Desulfurization wastewater treatment system and desulfurization wastewater treatment method

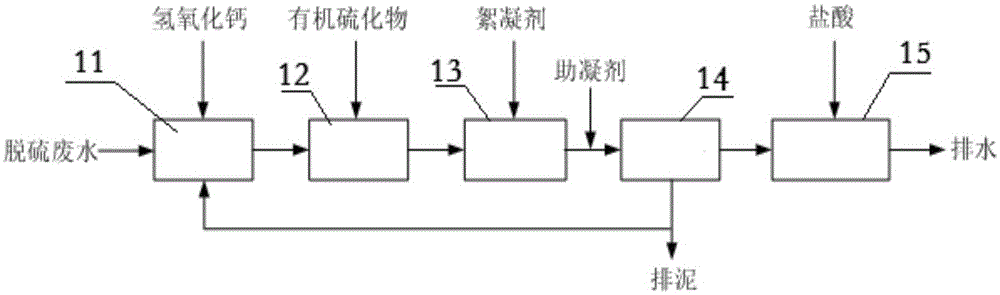

A desulfurization wastewater and treatment system technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of reducing the utilization of gypsum recyclable resources, increasing operating costs, and ammonia nitrogen content Advanced problems, to achieve the effect of reducing solid load and failure rate, reducing operating investment costs, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

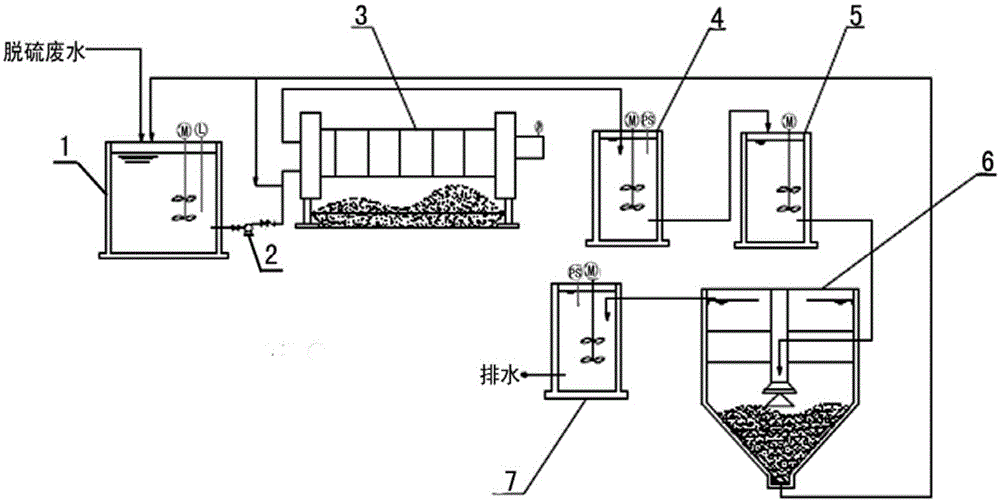

[0059] Such as figure 2 As shown, this embodiment provides a 2*1.2 million tons / year pellet machine flue gas wet desulfurization system wastewater treatment and reuse project, and the water quality parameters before desulfurization wastewater treatment are shown in Table 1.

[0060] Table 1 Water quality before and after treatment of pelletized wet flue gas desulfurization wastewater in this embodiment

[0061] project

unit

before processing

temperature

℃

45-55

20-30

pH value

-

4.0-6.0

6.0-9.0

Solid content

mg / l

10000-12000

≤50

mg / l

900-1700

≤8

mg / l

700-1100

-

Mg 2+

mg / l

300-1000

-

[0062] The specific treatment methods of wastewater are as follows:

[0063] (1) Flue gas desulfurization wastewater enters 25m 3 The waste water buffer pool, by collecting desulfurization waste water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com