Method for consolidation of photocatalyst nano TiO2 hydrosol in fabric and photocatalyst fabric

A photocatalyst and hydrosol technology, applied in the field of photocatalytic materials, can solve the problems of inability to agglomerate, affect the photoreaction area, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

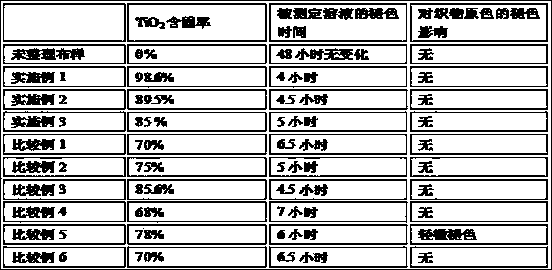

Examples

Embodiment 1

[0023] (1) The fabric is transported by the conveyor roller and immersed in the photocatalyst nano-TiO 2 The padding tank of the hydrosol, the temperature of the hydrosol is kept at 20°C, and the fabric walking speed is 20 m / min;

[0024] (2) After the fabric leaves the leaching tank, it is rolled, drawn, and shaped and dried to obtain a photocatalyst fabric. The shaped drying temperature is 160°C.

Embodiment 2

[0026] (1) The fabric is transported by the conveyor roller and immersed in the photocatalyst nano-TiO 2 The padding tank of the hydrosol, the temperature of the hydrosol is maintained at 50°C, and the fabric walking speed is 30 m / min;

[0027] (2) After the fabric leaves the leaching tank, the photocatalyst fabric is obtained by rolling, drawing, and setting and drying. The setting and drying temperature is 170°C.

Embodiment 3

[0029] (1) The fabric is transported by the conveyor roller and immersed in the photocatalyst nano-TiO 2 The padding tank of the hydrosol, the temperature of the hydrosol is kept at 60°C, and the fabric walking speed is 40 m / min;

[0030] (2) After the fabric leaves the leaching tank, the photocatalyst fabric is obtained by rolling, drawing, and setting and drying. The setting and drying temperature is 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com