Lithium metasilicate glass ceramic and preparation method thereof

A technology of glass ceramics and lithium metasilicate, which is applied in the field of ceramics, can solve the problems of narrow crystallization temperature range, cumbersome production process, and long processing time, and achieve the effects of low production equipment requirements, simple production process, and shortened processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (a) According to each component in Example 1 in Table 1, it is converted into the weight of corresponding raw material. Then take by weighing the corresponding raw materials of each component, grind for 3 hours through a ball mill, pass through a 100-mesh sieve after mixing evenly, and make a batch;

[0052] Put the batch material into a corundum crucible, heat it to 1500 °C in a sintering furnace at a heating rate of 13 °C / min, and keep it warm for 1 hour to completely melt the batch material, remove the gas and clarify and homogenize to obtain a matrix glass liquid.

[0053] (b) Pour the matrix glass liquid into a metal mold at 300° C., and cool to room temperature to obtain a matrix glass body.

[0054] (c) Place the matrix glass body in a resistance furnace for heat treatment. The process parameters for heat treatment include: heating up to 480° C. at a heating rate of 5° C. / min and holding the temperature for 150 minutes. After the heat treatment, cool down to roo...

Embodiment 2

[0056] Each component of matrix glass liquid is with reference to embodiment 2 in table 1, and the difference of its preparation method and embodiment 1 is:

[0057] After the matrix glass liquid is prepared in step (a), the matrix glass liquid is directly poured into cold water for water quenching to obtain fine matrix glass fragments, and then the matrix glass fragments are dried at a temperature of 150°C In 2 hours, the dried matrix glass fragments were melted at a temperature of 1500°C to form a matrix glass liquid; then the matrix glass liquid was poured into a metal mold at 350°C, and cooled to room temperature to obtain a matrix glass body.

[0058] The process parameters of the heat treatment include: heating up to 560° C. at a heating rate of 8° C. / minute, and keeping the temperature for 120 minutes.

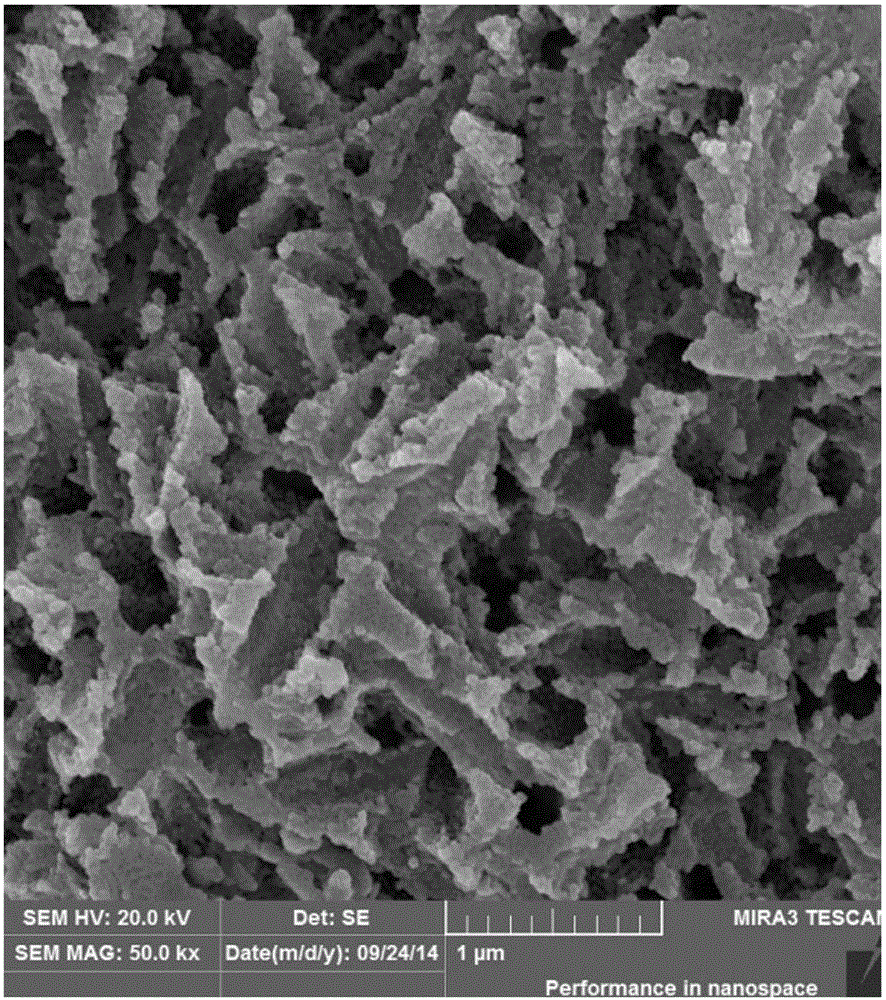

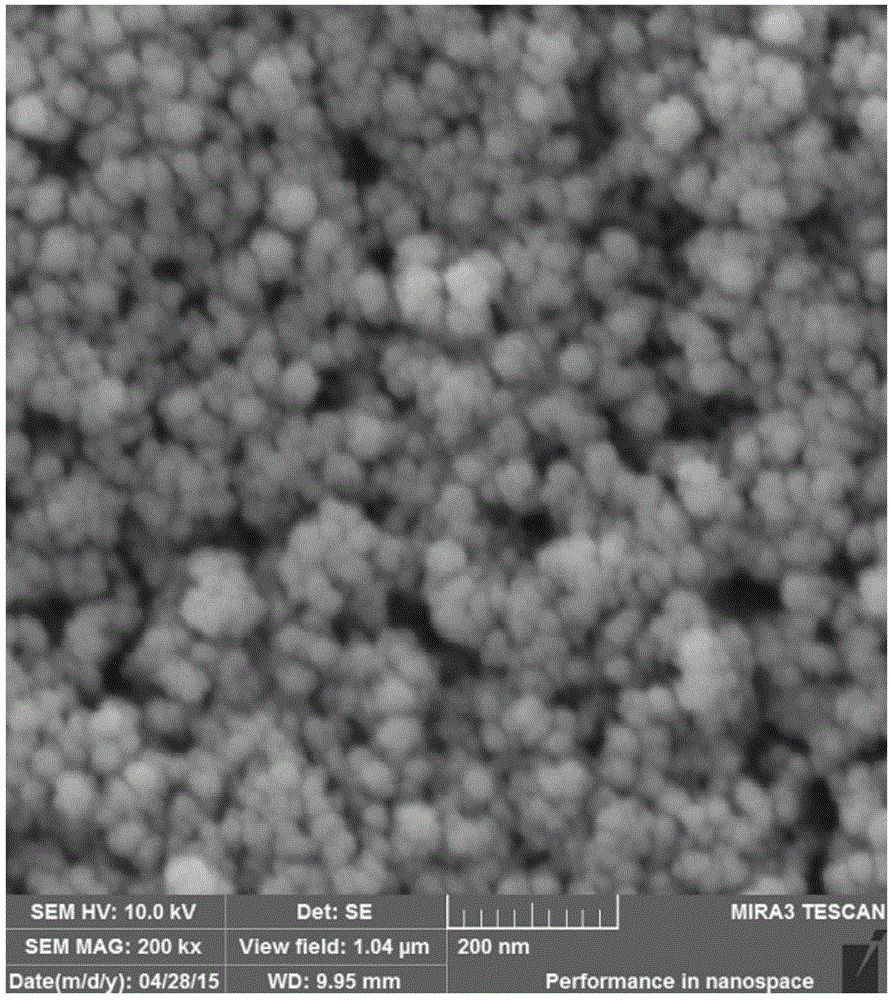

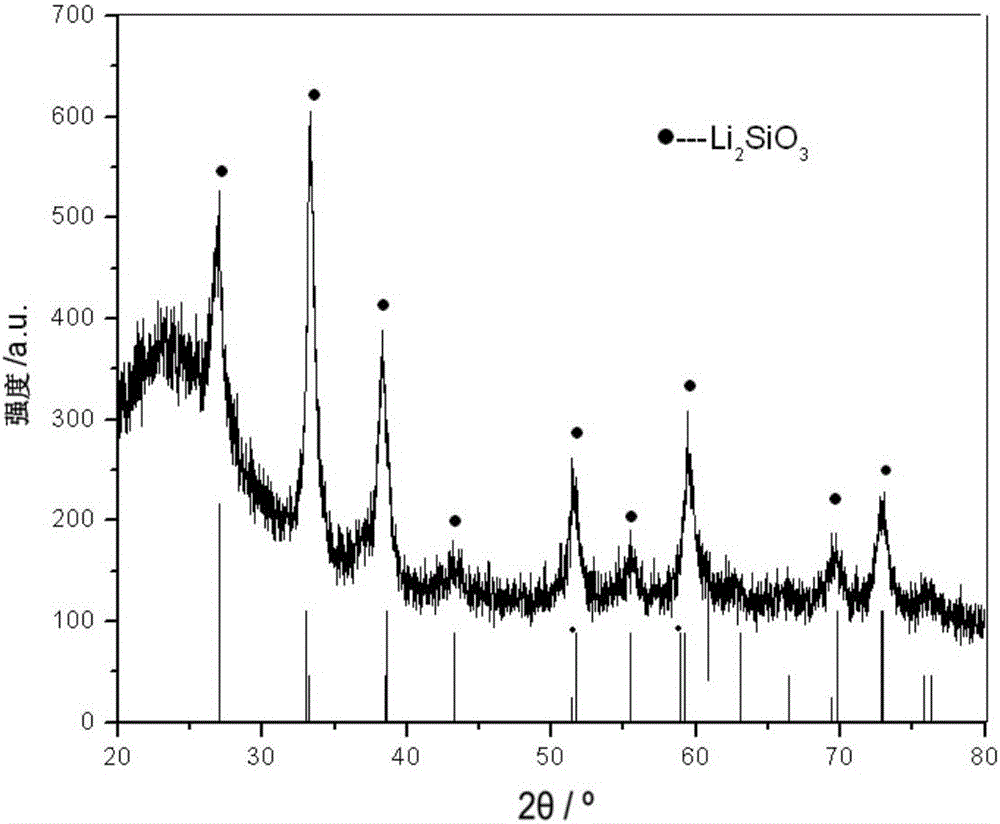

[0059] The prepared lithium metasilicate glass-ceramic is carried out scanning electron microscope test and XRD (X-ray diffraction) test, wherein,

[0060] The scannin...

Embodiment 3

[0077] Each component of matrix glass liquid is with reference to embodiment 3 in table 1, and the difference of its preparation method and embodiment 2 is:

[0078] The technical parameters of the heat treatment include: heating up to 520° C. at a heating rate of 5° C. / min, and keeping the temperature for 90 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com