Patents

Literature

60results about How to "Reduce solid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

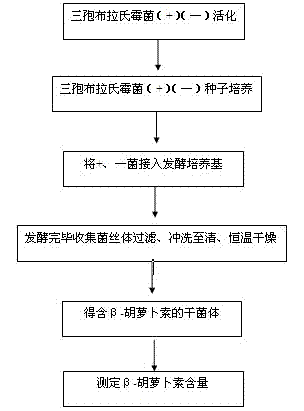

Method for preparing beta-carotene through fermentation of Blakeslea trispora

ActiveCN102757995ASignificantly progressiveSolid content reductionMicroorganism based processesFermentationBlakeslea trisporaBeta-Carotene

The invention discloses a method for preparing beta-carotene through fermentation of Blakeslea trispora. The method comprises the following steps of: after activating Blakeslea trispora ATCC14271 (+) and ATCC14272 (-), carrying out seed culture on the activated Blakeslea trispora; inoculating the Blakeslea trispora to a fermentation medium according to a certain inoculum concentration and inoculation ratio under an optimized fermentation process condition so as to ferment the Blakeslea trispora; and finally obtaining a mycelium with higher beta-carotene content. Through the adoption of the method disclosed by the invention, a natural high-quality beta-carotene product with low cost and high titer can be obtained.

Owner:HUBEI UNIV OF TECH

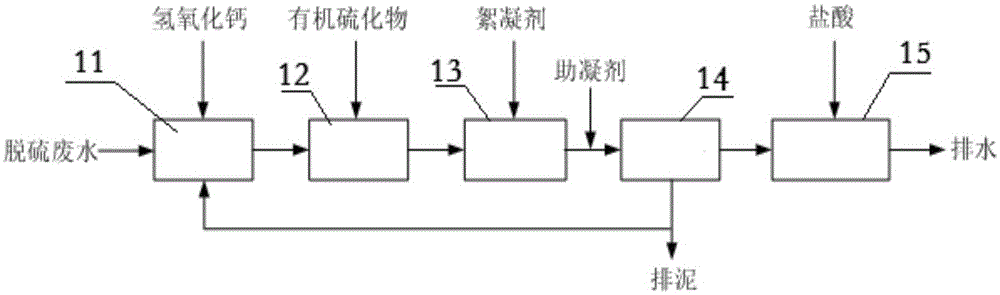

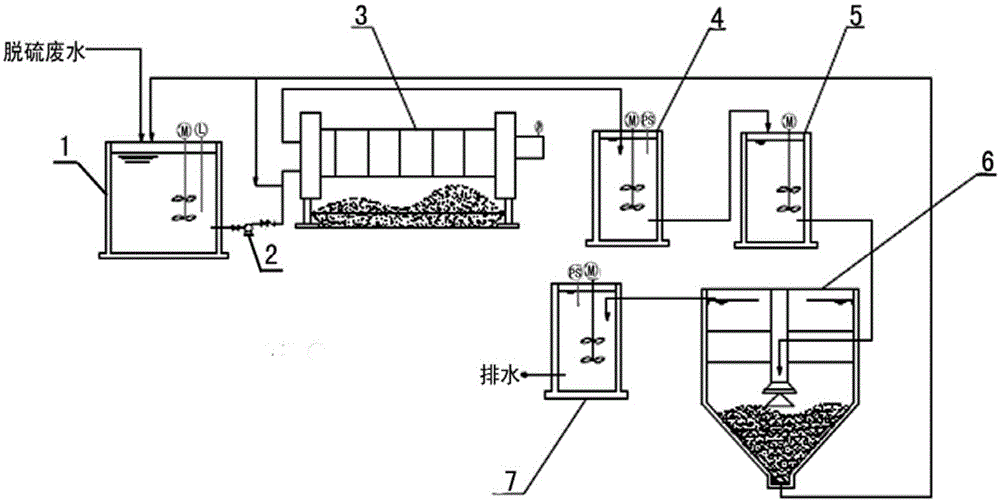

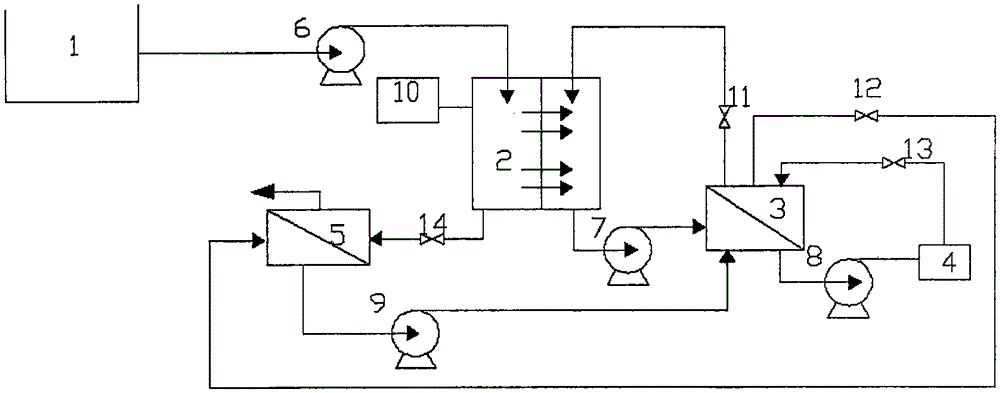

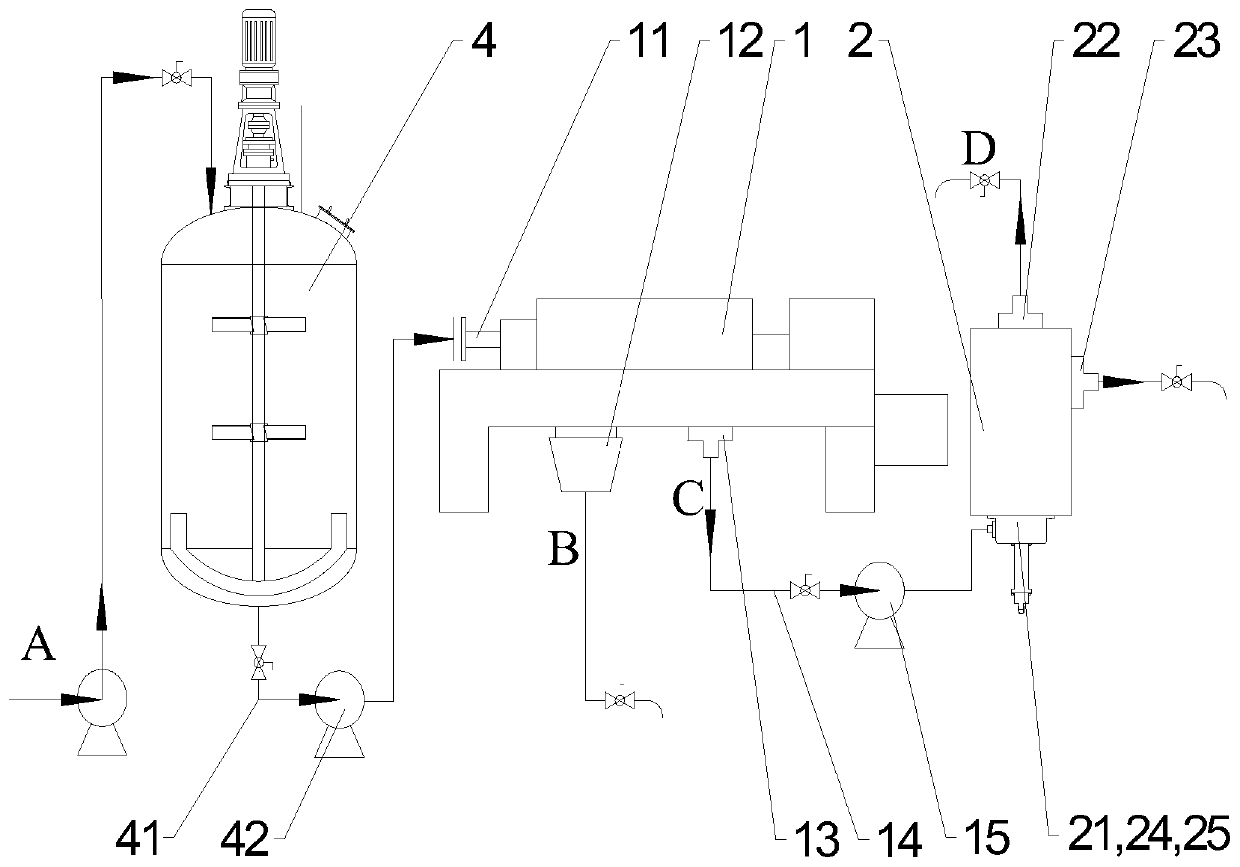

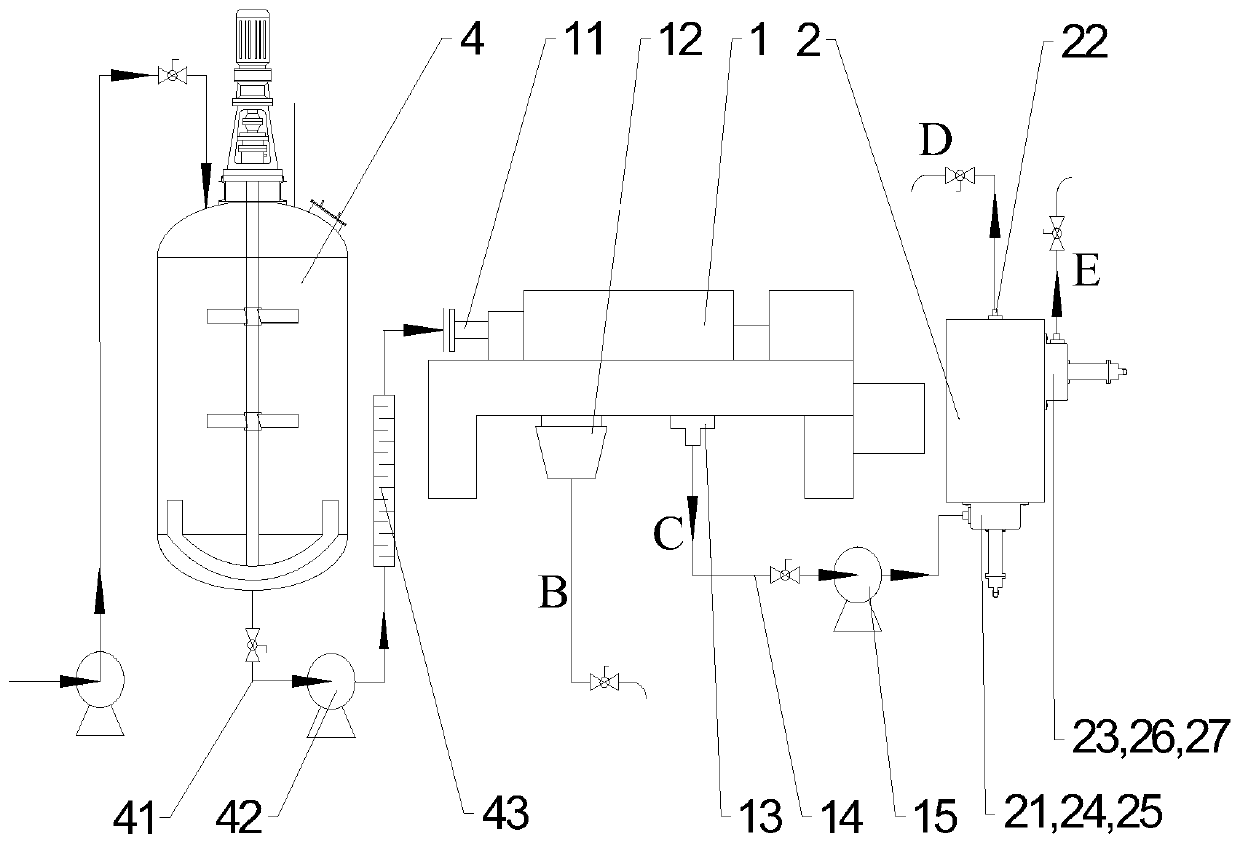

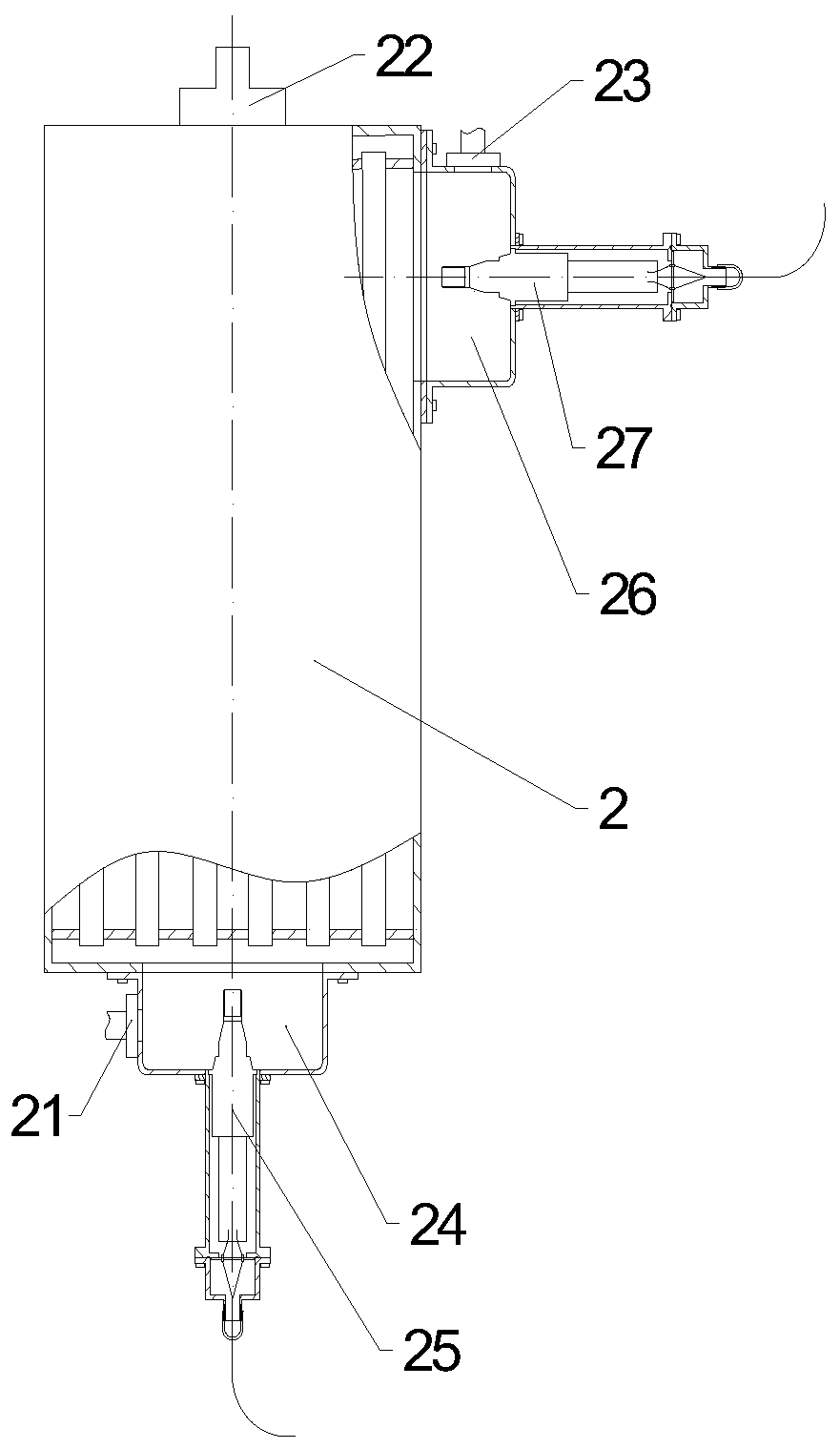

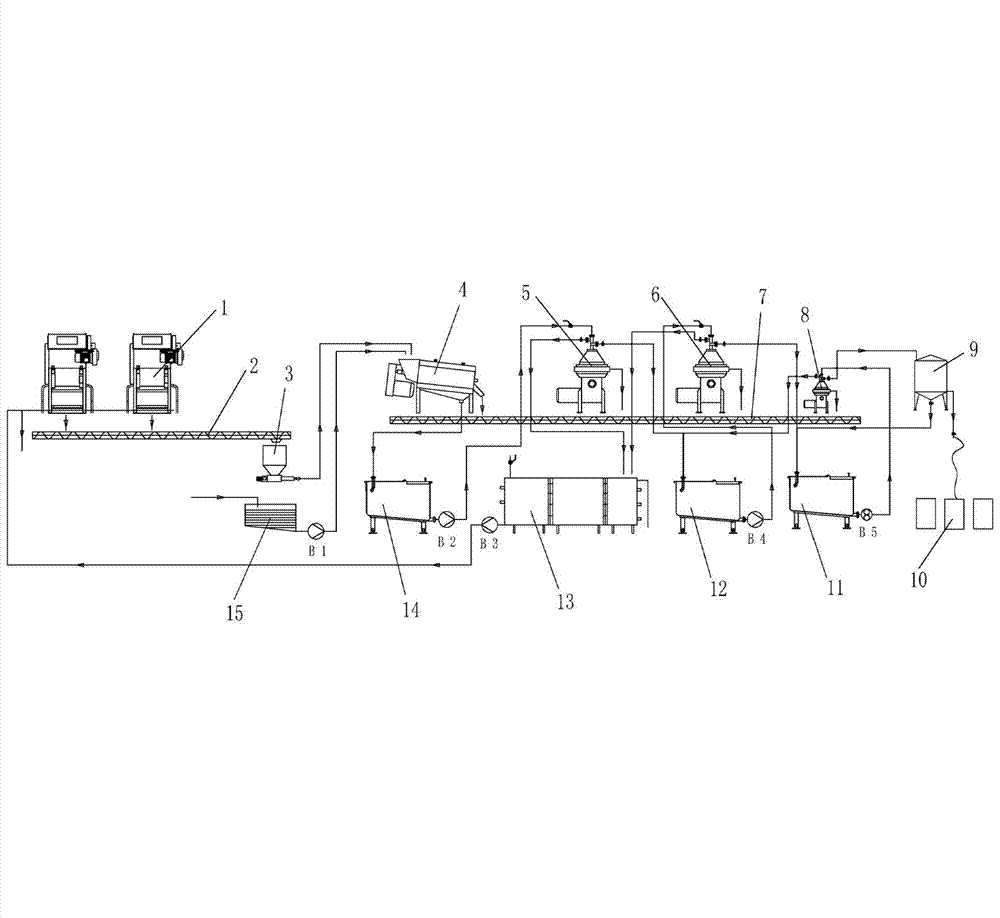

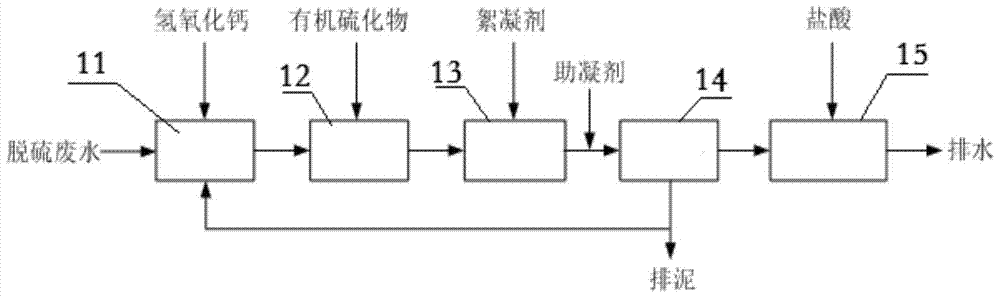

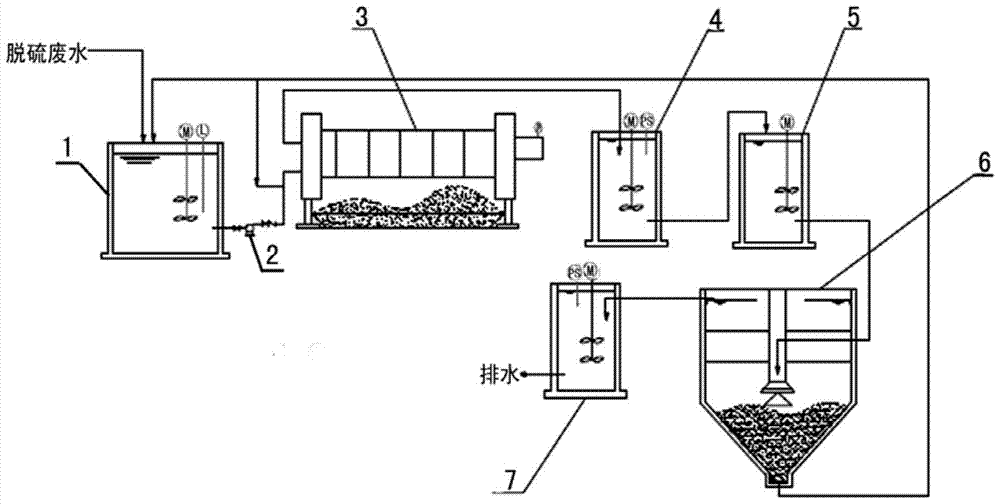

Desulfurization wastewater treatment system and desulfurization wastewater treatment method

ActiveCN105000713AReduce solid contentSolid load and failure rate reductionMultistage water/sewage treatmentFertilizerGypsum

The present invention discloses a desulfurization wastewater treatment system and a desulfurization wastewater treatment method. The desulfurization wastewater treatment system comprises: a wastewater buffer pool, wherein the water inlet is connected with the outlet of an apparatus for producing desulfurization wastewater; a sludge pressing device, wherein the input end and the water outlet of the wastewater buffer pool are connected; a multi-stage treatment pool, wherein the water inlet is connected with the water outlet of the sludge pressing device; a clarification pool, wherein the water inlet is connected with the water outlet of the multi-stage treatment pool; and a pH value re-adjusting box, wherein the water inlet is connected with the clear water outlet on the upper portion of the clarification pool. The invention further provides a wastewater treatment method adopting the system. According to the present invention, the wastewater treatment method is particularly suitable for pellet flue gas wet desulphurization wastewater, the process is simple, the solid content in the system is low, the operating cost is reduced while the desulfurization by-product gypsum and the slow-release fertilizer can be recycled, and the final effluent meets the national discharge standard.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

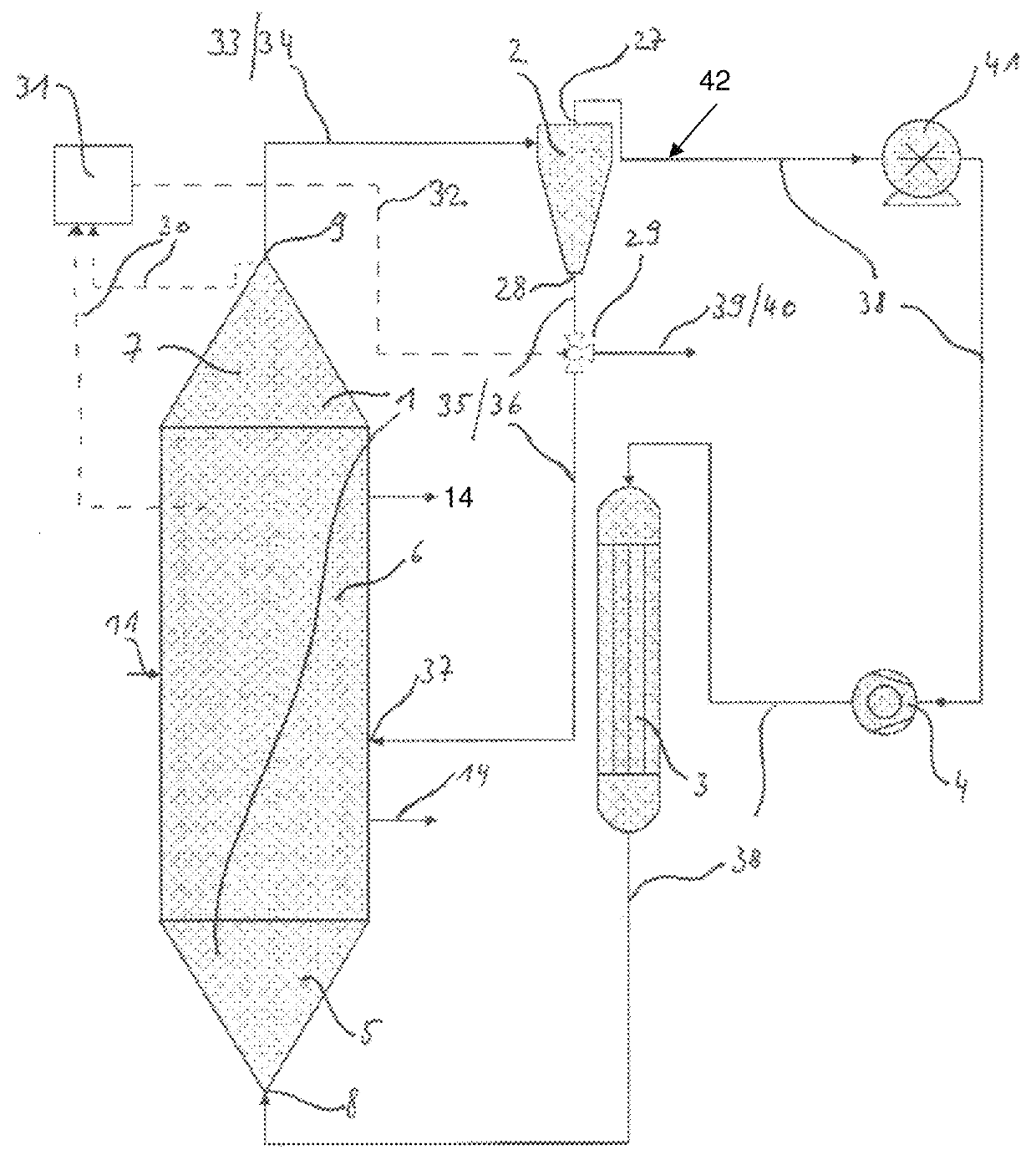

Reactor assembly and method for polymerization of olefins

ActiveUS9382359B2Great degree of separationLow amountChemical/physical/physico-chemical stationary reactorsFluidized bedOlefin polymerization

Reactor assembly for the production of polymers including a fluidized bed reactor and method for operating the reactor assembly.

Owner:BOREALIS AG

Method for achieving continuous pad-dry-cure dyeing of polyester

The invention discloses a method for achieving continuous pad-dry-cure dyeing of polyester. The method comprises the steps of padding of the polyester in a dyeing solution, drying, curing and water processing. The dyeing solution comprises liquid disperse dye, prepolymer A, prepolymer B, prepolymer C, a synthetic thickener and a penetrating agent. The method has the advantages that the dyeing uniformity is good, the dye is not prone to migration in the drying process, the relative fixation rate of the dye is high, the dyefastness is good, colored wastewater discharge almost does not exist, processing equipment is conventional equipment, and the method is a continuous dyeing processing technology achieving energy conservation and emission reduction.

Owner:SUZHOU UNIV

Sludge anaerobic digestion-high dryness dehydration method used for achieving adjustable high solid content based on double membrane system synchronous dehydration

ActiveCN105366898AReduce input requirementsImprove processing economySludge treatment by de-watering/drying/thickeningBiological sludge treatmentMembrane distillationDigestion

The invention discloses a sludge anaerobic digestion-high dryness dehydration method used for achieving adjustable high solid content based on double membrane system synchronous dehydration. A device of the sludge anaerobic digestion-high dryness dehydration method comprises a sludge anaerobic digestion reaction unit, a forward osmosis solid content adjusting unit, a membrane distillation draw solution concentrating unit, and a post-digestion high dryness dehydration unit. According to the sludge anaerobic digestion-high dryness dehydration method, the forward osmosis solid content adjusting unit is used for realizing sludge dehydration when sludge anaerobic digestion is carried out, so that solid content can be adjusted in sludge anaerobic digestion process, sludge anaerobic digestion process is promoted, problems that sludge water content is high and solid content is low, and digestion reactors is large in size and low in digestion efficiency are solved effectively, sludge volume is reduced, and at the same time sludge anaerobic digestion efficiency is increased. At the same time, forward osmosis high dryness dehydration technology is adopted, so that super low energy consumption quantitative reduction of sludge is realized finally. All the forward osmosis draw solution is concentrated and recycled using the membrane distillation draw solution concentrating unit, and full utilization of the temperature of anaerobic digestion solution is realized in the process.

Owner:BEIJING FORESTRY UNIVERSITY

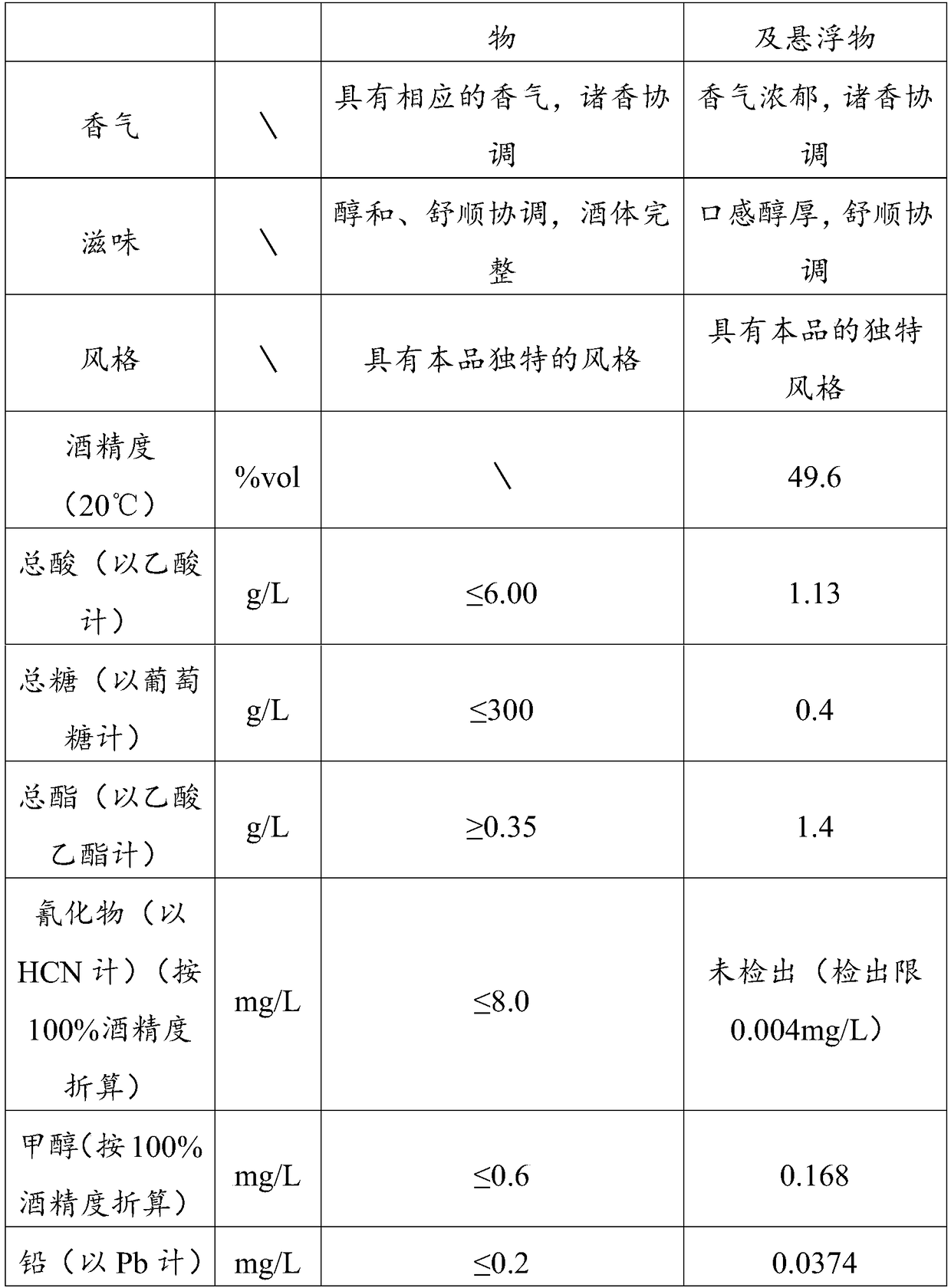

Processing method of birch juice brandy

InactiveCN105219597ALight aromaReduce solid contentAlcoholic beverage preparationBiotechnologyNutritive values

The invention relates to a processing method of birch juice brandy. The processing method is characterized by including: adding ginseng extract into birch juice brandy according to raw sun-cured ginseng weight of 3g / 500mL to enable final alcohol content of brandy to be 40%; using the ginseng extract as a blending raw material to be added into birch juice raw wine, freezing and concentrating birch juice, restoring the birch juice after being concentrated to normal temperature, adding sucrose, inoculating yeast for alcohol fermentation, and brewing birch juice raw wine through low-temperature fermentation. A low-temperature fermentation process is adopted, so that nutritional ingredients and aroma of the birch juice can be retained better; ginseng liquid can be used for blending, so that nutritional value of the birch juice brandy is increased, and taste of the birch juice brandy is improved.

Owner:JILIN AGRICULTURAL UNIV

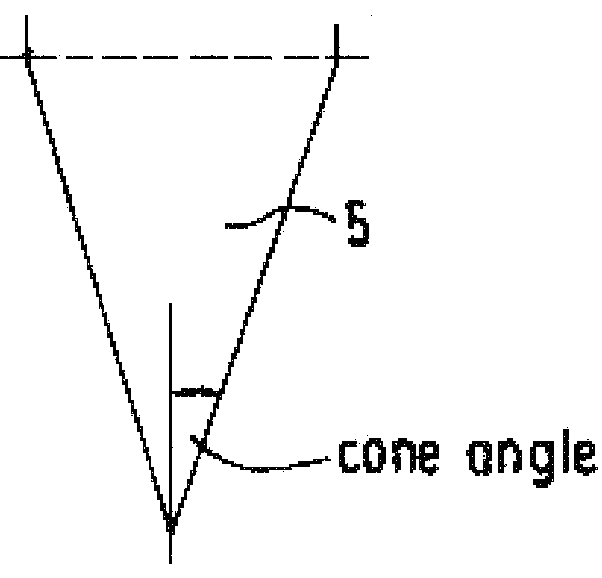

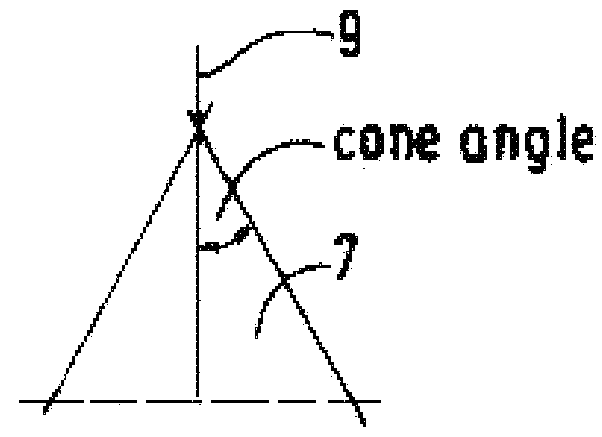

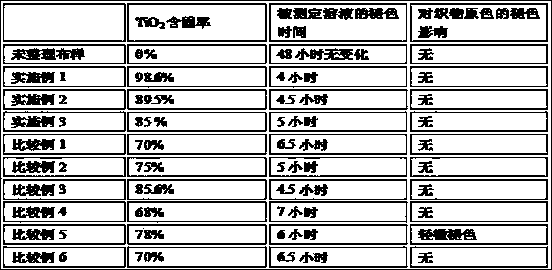

Method for consolidation of photocatalyst nano TiO2 hydrosol in fabric and photocatalyst fabric

ActiveCN105369594AImprove stabilityImprove final catalytic performanceSucessive textile treatmentsFibre treatmentNano tio2Engineering

The invention discloses a method for consolidation of photocatalyst nano TiO2 hydrosol in fabric and photocatalyst fabric. During production, the fabric walking speed is limited at 20-40m / min, the hydrosol temperature is maintained at 20-60DEG C, and the shaping and drying temperature is 160-180DEG C. The limitation purpose of the technological conditions is that the solid content of the finally produced photocatalyst fabric surface TiO2 hydrosol reaches more than 80% so as to improve the stability of the photocatalyst fabric product and the final catalytic properties of the photocatalyst.

Owner:JIANGSU TENGSHENG TEXTILE TECH GROUP

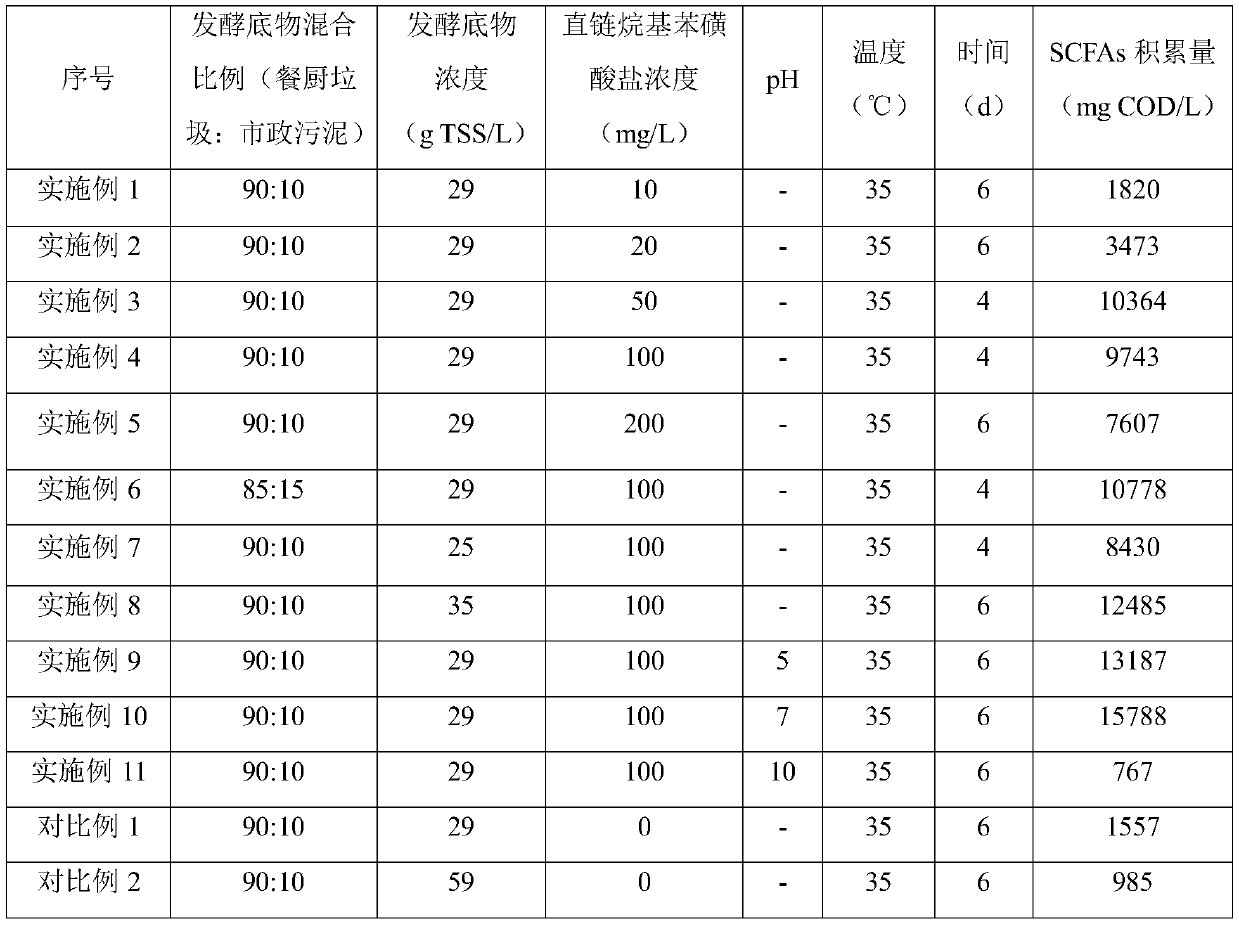

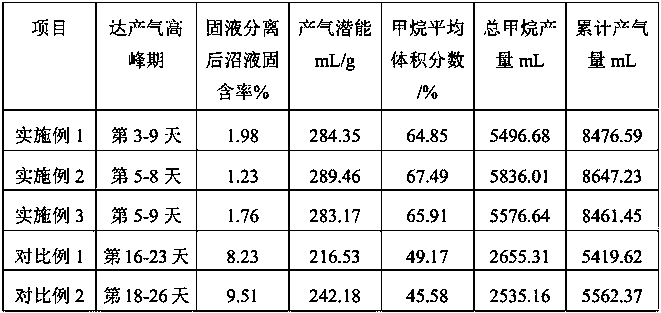

Method for improving resource utilization of kitchen waste

The invention discloses a method for improving the resource utilization of kitchen waste. The method comprises the following steps: (1) grinding and pulping kitchen waste to obtain an anaerobic fermentation substrate; (2) adding civil sludge into the substrate to serve as an inoculating microbe; (3) diluting the fermentation substrate with washing wastewater containing linear alkyl benzene sulfonates to obtain a fermentation system; and (4) performing oxygen removal and sealing on the fermentation system, and performing anaerobic fermentation. The method can improve the characteristics of kitchen waste by adding washing wastewater to realize resource utilization and recycling of the kitchen waste and the like and is favorable to reduction and harmless disposal of washing wastewater and kitchen waste; furthermore, relative to clean water, such as tap water, kitchen waste is diluted with washing wastewater, the solid content of the kitchen waste is reduced, and the treatment cost can bereduced; and the linear alkyl benzene sulfonates can be used for promoting dissolution of complex organic substances and increasing the generation rate and yield of short-chain fatty acids, the anaerobic fermentation time can be remarkably shortened, and the operation cost can be reduced.

Owner:HOHAI UNIV

Separation method of high-purity diosgenin

The invention discloses a separation method of high-purity diosgenin and belongs to the technical field of pharmaceutical raw material production. The method is characterized by comprising the steps as follows: adopting the ultrasonic assisted sodium lauryl sulfate extraction technology and utilizing the solubilization action of sodium lauryl sulfate to extract dioscin from dioscorea zingiberensis; adopting the flocculation technology to separate the dioscin from the extracting solution to obtain crude dioscin; obtaining crude diosgenin through hydrolyzation, filtration, water scrubbing, drying, reflux extraction and cooling crystallization of the crude dioscin; obtaining precision processed diosgenin through batch splitting precision processing of the crude diosgenin in warm water. The separation method has the benefits that the precision processing of the method overcomes the deficiency of difficulty in diosgenin separation and purification, and the degree of purity of the precision processed diosgenin is above 98.5%.

Owner:BAIHE YONGHONG CHEM CO LTD

Method for improving efficiency of anaerobic digestion of wastewater sludge

InactiveCN104261644AReduce solid contentImprove degradation rateSpecific water treatment objectivesBiological sludge treatmentAerobic digestionOrganic matter

The invention discloses a method for improving the efficiency of anaerobic digestion of wastewater sludge. The method comprises the following steps: (1) raw sludge generated by wastewater treatment and circulating sludge of an anaerobic digester are mixed, are heated by a heat exchanger, and enter a sludge anaerobic digester; the sludge is digested in the sludge anaerobic digester and constantly stirred in the digestive treatment process; (2) in the process of digestive treatment in the sludge anaerobic digester, the sludge enters an electrolytic cell from the lower part of the sludge anaerobic digester through an electrolytic metering pump to carry out closed electrolytic treatment, and the sludge entering the electrolytic cell every time is not larger than 10 percent of volume of the sludge anaerobic digester; (3) the electrolyzed sludge used as the circulating sludge of the anaerobic digester repeats the processes of the step (1) and the step (2) with the raw sludge, and the circulation is repeatedly carried out. The method has the advantages that compared with the digested sludge not to be electrolyzed, the solid content of the electrolyzed digested sludge is reduced by more than 30 percent, more than 30 percent of sludge quantity is reduced, and the degradation rate of organic matters anaerobically digested by sludge is increased by more than 40 percent.

Owner:黎荣

A kind of method of continuous heat-melt dyeing of polyester

The invention discloses a method for continuous heat-melt dyeing of polyester, which comprises the steps of padding the polyester with a dyeing solution, drying, baking and washing with water. The dyeing solution includes liquid disperse dye, prepolymer A, prepolymer B, prepolymer C, synthetic thickener and penetrant. The advantage of this method is that the uniformity of dyeing is good, the dye does not migrate during drying, the relative fixation rate of the dye is high, the color fastness is excellent, and there is almost no discharge of colored wastewater, and the processing equipment is all conventional equipment. Continuous dyeing processing technology for energy saving and emission reduction.

Owner:SUZHOU UNIV

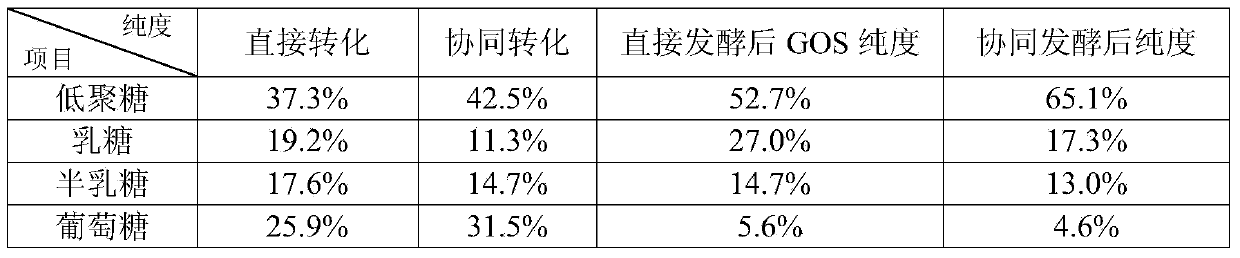

Method for preparing high-purity galactooligosaccharide through synergy of enzymes

ActiveCN103993054AHigh purityImprove toleranceMicroorganism based processesFermentationIon exchangeLiquid glucose

The invention relates to a method for preparing high-purity galactooligosaccharide through synergy of enzymes. The method comprises the steps of adding water into lactose, heating up for dissolving, and regulating the pH value to be 4.5-7.0; adding beta-galactosidase A and beta-glucosidase B into the lactose solution, converting for 10-30 minutes at 50-70 DEG C firstly, then keeping for 4-24 hours at 35-55 DEG C; deactivating the enzyme, cooling down to room temperature, adding highly-hypertonic resisting brewer yeast into the liquid glucose with the enzyme deactivated, and reacting for 12-24 hours at 35 DEG C; and decoloring the product, performing ion exchange, concentrating, spray drying so as to obtain the high-purity galactooligosaccharide. According to the method, two enzymes are simultaneously used to produce the galactooligosaccharide, so that the purity of the galactooligosaccharide is high, the content of the galactooligosaccharide is significantly improved, and the content of lactose is lowered.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

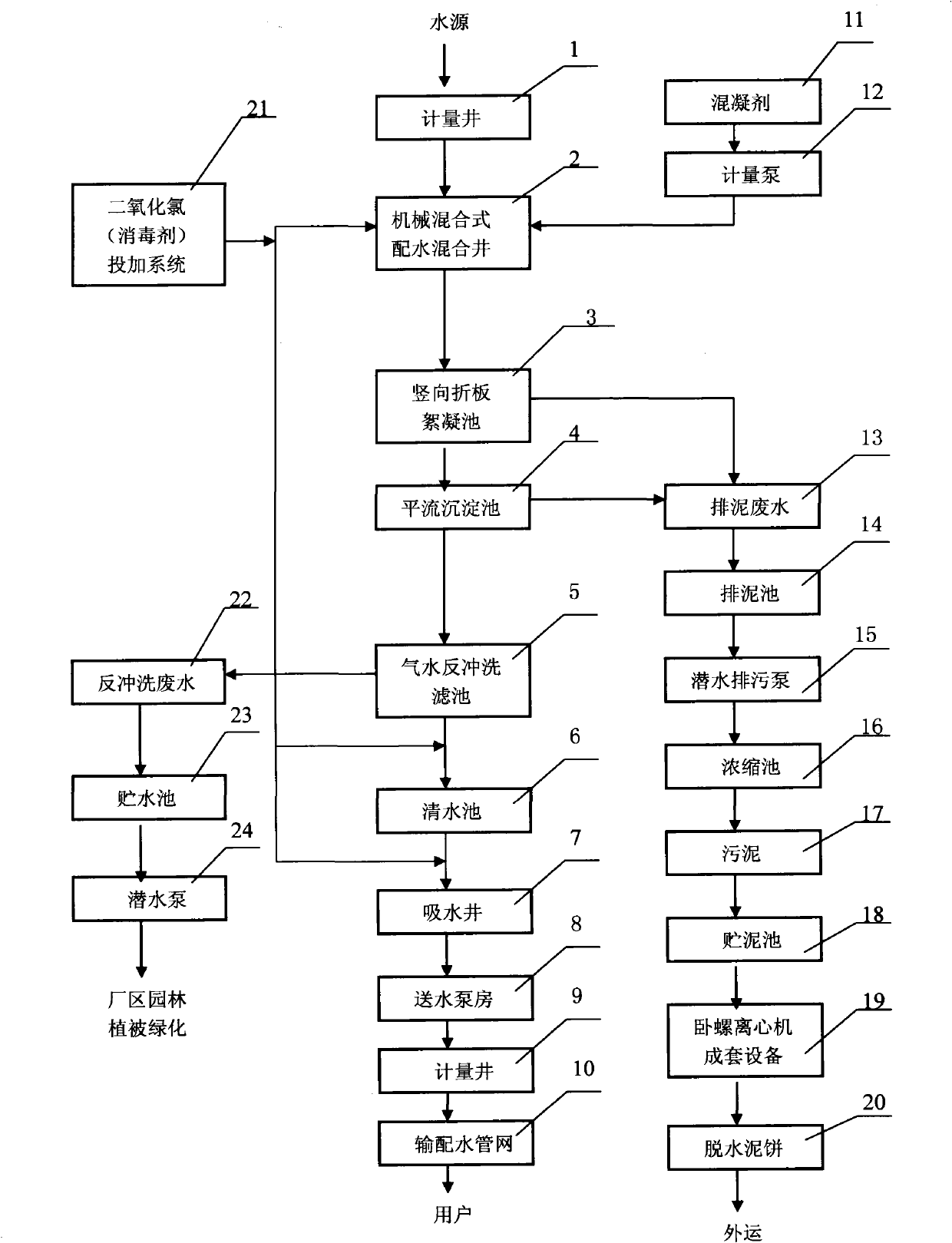

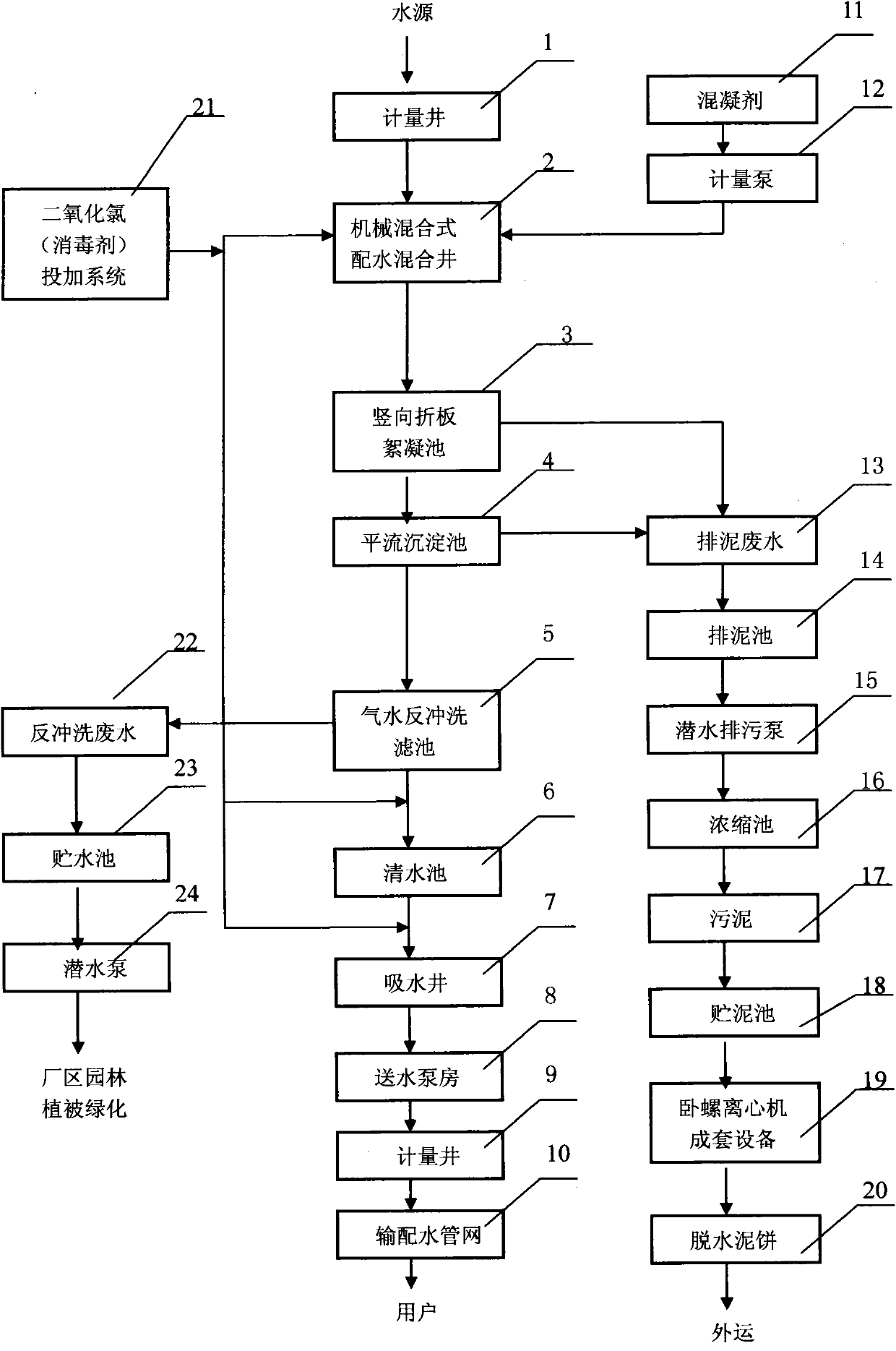

Low-carbon, environment-friendly, economical and reasonable water treatment process flow and method for water treatment plant

InactiveCN102167456AReduce volumeIncrease solid contentSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWastewaterWater resources

The invention discloses a low-carbon, environment-friendly, economical and reasonable water treatment process flow and method for a water treatment plant, and belongs to the fields of water resource reasonable utilization technology and environmental protection. The water treatment process flow and method comprises the following steps of: adding a coagulant; adding a disinfectant; purifying water; and utilizing and treating wastewater. The invention has the advantages that: problems of the conventional process are solved; and the water treatment process and method for the water treatment plant is low-carbon, environment-friendly, economical, reasonable, stable and reliable in operation and convenient to manage and maintain, ensures water treatment effect to reduce project investment and daily operating cost.

Owner:姚家泰

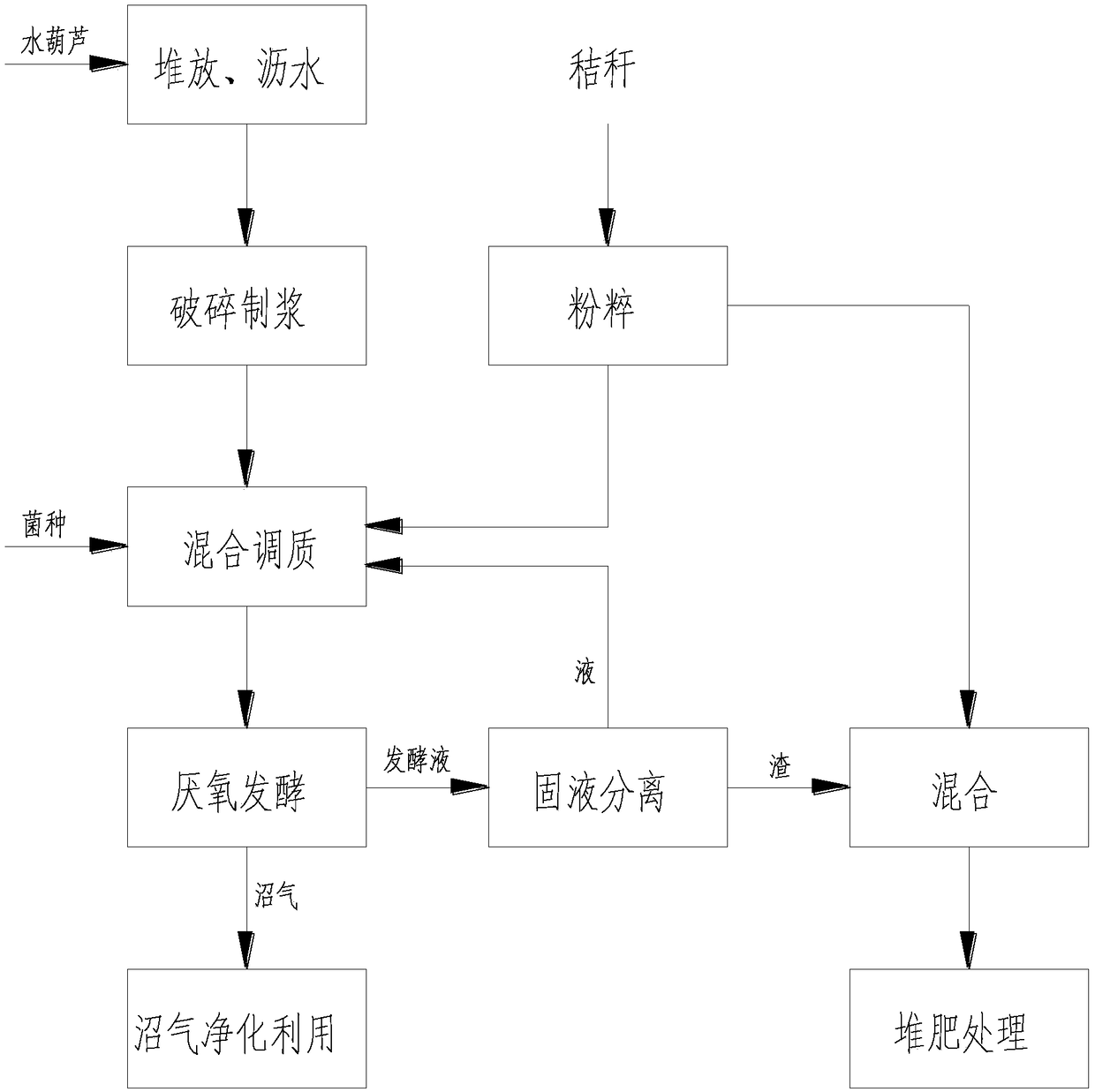

Method for resourceful treatment and use of water hyacinth

PendingCN109022531AEasy to handleAddressing Ecological ViolationsBio-organic fraction processingMicroorganism based processesResource utilizationSlurry

The invention belongs to the technical field of ecological protection and waste treatment and utilization and discloses a method for resourceful treatment and use of water hyacinth. The method comprises: pretreatment: stacking water hyacinth, draining the water hyacinth, breaking the water hyacinth, carrying out beating pulping through a pulping device to obtain water hyacinth slurry and crushingstraws to obtain straw powder, mixing conditioning: mixing the water hyacinth slurry and the straw powder, adding a strain and fermented biogas slurry into the mixture and carrying out conditioning toobtain a conditioned mixture, anaerobic fermentation: carrying out anaerobic fermentation on the conditioned mixture to obtain biogas and fermentation broth, biogas use: purifying and using the biogas, solid-liquid separation: carrying out solid-liquid separation on the fermentation broth to obtain biogas residues and biogas slurry for mixing conditioning, and composting treatment: mixing the biogas residues and the straw powder and carrying out composting treatment. The invention provides the high-efficiency method for resourceful treatment and use of water hyacinth. The method has a high resource utilization rate, produces rich varieties of products and has no secondary pollution.

Owner:中钢集团天澄环保科技股份有限公司

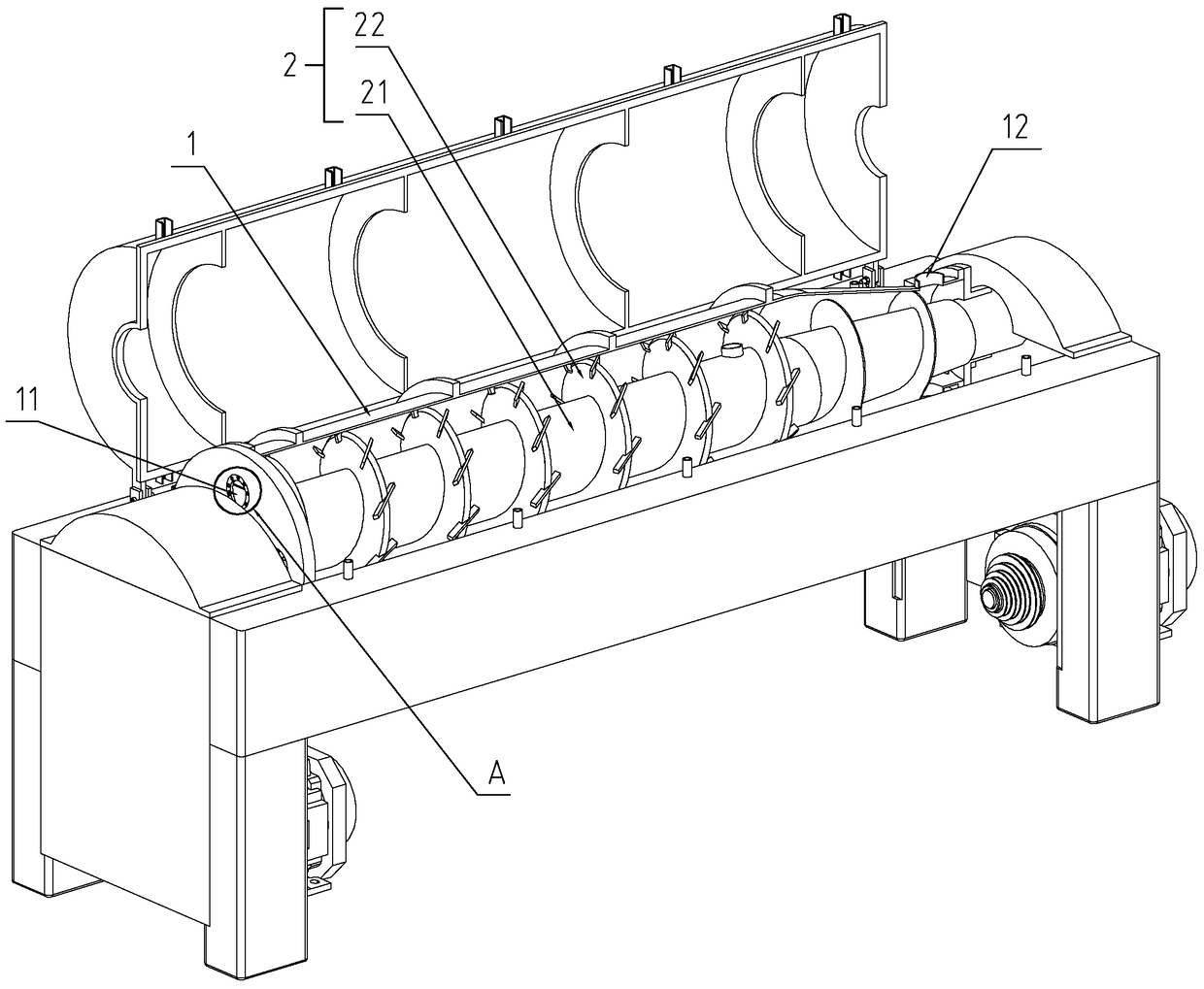

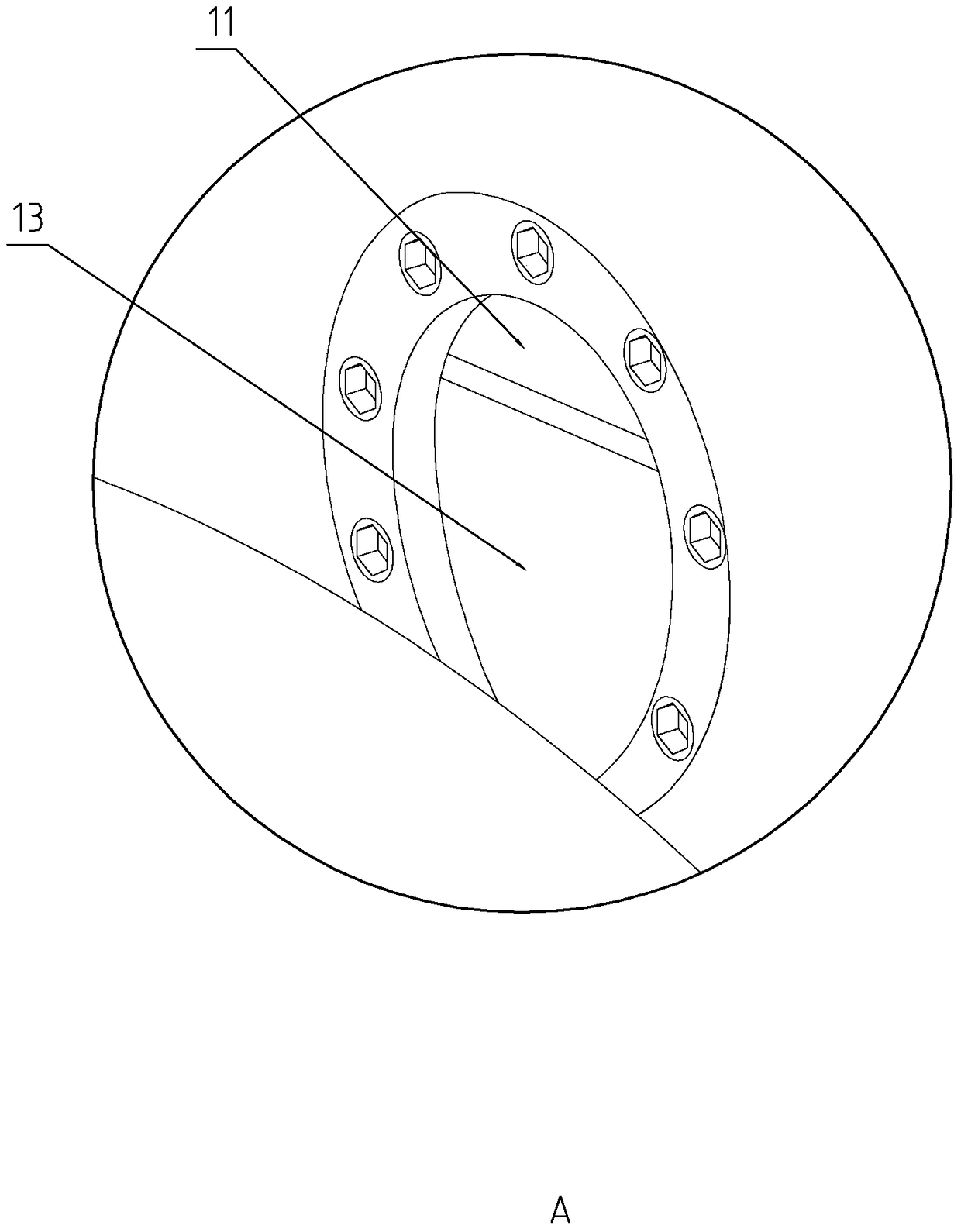

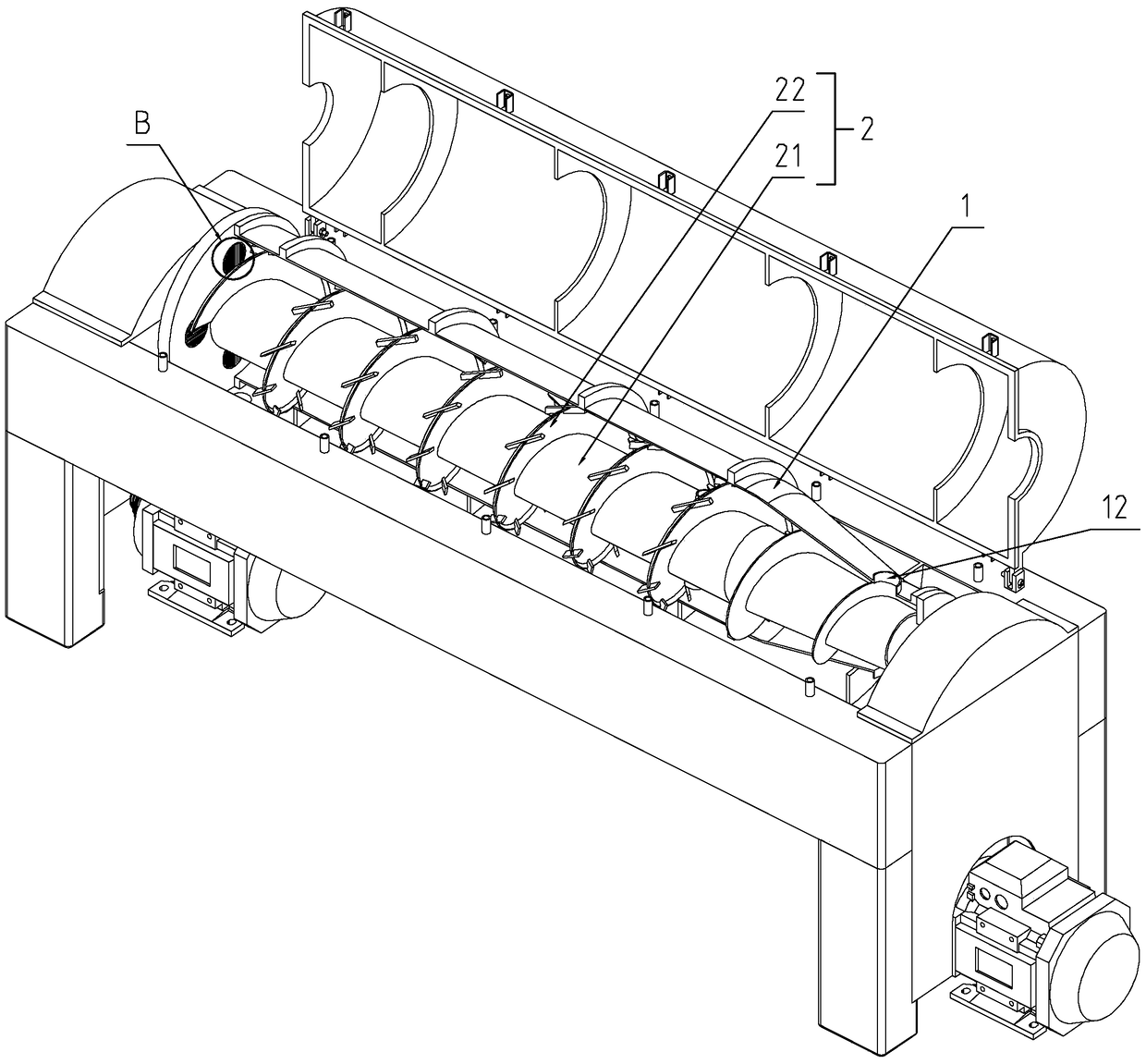

Horizontal screw discharge sedimentation centrifuge

ActiveCN106694241BLarge amount of processingReduced sediment effectRotary centrifugesEngineeringMechanical engineering

The invention discloses a horizontal screw-discharge sedimentation centrifuge. The technical scheme is characterized in that the horizontal screw-discharge sedimentation centrifuge comprises a rotary drum and a screw pusher, wherein the screw pusher comprises a mandrel and a push sheet; the mandrel is provided with a charge hole; the rotary drum is provided with a liquid outlet port and a residue outlet port; the liquid outlet port is provided with an overflow plate; a screw conveying sheet used for discharging a suspension is arranged on the inner wall of the charge hole in a winding manner; the liquid outlet port comprises filter holes which are uniformly and closely distributed in the end part of the rotary drum; and a scraping blade increasing a contact area with the inner wall of the rotary drum is arranged on the push sheet. According to the horizontal screw-discharge sedimentation centrifuge disclosed by the invention, the suspension is uniformly pushed into the rotary drum through the screw conveying sheet, and therefore the weakening of a residue sedimentation effect due to the increasing of the treatment capacity of the centrifuge can be avoided; in addition, filtering for a clear liquid is improved through the liquid outlet port formed by the filter holes, and therefore, the probability of particle discharge is lowered; and then the contact area between the push sheet and the inner wall of the rotary drum is increased through the scraping blade, the push effect of solid-phase particles is improved, and in addition, the scraping blade also extrudes the solid-phase particles during a push process and is further beneficial to lowering the water content of a mud cake.

Owner:SUZHOU RUIWEI CENTRIFUGAL SEPARATION TECH

Technology method for high-efficiency anaerobic fermentation production of biogas by lignocellulose-rich materials

InactiveCN108866110ASolve efficiency problemsSolve concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseOxygen

The invention belongs to the technical field of a biogas preparation method, and provides a technology method for high-efficiency anaerobic fermentation production of biogas by lignocellulose-rich materials. The technology method comprises the following steps of material pulping, biological treatment, facultative hydrolyzing and acid production, anaerobic fermenting, solid and liquid separating, refluxing and the like. The technology method solves the problems of low pretreatment efficiency of the lignocellulose-rich materials, overhigh concentration of reflux biogas, and low biogas productionefficiency in the prior art.

Owner:河北京安瑞能环境科技有限公司

Method for refining tea seed soil

InactiveCN107686772ASolid content reductionQuality improvementFatty-oils/fats refiningSalting outEvaporation

The invention discloses a method for refining tea seed soil, and relates to the technical field of vegetable oil refining. The method comprises the steps of heating a crude product of the tea seed soil, then mixing the heated tea seed soil with an inorganic acid solution, carrying out centrifugal separation, evaporation, alkali refining and salting-out, and filtering. According to the method, thesolid content of the tea seed soil is reduced by means of the step of salting-out; in a refining process, a ceramic membrane filter is used for filtering, so that colloid, pigment and other impuritiesare removed. The refining method provided by the invention does not involve the steps of high temperature treatment, thus avoiding the damage of high temperature to the nutrients in tea seed oil andimproving the quality of the refined tea seed oil. After the method is adopted, the refined tea seed oil is light in color.

Owner:三江县善茶轩工艺品有限公司

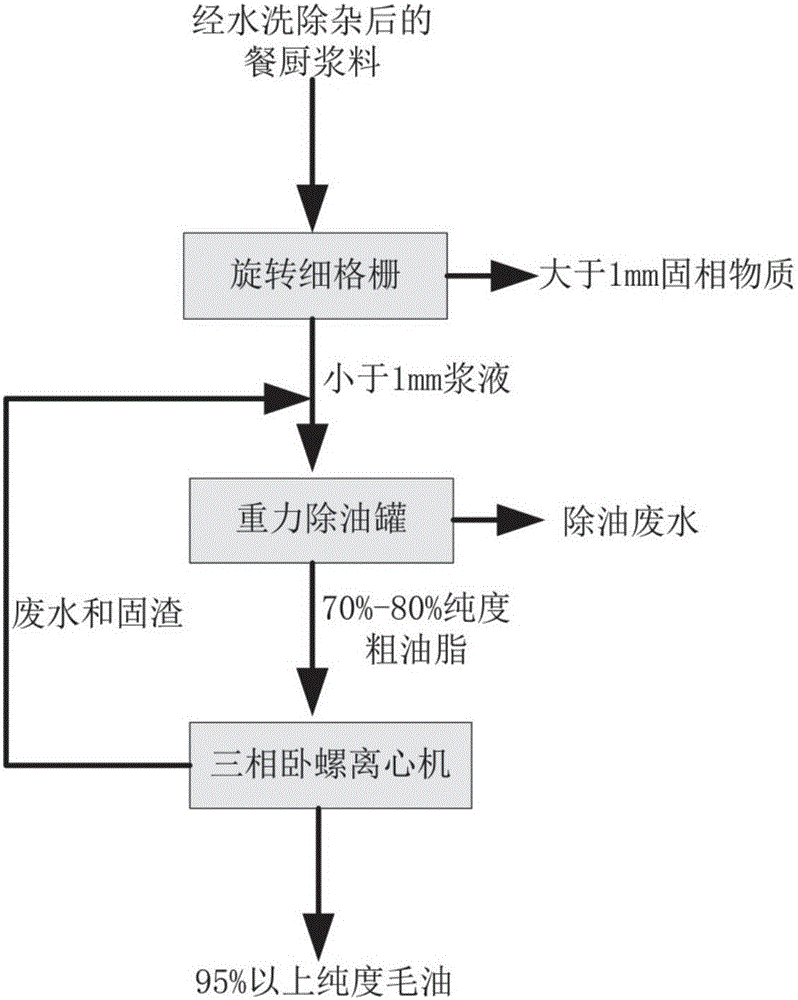

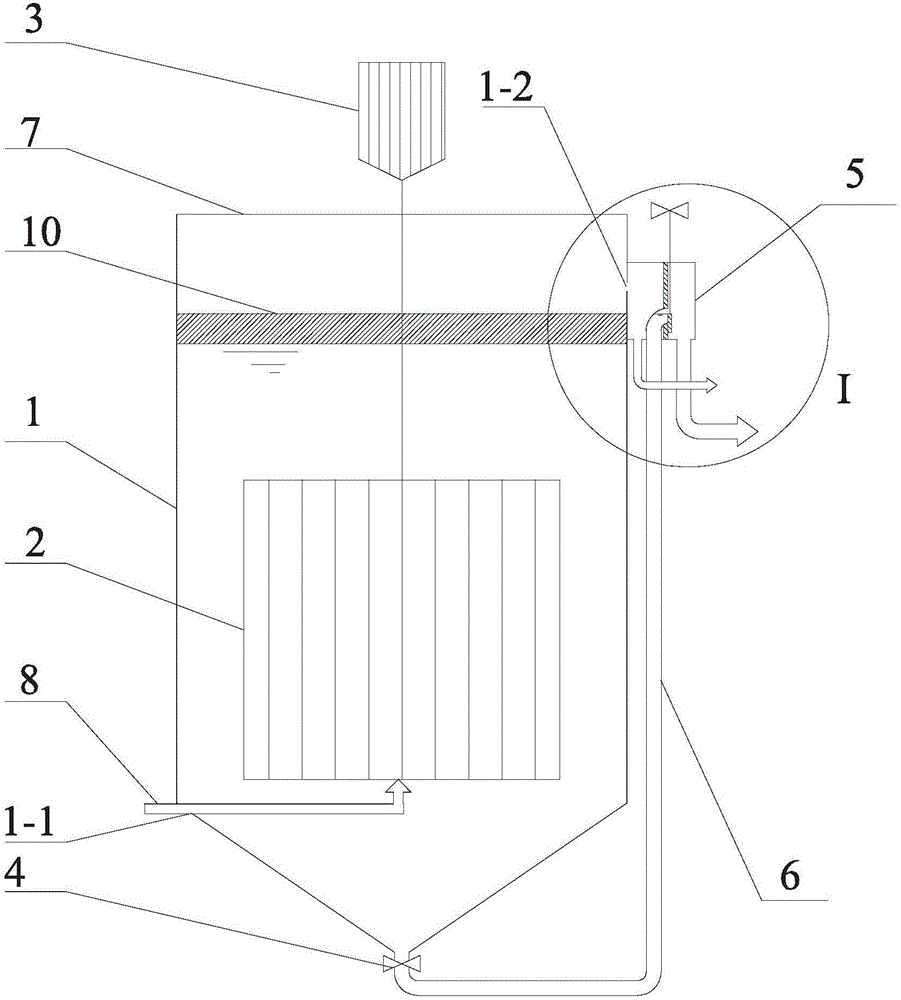

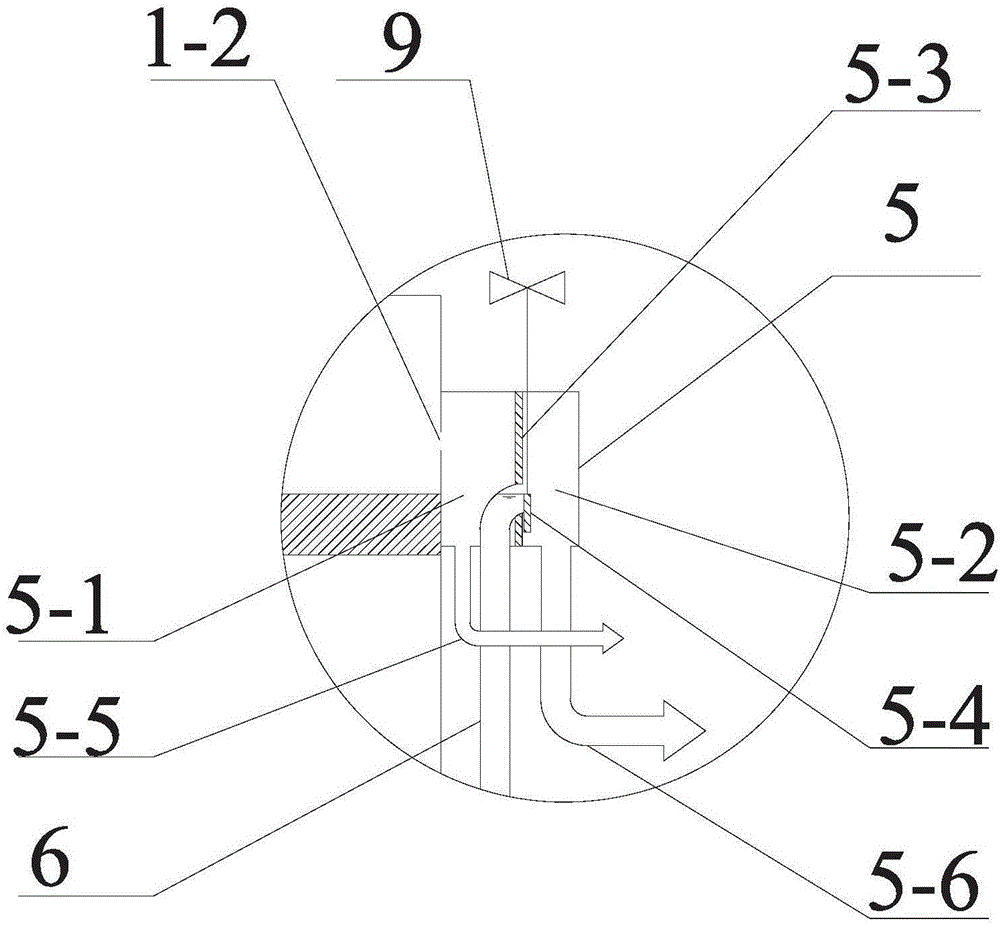

Kitchen waste oil removing method

InactiveCN105936555AReduce solid contentReduce steamFatty/oily/floating substances removal devicesTreatment involving filtrationOil and greaseSlurry

The invention discloses a kitchen waste oil removing method. The kitchen waste oil removing method comprises the following steps that 1, kitchen waste is uniformly delivered to a rotary drum screen through a shaft-free helix and is washed with circulating water of 45-50 DEG C to obtain kitchen slurry without large impurities; 2, the kitchen slurry is subjected solid-liquid separation through a rotary fine grille and then is separated into solid-phase substance greater than 1 mm and kitchen slurry oil-water mixed liquid smaller than 1 mm; 3, the kitchen slurry oil-water mixed liquid is fed into a gravitational oil removing tank through an oil-water mixture inlet to separate crude oil; 4, the crude oil separated from the gravitational oil removing tank is fed into a three-phase horizontal screw decanter centrifuge through a pump for further purification and separation, and separated solid residues and waste water flow back to the gravitational oil removing tank. The kitchen waste oil removing method can achieve oil separation and recovery of kitchen waste.

Owner:SUZHOU CLEAR IND CO LTD

Pig spleen transfer factor extracting method

ActiveCN103724420AShorten the production cycleSolid content reductionPeptide preparation methodsCytokines/lymphokines/interferonsHigh pressureFiltration technique

The invention provides a pig spleen transfer extracting method. The method has the characteristics that a high-pressure homogenizing machine is used for rapidly breaking spleen tissues and cells, a freezing step is not needed, and the production period can be more effectively shortened; the effective solid-liquid separation process is introduced after the homogenizing and before the filtering to demulsify the material and discharge gas in the material, so that the centrifugal difficulty is alleviated; the clear liquid supernatant is obtained through a centrifuging manner; the content of solids of the liquid filtered by a membrane can be obviously reduced, and the filtering rate and the service life of the membrane are increased; matched with the membrane filtering technology, the production period of the stock solution can be obviously shortened, convenience in operation is realized, the automation degree is high, and the large-scale production requirement can be met.

Owner:TIANJIN RINGPU BIO TECH

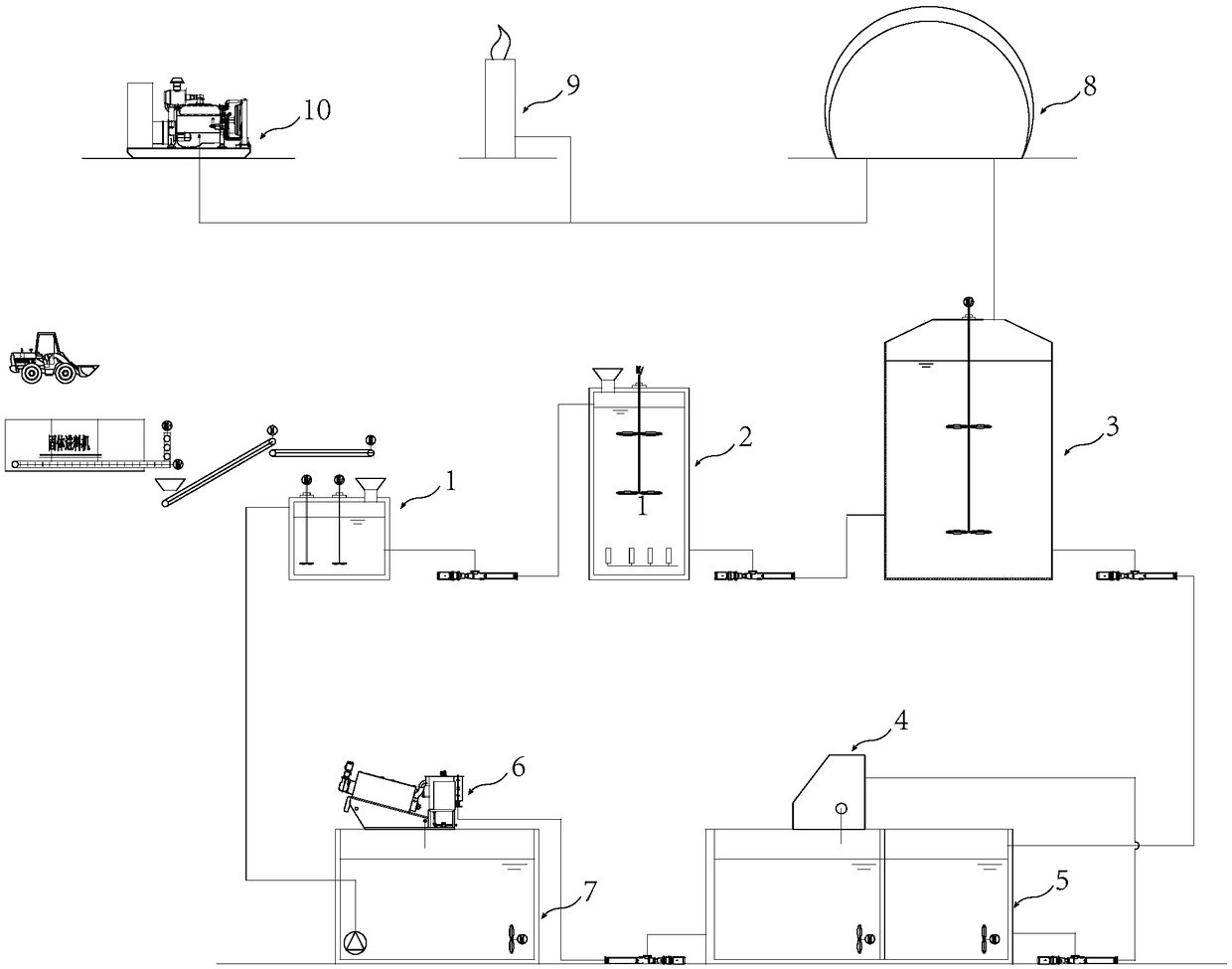

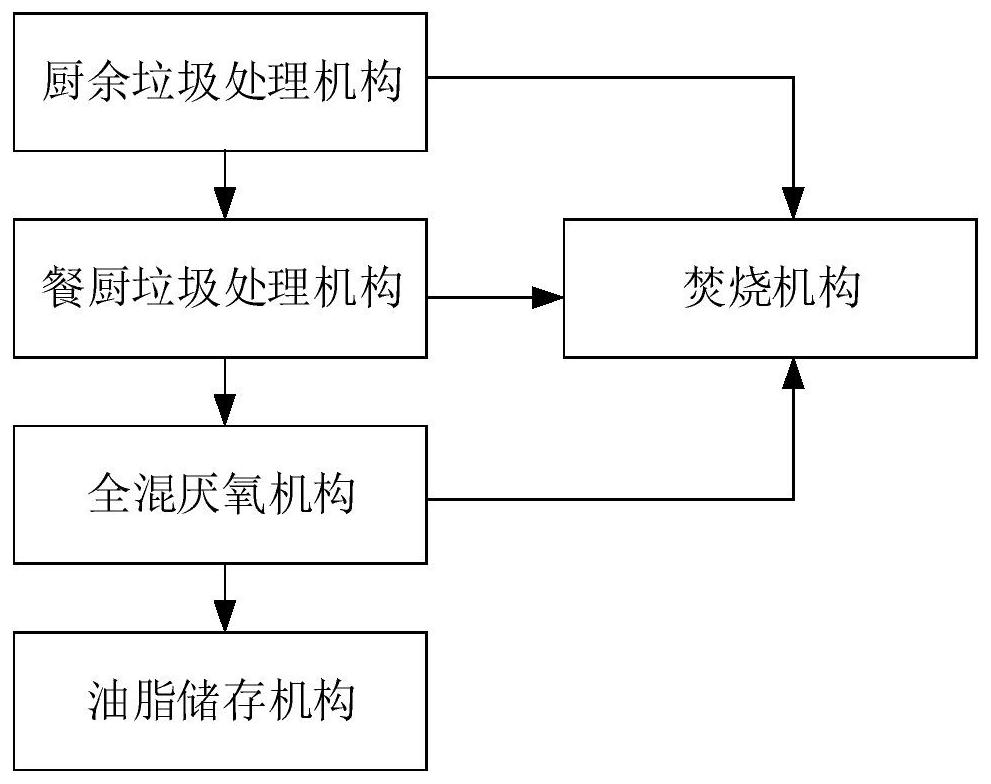

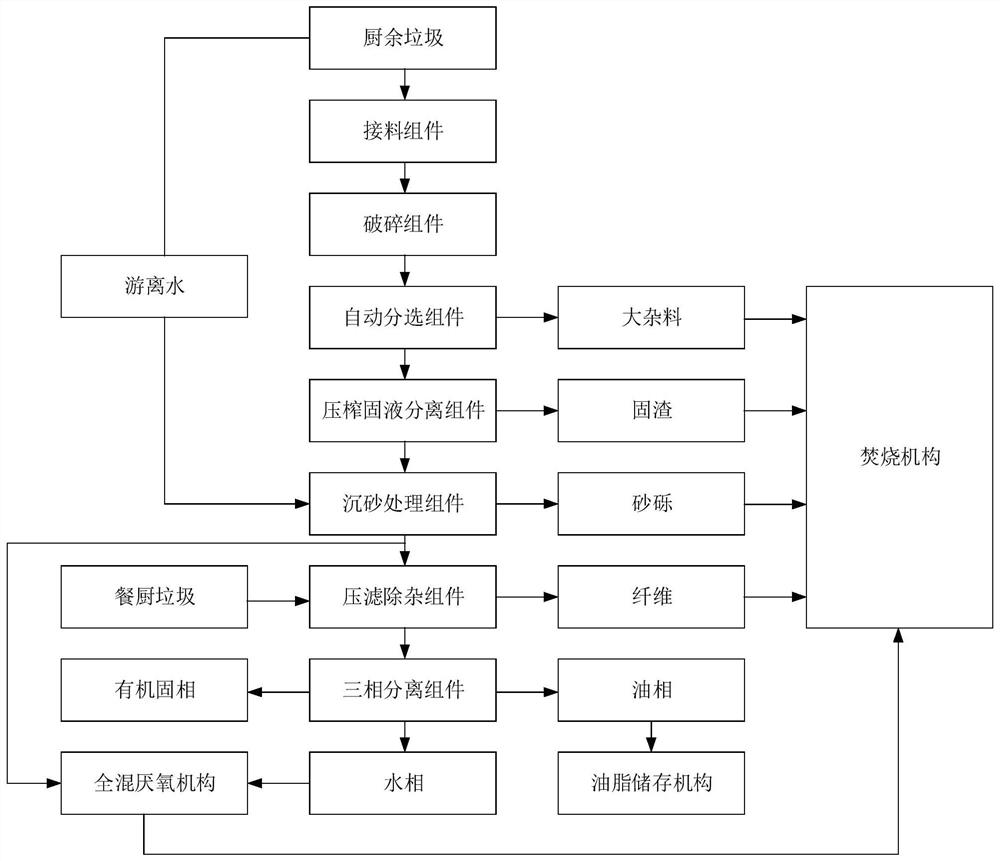

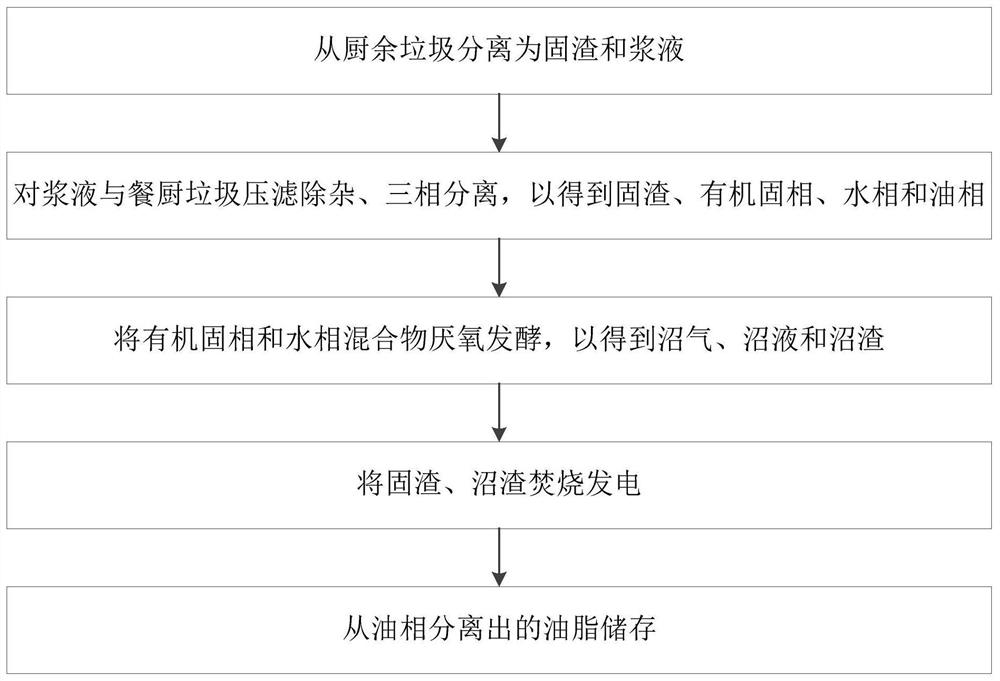

Food residue and kitchen waste co-processing system and co-processing method

PendingCN112191672AImprove stabilityReduce solid contentSolid waste disposalWaste processingProcess engineering

The invention particularly relates to a food residue and kitchen waste co-processing system and co-processing method. The food residue and kitchen waste co-processing system comprises a food residue processing mechanism, a kitchen waste processing mechanism, a full-mixing anaerobic mechanism, an incineration mechanism and a grease storage mechanism, wherein the kitchen waste processing mechanism is suitable for carrying out pressure filtration and impurity removal and three-phase separation on slurry produced by the kitchen waste processing mechanism and the food residue processing mechanism so as to obtain solid residue, an organic solid phase, a water phase and an oil phase; the full-mixing anaerobic mechanism is suitable for anaerobic fermentation to obtain biogas, biogas slurry and biogas residue; the grease storage mechanism is suitable for storing grease; and manual sorting is replaced with an efficient and stable automatic sorting assembly, manpower is saved, safety and environmental protection are achieved, the number of food residue processing mechanisms is reduced under the treatment condition of the kitchen waste processing mechanism, the equipment utilization rate is increased, three-treatment of food residue is further deepened, the oil extraction procedure is added, and grease in the food residue is effectively extracted.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION CHINA +2

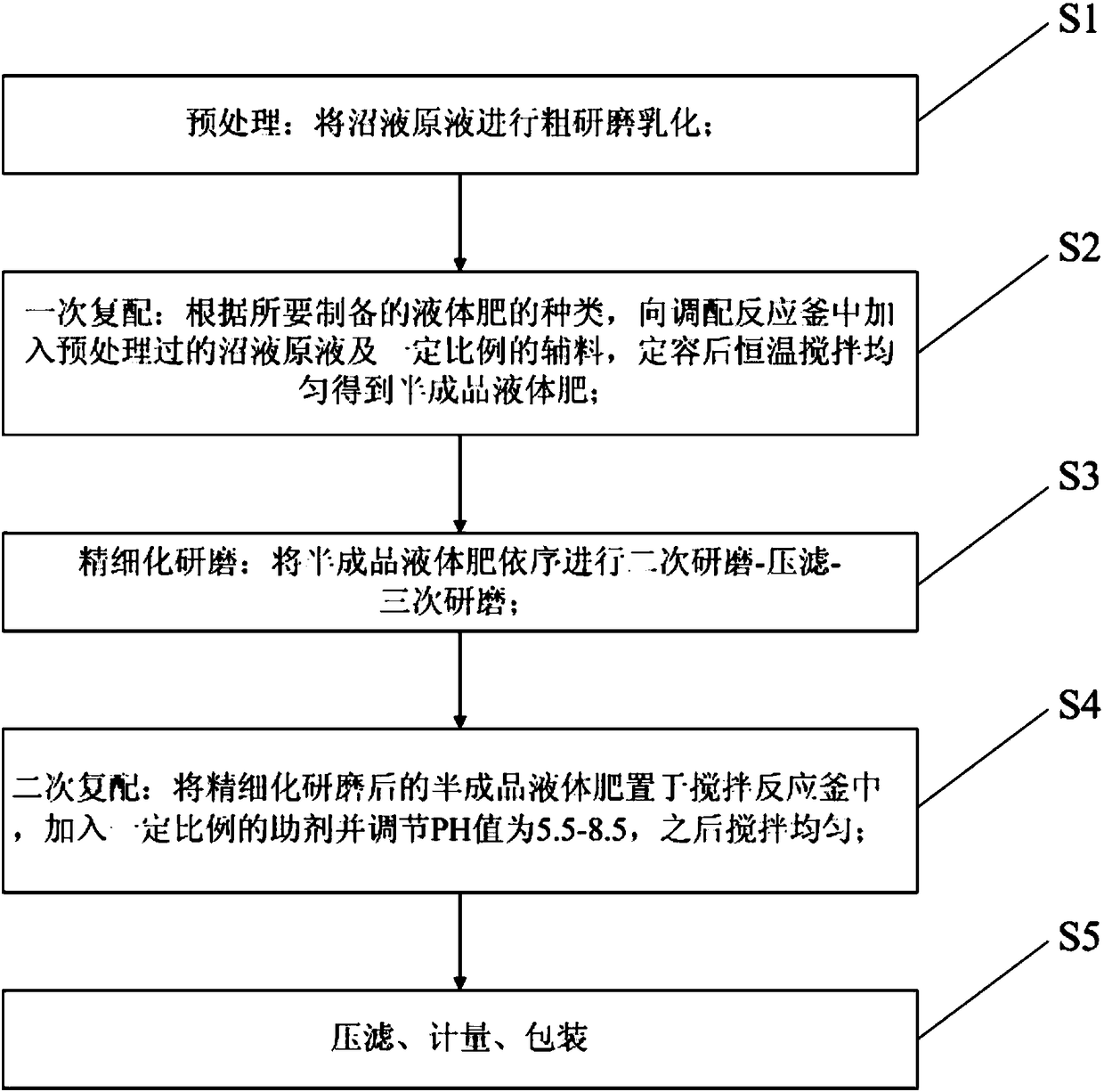

Method for production of liquid fertilizer from biogas slurry

InactiveCN108314536AMaintain macromolecular organic nutrientsHigh organic contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersWork in processPulp and paper industry

The invention provides a method for production of a liquid fertilizer from biogas slurry. The method includes: pretreatment: subjecting stock biogas slurry to rough grinding and emulsification; primary compounding: according to the variety of the to-be-prepared liquid fertilizer, adding the pretreated stock biogas slurry into a blending reaction kettle and performing stirring, adding an auxiliarymaterial of certain ratio to a constant volume, then conducting constant temperature stirring emulsification to obtain a semi-finished product liquid fertilizer; fine grinding: carrying out secondarygrinding, filter pressing and third grinding on the semi-finished product liquid fertilizer in order; secondary compounding: putting the semi-finished product liquid fertilizer subjected to fine grinding in a stirring reaction kettle, adding an assistant of certain ratio and adjusting the PH value to 5.5-8.5, and then stirring the substances evenly; and filter pressing, metering, and packaging. The method provided by the invention adopts a multiple grinding way for refining treatment of suspended matters in the biogas slurry, not only keeps the macromolecular organic nutrients in the biogas slurry, but also improves the organic matter content of the biogas slurry raw material, the organic matter content is up to 4%, and the fertilizer efficiency is greatly improved.

Owner:中节能绿碳(遵义)环保有限公司

Dry type anaerobic fermentation biogas slurry solid-liquid separation system and dry type anaerobic fermentation biogas slurry solid-liquid separation method for fruit and vegetable garbage

PendingCN110240329AAvoid cloggingAvoid wear and tearWater/sewage treatment by centrifugal separationTreatment involving filtrationFlocculationSewage

The invention relates to a dry type anaerobic fermentation biogas slurry solid-liquid separation system and a dry type anaerobic fermentation biogas slurry solid-liquid separation method for fruit and vegetable garbage. The system comprises a mechanical grid, a cyclone sand precipitator, a flocculation pool and a centrifugal dewatering machine, wherein the mechanical grid is connected to the pipeline of the cyclone sand precipitator, the sewage outlet of the cyclone sand precipitator is connected to the pipeline of the flocculation pool, and the water outlet of the flocculation pool is connected to the pipeline of the centrifugal dewatering machine. The method comprises that S1 biogas slurry passes through the mechanical grid to intercept the large-block impurities in the biogas slurry; S2, the obtained biogas slurry flows into the cyclone sand precipitator, and is subjected to sand removal; S3, the sand removed biogas slurry is mixed with an agent through a tubular mixer, and the uniformly mixed biogas slurry is flocculated in the flocculation pool to form large-block suspended matters; and S4, the flocculated biogas slurry is conveyed to the centrifugal dewatering machine, and is dewatered, and the dewatered biogas slurry is temporarily stored in a biogas slurry pool, and then is sucked out by a pump.

Owner:SHANGHAI INST FOR DESIGN & RES ON ENVIRONMENTAL ENG

Method for recycling lignin from low-boiling alcohol method pulping waste liquor

ActiveCN102877348ALess investmentHigh purityPulp liquor regenerationLignin derivativesCalcium hydroxideRecovery method

The invention relates to a method for recycling lignin from low-boiling alcohol method pulping waste liquor, which relates to the technical field of pulping papermaking engineering. The method for recycling the lignin from the low-boiling alcohol method pulping waste liquor is applicable to the waste liquor which is obtained by boiling reagent of plant raw materials with low-boiling alcohols, the waste liquor is processed in steps such as flash evaporation, diluting, cooling, precipitation, filtering, separating, drying and the like to obtain lignin, calcium hydroxide is added in filter liquor, and the precipitate is filtered, separated and dried again to obtain low-molecule lignin. The method has characteristics of high recycling rate, less investment, no pollution and low energy consumption.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Horizontal hydraulic secondary solid-liquid separator

PendingCN114228224AIntegrity guaranteedReduce wearSludge treatmentPressesThermodynamicsProcess engineering

The invention provides a horizontal hydraulic secondary solid-liquid separator which comprises a compression cavity, a feeding hopper, a hydraulic device, a compression cavity filter plate and a discharge port adjusting device, the feeding hopper is mounted above the compression cavity, the hydraulic device is mounted behind the compression cavity, the compression cavity filter plate is mounted in the compression cavity, and the discharge port adjusting device is mounted in front of the compression cavity. The spiral extrusion type secondary solid-liquid separator solves the technical problems of high solid content of liquid separated by a spiral extrusion type secondary solid-liquid separator in the prior art, serious equipment abrasion, high processing cost, high failure rate and high maintenance cost, adopts a hydraulic extrusion mode, can ensure the integrity of materials, is small in equipment abrasion, greatly reduces the secondary treatment cost of the liquid, and improves the working efficiency of the spiral extrusion type secondary solid-liquid separator. Compared with a screw extruder, the screw extruder has the biggest advantages of small abrasion of equipment parts, long service life of equipment and low maintenance cost.

Owner:HARBIN HUAMEI YIFENG COMPOUND MATERIALS

Dairy farm sewage treatment device and treatment method thereof

PendingCN110342772ARealize solid-liquid separationAchieve the purpose of purificationSludge treatmentWater/sewage treatment with mechanical oscillationsFiltrationWastewater

The invention relates to a dairy farm sewage treatment device and a treatment method thereof. The dairy farm sewage treatment device comprises a solid-liquid separation device, an osmotic membrane filtration device, an ultrasonic sterilization actuator and a waste storage tank; waste in the waste storage tank is conveyed to the solid-liquid separation device for solid-liquid separation, and wastewater mixture separated from the solid-liquid separation is conveyed to the osmotic membrane filtration device for filtration, and clear liquid from the osmotic membrane filtration device can be conveyed to the ultrasonic sterilizer actuator for sterilization; and the dairy farm sewage treatment device realizes the efficient separation and degradation of pollutants, and residual colon bacillus inthe clear liquid is treated through an ultra-high power ultrasonic, the sterilization rate reaches 100%, the whole treatment system is convenient to maintain, the treatment cost is lowered, and the operation and management are simple and convenient.

Owner:江苏连昌环保设备有限公司

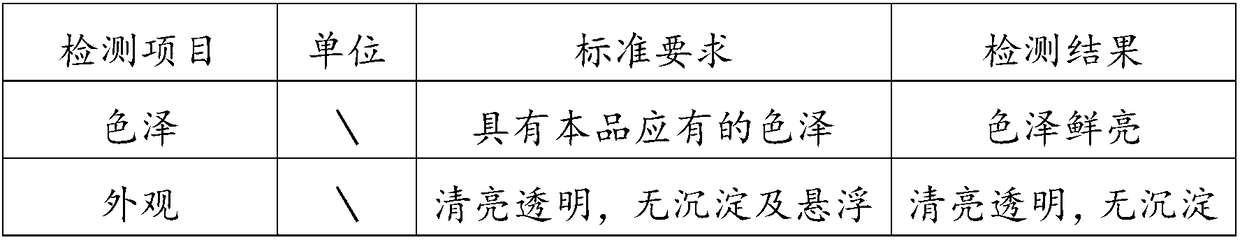

Heath care wine, and preparation method thereof

InactiveCN108795627ARemove bitter tasteIncrease profitMetabolism disorderDigestive systemPolygonum fagopyrumVinasse

The invention provides a heath care wine, and a preparation method thereof. According to the preparation method, glutinous rice, walnut kernel, and tartary buckwheat are taken as grain raw materials,glutinous rice hull, walnut shell, and tartary buckwheat hull are taken as hull raw materials, mutual cooperation of the raw materials is adopted, so that health care effect is improved, the bitter and astringent mouthfeel of the hull raw materials is eliminated, waste is changed into valuables, hull raw material utilization rate is increased, the obtained health care wine is rich in a plurality of amino acids and anti-oxidant active substances, is capable of relaxing muscles and tendons and promoting blood circulation, reliving fatigue, improving human immunity, and delaying skin aging. The preparation method is capable of realizing mutual cooperation of Daqu with after-run, so that wine quality is improved, and wine yield is increased; wine collection is carried out different temperatureand pressure conditions, the bitter and astringent substances capable of influencing mouthfeel in wine are removed, wine purity and fragrant smell are improved; in the cellaring process, the externalparts of terrines are covered with vinasse to improve wine quality further. The health care wine yield is high, the nutrients are abundant, the color is transparent, the solid substance content is low, and the mouthfeel is mellow and thick.

Owner:李延奎

Method for extracting essential oil from orange juicing peel and oil mixture

InactiveCN103497835AIncrease profitImprove adaptabilityEssential-oils/perfumesChemical oxygen demandSolid matter

The invention discloses a method for extracting an essential oil from an orange juicing peel and oil mixture, particularly discloses a way / method for linking a cup juicer and an oil grinding machine, and more particularly discloses an optimal method for mounting and configuring equipment. The method comprises the steps: directly obtaining a peel, oil and water mixture when oranges are juiced by using the oil grinding machine or the cup juicer, and collecting and conveying the peel, oil and water mixture to a spiral refiner for peel and oil separation; then, entering an oil and water mixture into a series of equipment to separate the essential oil in water; and finally, entering the essential oil into an essential oil storage tank, settling the essential oil, and then, flowing the essential oil into a packaging container and the water with very low oil content to enter a sedimentation tank, and entering the water into a spray water pipe of the cup juicer and the oil grinding machine through pumping and pressurizing so as to be recycled. The material delivery of a whole system and the material balance in a delivery process are considered in the method, and the method is convenient to operate, simple in installation and relatively high in water circular utilization ratio. The solid matter content, essential oil content and COD (Chemical Oxygen Demand) in wastewater generated by the peel and oil mixture can be up to the lowest, and the recovery rate of the essential oil in an orange processing process is up to an optimal value.

Owner:SHANGHAI BEYOND MACHINERY

A desulfurization wastewater treatment system and method

ActiveCN105000713BReduce solid contentLow failure rateMultistage water/sewage treatmentWater treatment systemSludge

The invention discloses a desulfurization wastewater treatment system and method. The wastewater treatment system comprises: a wastewater buffer tank, the water inlet of which is connected to the outlet of a device producing desulfurization wastewater; sludge squeezing equipment, the input end of which is connected to the outlet of the wastewater buffer tank Connection; multi-stage treatment tank, the water inlet is connected to the water outlet of the sludge squeezing equipment; the clarification tank, the water inlet is connected to the water outlet of the multi-stage treatment tank; pH callback box, the water inlet is connected to the upper clear water of the clarification tank At the same time, it also provides a wastewater treatment method using the above system. This treatment method is especially suitable for pelletizing flue gas wet desulfurization wastewater. The process is simple and the system has a low solid content. The products are gypsum and slow-release compound fertilizer, and the final wastewater discharge meets national standards.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

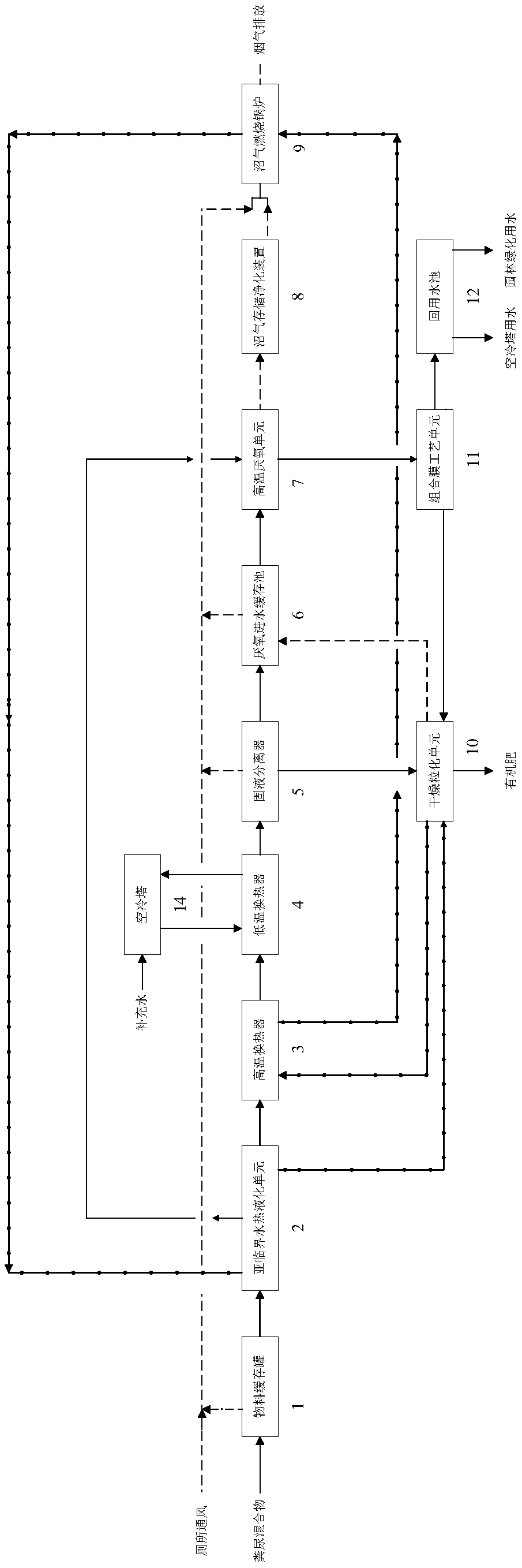

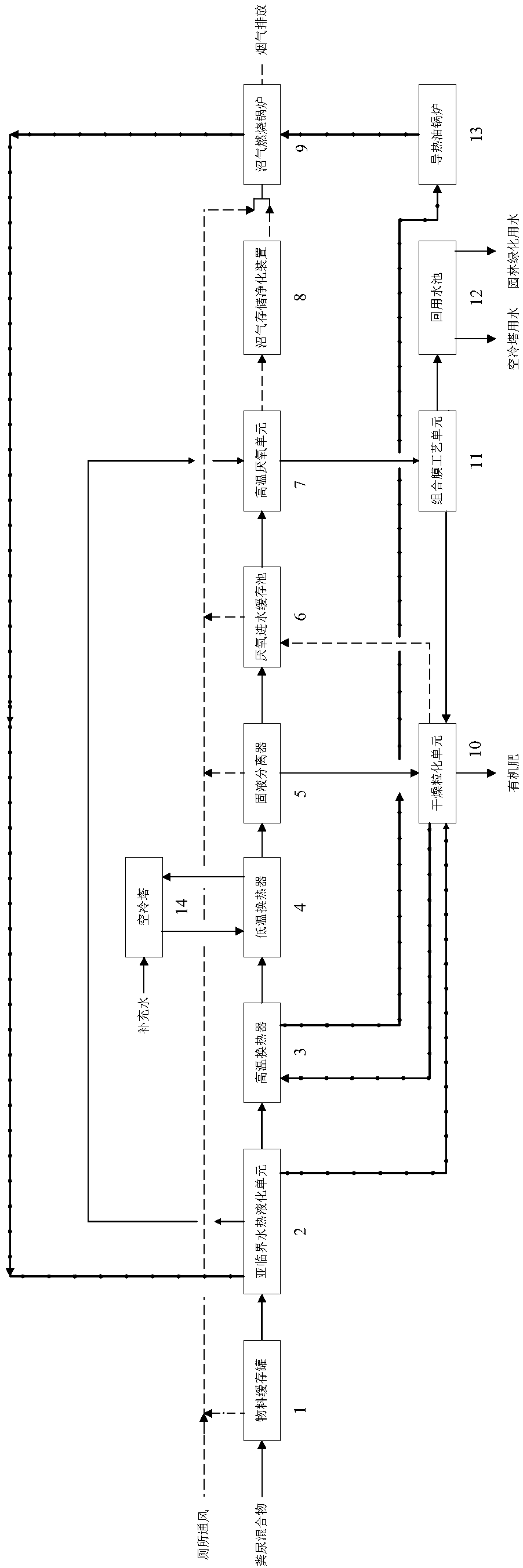

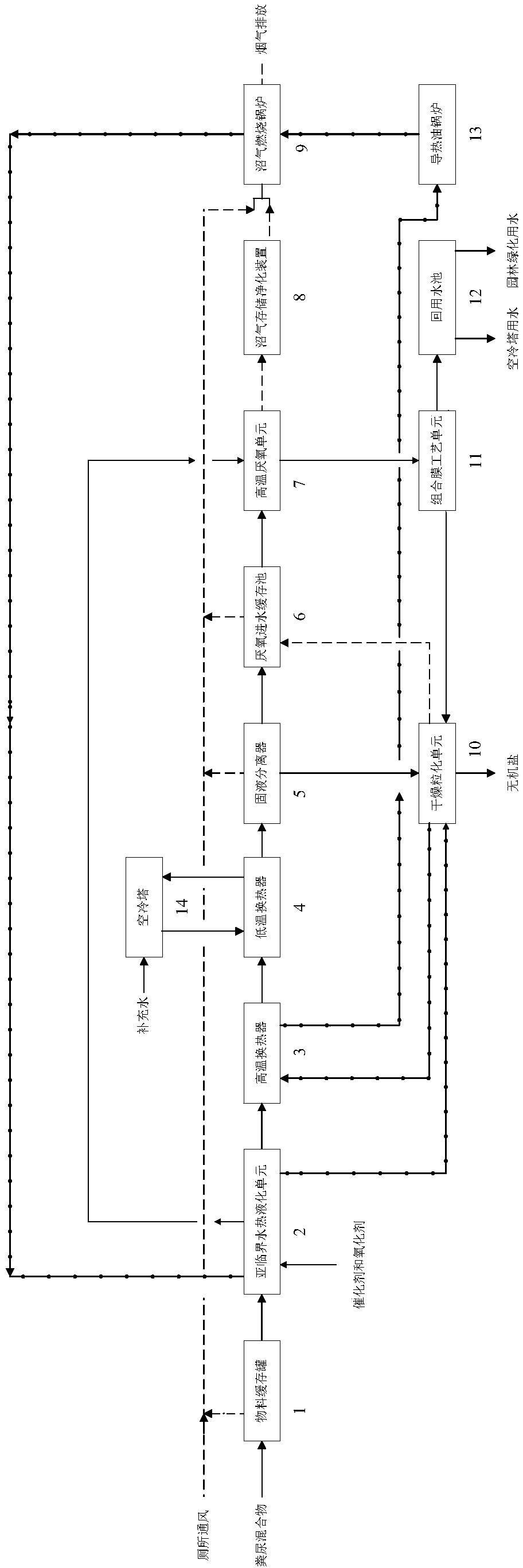

Bio-toilet system with subcritical hydrothermal liquefaction as core and fecaluria treatment method

ActiveCN109231793ABiochemical goodFast responseSludge treatment by thermal conditioningClimate change adaptationChemical industryLandscaping

The invention discloses a bio-toilet system with subcritical hydrothermal liquefaction as a core and a fecaluria treatment method and belongs to the technical field of chemical industry and environmental protection. The bio-toilet system comprises a material buffer tank, a subcritical hydrothermal liquefaction unit, a high temperature heat exchanger, a low temperature heat exchanger, a solid-liquid separator, an anaerobic water inlet buffer pool, a high temperature anaerobic unit, a biogas storage purification device, a biogas combustion boiler, a drying pelletization unit, a combined membraneprocess unit, a recycling water pool, a conduction oil boiler and an air cooling tower. According to the bio-toilet system with subcritical hydrothermal liquefaction as the core and the fecaluria treatment method, the subcritical hydrothermal liquefaction is used as the technical core, and meanwhile the high temperature heat exchanger, the low temperature heat exchanger, the solid-liquid separator, a high temperature anaerobic process, a biogas combustion system and the drying pelletization unit are combined, fecaluria substances are harmlessly stabilized into landscaping water, an organic fertilizer or an organic salt; bad smell is treated by high temperature combustion, the harmless disposal of gas, liquid and solid is implemented, excellent environmental benefits and economic benefitsare provided, and multi-level utilization and optimization of energies are implemented in combination with the conduction oil boiler.

Owner:陕西圣昊朗道科技有限公司

Method for recycling lignin from low-boiling alcohol method pulping waste liquor

ActiveCN102877348BLess investmentHigh purityPulp liquor regenerationLignin derivativesLiquid wastePollution

The invention relates to a method for recycling lignin from low-boiling alcohol method pulping waste liquor, which relates to the technical field of pulping papermaking engineering. The method for recycling the lignin from the low-boiling alcohol method pulping waste liquor is applicable to the waste liquor which is obtained by boiling reagent of plant raw materials with low-boiling alcohols, the waste liquor is processed in steps such as flash evaporation, diluting, cooling, precipitation, filtering, separating, drying and the like to obtain lignin, calcium hydroxide is added in filter liquor, and the precipitate is filtered, separated and dried again to obtain low-molecule lignin. The method has characteristics of high recycling rate, less investment, no pollution and low energy consumption.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com