Method for resourceful treatment and use of water hyacinth

A process method and technology of water hyacinth, which are applied in the fields of ecological protection and waste treatment and utilization, can solve the problems of single water hyacinth reuse method, low resource utilization rate, and long production cycle, so as to improve the degradation rate of organic matter and biogas production capacity, High utilization rate of resources and the effect of increasing biogas production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

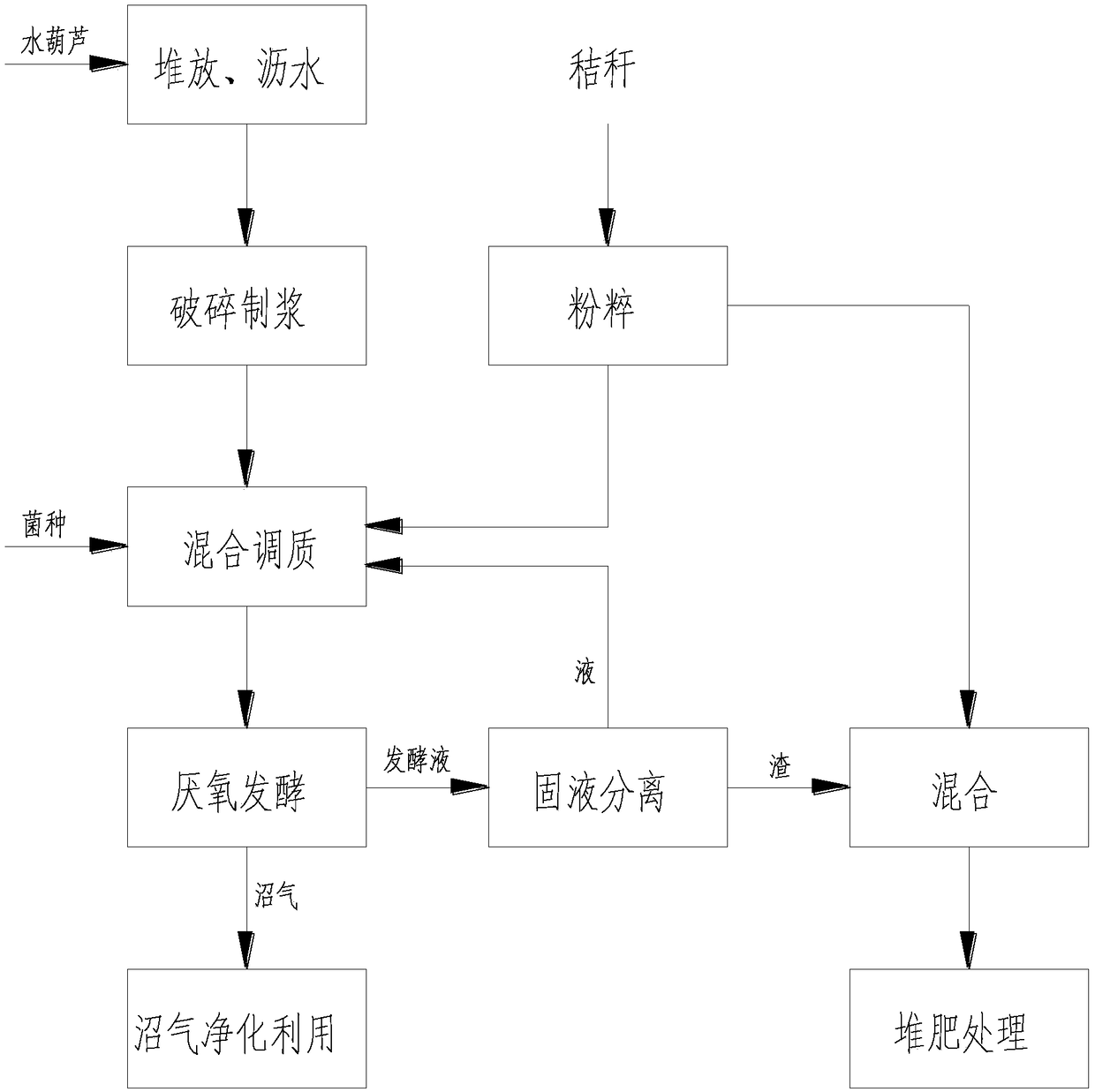

Image

Examples

Embodiment 1

[0049] The salvaged water hyacinths are naturally stacked in the open space, and the moisture content after natural drainage is 93% to 95%, and then crushed and beaten to form a slurry; the moisture content is 35% to 50% and the corn stalks are crushed into ≤ 1cm Minced: mix water hyacinth slurry, corn stalk minced and biogas slurry after anaerobic fermentation until the solid content of the mixture is 7% to 8%, and at the same time add nitrogen fertilizer to adjust the C / N to 20 to 25:1, add bacteria species (the strains include Acetobacter, Bacillus subtilis, and yeast, and the total number of effective viable bacteria in the strains is 2 to 7×10 7 cfu / ml), the ratio of the added mass of bacteria to the total mass of water hyacinth dry base and straw dry base is 5-7:1000; the hydraulic retention time of the mixed and tempered mixture is 1.5 days.

[0050] The mixture after staying for 1.5 days was subjected to anaerobic fermentation, the fermentation temperature was 35°C, an...

Embodiment 2

[0053] The salvaged water hyacinths are naturally stacked at the storage yard, and after natural drainage, the moisture content is 91% to 93%, and then crushed and beaten to form a slurry; the moisture content is 30% to 35%, and the wheat straw is crushed into ≤ 1cm minced water hyacinth slurry, wheat straw minced and biogas slurry after anaerobic fermentation are mixed together until the solid content of the mixture is 9% to 10%, and nitrogen fertilizer is added to adjust the C / N to 25 to 30:1. Strains (the strains include Acetobacter, Bacillus subtilis, and yeast, and the total number of effective viable bacteria in the strains is 5 to 10×10 7 cfu / ml), the ratio of the added mass of bacteria to the total mass of water hyacinth dry basis and straw dry basis is 7-10:1000; the hydraulic retention time of the mixed and tempered mixture is 2 days.

[0054] The mixture after staying for 2 days was subjected to anaerobic fermentation, the fermentation temperature was 35°C, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com