Method for improving resource utilization of kitchen waste

A food waste and recycling technology, applied in the direction of fermentation, etc., can solve the problems of key influencing factors and unclear mechanism of action, and achieve the effects of shortening anaerobic fermentation time, reducing solid content rate, and accelerating material transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

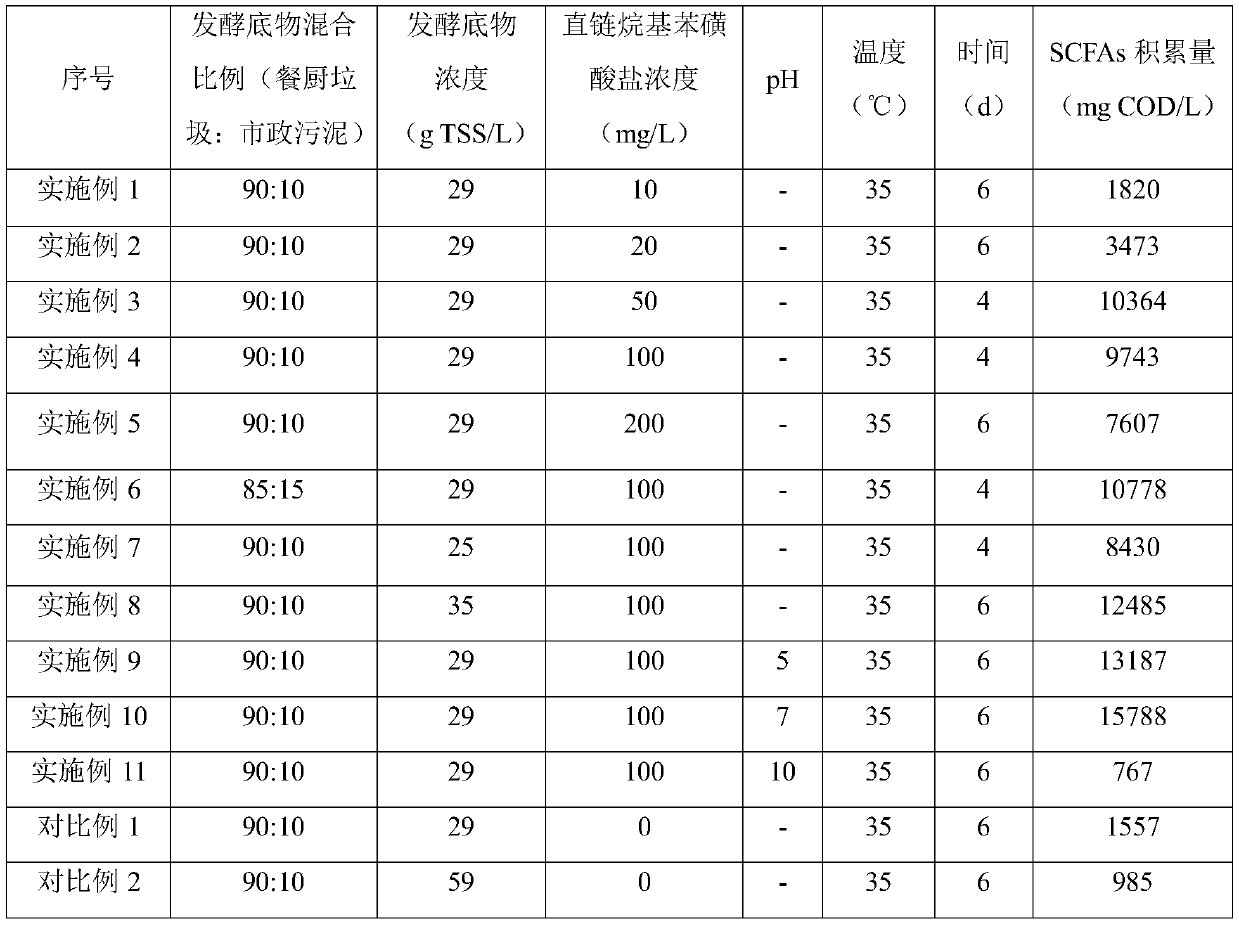

Embodiment 1

[0019] (1) In a plexiglass reactor with a working volume of 600mL, add pulverized and pulped food waste and sludge mixture (based on TSS, the mass ratio of food waste to sludge is 90:10) and manually configured washing Waste water (concentration of linear alkylbenzene sulfonate in waste water is 10mg / L), the total volume of the fermentation system obtained is 300mL, wherein TSS is 29g / L.

[0020] (2) Fill the reactor with nitrogen and drive oxygen for 10 minutes, seal the reactor, and use mechanical stirring to mix the substances in the fermentation system evenly; through the mixed anaerobic fermentation of washing wastewater and kitchen waste, the organic matter is converted into SCFAs. Among them, the mechanical stirring speed is 150-180rpm / min; the fermentation reaction temperature is controlled at 35±1°C, and the pH value is not controlled.

[0021] Calculated by CODcr, the accumulation of SCFAs reached 1820mg / L on the 6th day.

Embodiment 2

[0023] (1) In a plexiglass reactor with a working volume of 600mL, add pulverized and pulped food waste and sludge mixture (based on TSS, the mass ratio of food waste to sludge is 90:10) and manually configured washing Waste water (concentration of linear alkylbenzene sulfonate in waste water is 20mg / L), the total volume of the fermentation system obtained is 300mL, wherein TSS is 29g / L.

[0024] (2) Fill the reactor with nitrogen and drive oxygen for 10 minutes, seal the reactor, and use mechanical stirring to mix the substances in the fermentation system evenly; through the mixed anaerobic fermentation of washing wastewater and kitchen waste, the organic matter is converted into SCFAs. Among them, the mechanical stirring speed is 150-180rpm / min; the fermentation reaction temperature is controlled at 35±1°C, and the pH value is not controlled.

[0025] Calculated by CODcr, the accumulation of SCFAs reached 3473mg / L on the 6th day.

Embodiment 3

[0027] (1) In a plexiglass reactor with a working volume of 600mL, add pulverized and pulped food waste and sludge mixture (based on TSS, the mass ratio of food waste to sludge is 90:10) and manually configured washing Waste water (concentration of linear alkylbenzene sulfonate in waste water is 50mg / L), the total volume of the fermentation system obtained is 300mL, wherein TSS is 29g / L.

[0028] (2) Fill the reactor with nitrogen and drive oxygen for 10 minutes, seal the reactor, and use mechanical stirring to mix the substances in the fermentation system evenly; through the mixed anaerobic fermentation of washing wastewater and kitchen waste, the organic matter is converted into SCFAs. Among them, the mechanical stirring speed is 150-180rpm / min; the fermentation reaction temperature is controlled at 35±1°C, and the pH value is not controlled.

[0029] Calculated by CODcr, the accumulation of SCFAs reached 10364mg / L on the 4th day.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com