Automatic pin machine of PCB board

A PCB board, fully automatic technology, applied in the direction of assembling printed circuits with electrical components, etc., can solve the problem that loose needles or pre-broken needles cannot adapt to competitiveness, etc., to save secondary processing costs, high needle insertion efficiency, and needle length. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

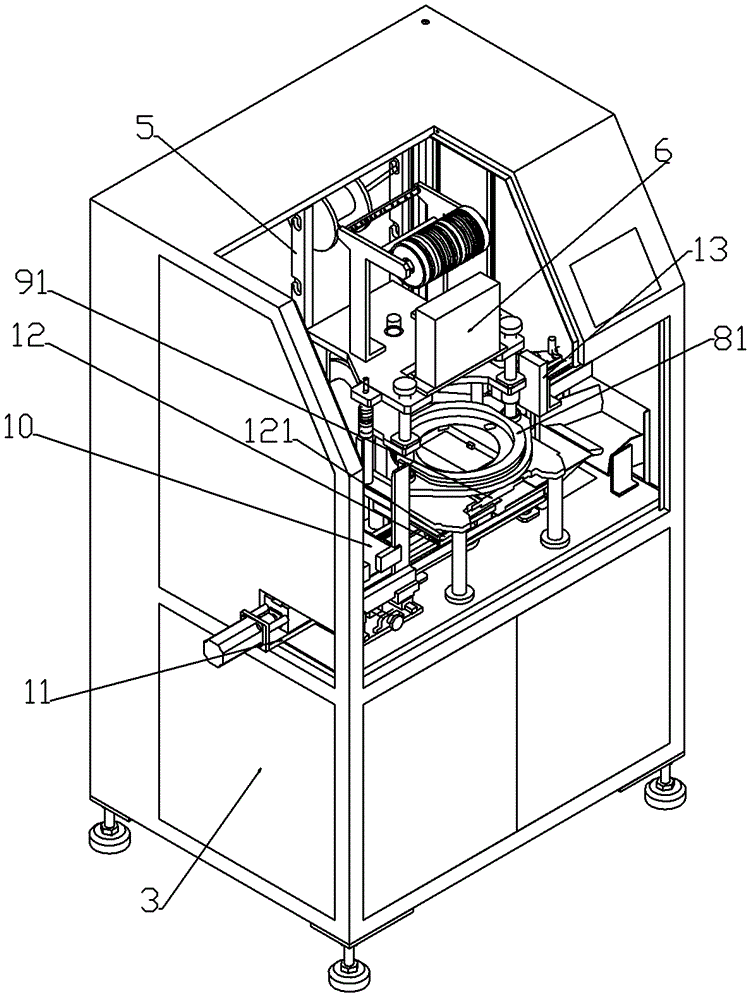

[0029] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

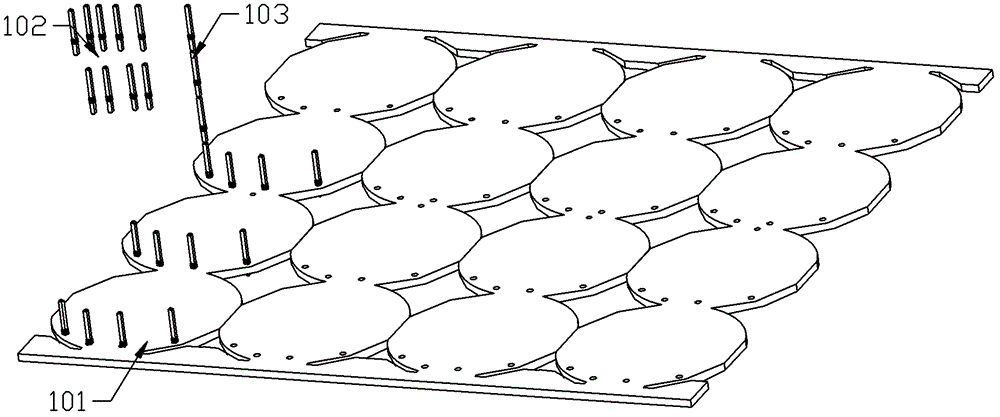

[0030] see figure 2 and image 3 , the PCB board fully automatic pin insertion machine includes: frame 3, spindle drive system 4, wire hanger 5, wire straightener 6, wire feeding mechanism 7, wire clamping and loosening module 8, needle cutting module 9, The board loading bin 10, the numerically controlled board separating system 11, the numerically controlled board shifting and positioning system 12, the automatic material return system 13 and the power system 14.

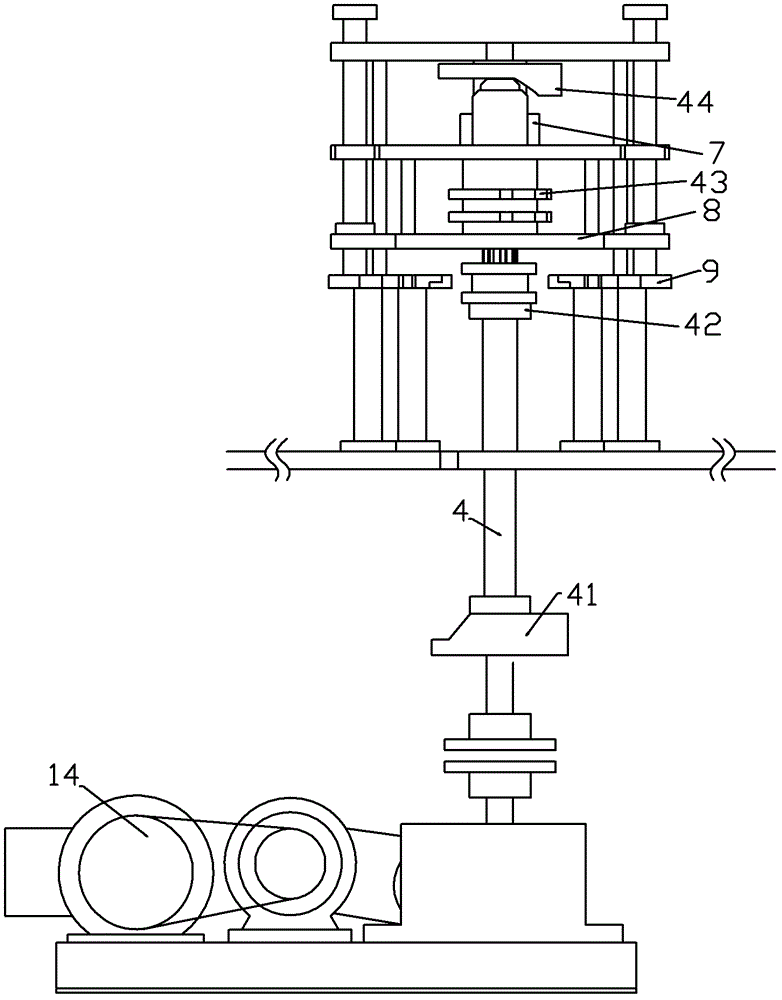

[0031] which, combined with Figure 4 It can be seen that the main shaft transmission system 4 is arranged on the lower part of the frame 3, and specifically includes: the main shaft and the lifting mechanism cam 41, the tangent cam 42, the output conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com