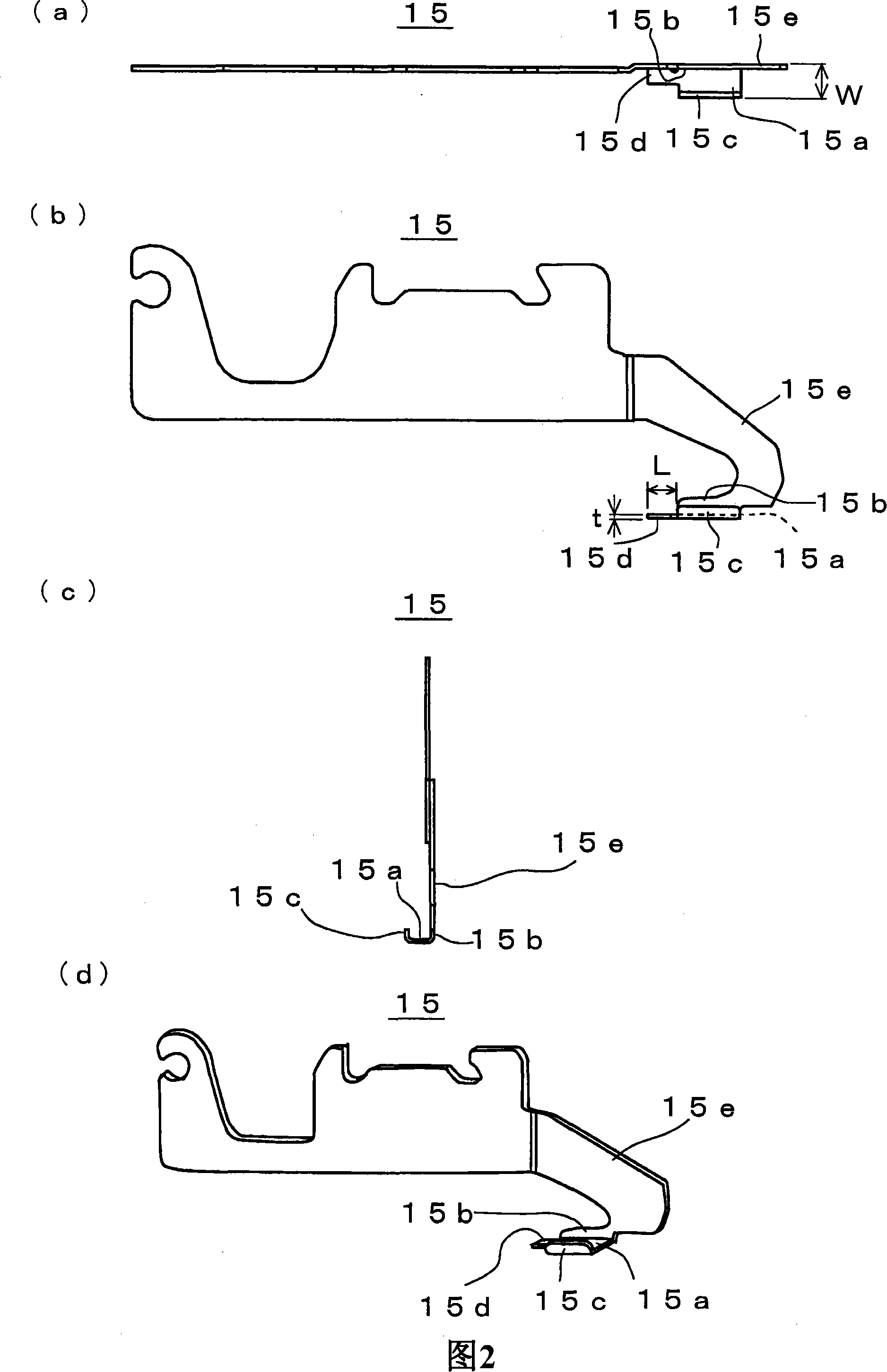

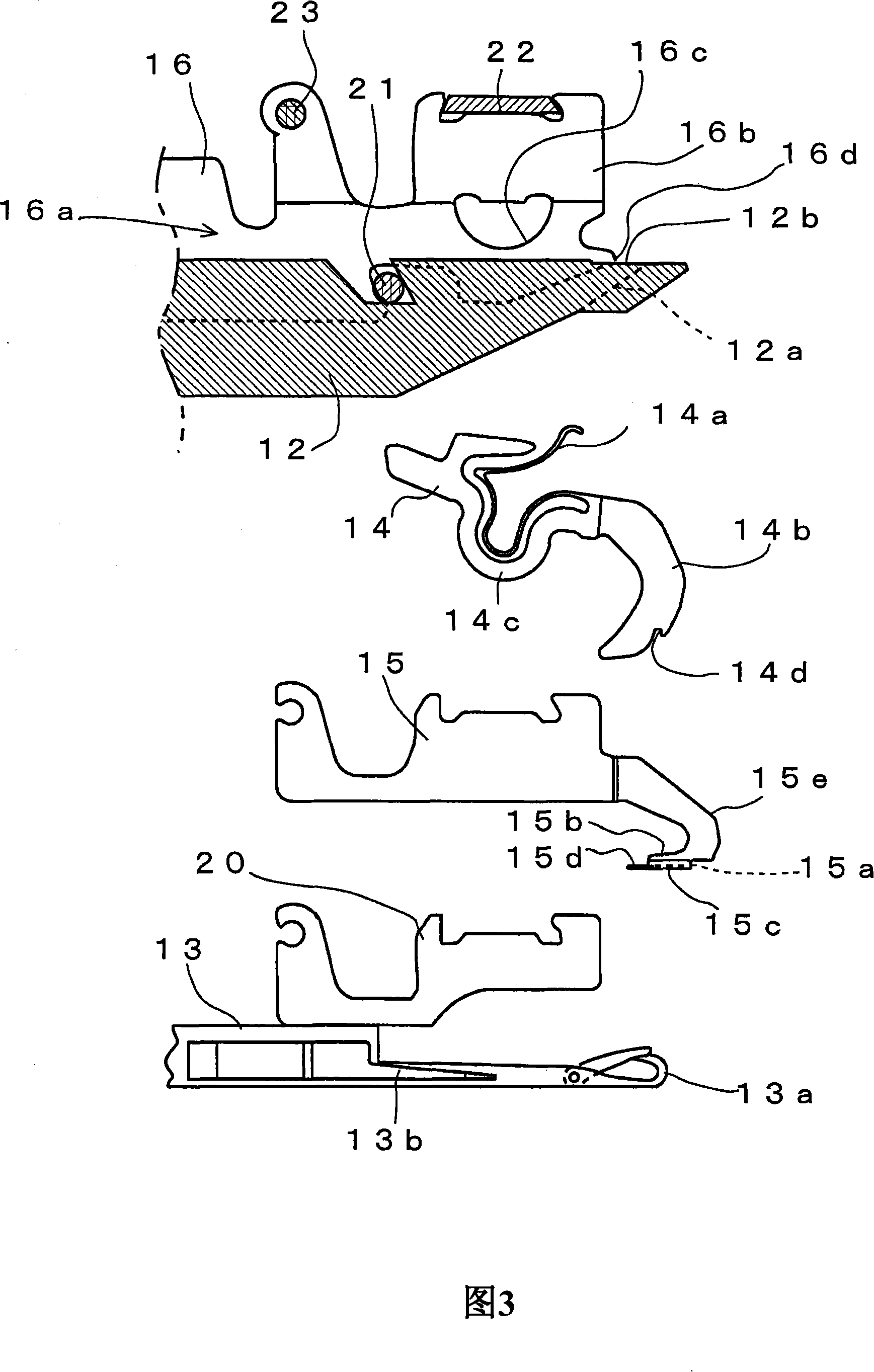

[0025] FIG. 1 shows the configuration of main parts of a sinker device 11 according to one embodiment of the present invention. (a) shows a partial planar structure near the front end of the needle bed 12, and (b) shows an enlarged part for preventing vibration. On the needle bed 12, needle plates 16 are arranged side by side at a pitch corresponding to the gauge of the flat knitting machine to accommodate the knitting needles 13, the sinker plate 14, and the yarn guide gauge 15. The needle bed 12 is provided with a groove for inserting the lower side of each needle plate 16 . The knitting needles 13 are housed in needle grooves 16a formed between the needle plates 16, and are slidably displaceable in the left and right directions of the drawing. As will be described later, the sinker plate 14 is integrally formed with a spring portion 14a that biases downward the side of the crest 18 that receives the yarn feed of the knitting yarn 17 and knits the knitted fabric. Near the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com