Horizontal hydraulic secondary solid-liquid separator

A solid-liquid separator and hydraulic technology, used in presses, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high liquid solids, high maintenance costs, high processing costs, and achieve maintenance The effect of low cost, low equipment wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

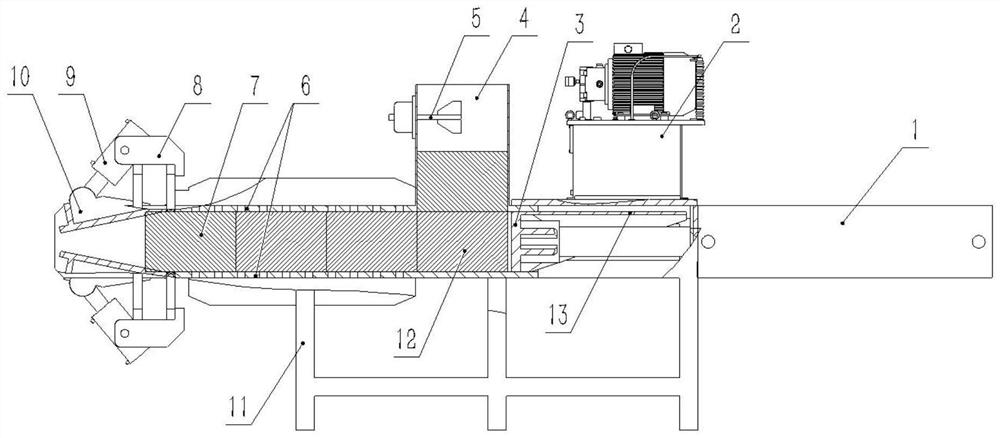

[0022] Specific implementation mode one: see figure 1 This embodiment will be described. The horizontal hydraulic secondary solid-liquid separator described in this embodiment includes a compression chamber 12, an upper hopper 4, a hydraulic device, a compression chamber filter plate 6 and an outlet adjustment device, and an upper hopper is installed above the compression chamber 12 4. A hydraulic device is installed at the rear, a compression chamber filter plate 6 is installed inside the compression chamber 12, and a discharge outlet adjustment device is installed at the front of the compression chamber 12.

[0023] The hydraulic device includes a main hydraulic cylinder 1 and a piston 3, and the main hydraulic cylinder 1 drives the piston 3 to expand and contract.

[0024] A material level sensor 5 is installed on the wall of the upper hopper 4 .

[0025] The outlet regulating device comprises two alligator mouth supports 8, two alligator mouth hydraulic cylinders 9 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com