Wet flue gas desulfurization gypsum dehydrator

A wet desulfurization and dehydrator technology, applied in separation methods, chemical instruments and methods, mobile filter element filters, etc., can solve the problems of large floor space and high energy consumption, and reduce floor space and equipment energy consumption. Low, clear filtrate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and not used to limit the scope of the present invention.

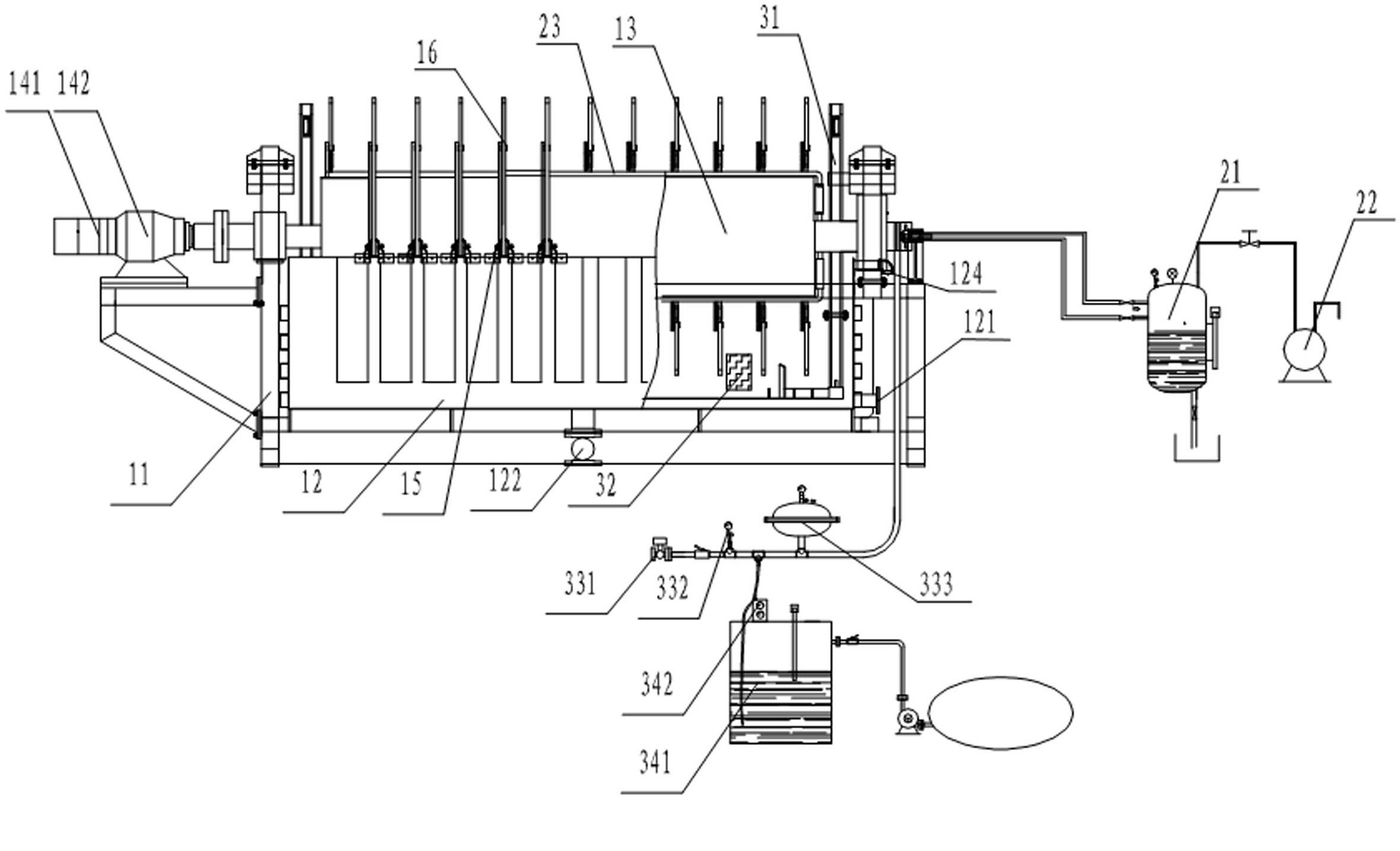

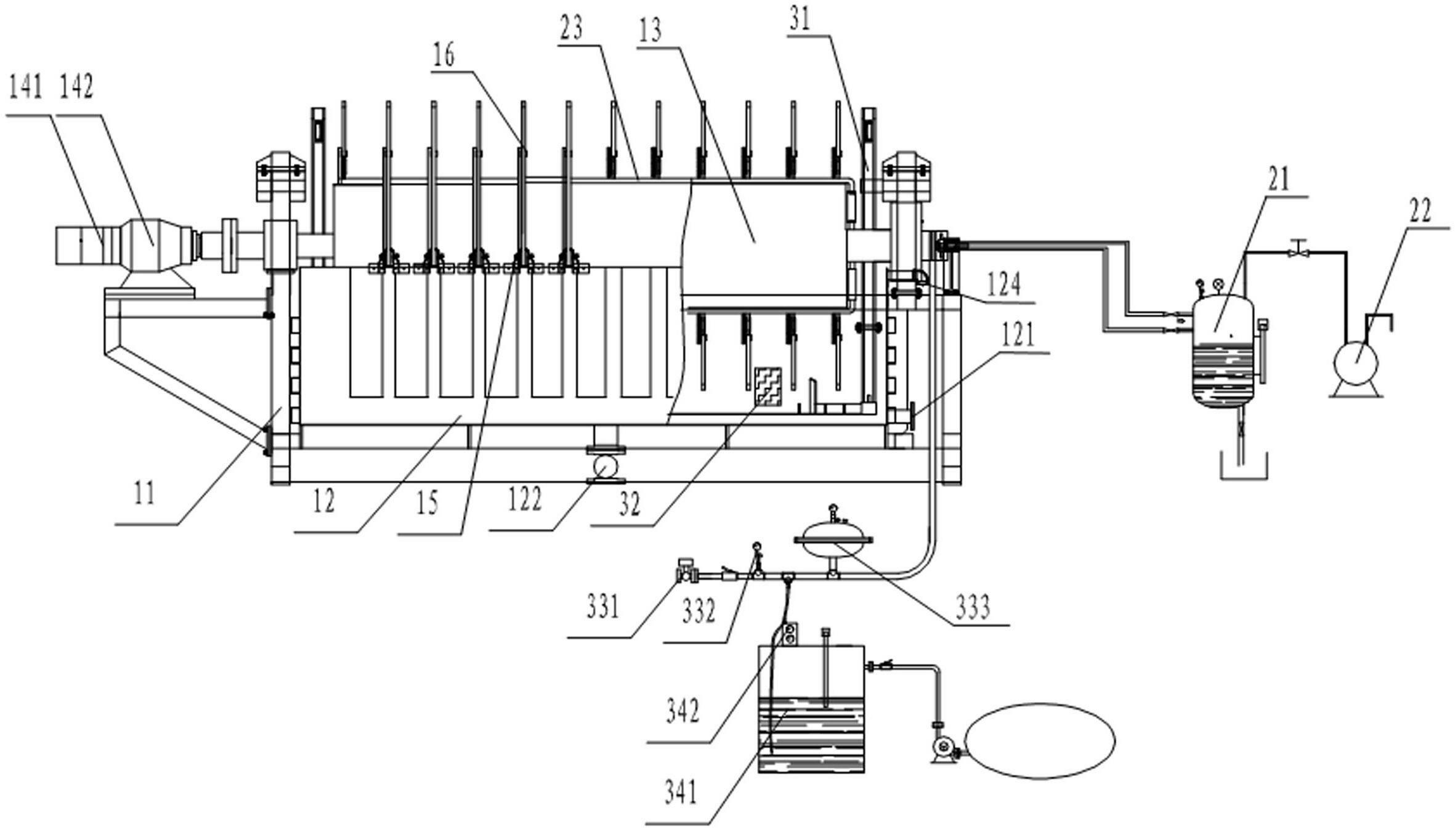

[0021] Such as figure 1 As shown, a flue gas wet desulfurization gypsum dehydrator includes a host system, a vacuum system, a cleaning system and a control system. The host system includes a frame 11, a slurry tank 12, a rotating device 13, a driving device, a discharge device 15 and a filter disc 16. The two ends of the slurry tank 12 are fixed on the frame 11, and the bottom of the slurry tank 12 is provided with The feed porous pipe 121 and the slurry discharge hole 122 are provided with an overflow hole 123 on the side wall of the slurry tank 12, and a flushing port 124 is also provided on the slurry tank 12. The rotating device 13 has a cylindrical structure, and its two ends are fixed to the two ends of the slurry tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com