Dairy farm sewage treatment device and treatment method thereof

A treatment device and farm technology, applied in the direction of sludge treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as environmental pollution, impact on treatment effect, and obstacles to sterilization treatment, and achieve High particle removal rate, wide treatment range and low liquid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

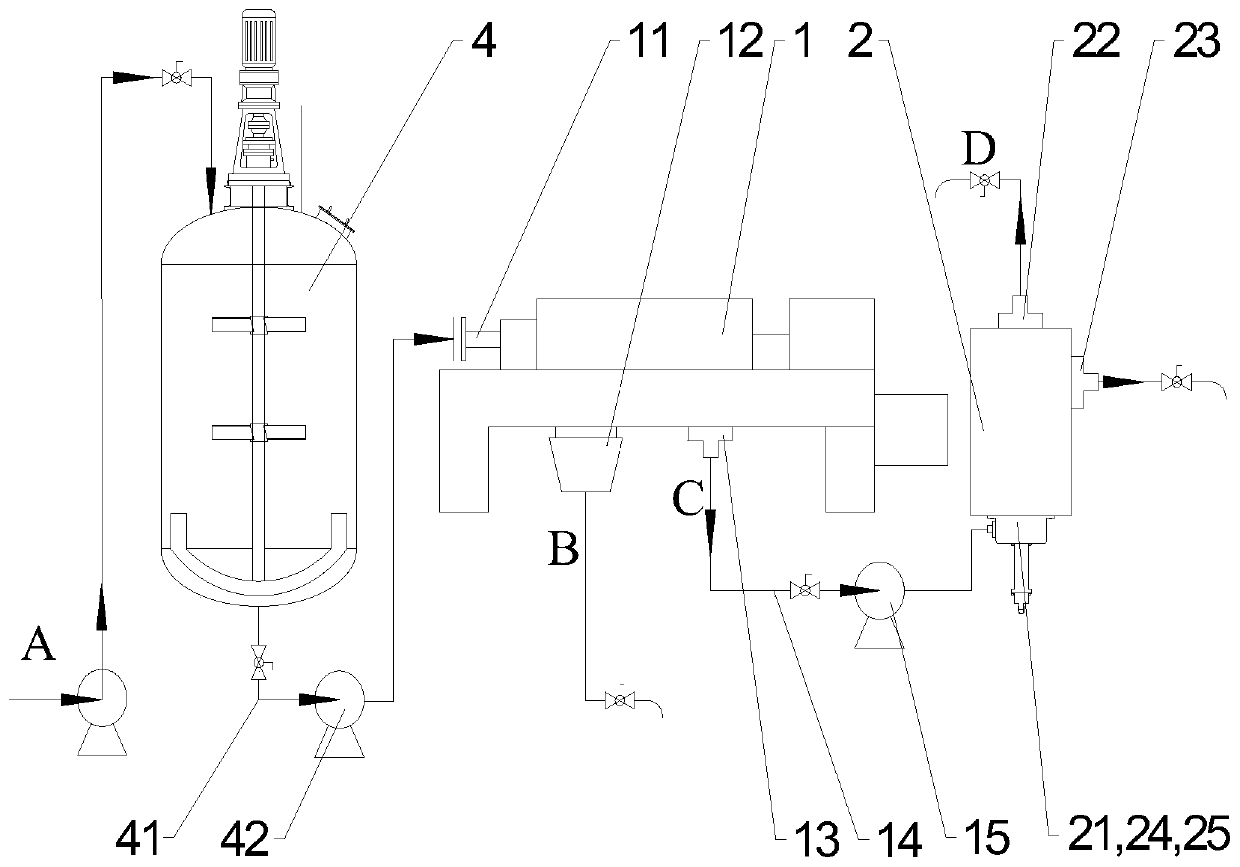

[0046] refer to figure 1 As shown, a dairy farm sewage treatment device includes a solid-liquid separation device 1, a permeable membrane filter device 2, and a dirt storage tank 4; an anchor frame agitator is installed in the dirt storage tank 4; the The said dirt storage tank 4 is connected with the inlet 11 of the solid-liquid separation device through the dirt delivery pipeline 41 and the feeding pump 42 arranged in the dirt delivery pipeline 41; the preferred high-speed horizontal spiral sedimentation centrifugal machine; the solid-liquid separation device 1 is provided with the first outlet 12 of the solid-liquid separation device and the second outlet 13 of the solid-liquid separation device, and the second outlet 13 of the solid-liquid separation device passes through the sewage mixture delivery pipeline 14 and is arranged on the sewage mixture delivery pipeline The sewage mixture pump 15 in 14 is connected with the inlet 21 of the osmotic membrane filter; the osmotic ...

Embodiment 2

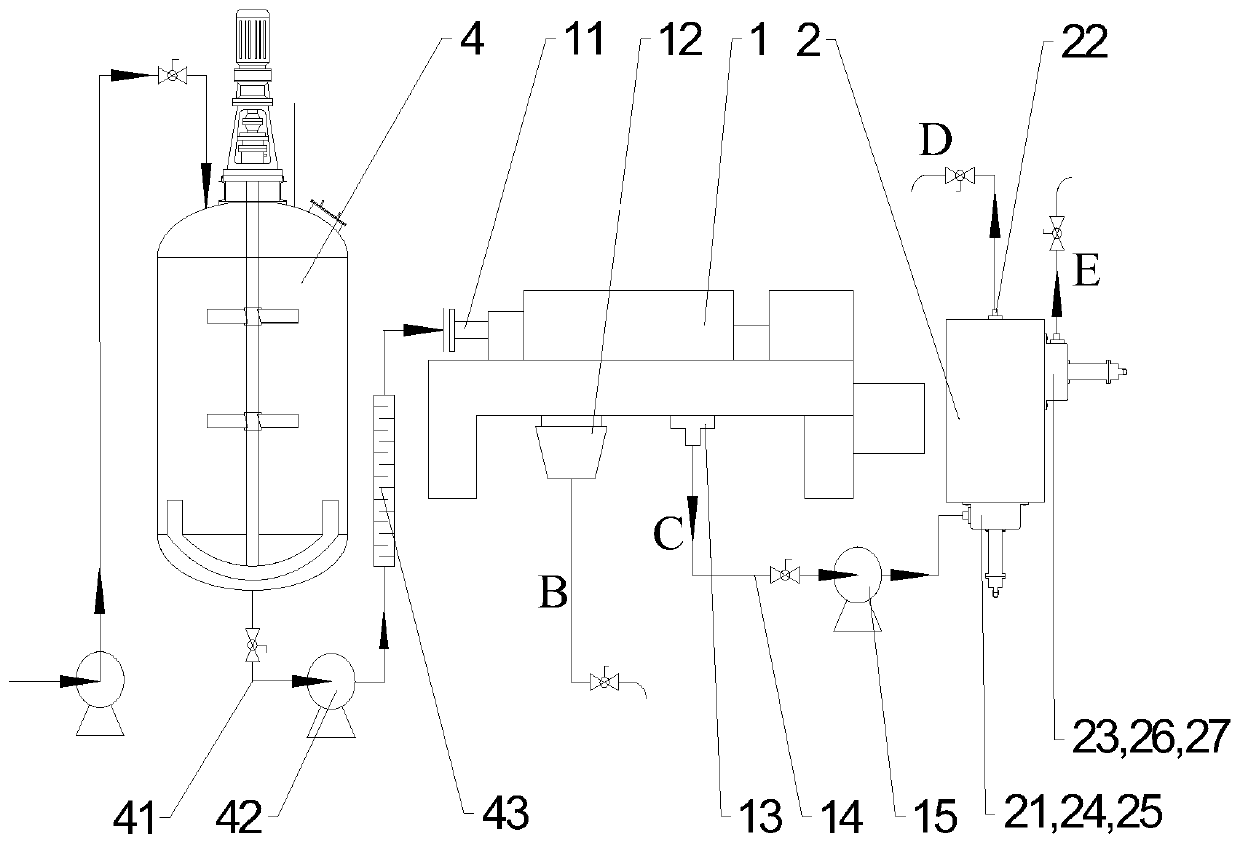

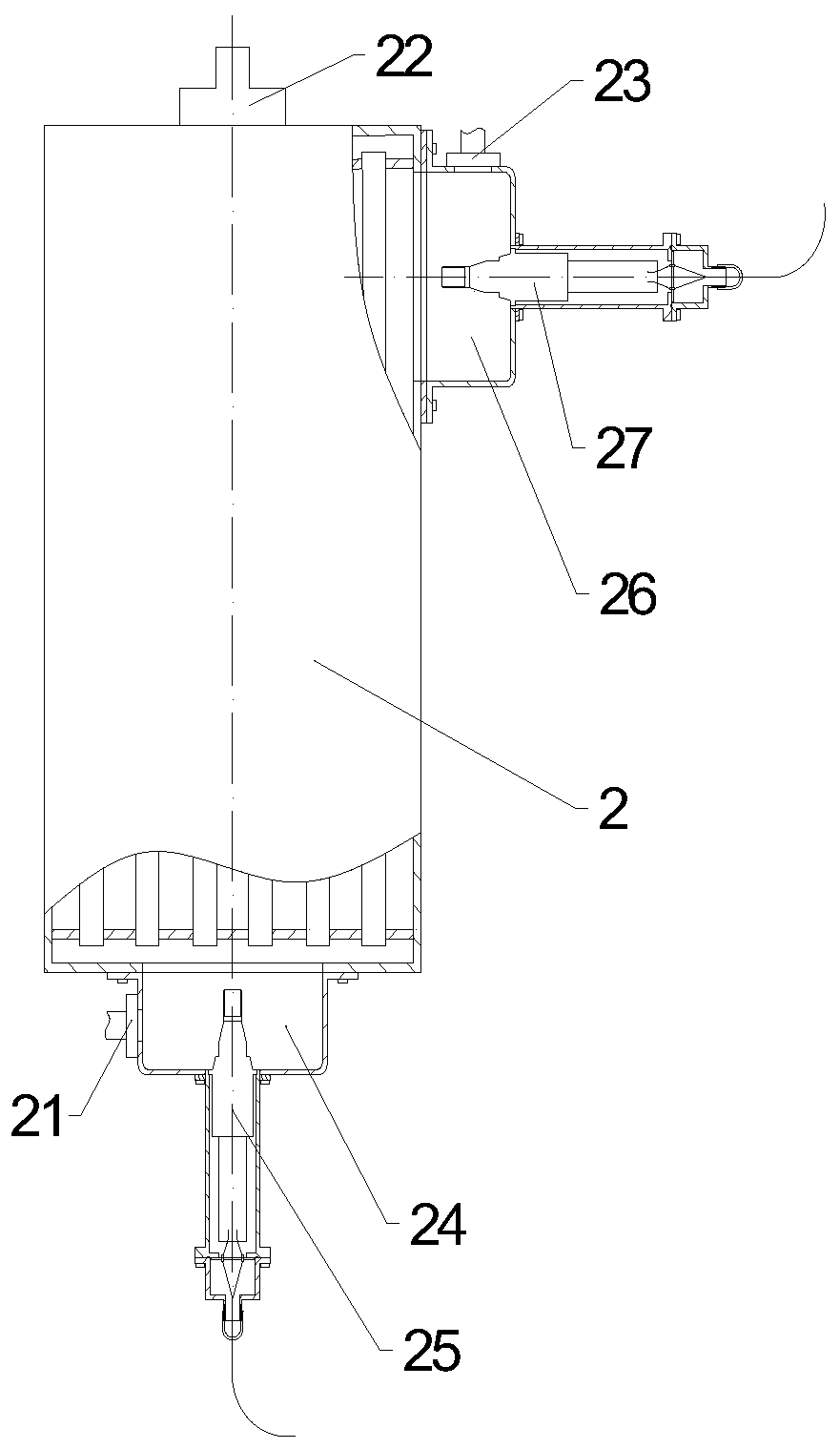

[0048] refer to figure 2 and image 3 As shown, a dairy farm sewage treatment device is basically the same as in Example 1, the difference is that: the clear liquid outlet 23 of the permeable membrane filter device 2 is also provided with an ultrasonic transducer action chamber 2 26, The second ultrasonic transducer 27 is installed on the second ultrasonic transducer action cavity 26, and the second ultrasonic transducer 27 is controlled by an ultrasonic driving power supply electrically connected to it; There is a static pipeline mixer 43; the static pipeline mixer 43 is arranged at the inlet 11 of the solid-liquid separation device.

Embodiment 3

[0050] refer to Figure 4 Shown, a kind of dairy farm sewage treatment device, on the basis of embodiment 1, has increased ultrasonic sterilizing device 3, is provided with the ultrasonic transducer 3 33 that is used for sterilization in the ultrasonic sterilizing device 3, by its electric Connected ultrasonic drive power supply control; the clear liquid outlet 23 of the osmotic membrane filter device 2 is connected with the ultrasonic sterilizer inlet 31 through the clear liquid delivery pipeline 28 and the clear liquid pump 29 arranged in the clear liquid delivery pipeline 28 . The dairy farm sewage treatment device also includes a cleaning pipeline 5, and the outlet 32 of the ultrasonic sterilizer is respectively connected with the inlet 31 of the ultrasonic sterilizer, the inlet 21 of the permeable membrane filter device, the inlet 11 of the solid-liquid separation device and the dirt storage through the cleaning pipeline 5. Tank 4 is connected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com