Mining pumping and spraying integrated vehicle

An integrated, mine-used technology, applied in road cleaning, construction, cleaning methods, etc., can solve the problems of high cost of auxiliary materials, high pump power, high cost, etc., to reduce secondary treatment costs, fast water treatment speed, and engineering volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

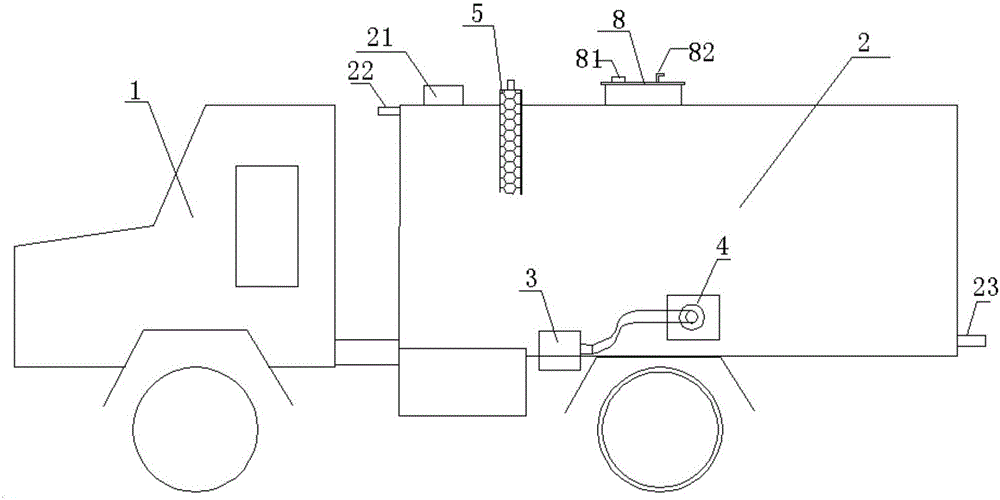

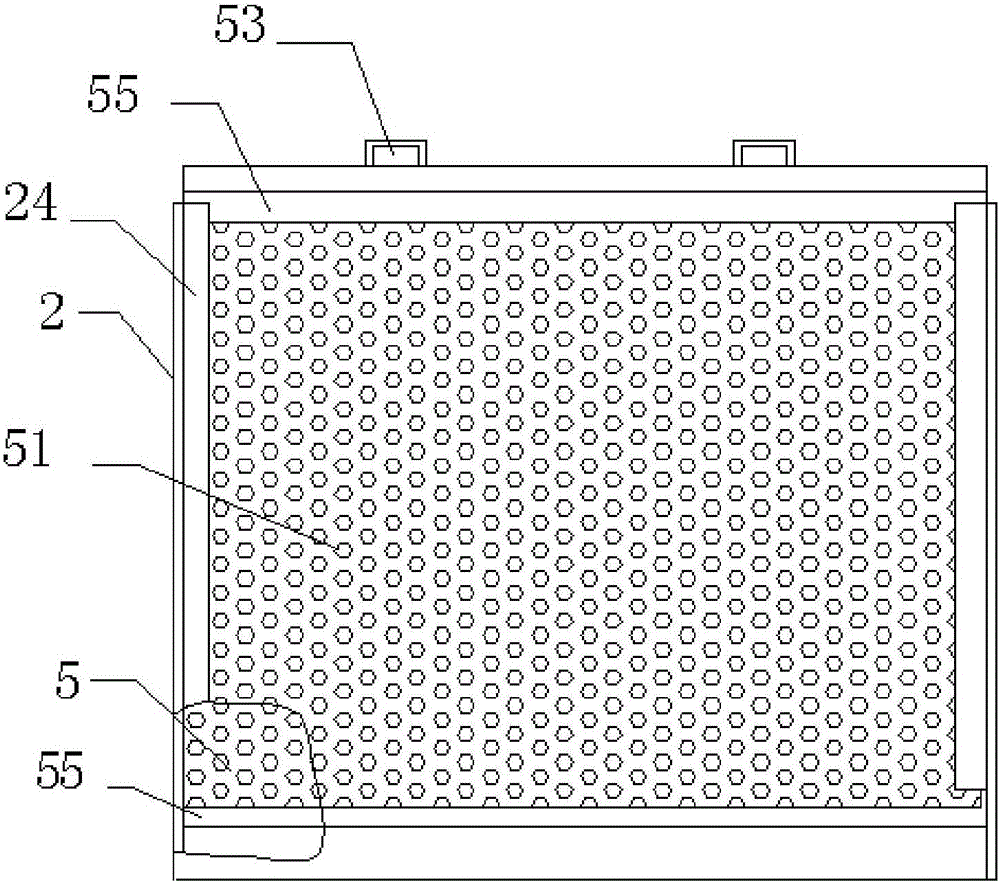

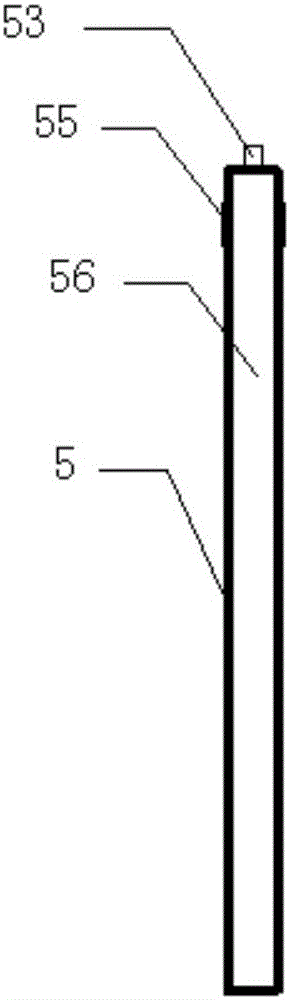

[0034] figure 1 Shown is the overall structure of the integrated mine pumping and sprinkler vehicle according to the embodiment of the present invention, which includes: a car body 1, a water tank 2, a filter plate 5 and a pumping and sprinkler device. Wherein, the water tank 2 is installed on the car body 1, and the filter plate 5 is installed inside the water tank 2, figure 1 shows schematically the upper half of the filter plate 5, the entire filter plate 5 divides the internal space of the water tank 2 into a muddy water chamber and a clean water chamber, figure 1 The left side of the middle filter plate 5 is a muddy water chamber, and the right side is a clean water chamber. The water inlet 21 of the water tank 2 is located at the top of the muddy water chamber. The extraction unit is located under the solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com