Horizontal screw discharge sedimentation centrifuge

A decanting centrifuge and horizontal screw technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of uneven discharge at the discharge end, increasing the solid content of the clear liquid, and reducing work efficiency. , to avoid the reduction of processing efficiency, reduce the solid content of the clear liquid, and increase the work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

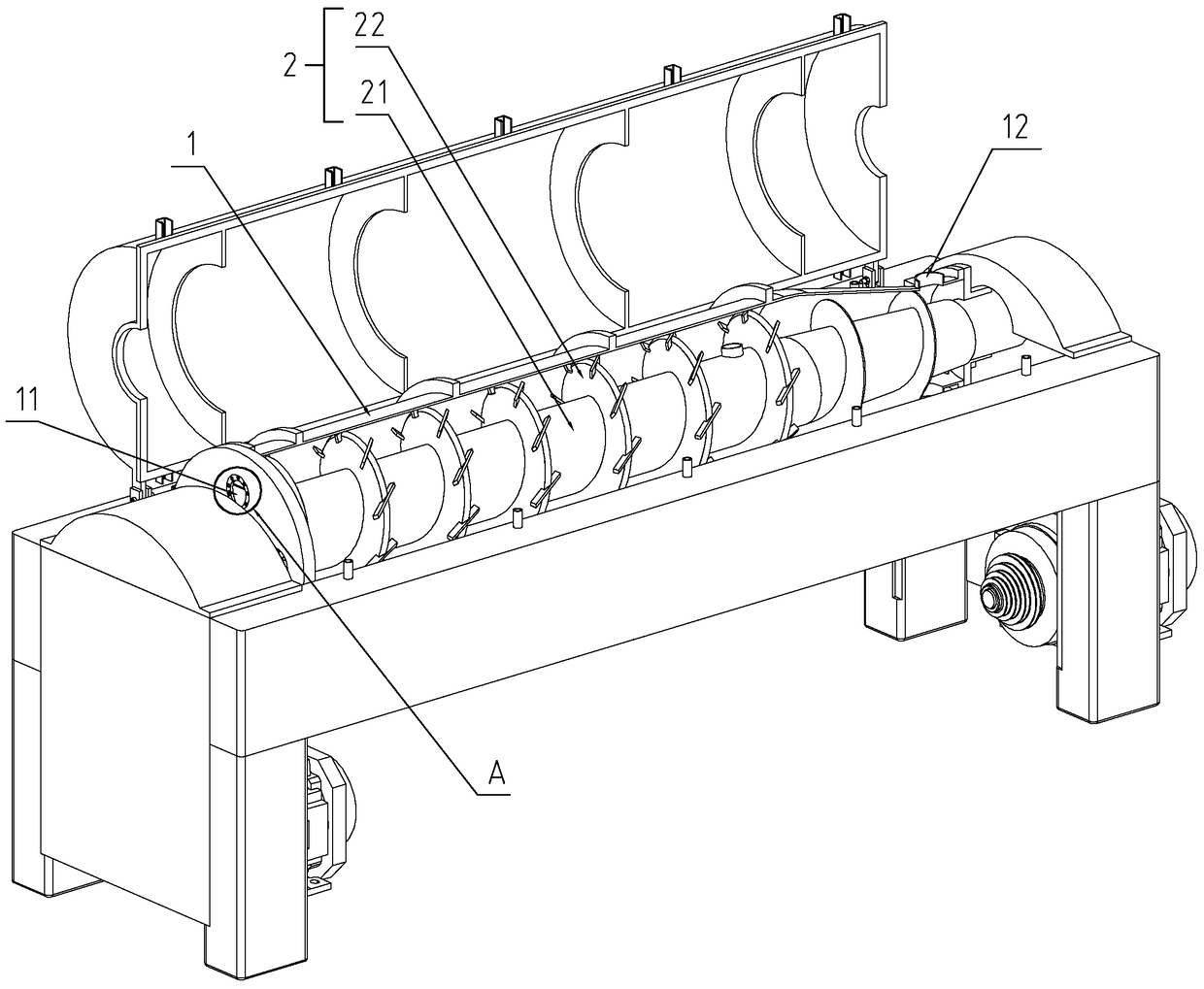

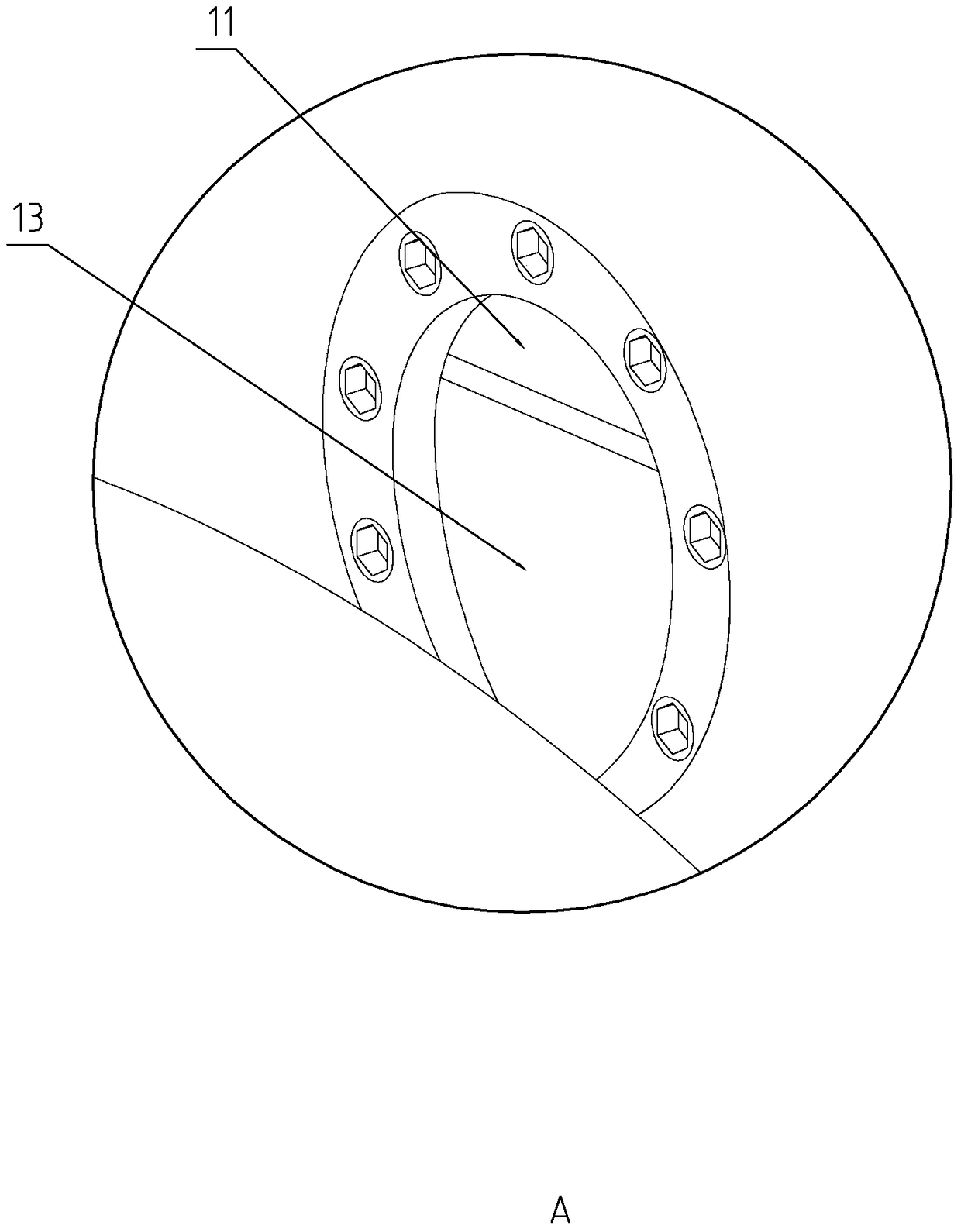

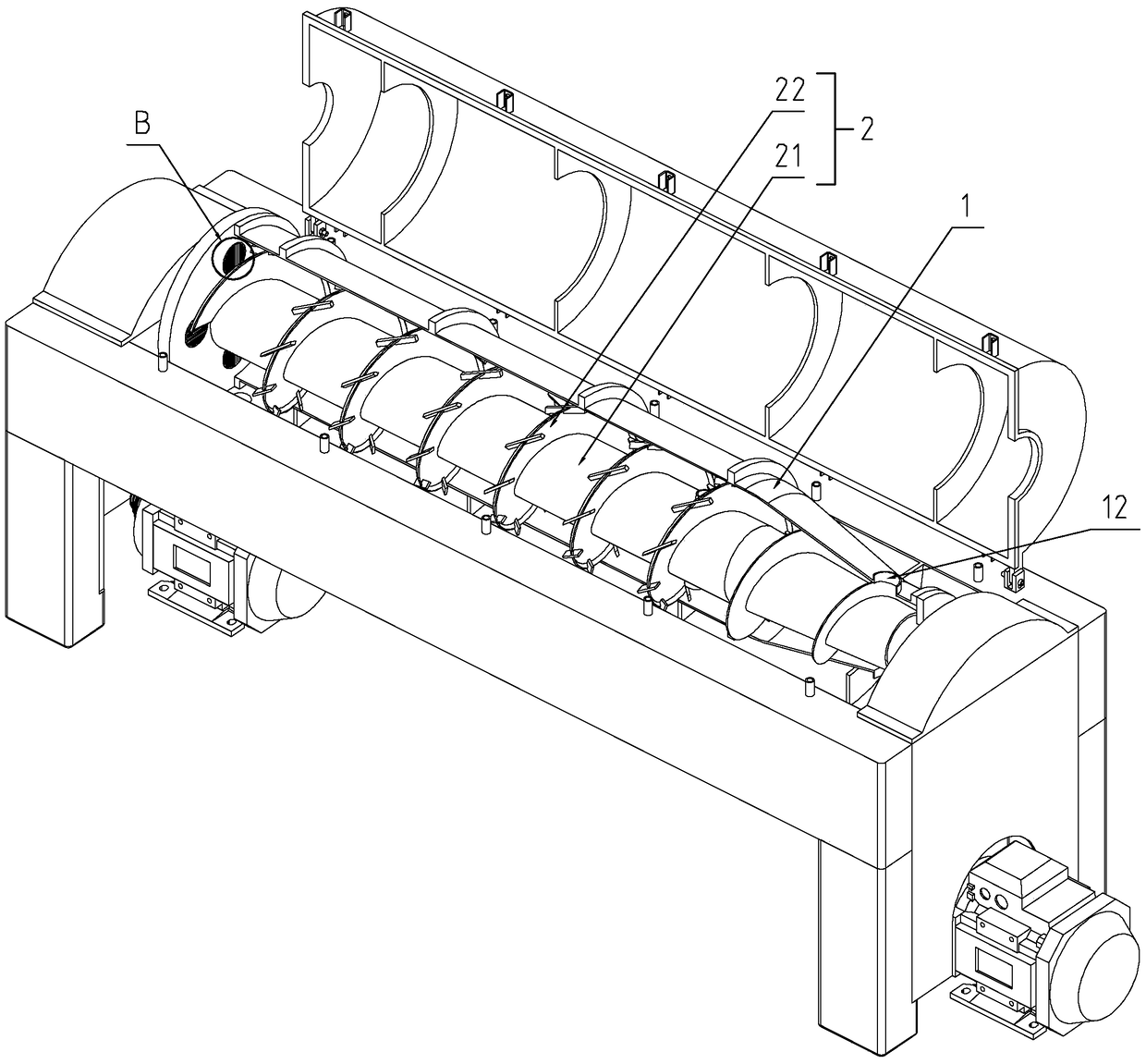

[0026] refer to Figure 1 to Figure 6 The embodiment of the inventive horizontal screw discharge sedimentation centrifuge will be further described.

[0027] A horizontal screw unloading sedimentation centrifuge, comprising a drum 1, a screw pusher 2 and a differential, wherein the screw pusher 2 is arranged in the drum 1, the drum 1 is driven by a main motor, and the screw pusher The feeder 2 is driven by the auxiliary motor through the differential. The drum 1 and the screw pusher 2 rotate in the same direction during high-speed rotation, but there is a certain speed difference between the two by the differential to perform the work. , wherein the drum 1 includes a settling area and a drying area, the settling area of the drum 1 is arranged in a cylindrical structure, the drying area of the drum 1 is arranged in a hollow frustum-shaped structure, and the screw pusher adapted to the drum 1 The feeder 2 includes a rod-shaped mandrel 21 and a helical pusher piece 22. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com