Patents

Literature

60results about How to "Improve processing economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Caprolactam refining method

ActiveCN109721537AImprove process economyReduce effluxLactams separation/purificationSolventChemistry

The invention relates to the field of caprolactam production, and discloses a caprolactam refining method. The method comprises the following steps: (1) reduced pressure distillation is carried out ona caprolactam crude product containing impurities with a boiling point higher than the boiling point of caprolactam and impurities with a boiling point lower than the boiling point of caprolactam, sothat impurities with the boiling point lower than he boiling point of caprolactam is removed, and a light removed product is obtained; (2) the light removed product is mixed with a crystallization solvent, and then crystallizing is carried out to obtain a crystal; and (3) a hydrogenation reaction is carried out on the crystal, wherein the reduced pressure distillation is carried out under a condition of variable temperature and variable pressure, and the mass ratio of the crystallization solvent to the light removed product is (0.2-5):1. Premium-grade caprolactam can be obtained through the method provided by the invention, a heavy removal step is omitted, the process flow is simple, and the method is easy for industrial implementation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pretreatment method for cathode deposition of molten salt electrorefining

InactiveCN103111354AAchieve separationLower electrolyte levelsGrain treatmentsElectrolysisPretreatment method

The invention discloses a pretreatment method for cathode deposition of molten salt electrorefining. The method comprises the following steps of: breaking and ball-milling the cathode deposition in an inert gas shielding environment to obtain a mixture of metal powder and electrolyte powder, wherein the granularity of the mixture is 44-150 microns; and pneumatically separating the mixture powder through airflow so as to separate the metal powder and the electrolyte powder. The pretreatment method disclosed by the invention has the advantages that the separation of the electrolyte and the metal powder is achieved so as to effectively reduce the electrolyte content of the cathode deposition; and the dosage of diluted acid and the frequency of clean water washing in a wet treatment process can be reduced so as to improve process economical efficiency and reduce environment pressure.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

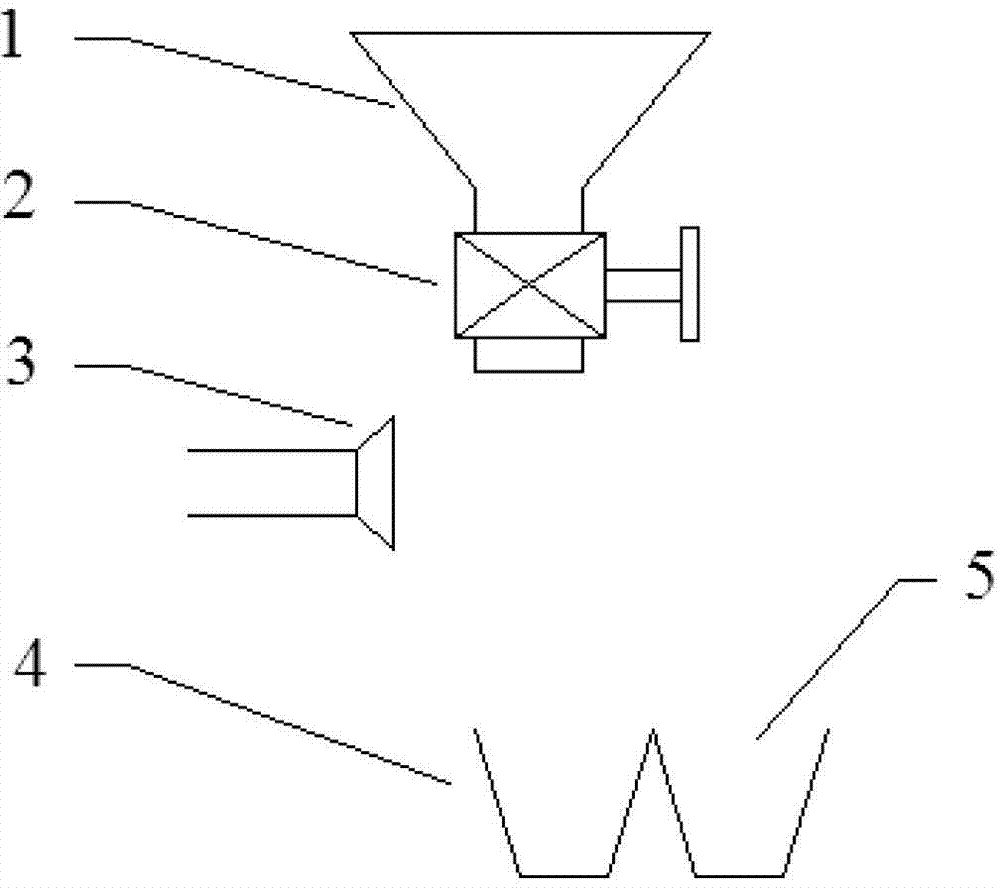

Method for catalytic hydrocracking of phenol-containing tar to recycle diphenol and catalyst

ActiveCN109647387AReduce solid waste treatment costsHigh yieldOrganic chemistryOrganic compound preparationHydroquinone productsSolvent

Owner:WANHUA CHEM GRP CO LTD

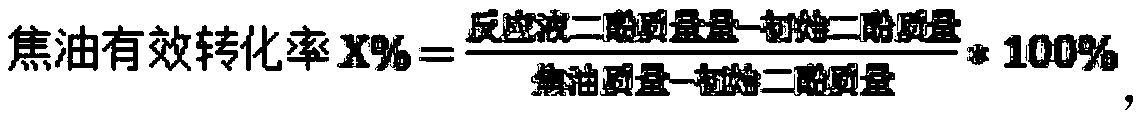

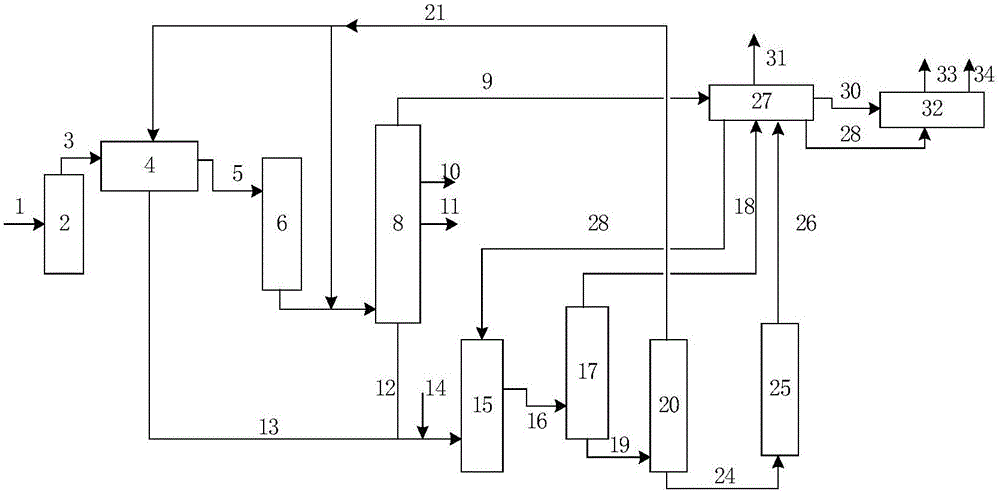

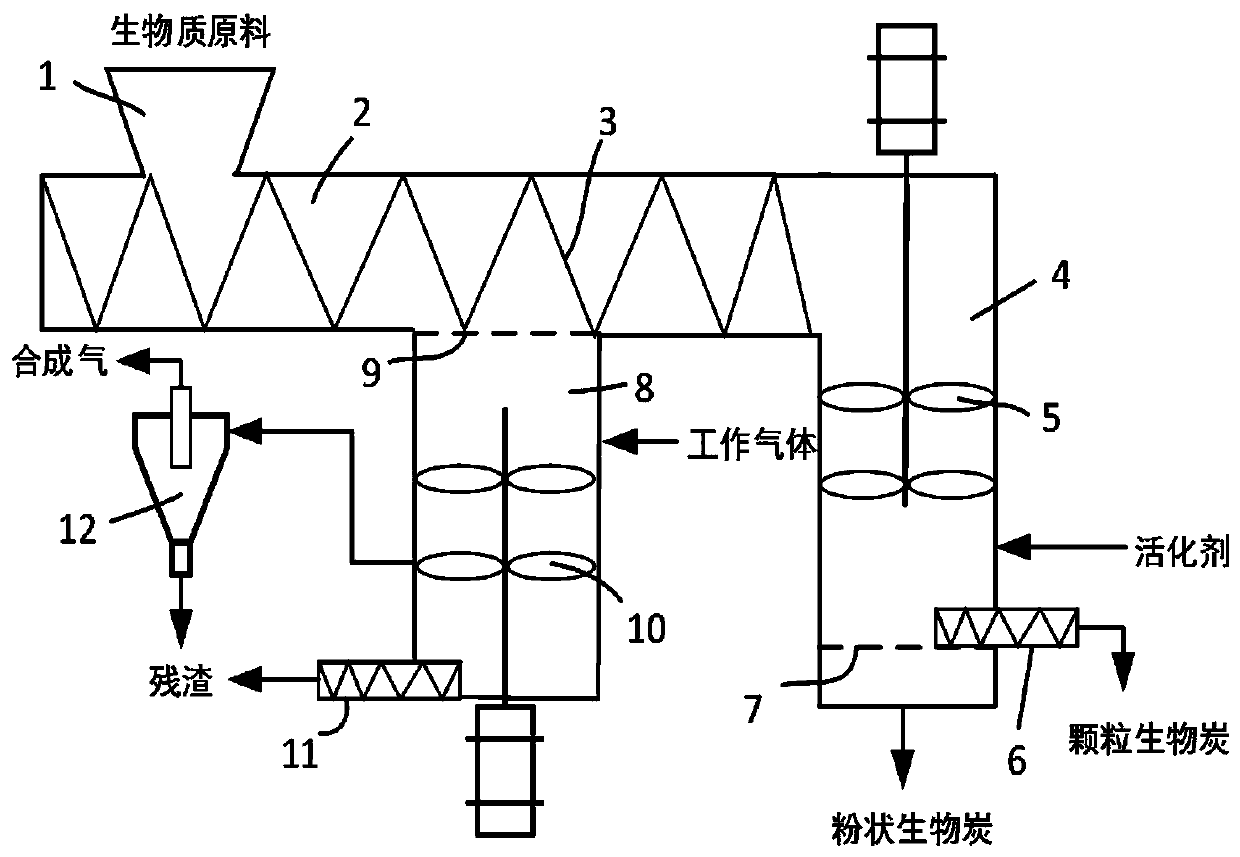

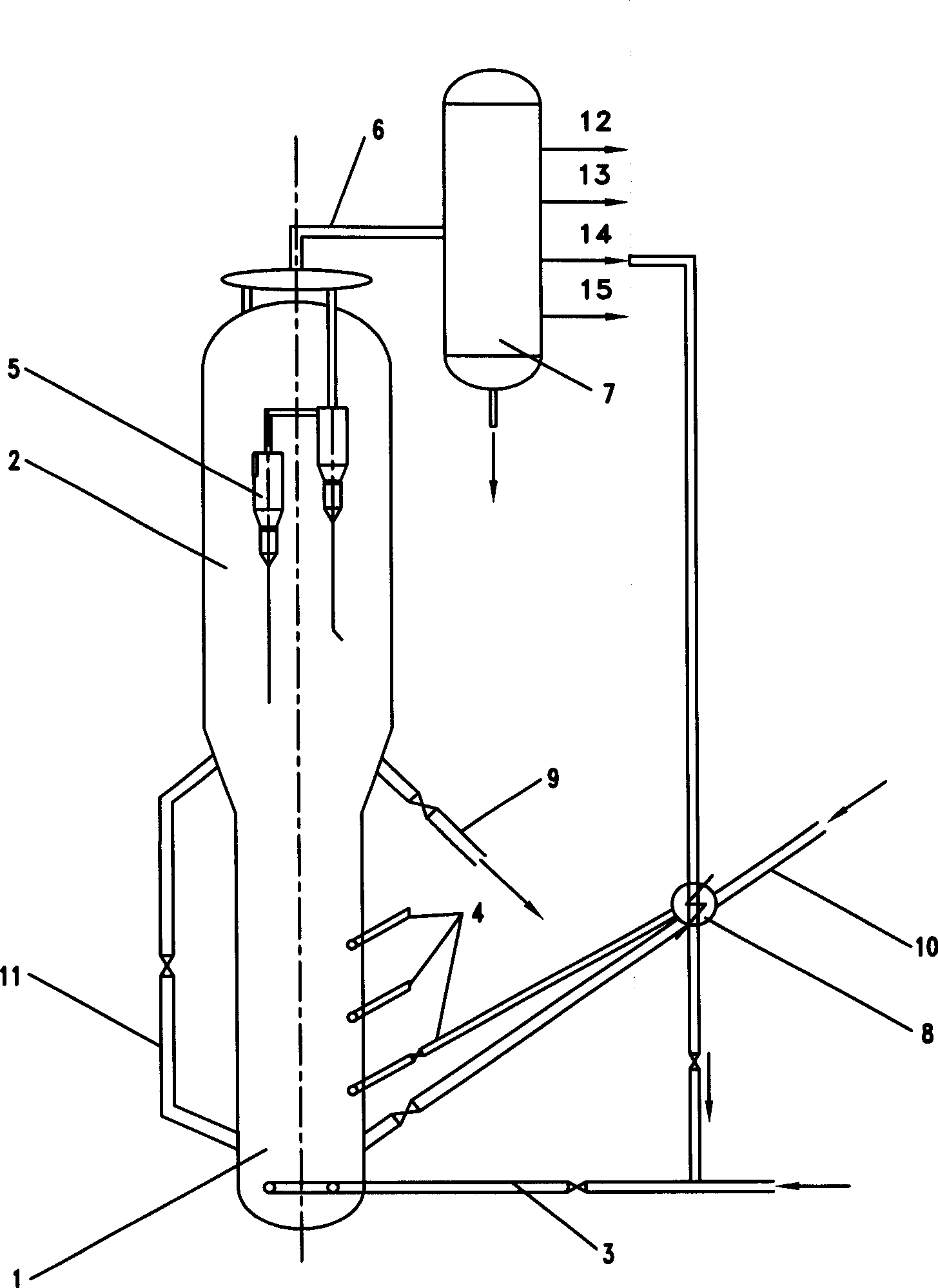

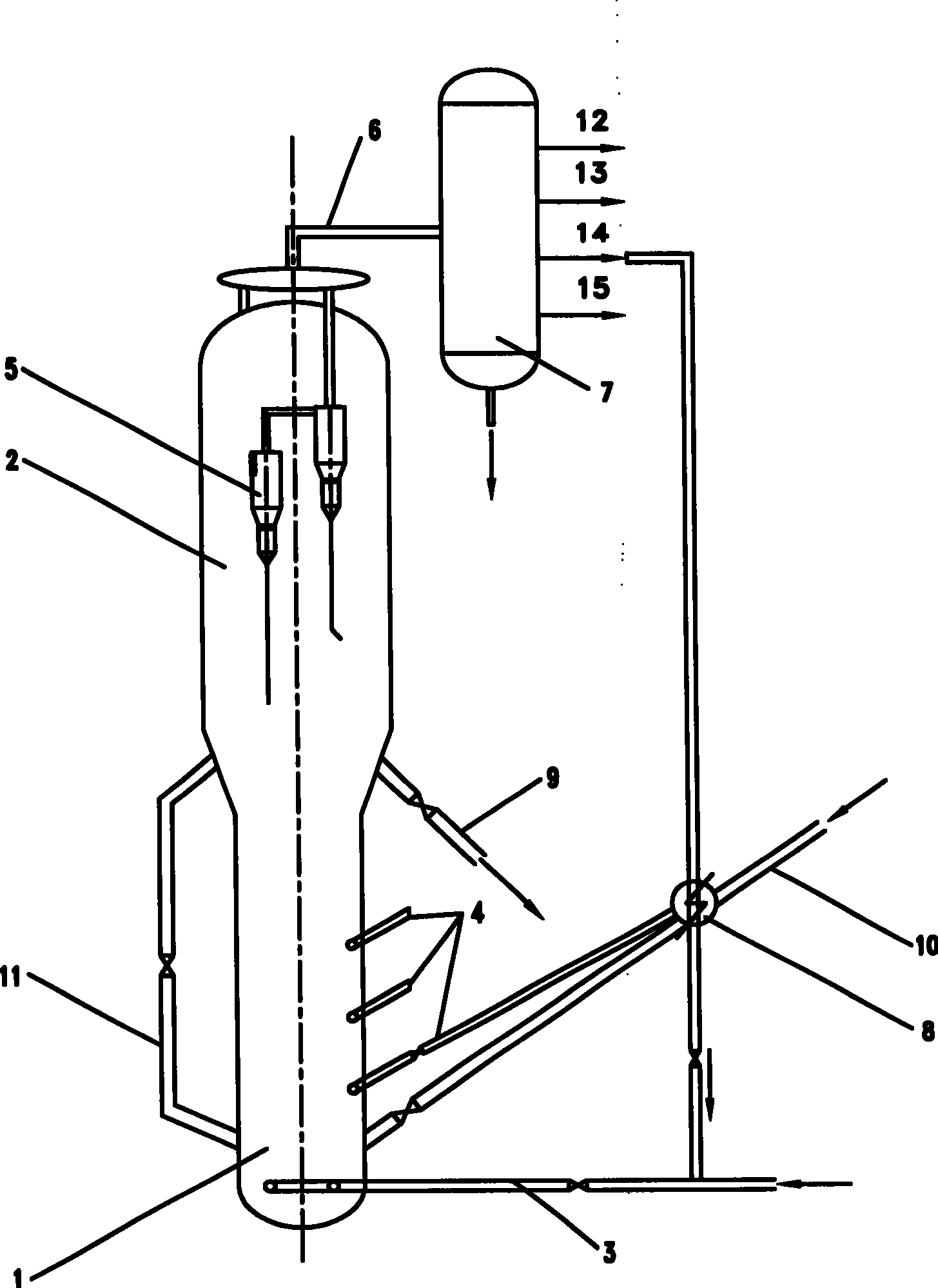

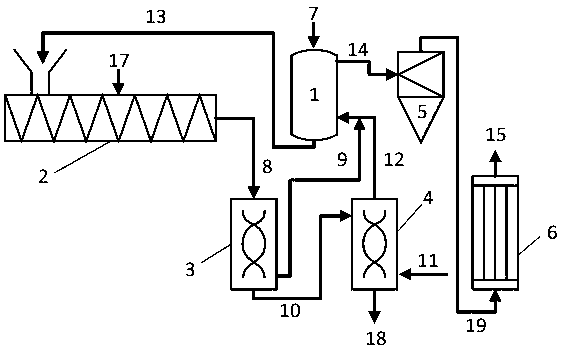

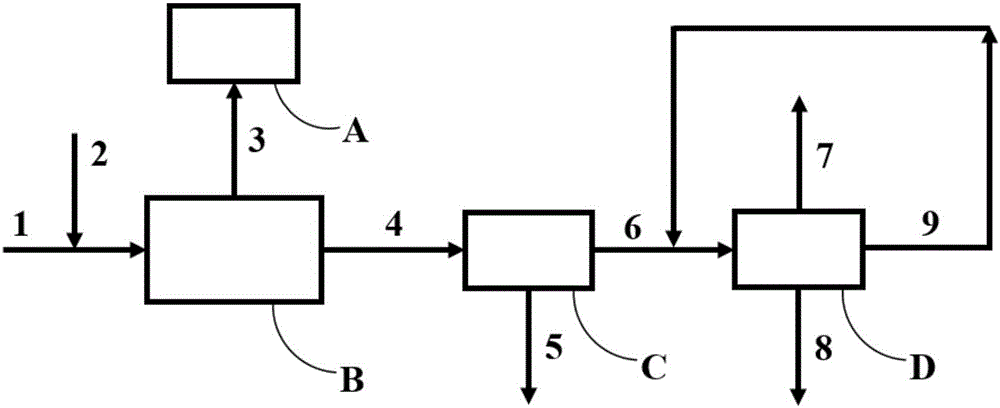

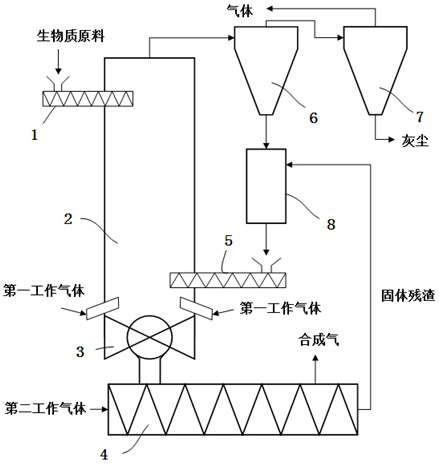

Method for preparing synthesis gas through biomass pyrolysis gasification coupling and system adopted by method

InactiveCN111378463AEasy to controlRealize joint productionProductsReagentsMicrowave pyrolysisProcess engineering

The invention belongs to the field of biomass energy, and particularly relates to a method for preparing synthesis gas by biomass pyrolysis gasification coupling and a system adopted by the method. The method comprises the following steps of (1) feeding a biomass raw material into a microwave pyrolysis reactor for reaction to obtain a pyrolysis volatile component and a pyrolysis solid-phase material, (2) feeding the pyrolysis solid-phase material into a gasification reactor to be in contact with an activating agent for gasification reaction, so as to obtain crude synthesis gas and biochar, (3)converging the pyrolysis volatile component and the crude synthesis gas, and feeding into a gas reforming converter from one direction, and feeding the biochar into a gas reforming converter from another direction to prepare a target product. The system comprises a biomass bin (1), a microwave pyrolysis reactor (2), a gasification reactor (3), a gas reforming converter (8) and a gas-solid separator (12). The method is beneficial to gas-solid two-phase sufficient reaction, the process cost of preparing the synthesis gas from the biomass can be remarkably reduced, and the target product qualityis high.

Owner:DALIAN OCEAN UNIV +1

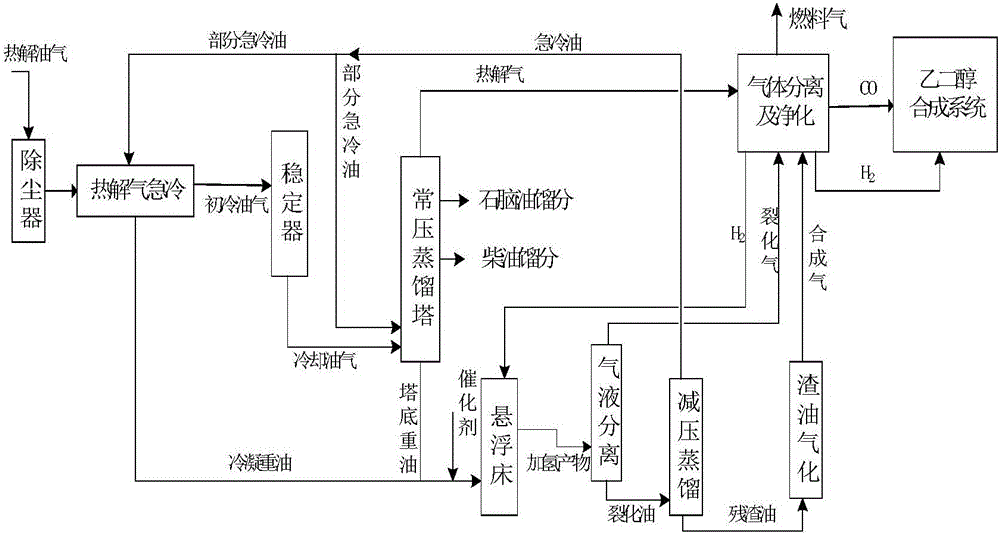

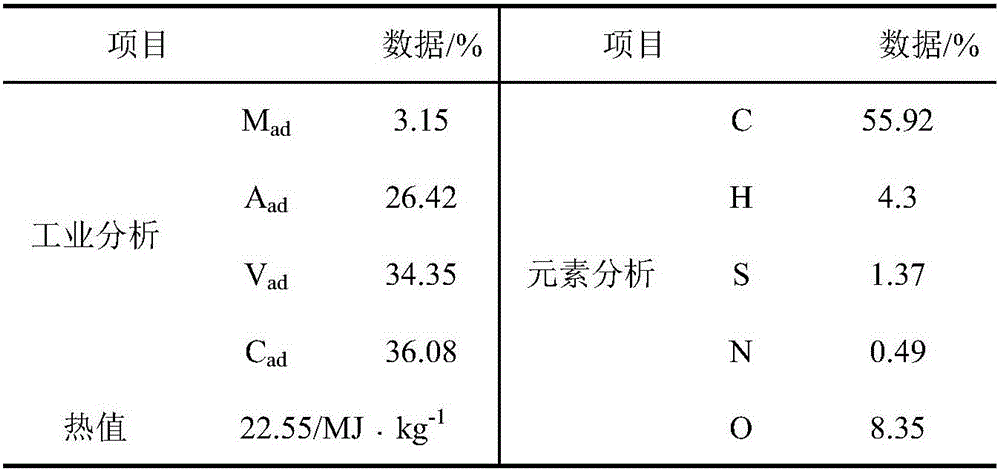

Combined system and method for processing oil gas generated by pyrolysis of low rank coal

InactiveCN105936834AAvoid it happening againIncrease flexibilityLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesFuel oilGlycol synthesis

The invention discloses a combined system and method for processing oil gas generated by pyrolysis of low rank coal. The system comprises a quench cooler, a normal pressure distillation column, a suspended bed hydrogenation reactor, a gas-liquid separator, a vacuum distillation tower, a residuum gasifying device, a gas separation and purification device, and a glycol synthesis system. The method comprises the following steps: quenching pyrolysis oil gas to generate cooled oil gas; subjecting cooled oil gas to normal pressure distillation to obtain heavy oil in the bottom of a distillation column and light fuel; cracking the heavy oil, separating gas and liquid to obtained cracked oil; subjecting cracked oil to vacuum distillation to obtain residual oil; gasifying the residual oil to obtain syngas; separating and purifying syngas to obtain hydrogen and carbon monoxide; and synthesizing carbon monoxide and hydrogen to obtain glycol. After vacuum deep extraction, the heavy residual oil is not returned to the suspended bed hydrogenation reactor, and thus the coking during the hydrogenation process in the suspended bed is avoided. The gas prepared from residual oil is used to produce glycol, the flexibility of heavy component processing is improved, and the economy of the technology is increased.

Owner:SHENWU TECH GRP CO LTD

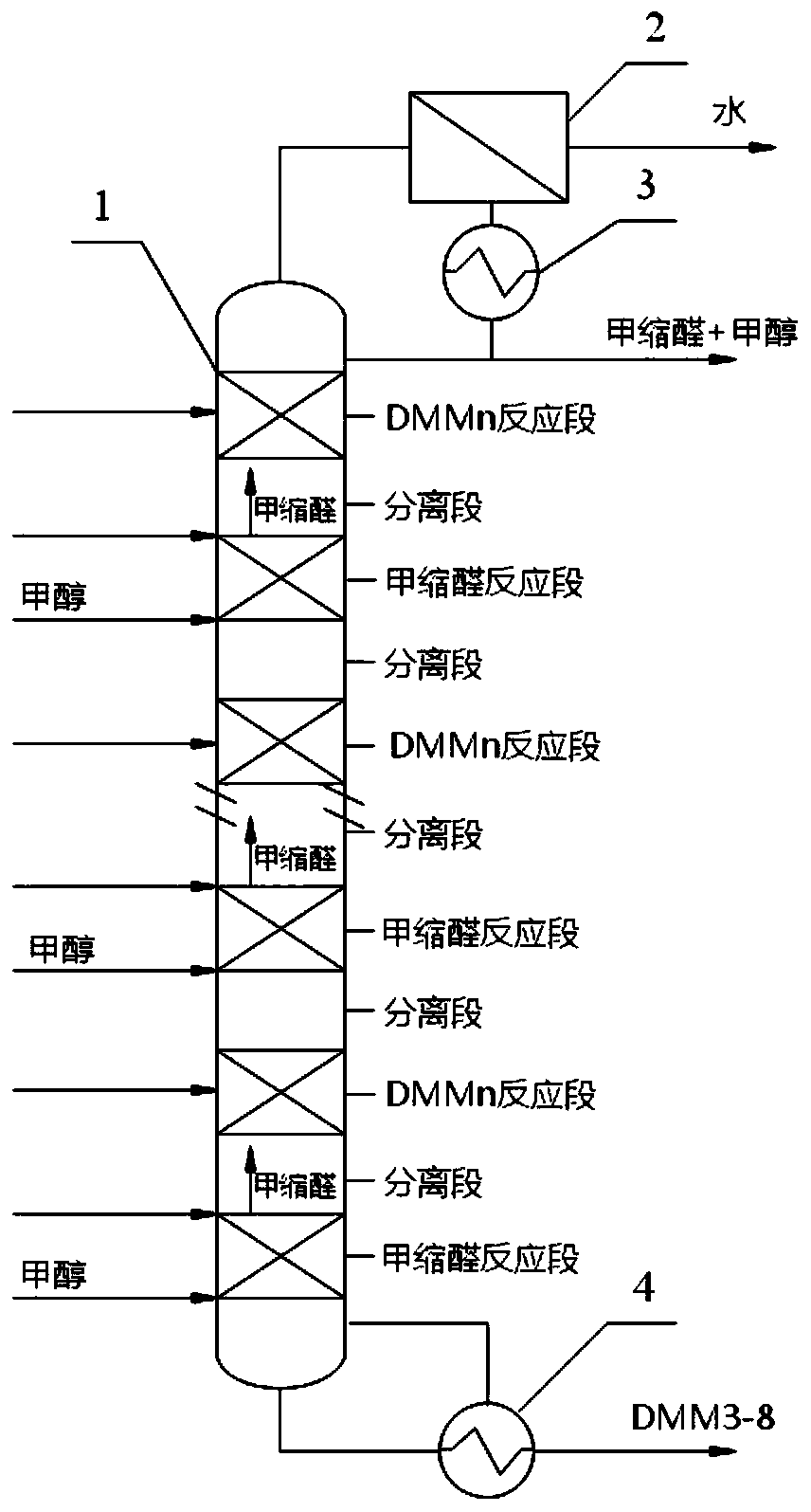

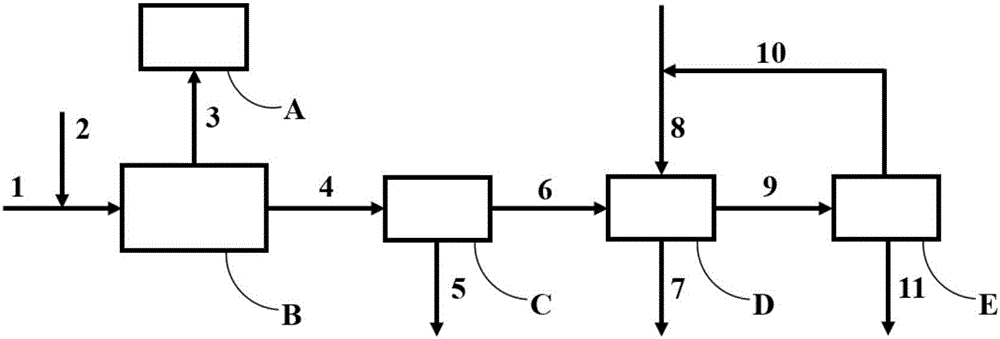

Multi-stage reactive distillation synthesis technique and device of PODEn (polyoxymethylene dimethyl ethers)

ActiveCN110078598ALow priceImprove processing economyOrganic chemistryOrganic compound preparationCouplingStream flow

The invention provides a multi-stage reactive distillation synthesis technique and device of PODEn (polyoxymethylene dimethyl ethers). According to the technique, industrial methanol and a formaldehyde solution are taken as raw materials, a methylal reactive distillation column and a PODEn reactive distillation column are combined in one set of equipment, two reaction processes are combined by sufficient use of advantages of the reactive distillation columns and equipment coupling advantages, the reaction conversion rate and the target product yield are effectively increased, the circular stream flow is reduced, and the equipment efficiency is improved. According to the technique, the cost of used raw materials is low, the reaction process is controllable, the investment and the cost are low, no other substances are introduced, the process is environmentally friendly, and the technique has good application prospects.

Owner:TIANJIN UNIV

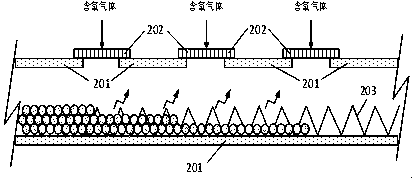

Method for preparing synthesis gas from biomass and system adopted by method

InactiveCN111378462AReach the goal of joint productionAchieve continuous operationBiofuelsIndirect heating destructive distillationMicrowave pyrolysisBiochar

The invention belongs to the field of biomass energy, and particularly relates to a method for preparing synthesis gas from biomass and a system adopted by the method. The method comprises the following steps of (1) feeding a pretreated biomass raw material into a microwave pyrolysis reactor for reaction to obtain a pyrolysis volatile component and a pyrolysis solid-phase material, (2) feeding large-particle pyrolysis solid-phase materials in the pyrolysis solid-phase materials into a biochar gasifier to obtain a biochar product and crude synthesis gas under the action of an activating agent,and (3) feeding the pyrolysis volatile component, the small-particle pyrolysis solid-phase material and the crude synthesis gas into a tar cracker, and carrying out tar removal treatment and reformingreaction of hydrocarbon small molecules under the action of working gas to prepare the target product of biomass synthesis gas. The method is convenient for reaction process control and product regulation and control, can significantly reduce the process cost of preparing the synthesis gas from the biomass, and is high in target product quality.

Owner:DALIAN OCEAN UNIV +1

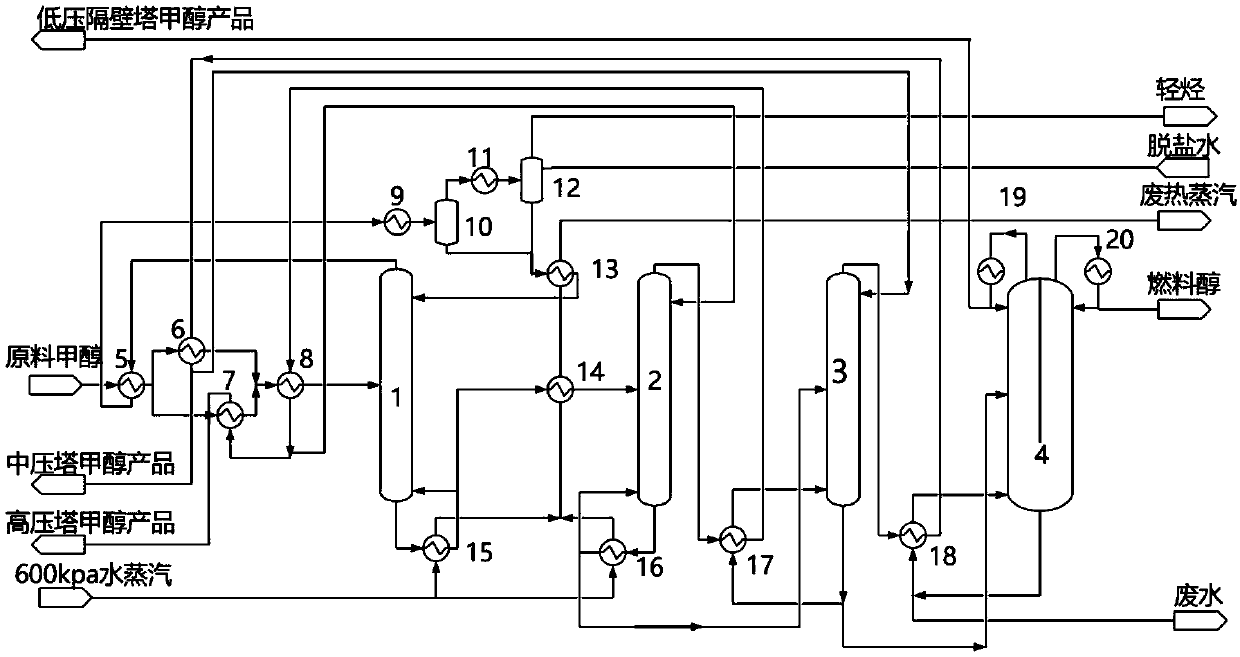

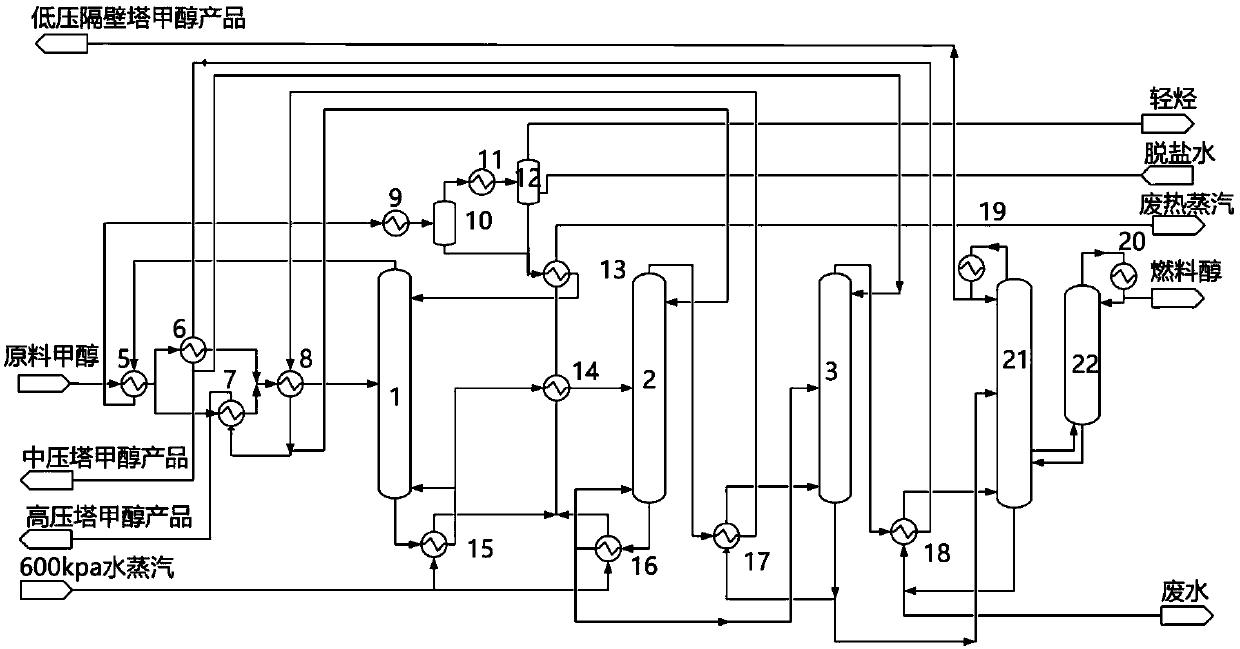

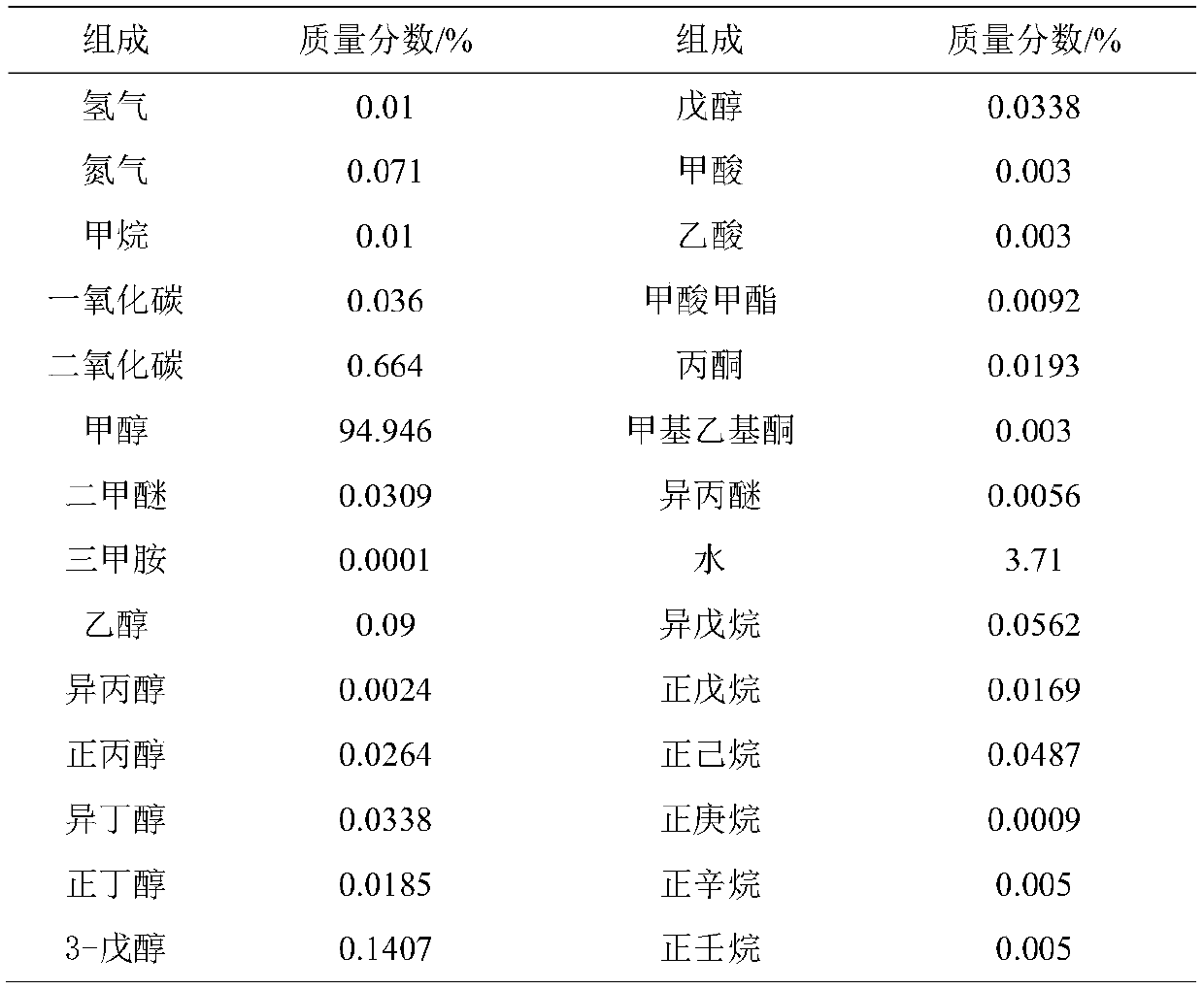

Energy-saving non-fusel oil dividing wall column-coupled multi-effect methanol rectification device and method

The invention relates to energy-saving non-fusel oil dividing wall column-coupled multi-effect methanol rectification device and method. The device comprises a light component removal tower, a high-pressure tower, a medium-pressure tower a low-pressure non-fusel oil dividing wall column; the bottom of the light component removal tower is connected with a steam primary heat exchanger and the middle-lower part of the high-pressure tower through a pipeline; and the bottom of the high-pressure tower is connected with the middle-lower part of the medium-pressure tower. The bottom of the medium-pressure tower is connected with the middle-lower part of the low-pressure non-fusel oil dividing wall column through a pipeline. The energy-saving non-fusel oil dividing wall column-coupled multi-effectmethanol rectification is different from conventional double-effect methanol rectification, and the pressures and the tower top methanol extraction distribution of the high-pressure column, the medium-pressure tower and the low-pressure non-fusel oil dividing wall column are adjusted to make tower top steam of the high-pressure tower provide heat for a reboiler at the bottom of the medium-pressuretower and tower top steam of the medium-pressure tower provide heat for the low-pressure non-fusel oil dividing wall column in order to form the multi-effect rectification. The preheating of a raw material fully utilizes hot stream in the process to replace steam, so the steam consumption is saved, and the methanol consumption is 0.6-0.8 t / t steam.

Owner:TIANJIN UNIV

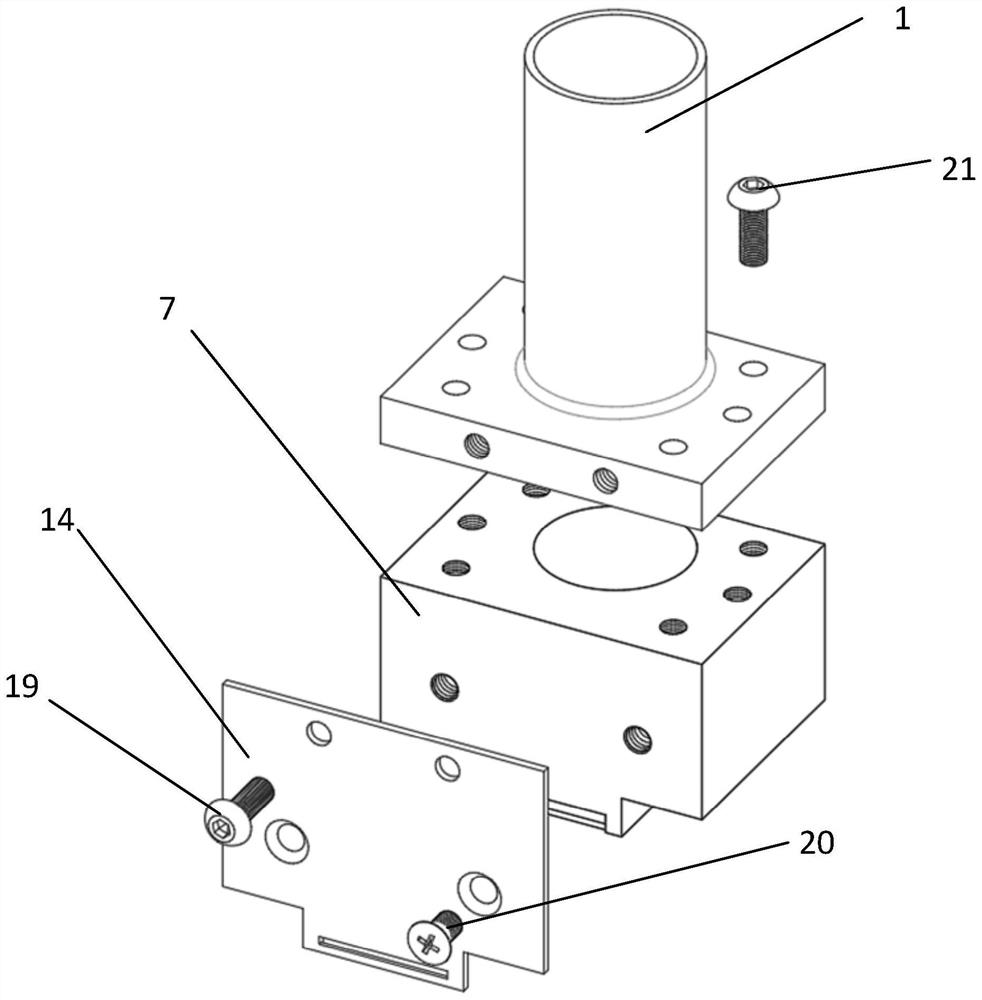

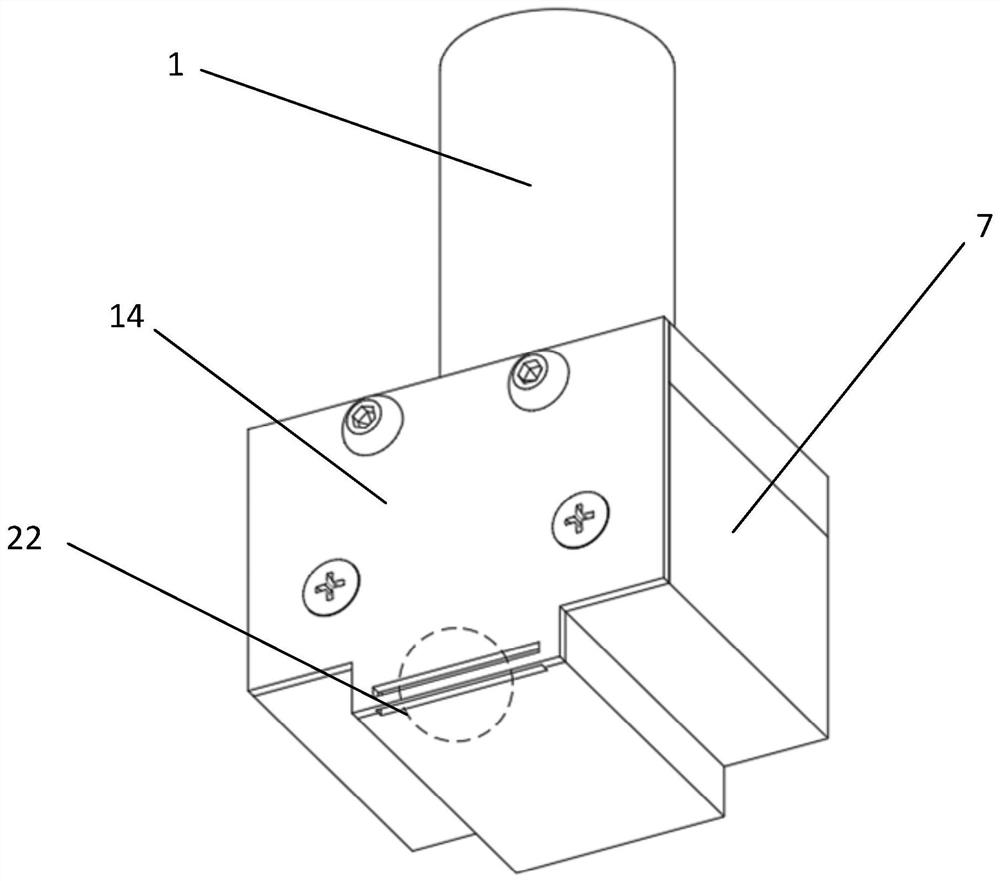

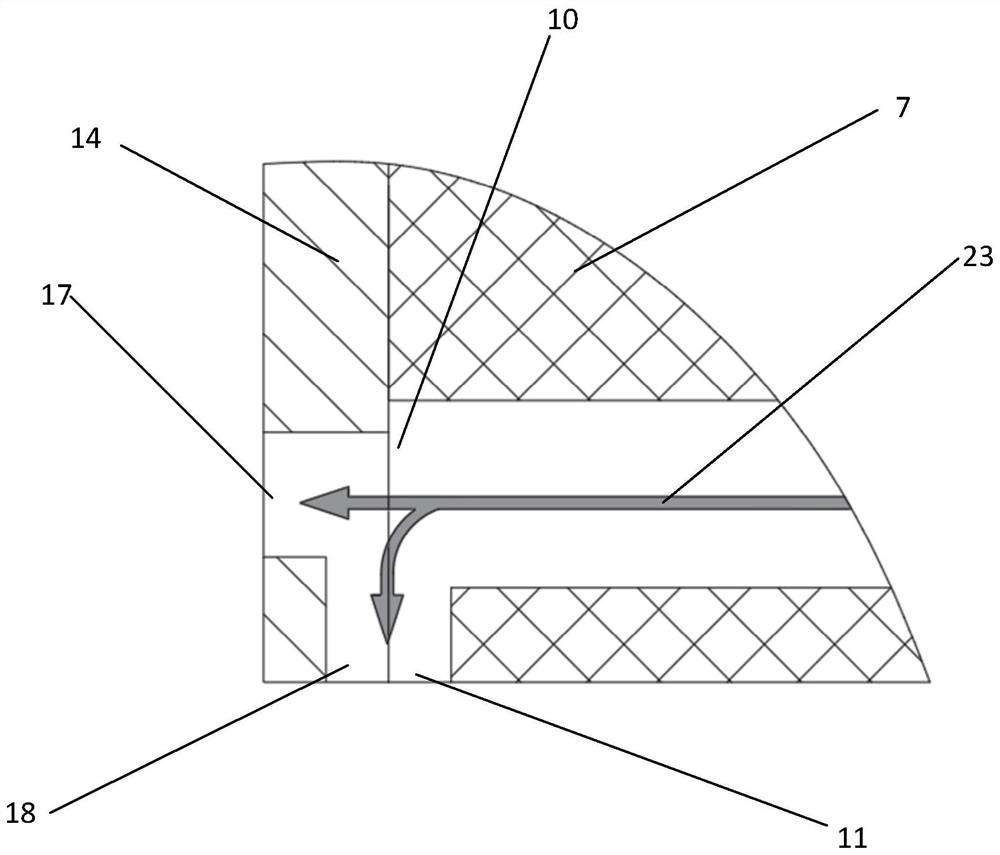

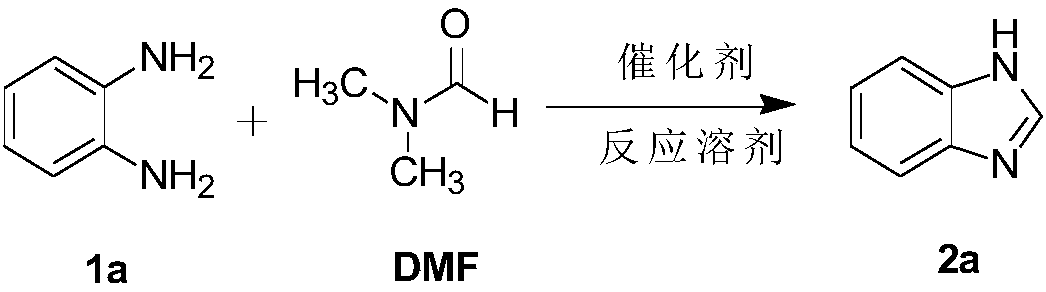

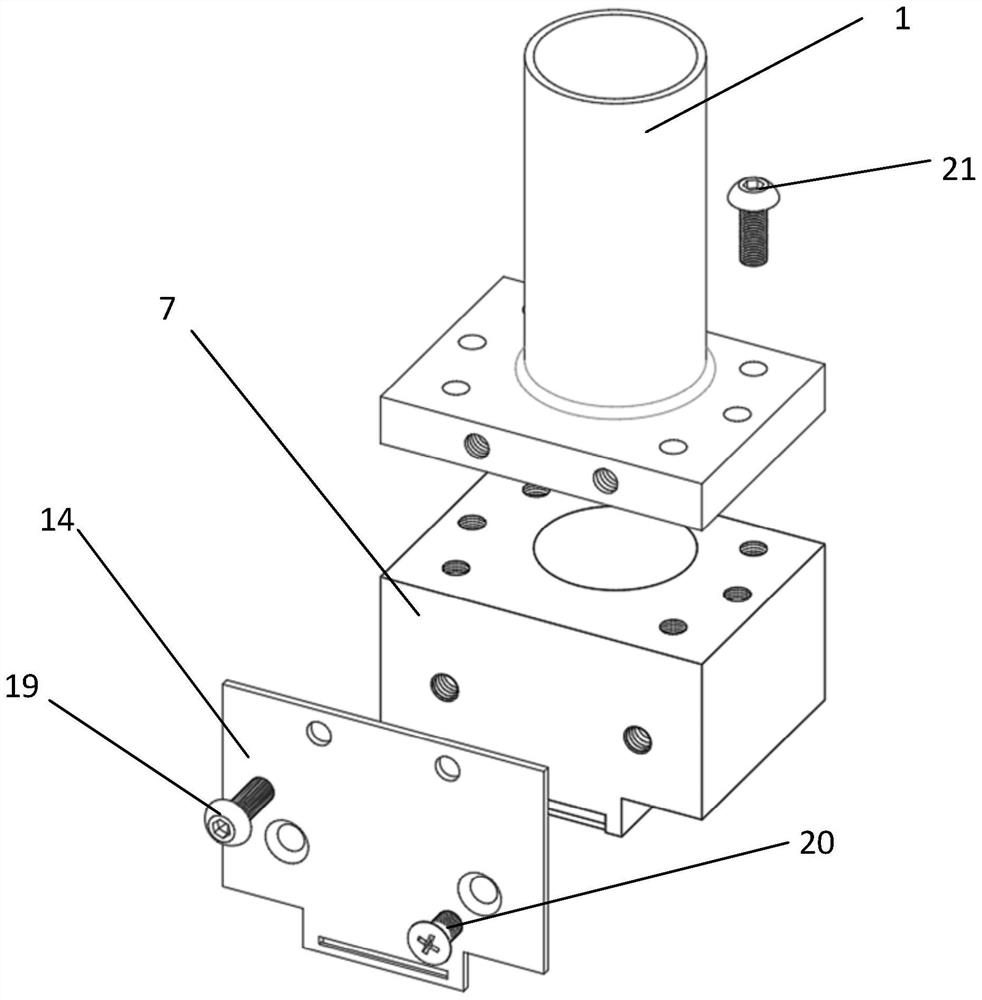

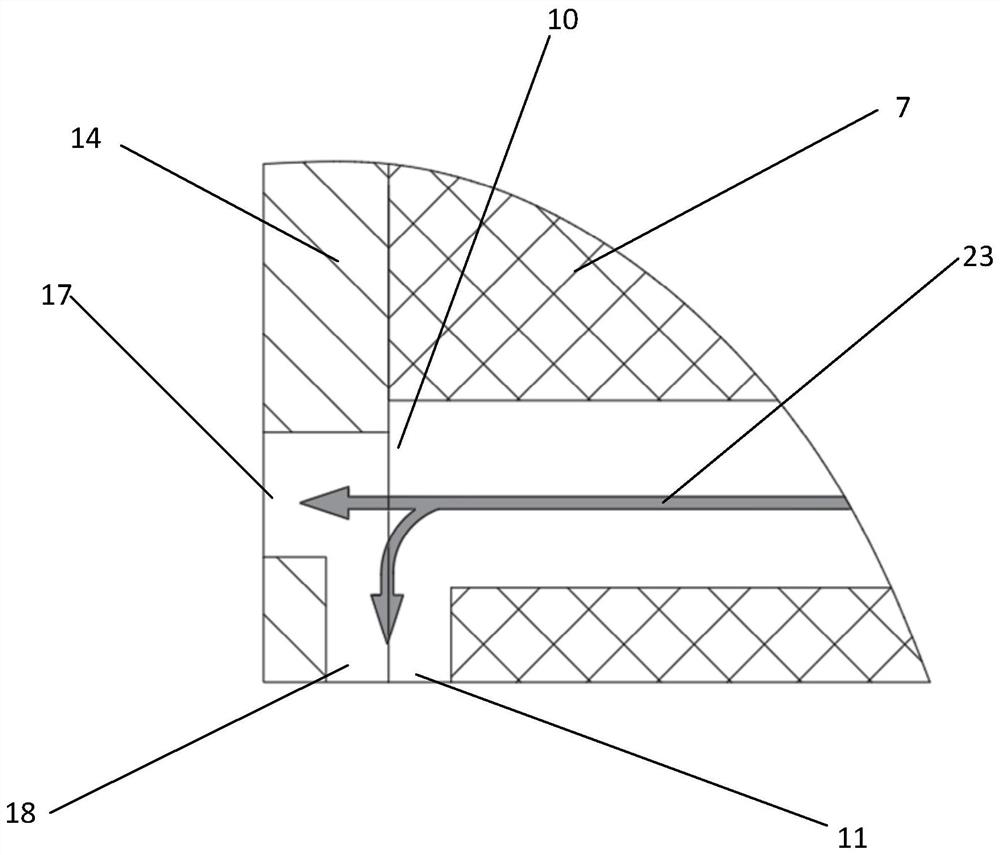

Combined Electrolytic Machining Tool Cathode and Method for Improving Flatness of Machining Bottom Surface

ActiveCN112091338BSimple structureLow costMachining electrodesElectrical-based machining electrodesElectrolytic agentMachined surface

The invention relates to a combined electrolytic machining tool cathode and a method, belonging to the field of electrolytic machining. The tool cathode of the present invention includes a tool handle, an insulating block, a conductive plate, a lead screw and a fastening screw. Aiming at the problems of stray corrosion and poor flatness of the bottom surface when the rod-shaped cathode tool is machining grooves, a combined electrolytic machining tool cathode for machining plane and shaft parts is proposed. Using a conductive plate with a thickness of less than 1mm limits the conductive area between the tool and the machined surface. Compared with the previous circular conductive area, the conductive area at the bottom is greatly reduced, and the machining along the radial feed direction of the tool cathode The electricity distribution at the bottom of the groove is equal everywhere, which effectively improves the flatness of the bottom of the groove in electrolytic machining. A long insulating boss and an insulating area larger than the width of the machining groove are designed, which increases the resistance and back pressure of the electrolyte flowing from the bottom of the tool to the machined surface, improves the flow field in the machining area, and effectively suppresses stray corrosion.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

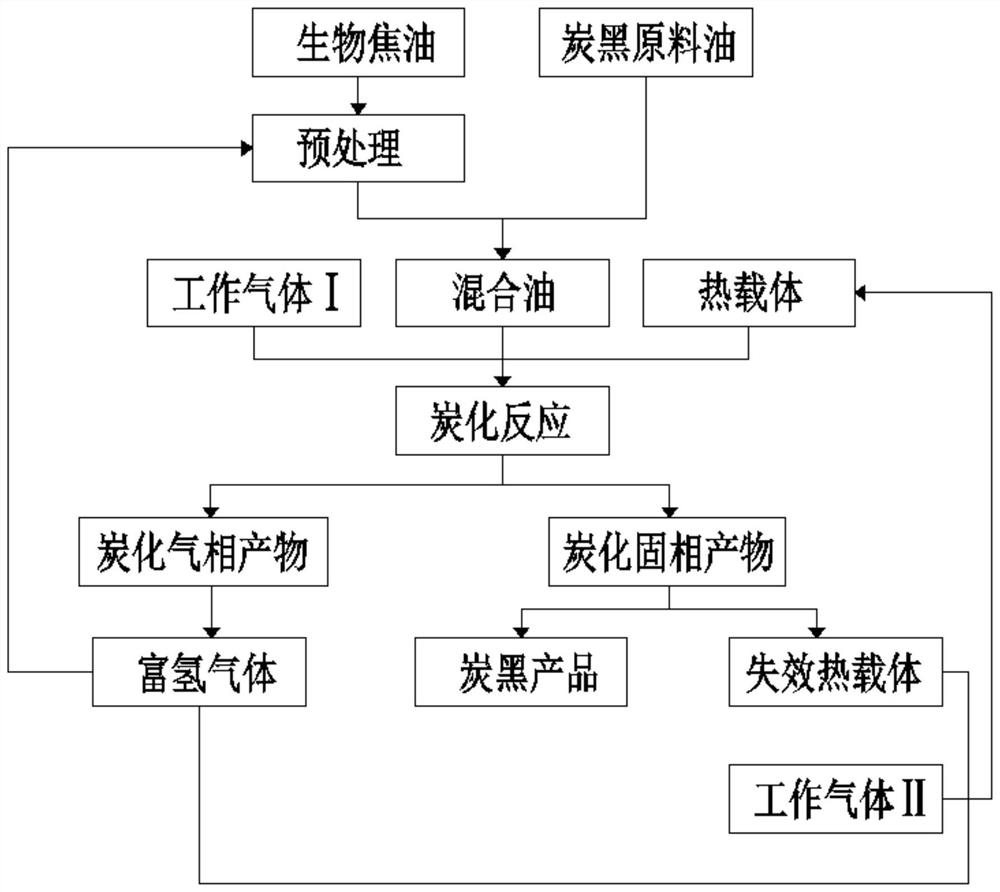

Method for producing carbon black by blending biological tar

ActiveCN111662733AReduce oxygen contentMeet the requirements of production conditionsPigmenting treatmentDirect heating destructive distillationGas solidHeat carrier

The invention belongs to the technical field of carbon black production, and particularly relates to a method for producing carbon black by blending biological tar. The method comprises the followingsteps: blending pretreated biological tar into carbon black raw oil to form mixed oil, and carrying out carbonization reaction on the mixed oil and a high-temperature heat carrier under the action ofworking gas I to obtain a carbonized gas-phase product and a carbonized solid-phase product; carrying out gas-solid separation and fine filtration on the carbonized gas-phase product, then using one part of the carbonized gas-phase product for pretreatment of biological tar, and carrying out gas-solid separation on the carbonized solid-phase product for multiple times to obtain a carbon black product and an inactivated heat carrier containing part of the carbon black product; and regenerating the inactivated heat carrier under the action of the working gas II. The method fundamentally solves the problem that the biological tar is difficult to be directly used for raw material matching, process regulation and control and the like in the carbon black production process, reduces the consumption of exogenous substances and energy sources in the process and has favorable application prospects.

Owner:营口辽滨炭黑有限公司

Molten salt electrolytic refining method and method for recovering and treating cathode deposition thereof

ActiveCN103556187AReduction of recycling energy consumptionImprove process economyElectrolysis componentsAqueous solutionAfter treatment

The invention provides a molten salt electrolytic refining method and a method for recovering and treating cathode deposition thereof. The recovering and treating method comprises the following steps: putting the cathode deposition in a dilute acid solution having the acid concentration not lower than 0.01mol / L for extraction to obtain an extract solution; continuously carrying out extraction to obtain a saturated extract solution; adjusting the pH value of the saturated extract solution to form a precipitate; filtering to obtain a settled solution; carrying out crystallization treatment to obtain electrolyte crystals. The refining method comprises the following step: treating the cathode deposition containing the target product by using the recovering and treating method. The method for recovering and treating cathode deposition provided by the invention has the beneficial effects that the electrolyte entrained in the cathode deposition of molten salt electrolytic refining can be separated and recovered without affecting the after treatment process effect of the cathode deposition, and the method is low in recovery energy consumption, good in process economical efficiency and low in environment stress.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

Method for treating waste generated during pesticide intermediate production

InactiveCN106430110AMeet environmental protection requirementsIncrease economic benefitsWater contaminantsTreatment involving filtrationChemistryPesticide

The invention discloses a method for treating waste generated during pesticide intermediate production. The waste generated during pesticide intermediate production is treated by the aid of acid adding reaction processes, and accordingly sulfur-containing substances in the waste can be completely transformed; sulfur and byproducts can be recycled by the aid of filter and solvent-out crystallization processes. The method includes operation of reaction, absorption, filter, solvent-out crystallization, distillation, liquid and solid separation and the like. The method has the advantages of low cost, high efficiency, environmental protection and energy conservation. Besides, the sulfur and the byproducts can be recycled, accordingly, environmental protection requirements can be met, and economic benefits can be increased.

Owner:天津海威欧能源科技有限责任公司

Method for increasing yield of ethylene and propylene

ActiveCN101239868BReduce partial pressureHigh yieldMolecular sieve catalystsMolecular sieve catalystDimethyl etherEthylene

The invention relates to a method for improving yield of ethylene and propylene, which solves the problem of low yield of ethylene and propylene during lower olefins preparing process from conversion of methanol and dimethyl ether. The invention uses at least one of methanol and dimethyl ether and C4 hydrocarbon as materials, the materials enter into a reaction region from a distributor at the bottom of a fluidization bed reactor or from at least a position axially separated along the reaction region, and contact and react with a catalyst to generate an effluent containing ethylene, propylene and C4 hydrocarbon, the effluent is separated to obtain ethylene, propylene and C4 hydrocarbon; wherein, the C4 hydrocarbon material is from fresh mixed C4 hydrocarbon or mixed C4 hydrocarbon obtained by separation or mixtures thereof. In this way, the invention solves the problem well, and is useful in industrial production of ethylene and propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

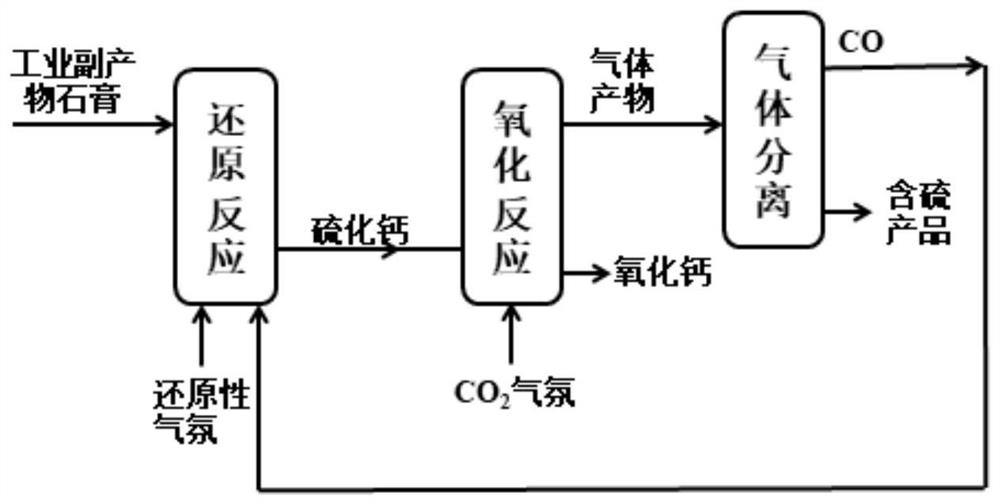

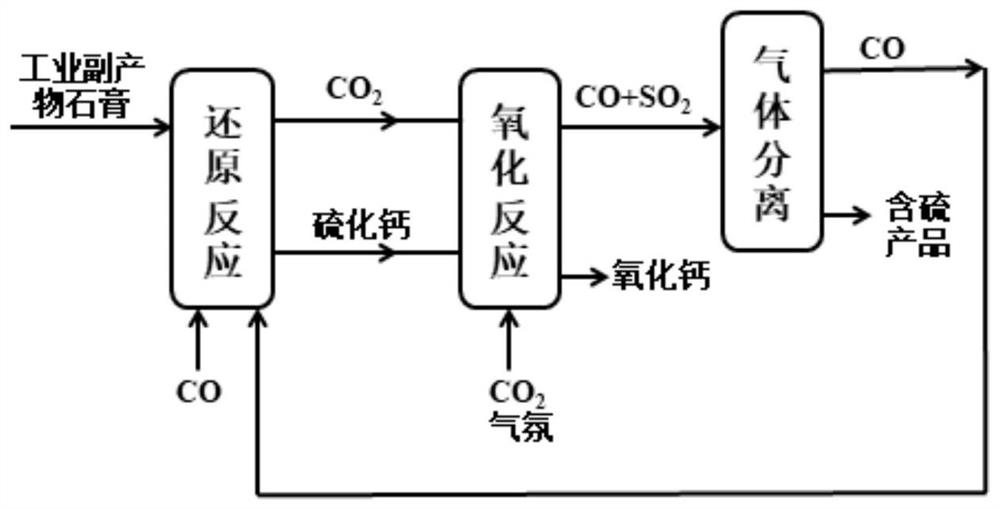

Method for preparing calcium oxide by using industrial byproduct gypsum

ActiveCN113603126AAvoid the problem of low selectivityHigh puritySulfur compoundsCarbon monoxideReduction treatmentCalcium sulfide

The invention provides a method for preparing calcium oxide by using industrial byproduct gypsum, which comprises the following steps: carrying out reduction treatment on the industrial byproduct gypsum, and carrying out oxidation treatment on the obtained calcium sulfide in a CO2 atmosphere. According to the method, two treatment processes of reduction and oxidation are adopted, the initial reaction temperature can be effectively reduced, the decomposition rate and the conversion rate of raw materials can be increased, heat released in oxidation treatment can provide heat for self reaction and can also provide heat for reduction reaction, system energy consumption and operation cost are reduced, and the economical efficiency of the process is improved. No secondary pollutant is discharged in the calcium oxide preparation process, gas generated in the process can be recycled, the gypsum decomposition rate reaches 99%, the calcium oxide conversion rate reaches 97%, and efficient resource utilization of the industrial byproduct gypsum waste residues is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

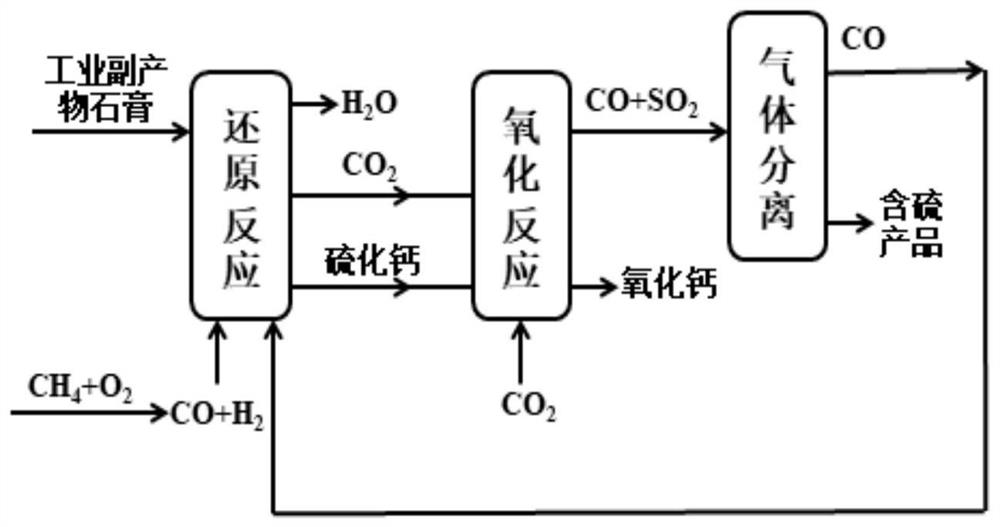

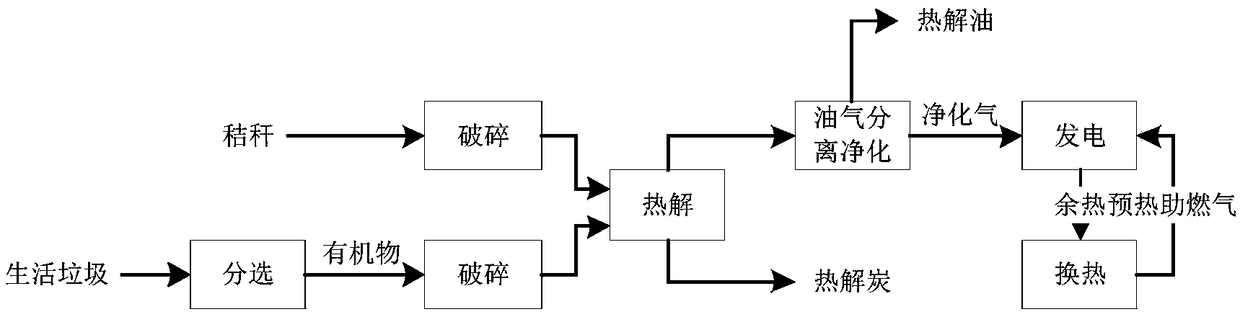

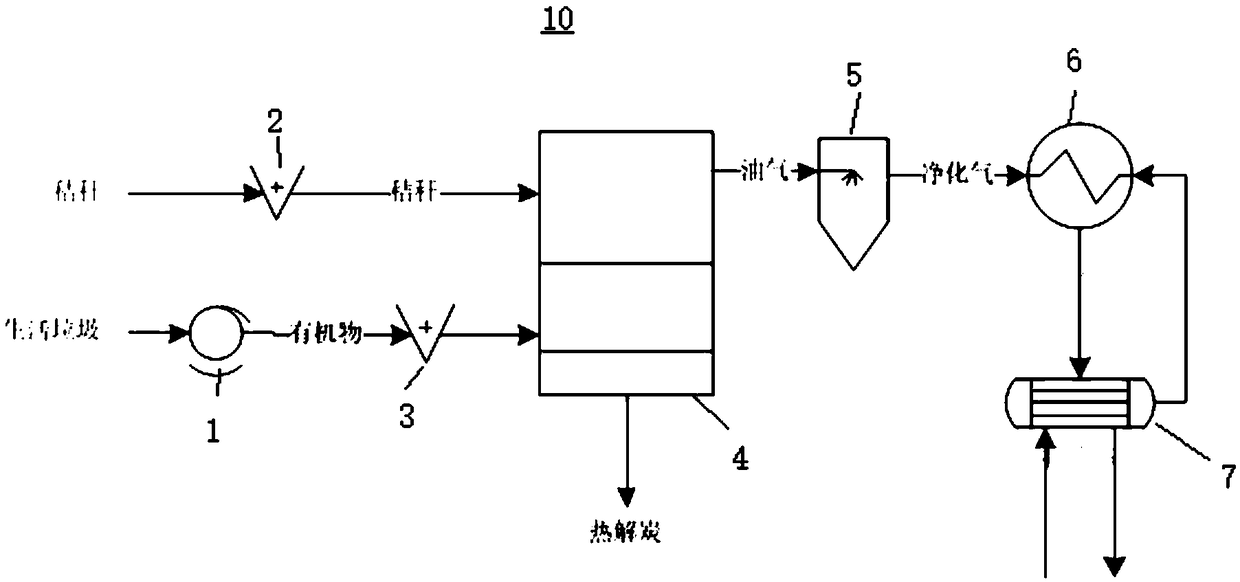

Method for co-treating domestic garbage and straws and system for implementing method

PendingCN109456775ASolve pollutionSolve problems such as pollutionInternal combustion piston enginesBiofuelsSolid carbonCombustion

The invention discloses a method for co-treating domestic garbage and straws and a system for implementing the method. The method comprising the following steps: S1, sorting the domestic garbage to obtain organic matters; S2, respectively crushing the organic matters and straws into granular forms; S3, conveying the crushed organic matters and straws into a pyrolysis device for pyrolysis treatmentto obtain pyrolyzed oil gas and pyrolyzed carbon; and S4, separating the pyrolyed oil gas to obtain pyrolyzed oil and pyrolyzed gas, wherein the pyrolyzed gas is used for combustion power generation.Therefore, by using the above method, the purified pyrolyzed gas is fed into an internal combustion engine for power generation, and the solid carbon and the pyrolyzed oil are sold as products. The technological method not only solves the problems of dioxin and fly ash pollutions and the like in the garbage treatment process, but also efficiently utilizes agricultural and forestry waste straws, thereby reducing the operation cost, improving the process economy and facilitating industrial popularization.

Owner:HAINAN HEDING TECH CO LTD

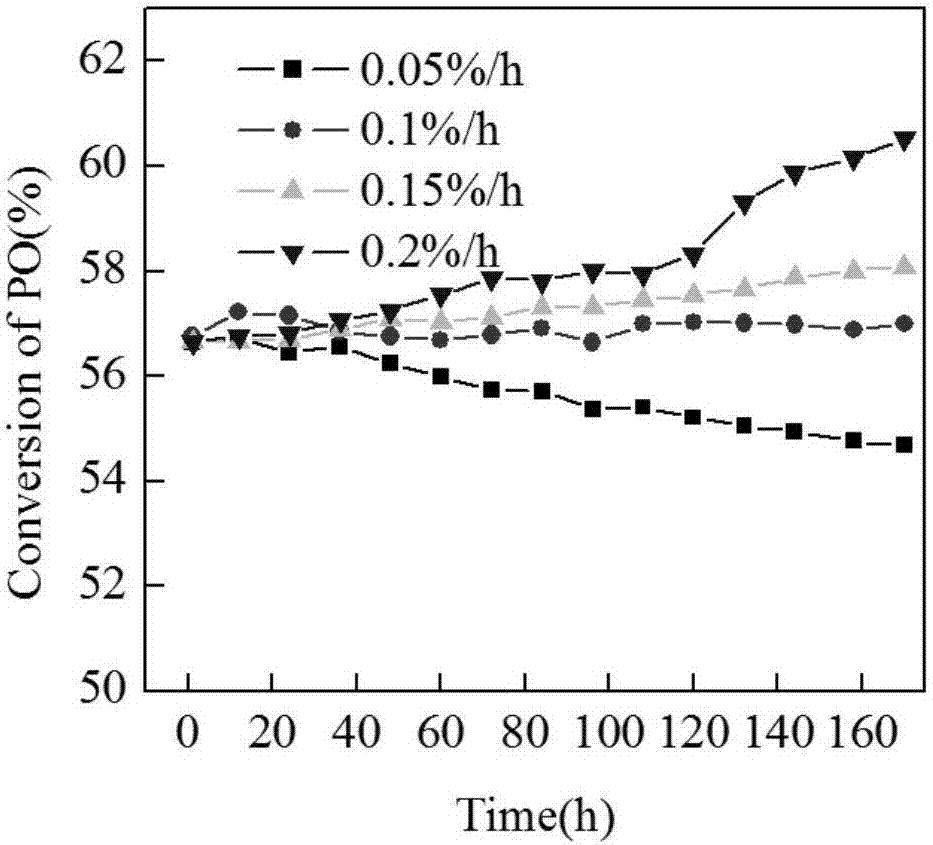

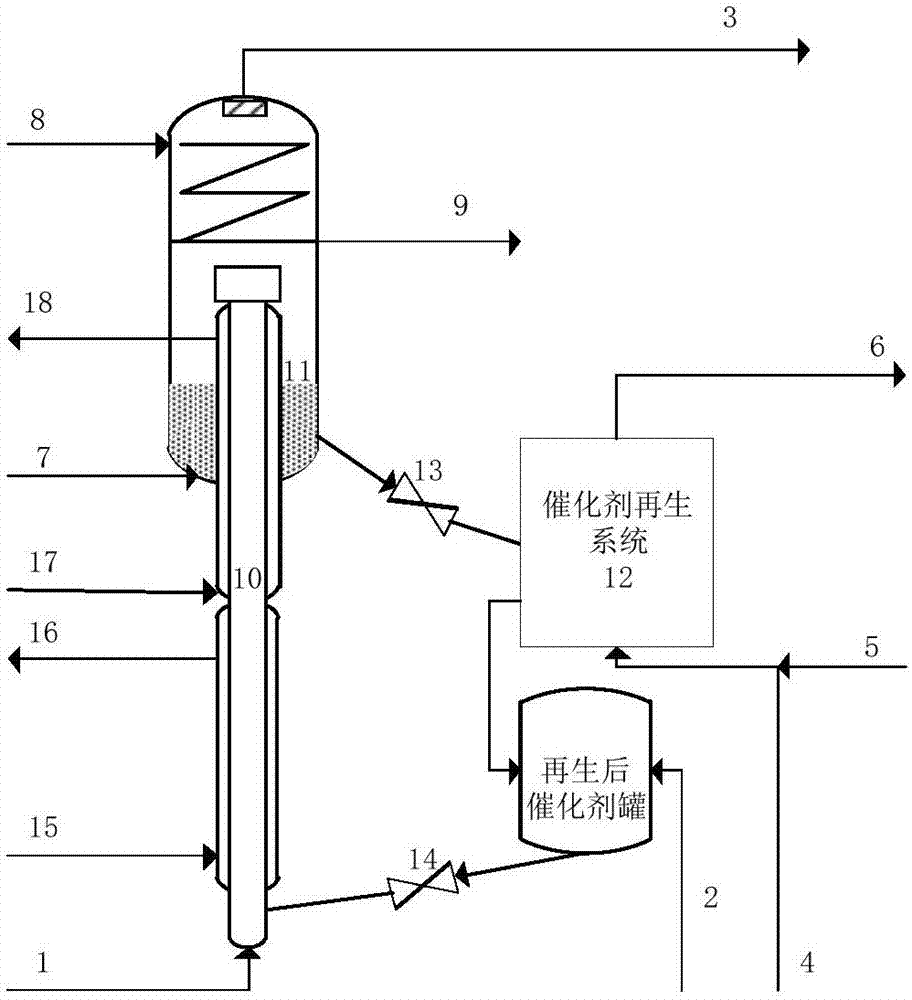

Device and method for continuously isomerizing epoxide

ActiveCN107879899APrecise control of reaction temperatureImprove reliabilityPreparation by isomerisationPhysical/chemical process catalystsIsomerizationFluidized bed

The invention relates to a device and a method for continuously isomerizing epoxide, which can be used for continuous isomerizing preparation of corresponding allyl alcohol products from epoxide. Themethod comprises steps as follows: reaction raw materials and carrier gas are preheated to certain temperature, the raw materials are contacted with a regenerated catalyst and a newly supplemented catalyst in a fluidized state in a fluidized bed reactor at a certain air speed, an isomerization reaction is performed under certain pressure, reaction gas and a carbon deposit catalyst are obtained through separation in a settler, wherein reaction gas rises and enters a product separation system via a reaction liquid pipeline at the top of the settler, the carbon deposit catalyst enters a regenerator for regeneration, and the regenerated catalyst returns to a lifting pipe reactor via a regenerated catalyst pipeline. The process has the characteristics of high atom economy, product yield and selectivity and no pollution and is notably superior to a current slurry bed process.

Owner:WANHUA CHEM GRP CO LTD

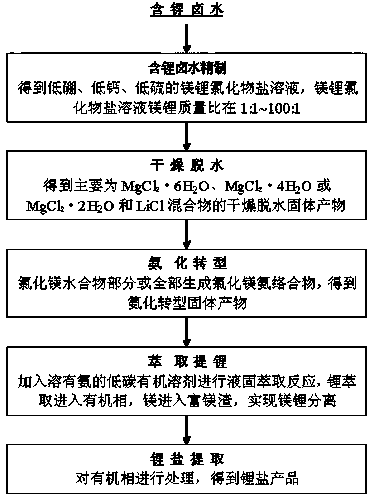

Method for extracting lithium salt from high magnesium-lithium ratio salt lake brine

ActiveCN106082285BHigh purityImprove processing economyProcess efficiency improvementLithium carbonates/bicarbonatesLithium soapLithium chloride

Owner:湖南中大技术创业孵化器有限公司

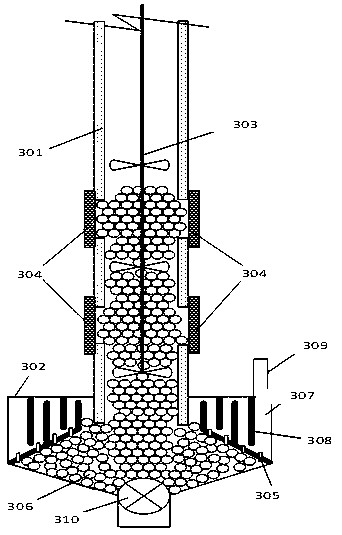

Biomass microwave pyrolysis gasification method and system

ActiveCN111378509AReduce outputReduce energy consumptionGasification catalystsWaste based fuelChemistryActivated carbon

The invention discloses a biomass microwave pyrolysis gasification method and system. The method comprises the following steps: preheating a biomass raw material, and feeding the preheated biomass rawmaterial into a microwave pyrolysis reactor for oxidative pyrolysis reaction; feeding a pyrolysis product into a microwave cracking reactor for cracking reaction, thus obtaining cracking crude synthesis gas and a solid-phase material after the reaction; feeding the solid-phase material into a biochar microwave gasification reactor for reaction, thus obtaining gasified crude synthesis gas and activated carbon; feeding cracked crude synthesis gas and gasified crude synthesis gas into a raw material preheating tank to preheat a biomass raw material, performing gas-solid separation on the crude synthesis gas subjected to heat exchange, and feeding a gas-phase material obtained after gas-solid separation to a purification reactor, and treating the gas-phase material through a membrane filter in the purification reactor to obtain purified synthesis gas. According to the biomass microwave pyrolysis gasification method and system, the yield of the synthesis gas can be increased, the tar content in the obtained synthesis gas product is low, and meanwhile, a high-quality activated carbon product is co-produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

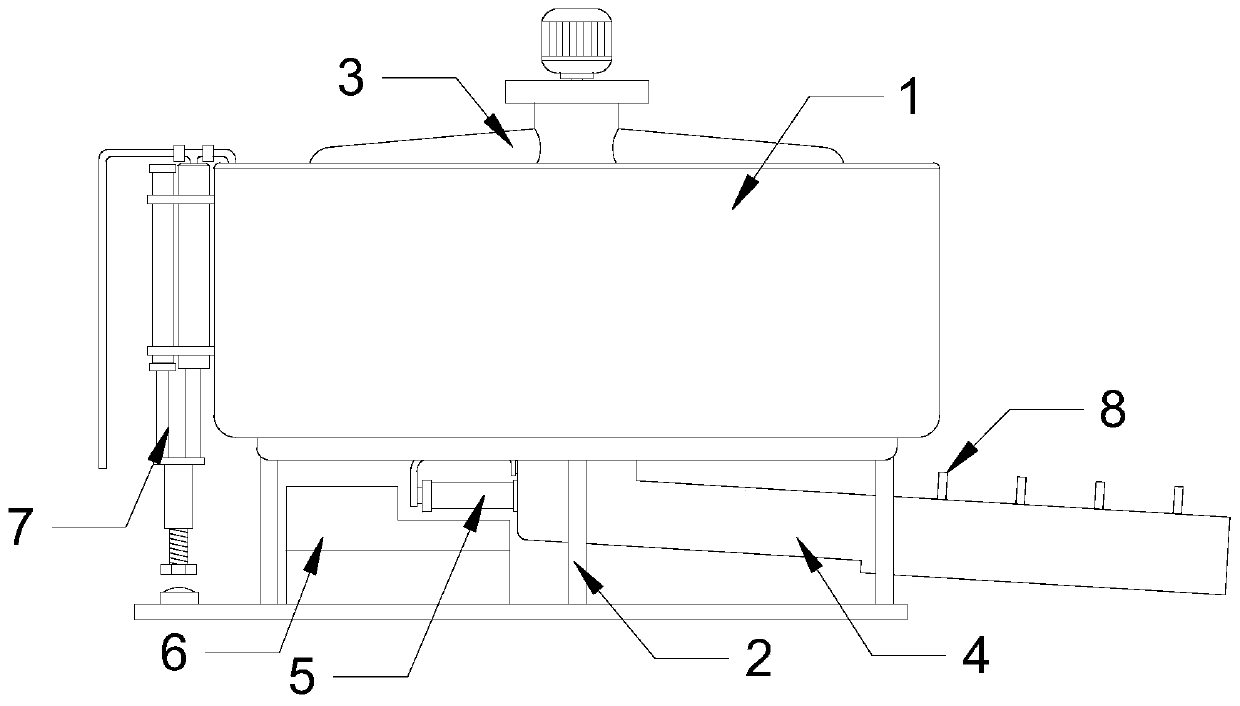

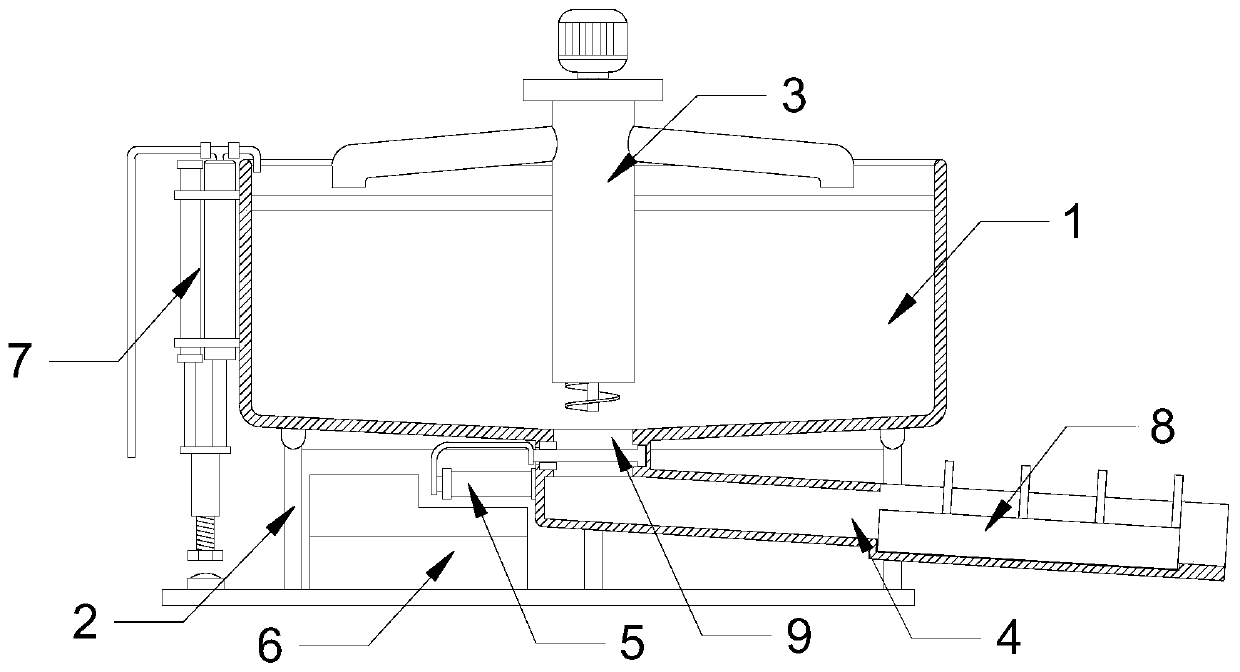

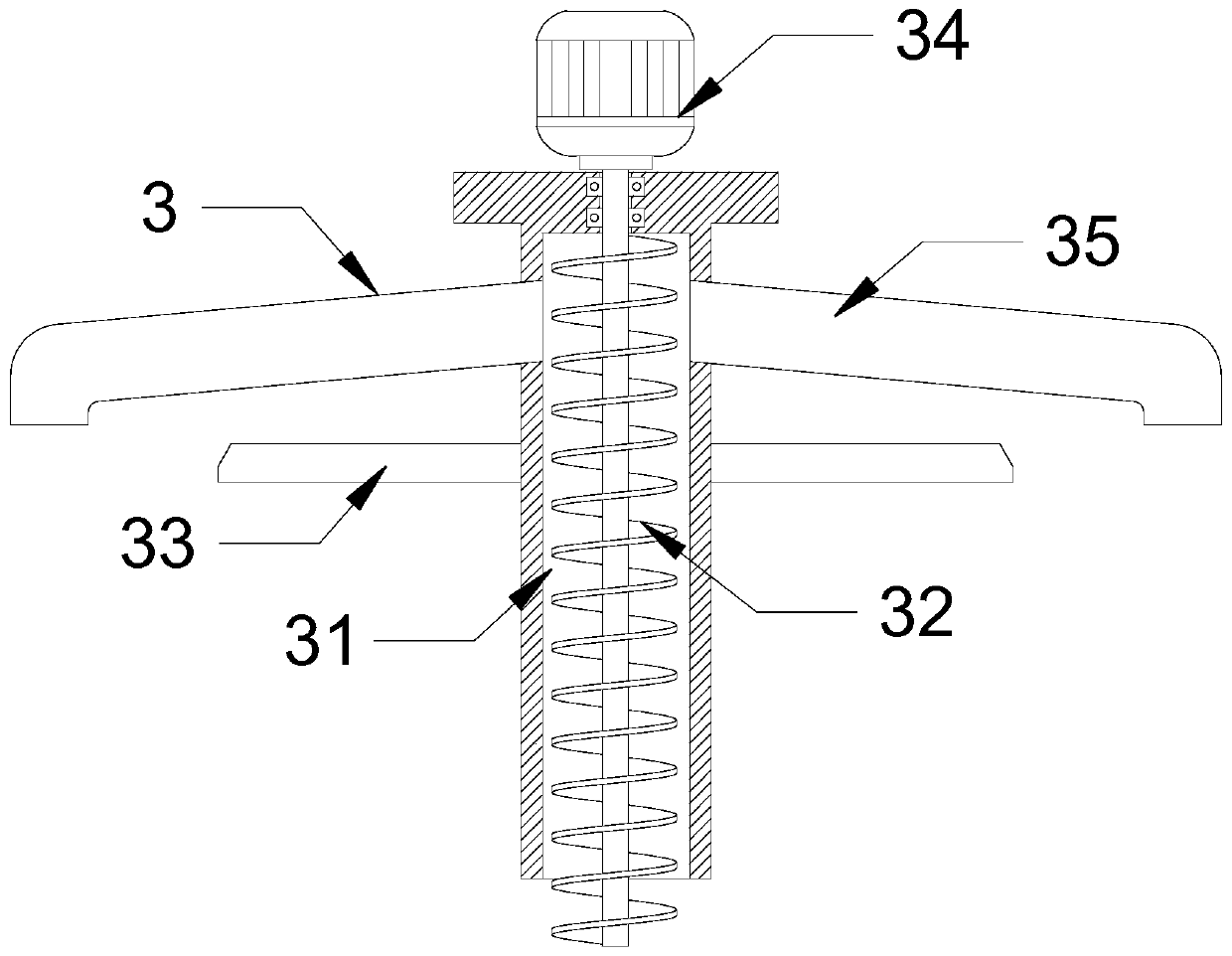

Purification device for traditional Chinese medicine production

PendingCN111494981AEasy to add quantitativelyFeeding volume adjustmentSolid solvent extractionStationary filtering element filtersProcess engineeringIndustrial engineering

The invention discloses a purification device for traditional Chinese medicine production and processing, and belongs to the field of traditional Chinese medicine processing. The invention discloses apurification device for traditional Chinese medicine production. The device comprises a tank body, a bottom frame, a stirring mechanism, a discharging square pipe, a switching mechanism, an electriccontrol box, a liquid injection mechanism, a filtering mechanism and a discharging port; a bottom frame is fixed to the bottom of the tank body, a discharging port is formed in the center of the bottom face of the tank body, a discharging square pipe communicated with the discharging port is fixed to the bottom face of the tank body, a filtering mechanism is placed on the inner side of the end ofthe discharging square pipe, a switching mechanism is installed at the end, close to the tank body, of the discharging square pipe, and a liquid injection mechanism is installed on the outer wall of the tank body. Traditional Chinese medicine solvents are fully mixed through the stirring mechanism, the purification efficiency and precision are improved, adjustable quantitative solvent adding is achieved through the liquid injection mechanism, solvent waste is reduced on the premise that medicine components are fully absorbed, and the processing economy is improved.

Owner:陈宝强

Semi-aqueous cleaning agent composition as well as preparation method and optical cleaning application thereof

PendingCN114410393AEnhanced removal of putty and solid impuritiesHigh solubilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolventKetone

The invention discloses a semi-aqueous cleaning composition and a preparation method and application thereof. The composition comprises 5-20% of a permeation solvent, 1-5% of surface active peptide, 2-10% of sophorolipid, 1-5% of NaOH, 1-5% of sodium carbonate, 3-8% of sodium metasilicate, 2-15% of N, N-diethylhydroxylamine and water. The osmotic solvent is one or two of aldehyde condensation 2, 3-butanediol and ketone condensation 2, 3-butanediol, and the osmotic solvent is one or two of aldehyde condensation 2, 3-butanediol and ketone condensation 2, 3-butanediol; the mold cleaning agent for resin lens production, provided by the invention, has small damage to a mold, has a good removal effect on residual adhesives, resin monomers and resin solids at the edge of the mold, and effectively improves the qualified rate of resin lens production. Meanwhile, the cleaning agent provided by the invention has the characteristics of thorough oil removal, dust removal, surface residual fiber removal and the like, and the qualified rate of resin lens coating is effectively improved.

Owner:新沂肽科生物科技有限公司

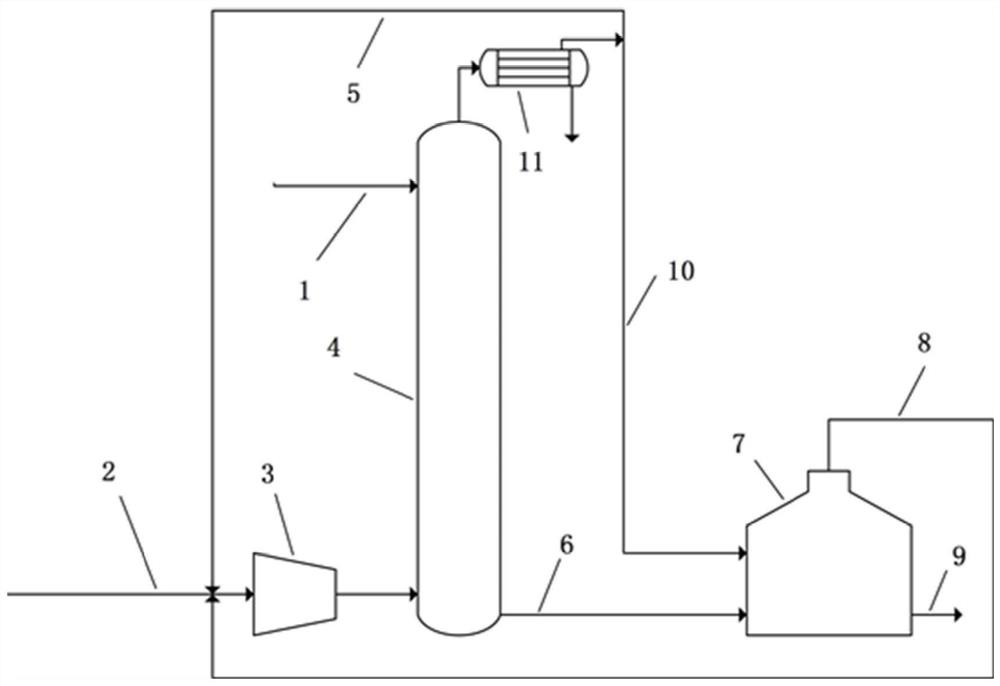

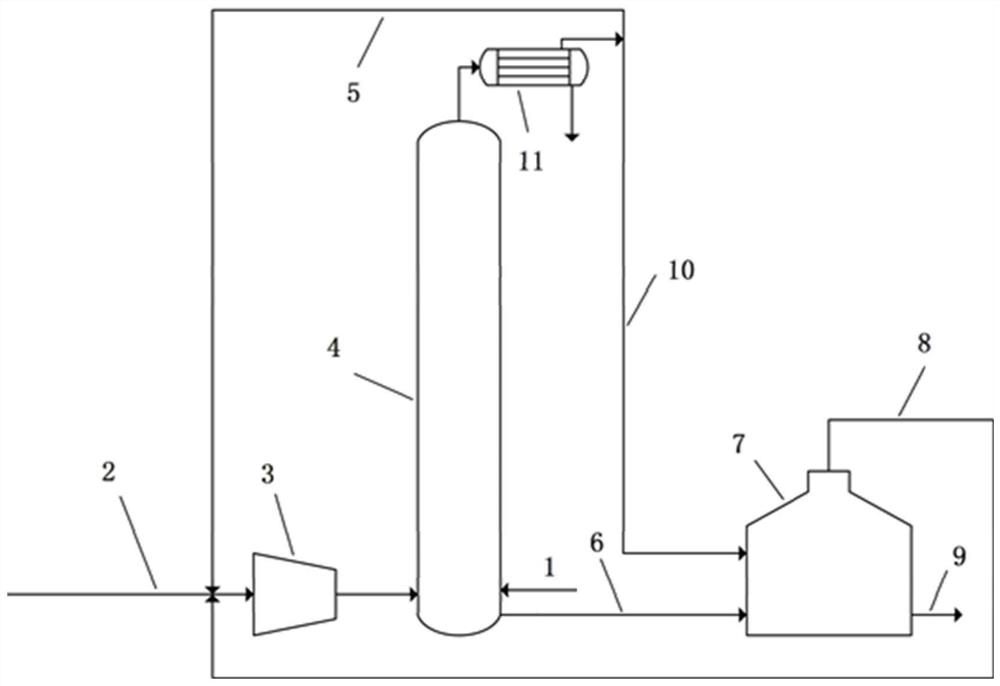

Zero-emission oxidation device and method for producing hydrogen peroxide by anthraquinone method

InactiveCN111717894AEliminate emissionsSecurePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDispersed particle separationAnthraquinonesHydrogen peroxide breakdown

The invention relates to the field of hydrogen peroxide preparation, and discloses a zero-emission oxidation device and method for producing hydrogen peroxide by an anthraquinone method. The oxidationdevice comprises an oxidation tower (4) and an oxidation liquid receiving tank (7), wherein the oxidation tower (4) supplies oxygen-enriched gas through a gas supply unit (3), introduces hydrogenation liquid through a hydrogenation liquid inlet (1), and is used for carrying out an oxidation reaction on the hydrogenation liquid and the oxygen-enriched gas to obtain oxidation liquid containing hydrogen peroxide, leading out the oxidation liquid through an oxidation liquid leading-out pipe (6) and storing the oxidation liquid in the oxidation liquid receiving tank (7). The device and the methodhave good safety, can ensure safe and stable operation of the device, and reasonably utilize oxygen generated by decomposition of hydrogen peroxide in the oxidation liquid receiving tank.

Owner:CHINA PETROLEUM & CHEM CORP +1

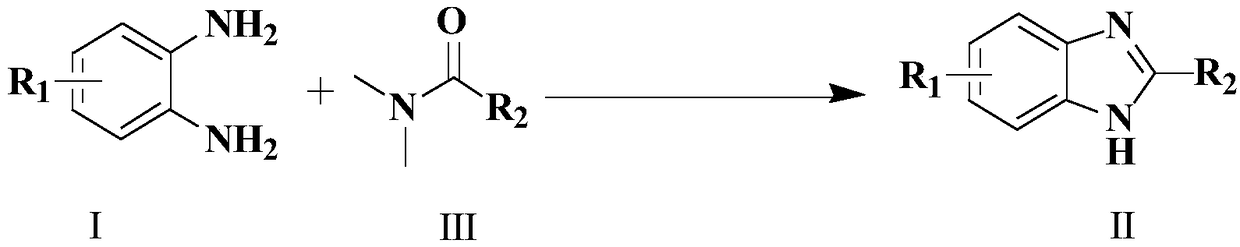

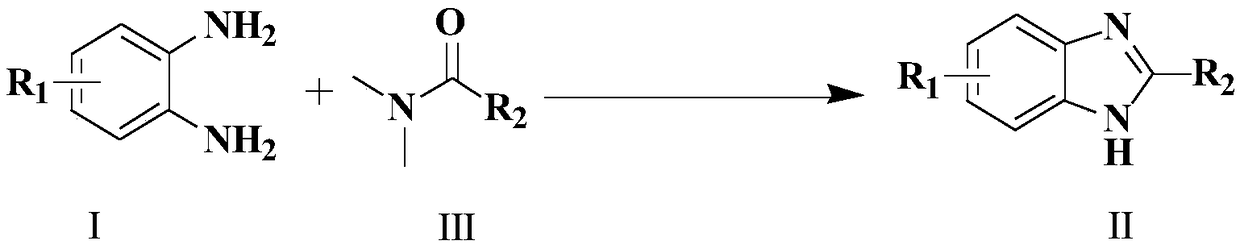

Method for synthesizing benzimidazole and derivative

InactiveCN109265403AGood functional group toleranceGood yield and purityOrganic chemistryBenzimidazoleChloride

The invention provides a method for synthesizing benzimidazole and its derivative. The synthesis of polyfunctional benzimidazole and 2-substituted benzimidazole is achieved by imidazole chloride catalyzed o-phenylenediamine cyclization. The method is simple and economical and strong in practicability. No catalyst or additive is added. The synthesis method has good functional group tolerance, excellent yield and purity and short reaction time, does not require harsh reaction conditions and is suitable for industrial production.

Owner:CHONGQING MEDICAL UNIVERSITY

Combined electrolytic machining tool cathode and method for improving flatness of machined bottom surface

ActiveCN112091338AIncrease resistanceHigh trafficMachining electrodesElectrical-based machining electrodesElectrically conductiveEngineering

The invention relates to a combined electrolytic machining tool cathode and method, and belongs to the field of electrolytic machining. The tool cathode comprises a knife handle, an insulating block,a current-conducting plate, an electricity leading screw and a fastening screw. The combined electrolytic machining tool cathode aims to solve the problems of stray corrosion, poor flatness of bottomsurface and the like generated when a rod-shaped cathode tool is used for machining a groove. The current-conducting plate with the thickness smaller than 1 mm is used, and a current-conducting area between a cutter and a machined surface is limited. Compared with a previous circular current-conducting area, the bottom current-conducting area is greatly reduced, electric quantity distribution of the bottom of a machining groove in the radial feeding direction of a tool cathode is equal everywhere, and the flatness of the bottom of the groove in electrolytic machining is effectively improved; and the long insulating boss and the insulating area with the width larger than that of the machined groove are designed, resistance and back pressure of electrolyte flowing through the machined surface from the bottom of the cutter are increased, flow field of the machining area is improved, and stray corrosion is effectively restrained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

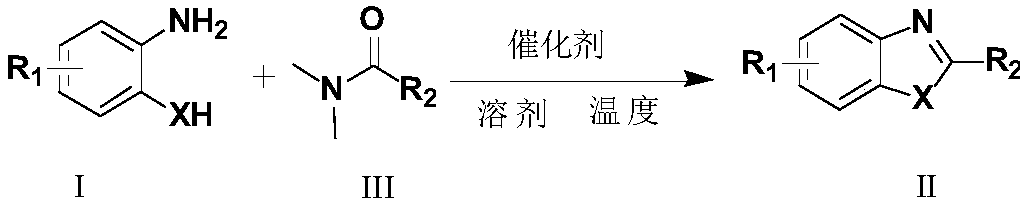

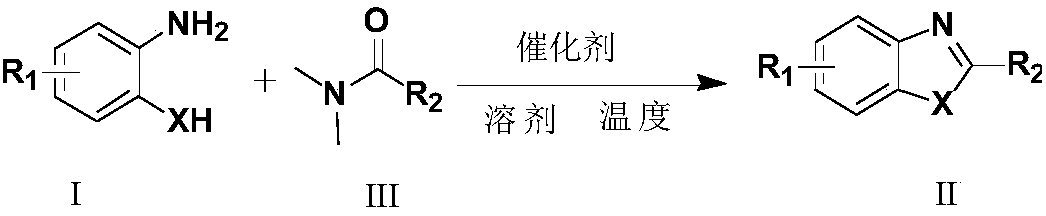

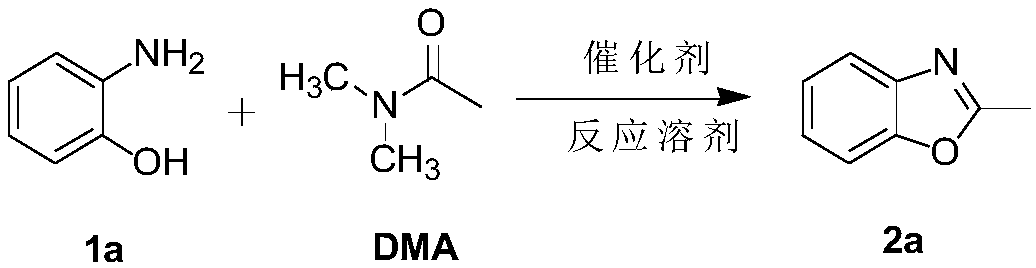

Synthesis method of 2-substituted benzoxazole, 2-substituted benzothiazole and derivatives thereof

The invention provides a synthesis method of 2-substituted benzoxazole, 2-substituted benzothiazole and derivatives thereof. In the method, through ortho-aminophenol / 2-aminothiophenol cyclization catalyzed by imidazole hydrochloride, synthesis of functionalized 2-substituted benzoxazole and 2-substituted benzothiazole is realized; the method is simple, economical and high in practicality. No othercatalysts or additives are used, the synthesis method ensures good functional group tolerance and excellent yield and purity, the reaction time is short, no harsh reaction conditions are needed, andthe method is suitable for industrial production.

Owner:CHONGQING MEDICAL UNIVERSITY

Treatment method of sulfur-containing slurry

InactiveCN106587546AMeet environmental protection requirementsIncrease economic benefitsSludge treatmentSulfur preparation/purificationChemistrySulfur containing

The invention provides a treatment method of sulfur-containing slurry. In the method, the slurry is treated in a manner of adding acid to carry out a reaction, so that sulfur-containing substances in the slurry are completely converted. Through filtration and evaporative crystallization, the sulfur, as well as by-products, is recovered. The treatment method includes the operations of reaction, absorption, filtration, evaporative crystallization and liquid-solid separation. The treatment method has low cost and high efficient, is environment-friendly and saves energy, and can achieve recovery of the sulfur and the by-products, thereby satisfying environment protection and increasing economic benefit.

Owner:天津海威欧能源科技有限责任公司

Biomass pyrolysis gasification method and system

PendingCN114479951AImprove pyrolysis gasification efficiencyReduce generationGasification processes detailsCombustible gas productionCarbon layerHeat carrier

The invention discloses a biomass pyrolysis gasification method and system.The method comprises the steps that firstly, a biomass raw material is subjected to rapid heating treatment, and the biomass raw material with the surface carbonized is obtained after treatment; and then feeding the surface-carbonized biomass raw material into a microwave pyrolyzer for gasification reaction to obtain a synthesis gas product and solid residues after the reaction. The biomass pyrolysis gasification system comprises a preprocessor, a microwave pyrolyzer, a gas-solid separation unit and a heat carrier regenerator. According to the method, firstly, biomass raw materials are pretreated, the outer surfaces of the biomass raw materials are subjected to rapid carbonization treatment to form a carbon layer, pyrolysis volatile components released from inside to outside in the subsequent microwave pyrolysis gasification process can be subjected to cracking and reforming reaction with the formed carbon layer, endogenous power formed by tar is inhibited from the source, and the biomass raw materials can be recycled. The biomass pyrolysis gasification efficiency is improved, the economical efficiency of the process is improved, and the method has a good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

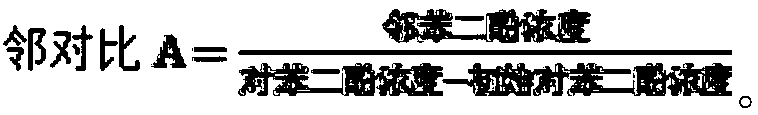

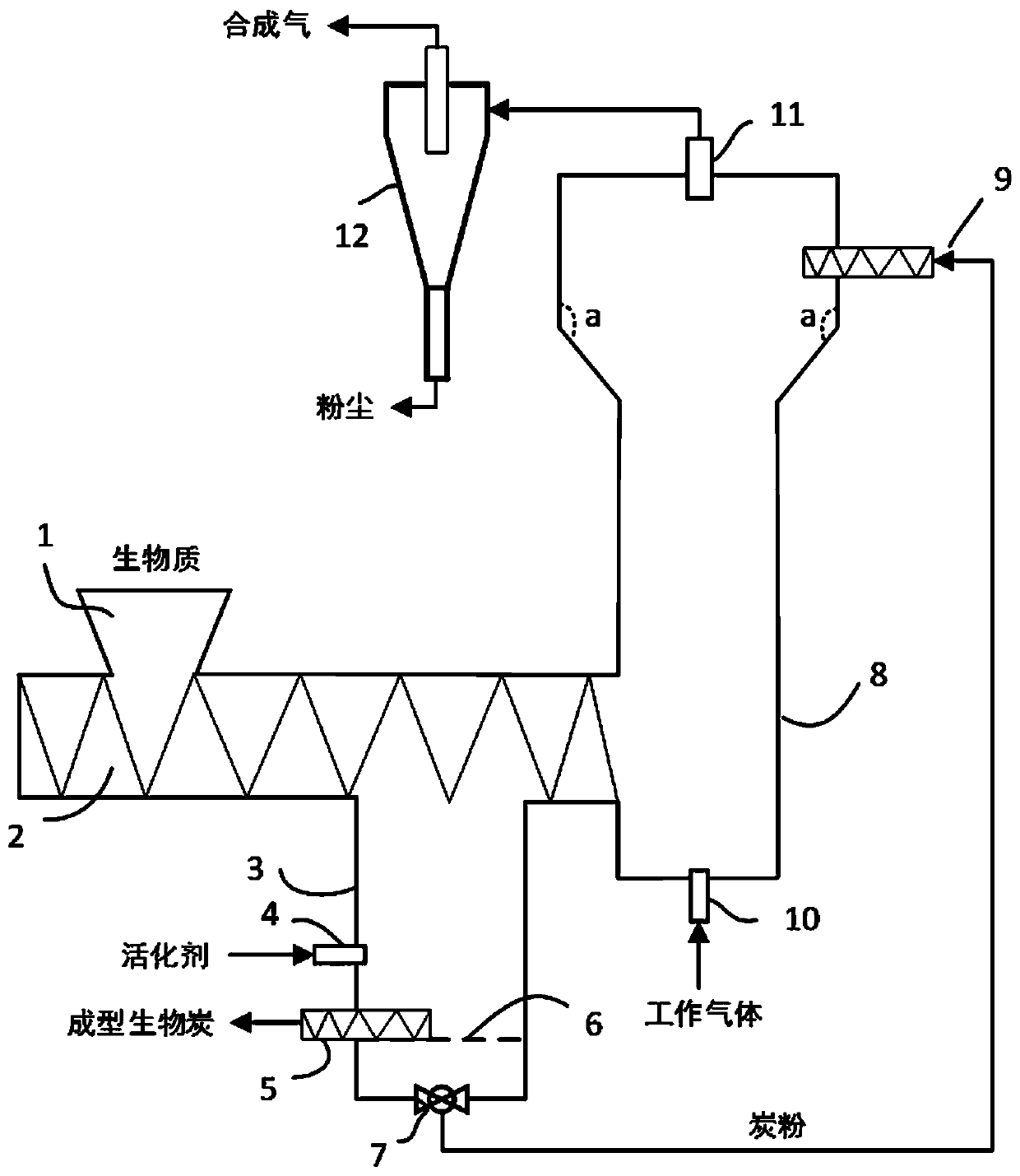

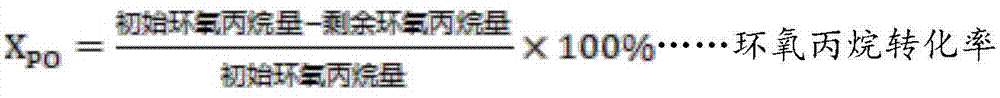

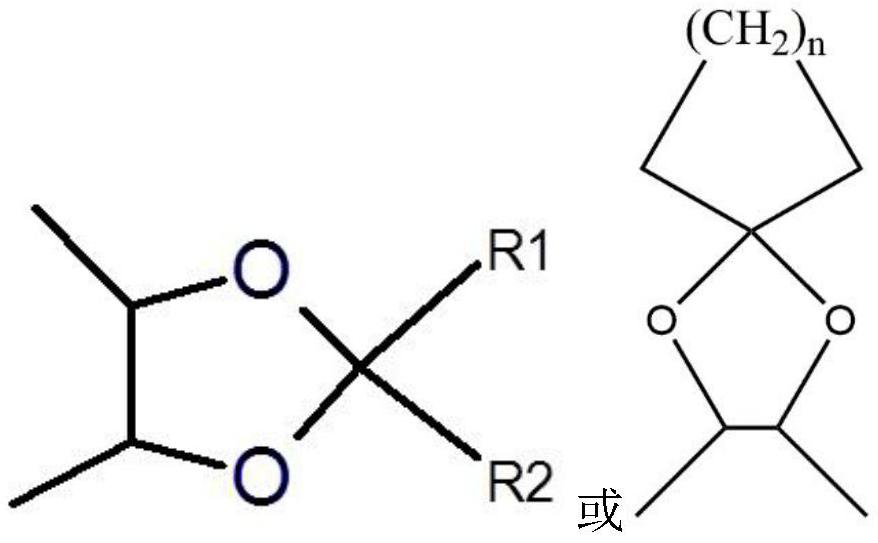

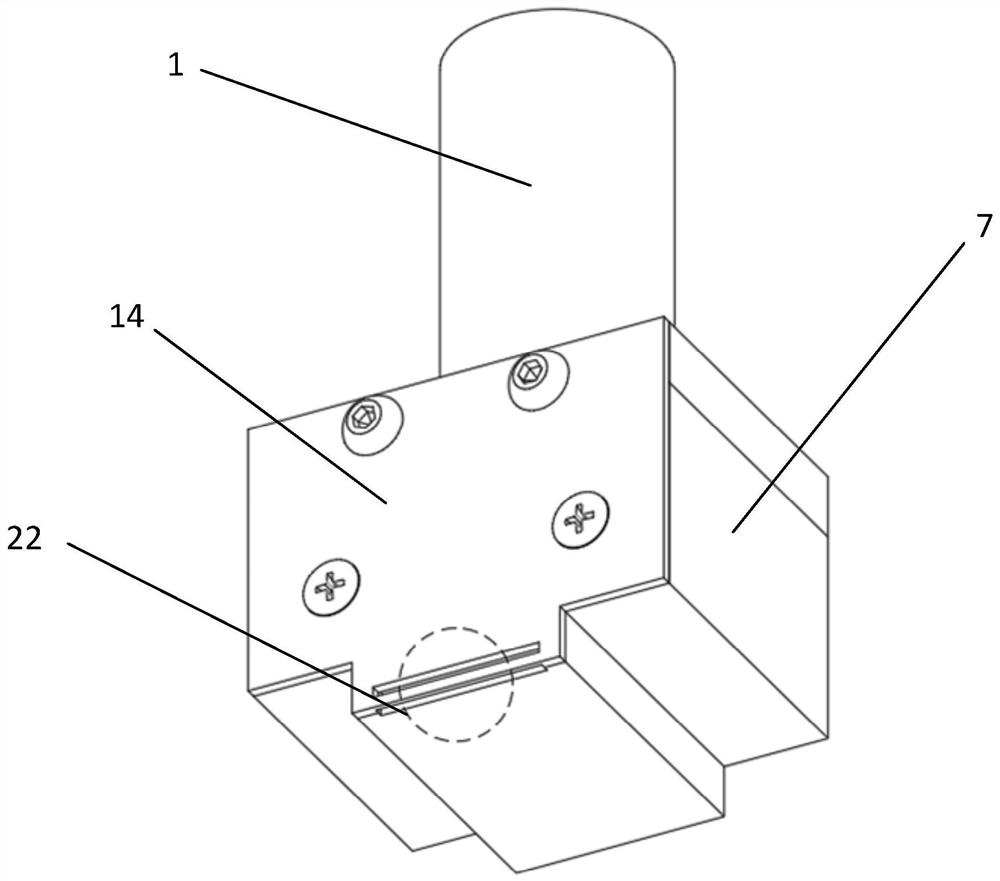

Synthesis method of 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone

ActiveCN112794849AImprove securityImprove processing economyOrganic compound preparationCarboxylic acid esters preparationEthyl groupKetone

The invention provides a synthesis method of 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone. The method comprises the following steps: carrying out substitution reaction on ethyl acetoacetate and 1-bromo-2-chloroethane under an alkaline condition to obtain 2-acetyl-4-chlorobutyric acid ethyl ester, and reacting the 2-acetyl-4-chlorobutyric acid ethyl ester with 2-aminopyridine to obtain a risperidone intermediate 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone. The method is simple to operate and suitable for industrial production. The compound 2-acetyl-4-chlorobutyric acid ethyl ester provided by the invention can be used as a raw material or an intermediate for synthesizing 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone, and then risperidone is synthesized. The invention also provides an application of the compound 2-acetyl-4-chlorobutyric acid ethyl ester as an impurity reference substance of the 3-(2-chloroethyl)-2-methyl-4H-pyrido [1, 2-a] pyrimidine-4-ketone.

Owner:CHONGQING MEDICAL UNIVERSITY

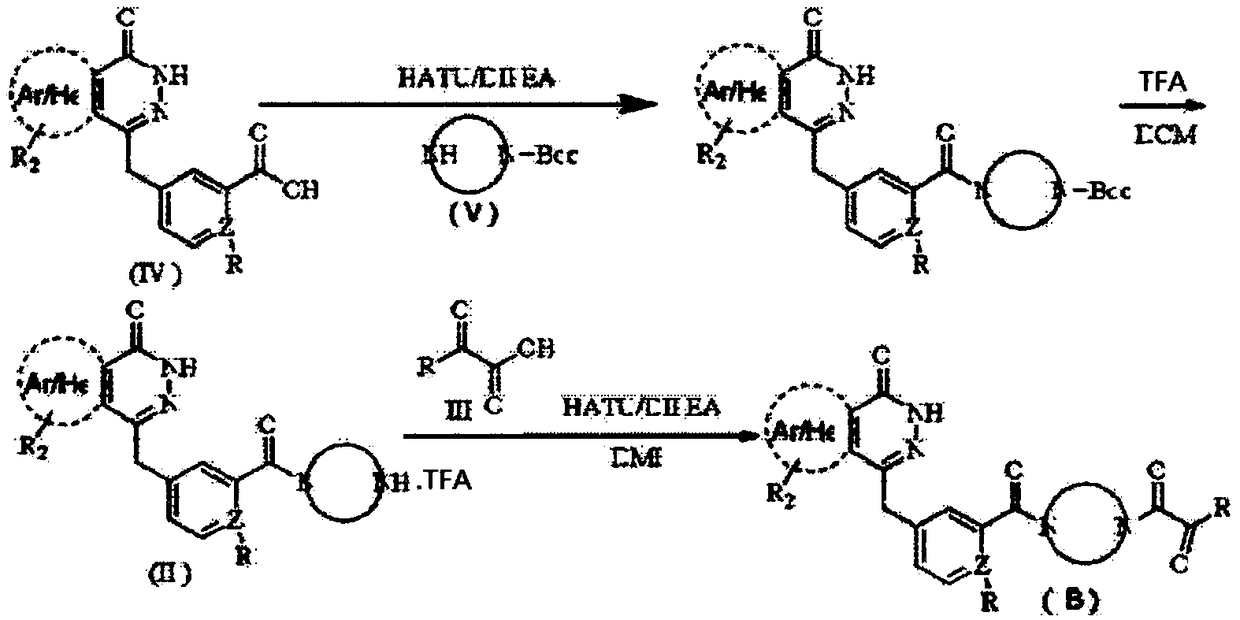

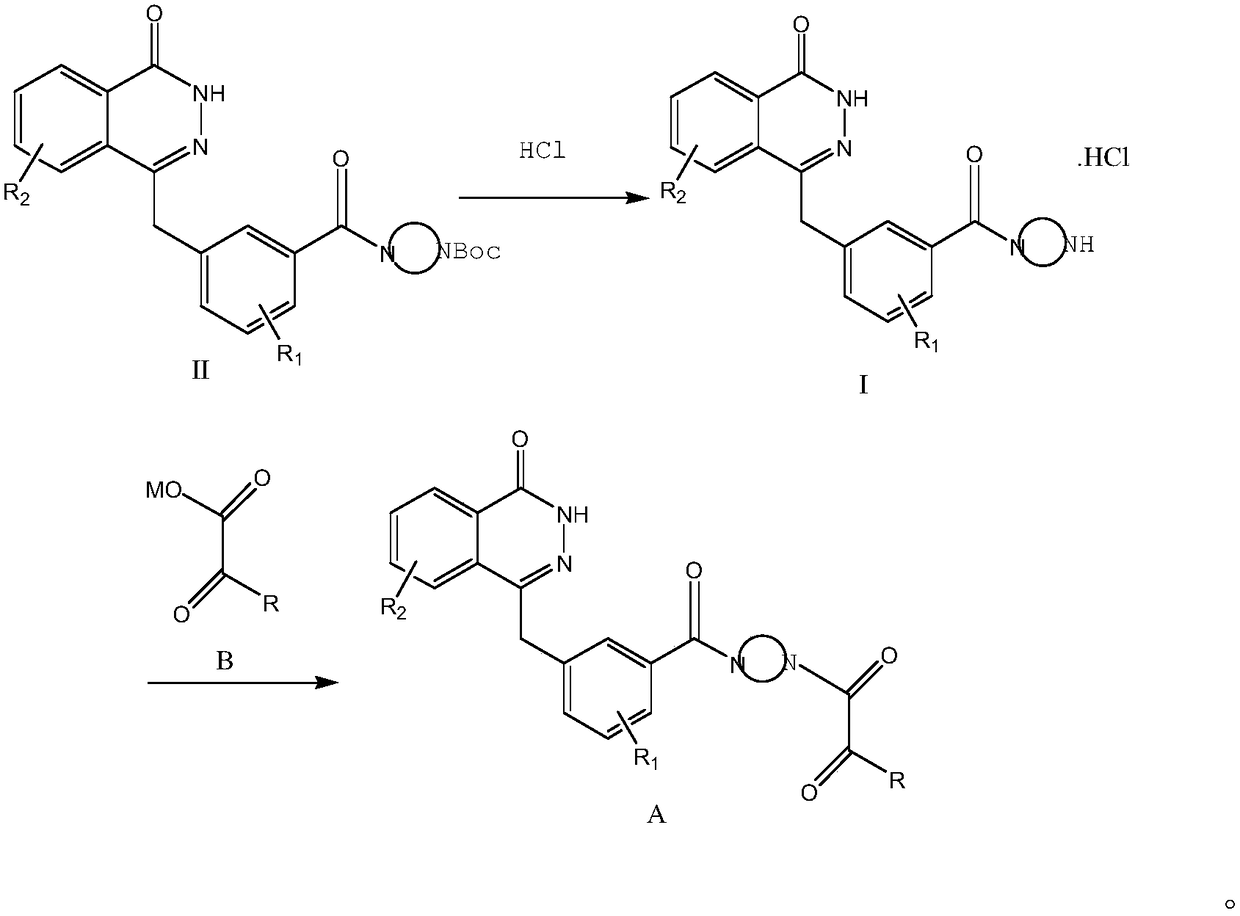

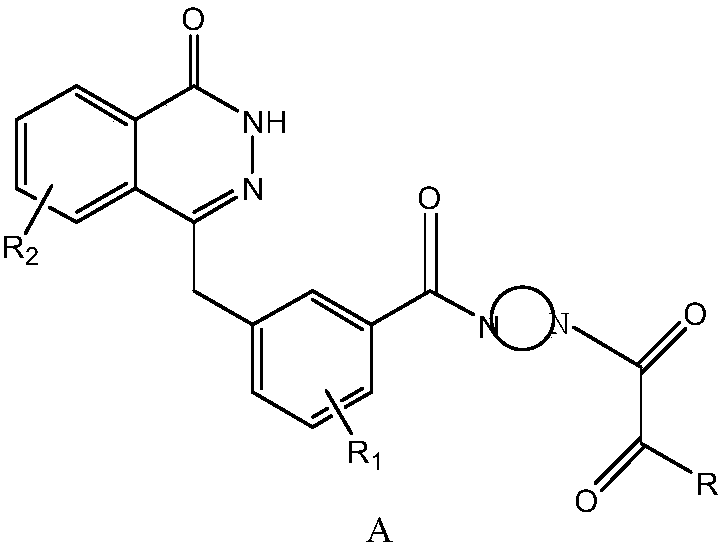

Preparation method and intermediate of compound for inhibiting activity of PARP

Owner:SHANGHAI DE NOVO PHARMA

Method and catalyst for recovering diphenols by catalytic hydrocracking of phenol-containing tar

ActiveCN109647387BReduce solid waste treatment costsHigh yieldOrganic chemistryOrganic compound preparationPtru catalystHydroquinone products

The invention relates to a method for recovering diphenol by catalytic hydrocracking of phenol-containing tar, a catalyst and a catalyst used in the method. The method uses cesium salt-modified titanium dioxide loaded with palladium and silver as a catalyst, and uses phenol-containing tar as a reaction raw material in an ethanol solvent to directly synthesize ortho / hydroquinone through catalytic hydrogenation. The method is simple to operate and environmentally friendly. On the one hand, the residual hydroquinone product in the phenol-containing tar is recovered, and at the same time, the tar produced by phenol dimerization and deep oxidation is rehydrocracked into a high value-added diphenol product. , which not only reduces the treatment cost of solid waste, but also significantly increases the yield of diphenol products.

Owner:WANHUA CHEM GRP CO LTD

A kind of refining method of caprolactam

ActiveCN109721537BHigh yieldEliminate de-weighting stepsLactams separation/purificationHydrogenation reactionDistillation

The invention relates to the field of caprolactam production, and discloses a caprolactam refining method. The method comprises the following steps: (1) reduced pressure distillation is carried out ona caprolactam crude product containing impurities with a boiling point higher than the boiling point of caprolactam and impurities with a boiling point lower than the boiling point of caprolactam, sothat impurities with the boiling point lower than he boiling point of caprolactam is removed, and a light removed product is obtained; (2) the light removed product is mixed with a crystallization solvent, and then crystallizing is carried out to obtain a crystal; and (3) a hydrogenation reaction is carried out on the crystal, wherein the reduced pressure distillation is carried out under a condition of variable temperature and variable pressure, and the mass ratio of the crystallization solvent to the light removed product is (0.2-5):1. Premium-grade caprolactam can be obtained through the method provided by the invention, a heavy removal step is omitted, the process flow is simple, and the method is easy for industrial implementation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

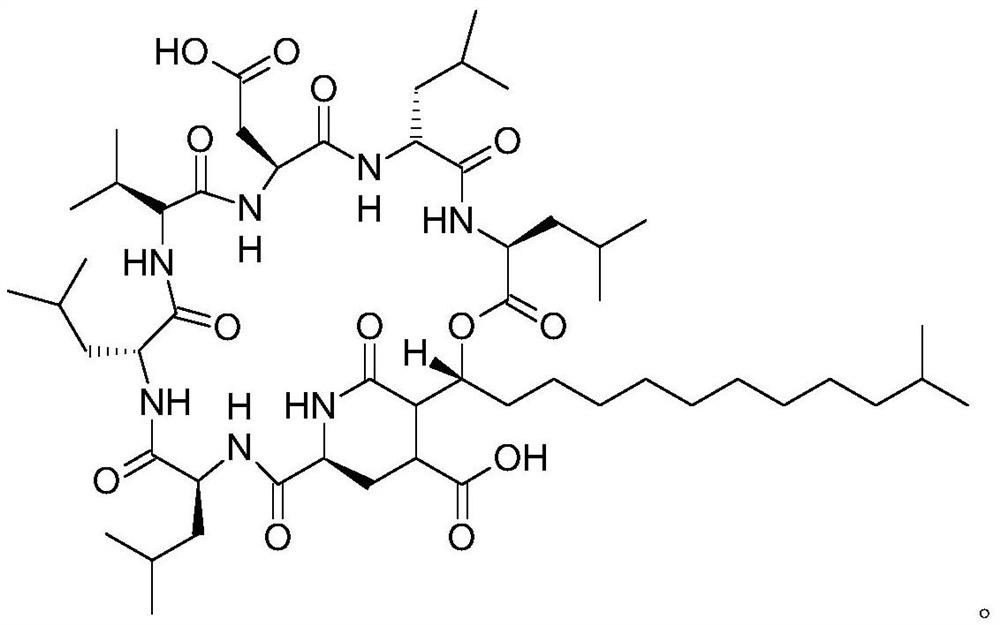

![Synthesis method of 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone Synthesis method of 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone](https://images-eureka.patsnap.com/patent_img/1cd53355-15fc-4ada-8a5d-42c64bed9cbf/FDA0002880357390000011.png)

![Synthesis method of 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone Synthesis method of 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone](https://images-eureka.patsnap.com/patent_img/1cd53355-15fc-4ada-8a5d-42c64bed9cbf/FDA0002880357390000021.png)

![Synthesis method of 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone Synthesis method of 3-(2-chloroethyl)-2-methyl-4H-pyrido [1,2-a] pyrimidine-4-ketone](https://images-eureka.patsnap.com/patent_img/1cd53355-15fc-4ada-8a5d-42c64bed9cbf/BDA0002880357400000011.png)