Microdissection device based on piezoelectric ultrasonic vibration

A technology of microdissection and piezoelectric ultrasound, which is applied in the fields of sampling device, medical science, inoculation and ovulation diagnosis, etc. It can solve the problems of high work intensity, easy fatigue and human error of the operator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

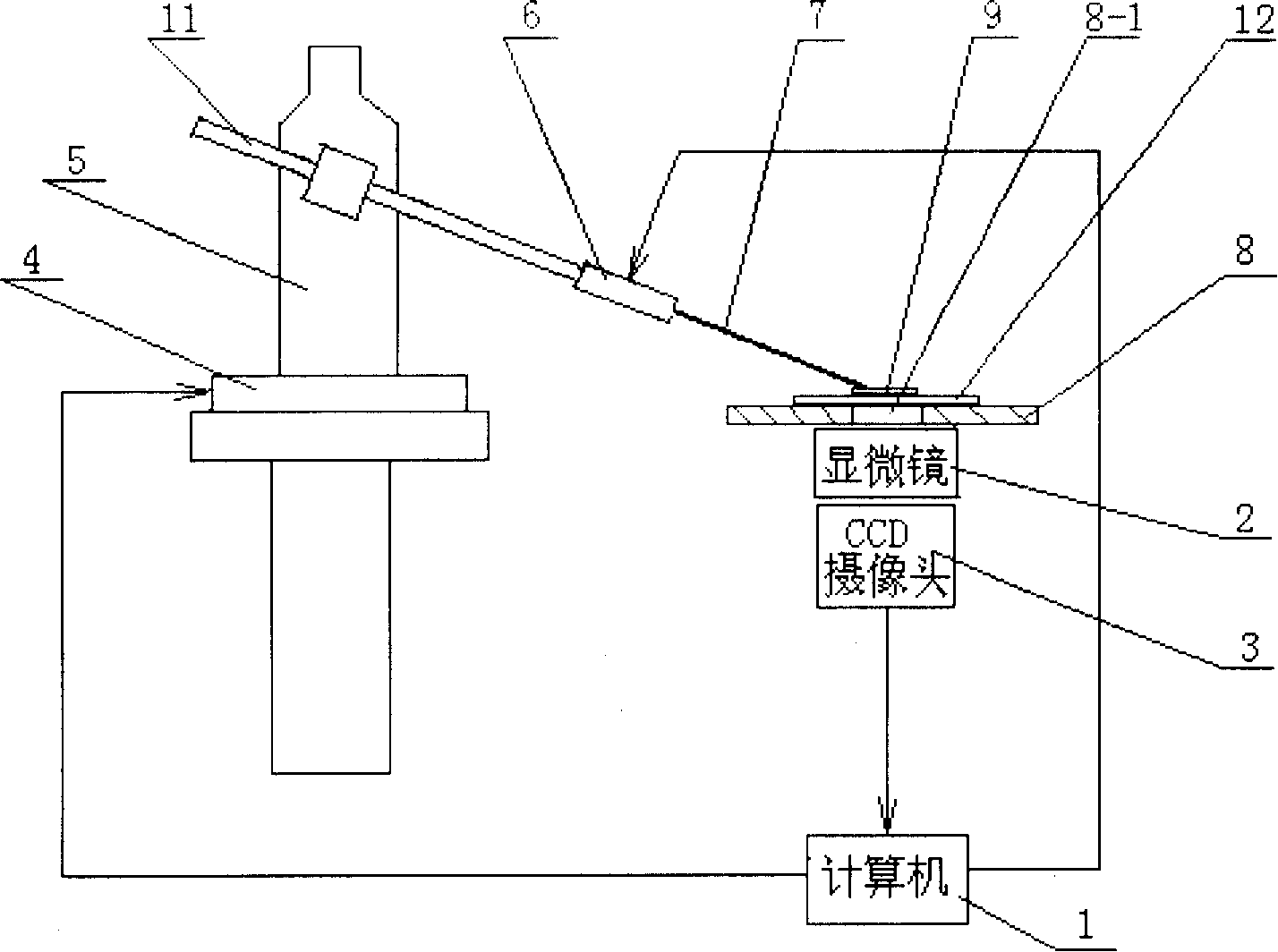

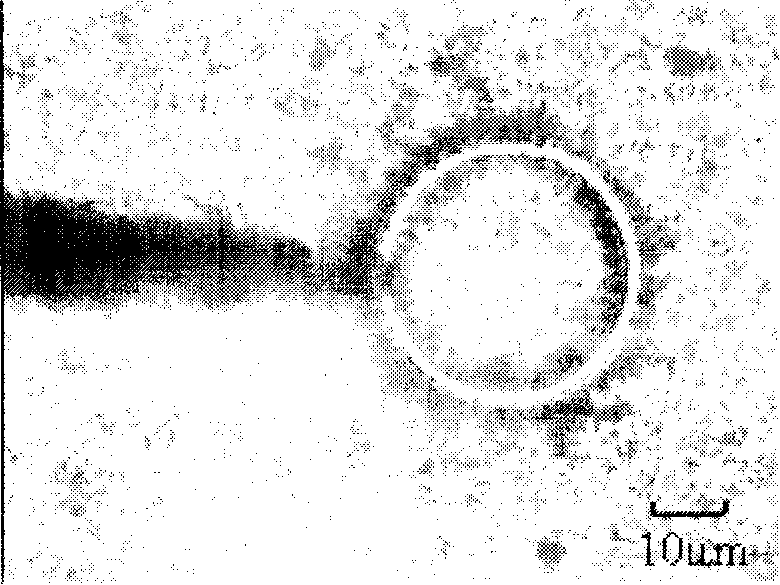

[0005] Specific implementation mode one: the following combination figure 1 with figure 2 This embodiment will be specifically described. This embodiment is composed of a computer 1, a microscope 2, a CCD camera 3, a three-degree-of-freedom mechanical micro-motion table 4, a clamp body 5, an ultrasonic vibration generator 6, a cutting needle 7, a biological slice platform 8, and a tool bar 11. The microscope 2 is arranged under the opening 8-1 of the biological slice stage 8, the CCD camera 3 is connected to the microscope 2 to collect the object image enlarged by the microscope 2, the signal output end of the CCD camera 3 is connected to the signal input end of the computer 1, The mechanical micro-motion table 4 with three degrees of freedom in space is arranged on the side of the biological slice platform 8, and one signal output terminal of the computer 1 is connected to the controlled end of the mechanical micro-motion table 4 with three degrees of freedom in space to re...

specific Embodiment approach 2

[0006] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between the present embodiment and the first embodiment is that the ultrasonic vibration generator 6 uses an ultrasonic transducer or a stacked ceramic driver. Other components and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com