Patents

Literature

35results about How to "Reduce solid waste treatment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desulfurization waste water zero discharge processing system and processing method

InactiveCN106365371AQuality assuranceSave on medicine costsWater treatment parameter controlWater contaminantsSludgeClarifier

The invention discloses a desulfurization waste water zero discharge processing system and a processing method. The desulfurization waste water zero discharge processing system comprises a regulation sedimentation basin, triple connecting tanks, a defecator and a nanofilter which are connected in sequence, wherein the concentrated water outlet end of the nanofilter is connected with a mistorizer which sprays the concentrated water into a chimney flue; the triple connecting tanks include a neutralization tank, a reaction tank and a flocculation tank which are connected in sequence, wherein the neutralization tank is communicated with the water outlet of the regulation sedimentation basin, and is used for adjusting the pH value of desulfurization waste water, so that bicarbonate ions in the desulfurization waste water are removed; the reaction tank provides a reaction chamber for removing calcium ions in the desulfurization waste water; the flocculation tank is connected with the defecator. The desulfurization waste water zero discharge processing system and the processing method have the advantages of saving the cost of the agent for removing magnesium ions in the desulfurization waste water, reducing the quantity of sludge, lowering the operating cost, using no lime milk and improving the site working conditions. The sodium chloride salt in the waste water is purified and then crystallized, thus the recycle of the sodium chloride salt in the desulfurization waste water is achieved, the solid waste disposal cost is reduced, and certain economic benefits are produced.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

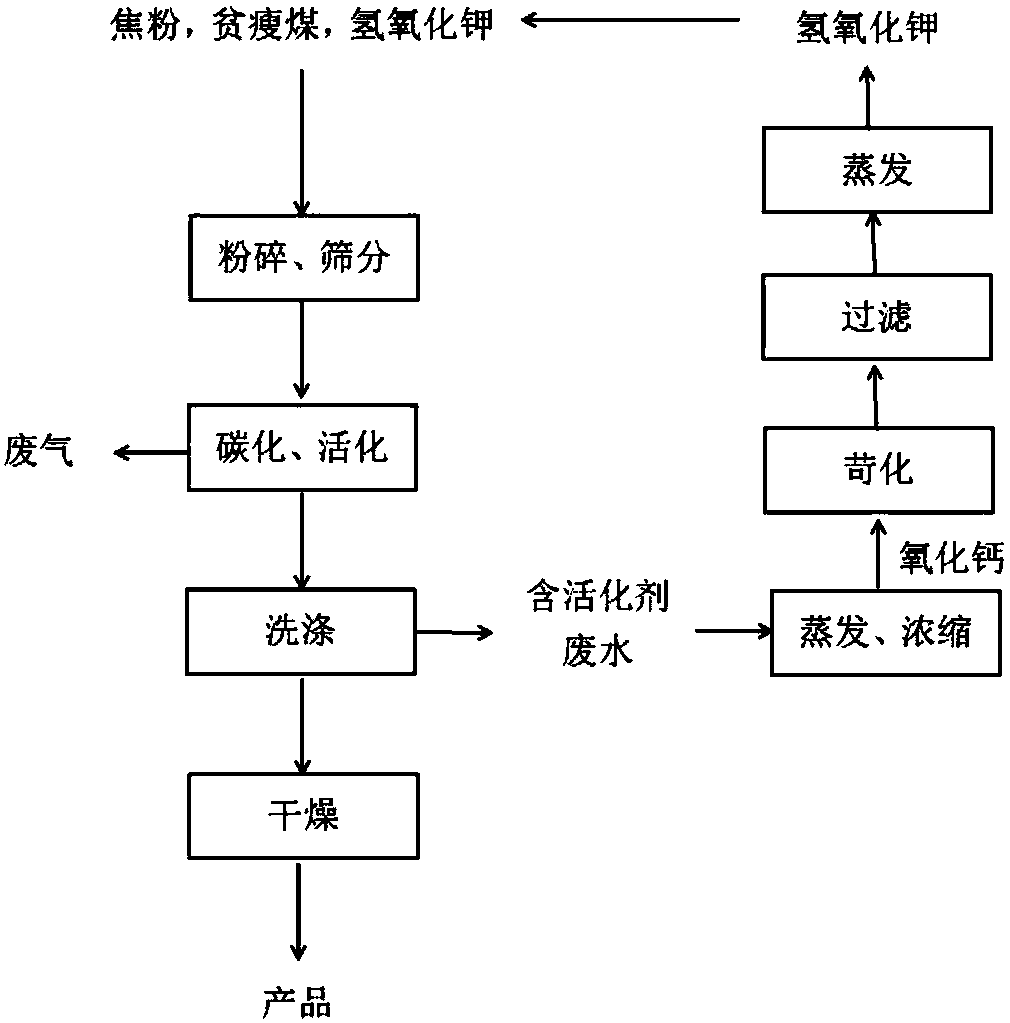

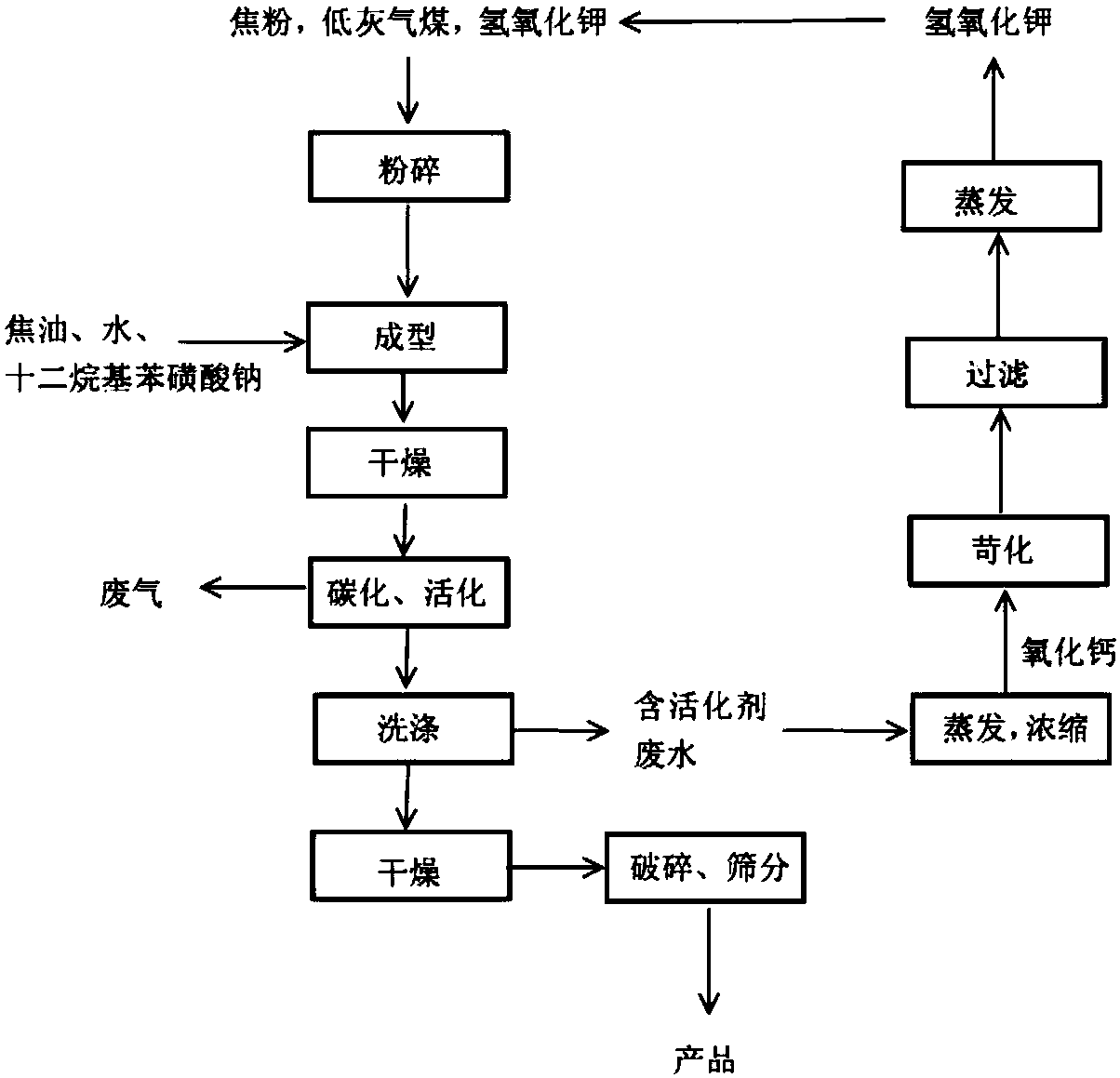

Method for preparing high-specific-surface-area activated carbon from blend coal of coke powder and/or quenched coke powder

InactiveCN108622894ASave resourcesReduce solid waste treatment costsCarbon compoundsOther chemical processesPulverizerActivated carbon

The invention relates to utilization processes for coking by-products, i.e., coke powder and quenched coke powder, especially a method for preparing high-specific-surface-area activated carbon from blend coal of coke powder and / or quenched coke powder. The method comprises the following steps: (a) batching: compounding coke powder and / or quenched coke powder, other carbon-containing materials andan activator; (b) crushing: putting a mixture obtained in the step a) in a crusher for crushing to a powder form, wherein the desired particle size of the powder allows the powder to pass through 70%or more of mesh holes in a 120-mesh sieve; (c) carbonization and activation: subjecting a material obtained in the previous step to carbonization at 500 to 650 DEG C for 1 to 3 h, and then to activation at 750 to 950 DEG C for 0.5 to 4 h; and (d) post-treatment: subjecting the activated material to pickling and / or washing to remove ash and carrying out drying so as to obtain an active carbon product, wherein a weight ratio of the total weight of the coke powder and / or quenched coke powder and the other carbon-containing materials to the activator is 1: 1 to 6: 1, and a weight ratio of the cokepowder and / or quenched coke powder to the other carbon-containing materials is 1: 1 to 6: 1.

Owner:BEIJING RISUN TECH CO LTD

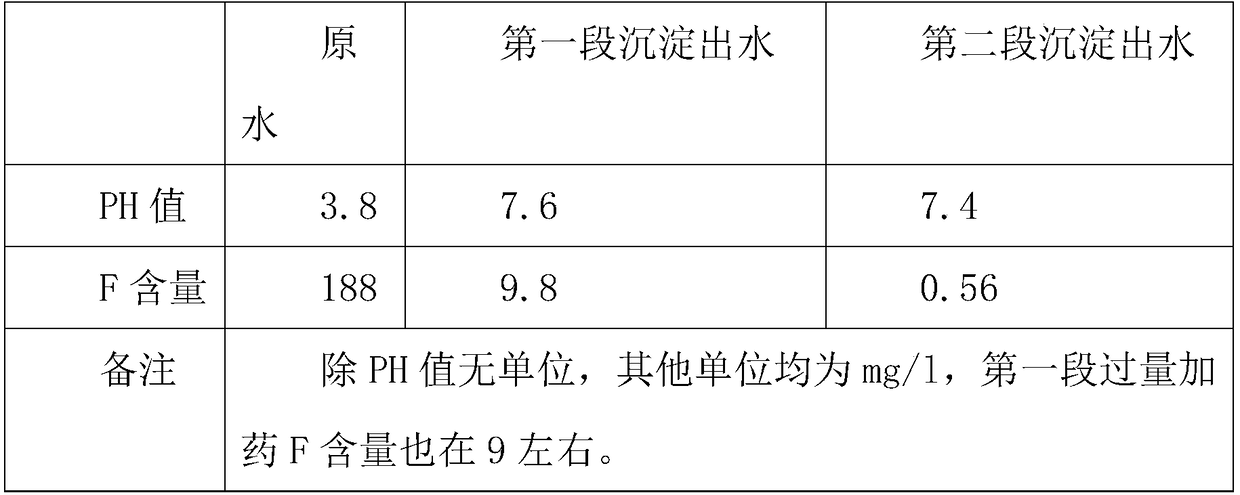

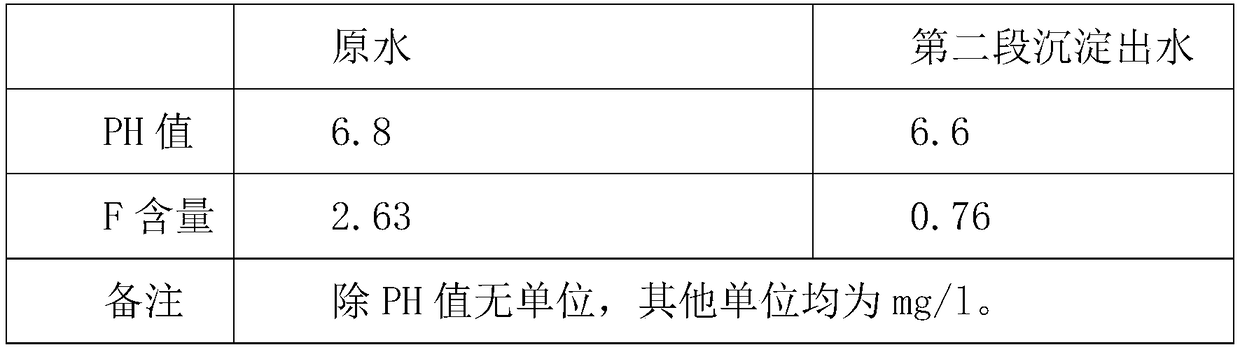

Composite fluorine removal agent and preparation method thereof

InactiveCN108911091AIncrease profitEffective control of fluorine contentWater contaminantsWater/sewage treatment by flocculation/precipitationIron saltsFree cooling

The invention discloses a composite fluorine removal agent and a preparation method thereof. The composite fluorine removal agent is prepared from the following components: in percent by mass, 70.00%of calcium salts, 15.80% of water, 5.5% of water glass, 2.00% of acids, 1.5% of iron salts, 5.00% of aluminum salts and 0.20% of polydimethyldiallyl ammonium chloride, and the preparation method comprises the steps: injecting the calcium salts into an enamel reaction kettle, adding water, and performing full and even mixing; then adding the acids to the reaction kettle, and performing full mixing;continuously inputting the iron salts, performing full dissolution, adding the aluminum salts continuously, and performing full dissolution; slowly adding the water glass at an adding speed of 275 kg / h for an adding period of 1 h, adding the acids, and performing guarantee of a constant temperature; adding the polydimethyldiallyl ammonium chloride slowly and uniformly under the conditions of theconstant temperature and stirring, performing stirring for polymerization for 3 hours, transferring the polymerized product to a finished product barrel, and performing natural cooling to normal temperature so as to obtain the target product. The composite fluorine removal agent has the advantages of a good fluorine removal effect, a high utilization rate and the like.

Owner:湖北蓝钴环保科技有限公司

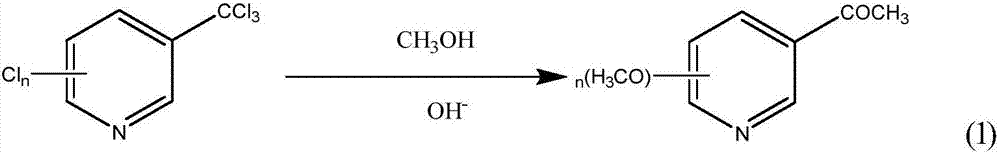

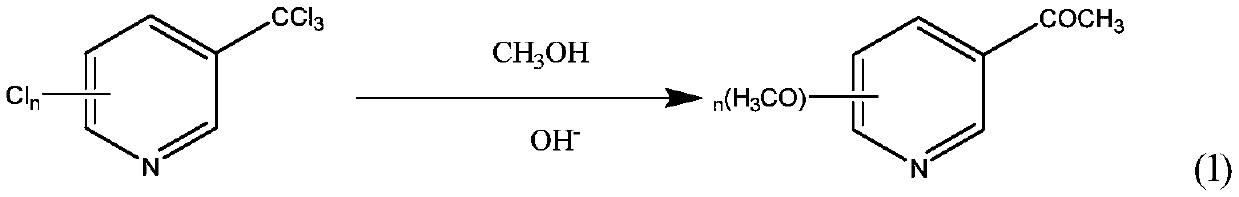

Treatment method for CTC rectifying still residues

ActiveCN106902489AEasy to incinerateReduce solid waste treatment costsChemical protectionChemical industrySolvent

The invention discloses a treatment method for CTC rectifying still residues and belongs to the technical field of treatment of solid waste in chemical industry production processes. According to the method, a solvent is added into the rectifying still residues for an impurity removing technique at first; and then solid alkali is added into a mixed liquid subjected to impurity removing in batches, a temperature increasing refluxing reaction is conducted, high-content pyridine chlorides are converted into carbon, hydrogen, oxygen and nitrogen compounds, and incineration treatment is facilitated. The economic pressure of enterprises for treating the still residues is relieved, and the environment is protected.

Owner:内蒙古佳瑞米精细化工有限公司

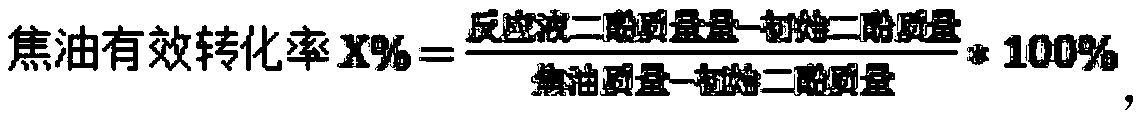

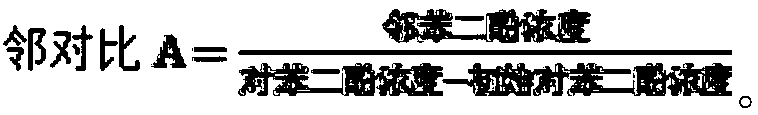

Method for catalytic hydrocracking of phenol-containing tar to recycle diphenol and catalyst

ActiveCN109647387AReduce solid waste treatment costsHigh yieldOrganic chemistryOrganic compound preparationHydroquinone productsSolvent

Owner:WANHUA CHEM GRP CO LTD

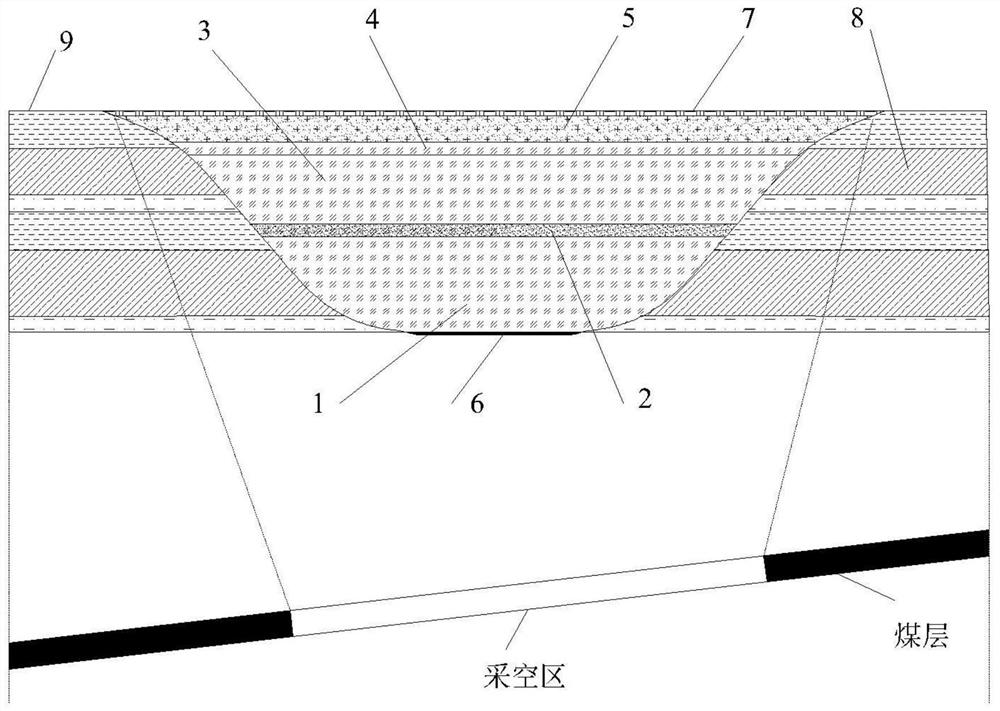

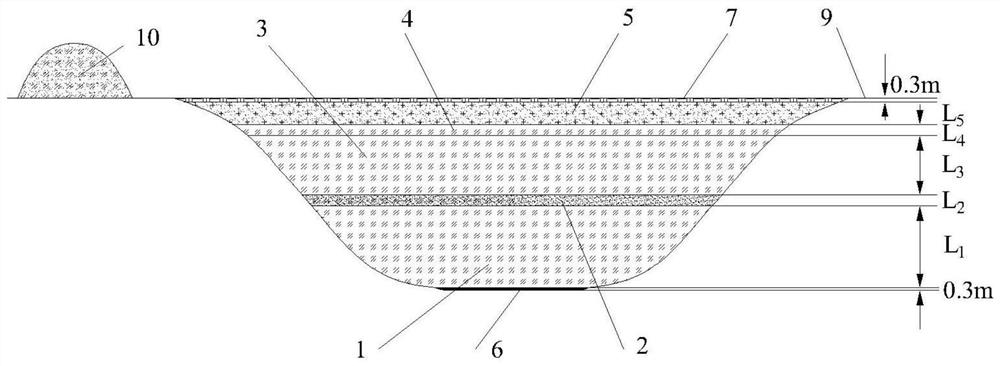

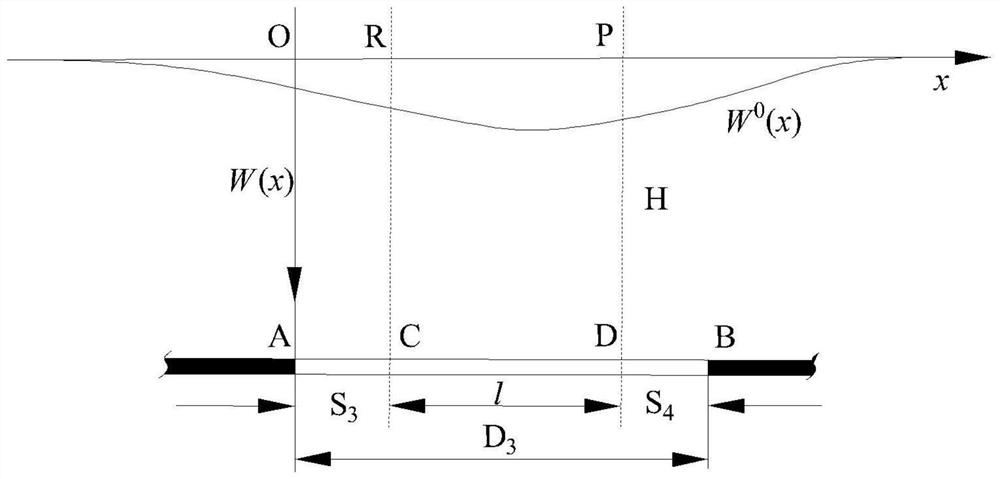

Method for reconstructing soil in coal mining subsidence area by using coal-based solid waste

ActiveCN113841478AReduce solid waste treatment costsPromote ecological governanceContaminated soil reclamationSoil-working methodsSoil scienceEnvironmental engineering

The invention provides a method for reconstructing soil in a coal mining subsidence area by using coal-based solid waste on the basis of a coal mining subsidence area treatment technology of deep excavation, shallow filling and recovery while mining. On the basis of surface dynamic subsidence prediction based on a Logistic time function, the coal mining subsidence area is divided into a heavy metal pollution prevention layer, a first filling layer, a sandwich soil layer, a second filling layer, a subsoil layer, a surface soil layer and a blocking layer according to the layering height proportion, layered backfilling is conducted in sequence, coal-based solid waste and original soil are laid in each layer according to the design proportion, meanwhile, auxiliary materials such as a soil conditioner and compost are added, and a near-natural soil structure is constructed, so that the soil reconstruction target is achieved. The effects of moisture and fertilizer retention of reconstructed soil and providing of real soil are achieved, the cultivated area can be increased to the maximum extent, environmental deterioration of the coal mining subsidence area is reduced, meanwhile, a large amount of the coal-based solid waste is consumed, the treatment cost of the coal-based solid waste is reduced, pollution of heavy metal to soil and a water system is weakened, and ecological treatment of the coal mining subsidence area and safe and green coal mining are promoted.

Owner:ANHUI UNIV OF SCI & TECH

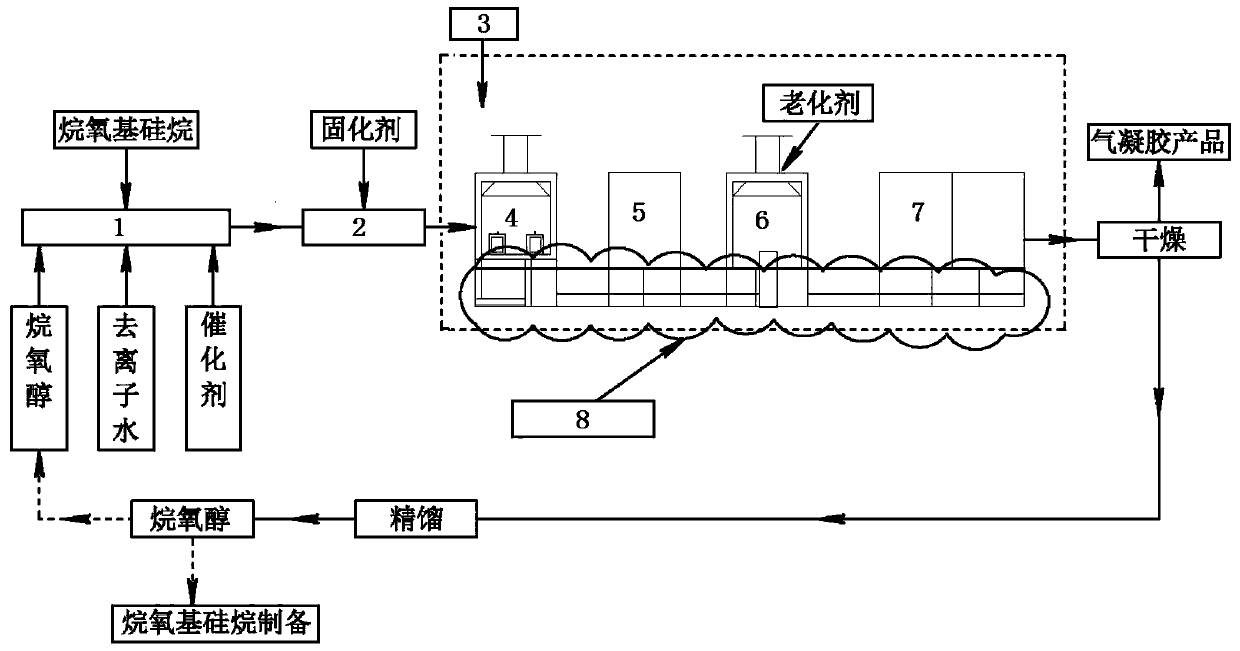

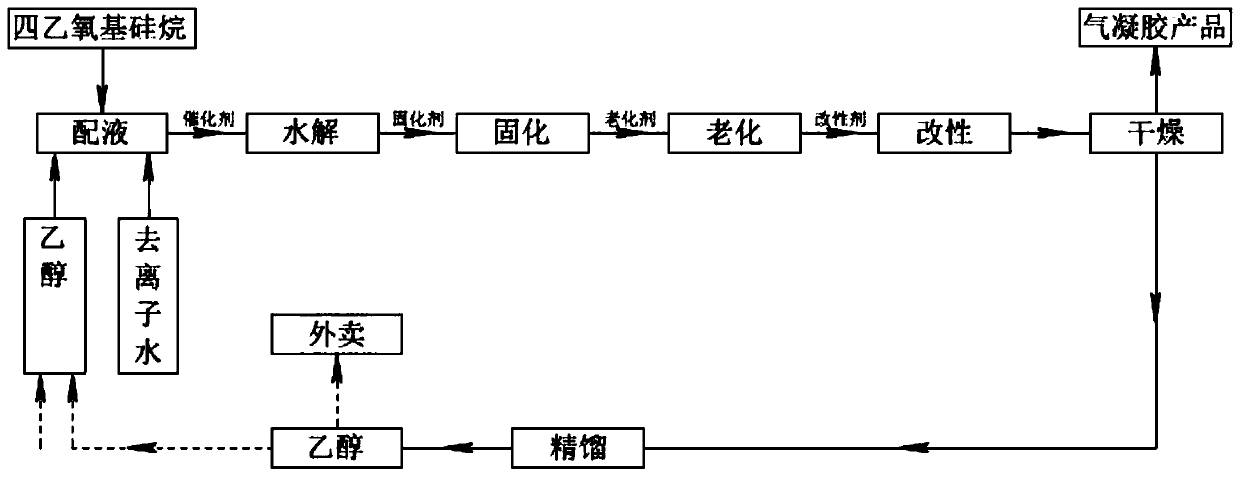

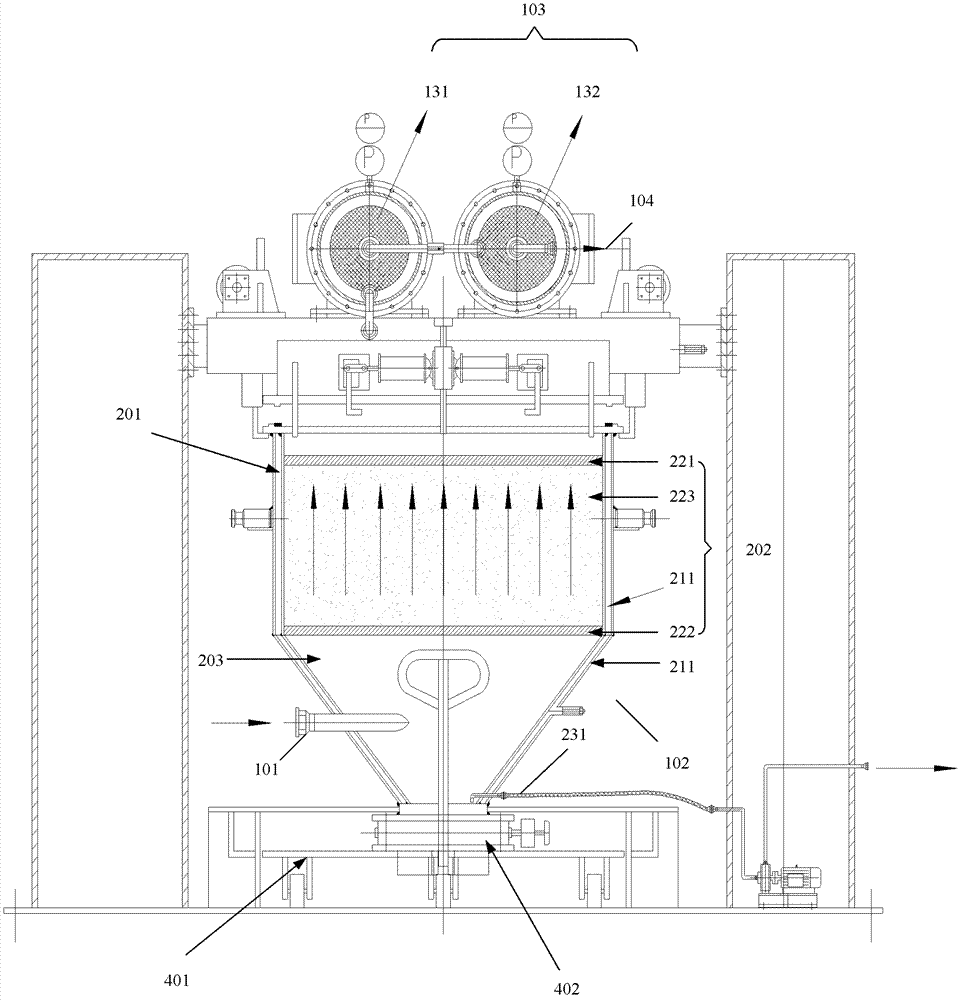

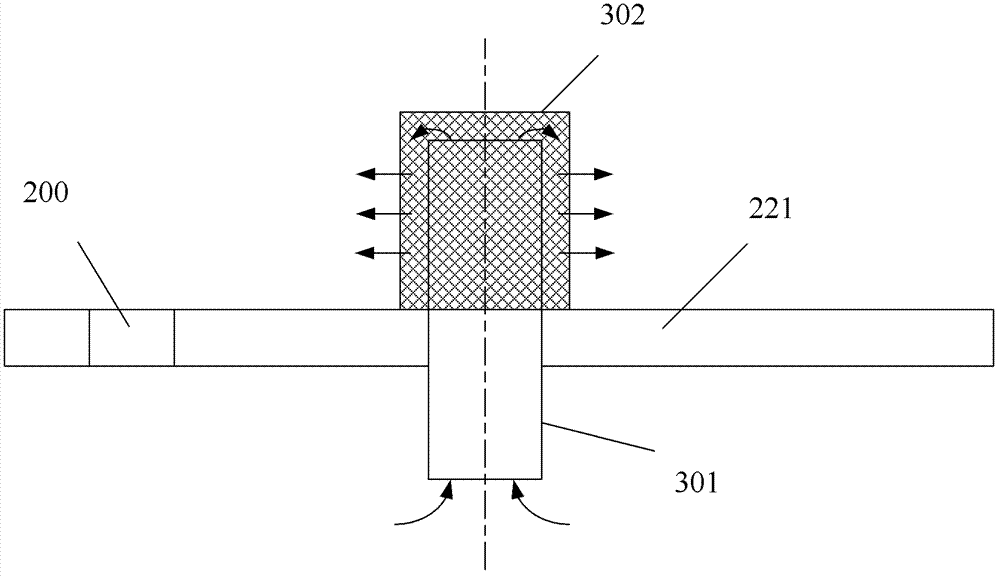

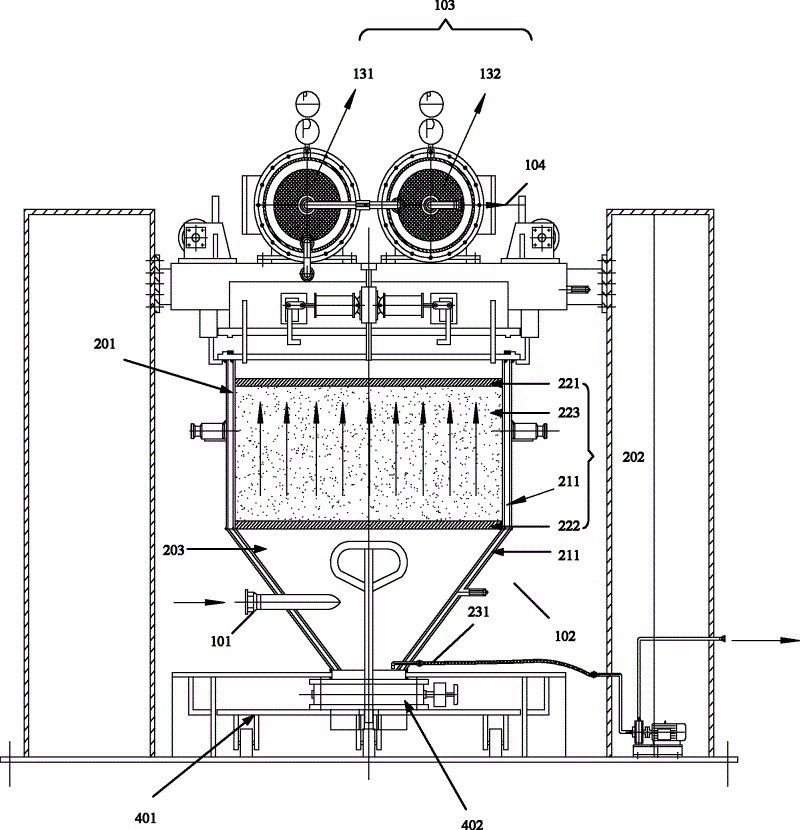

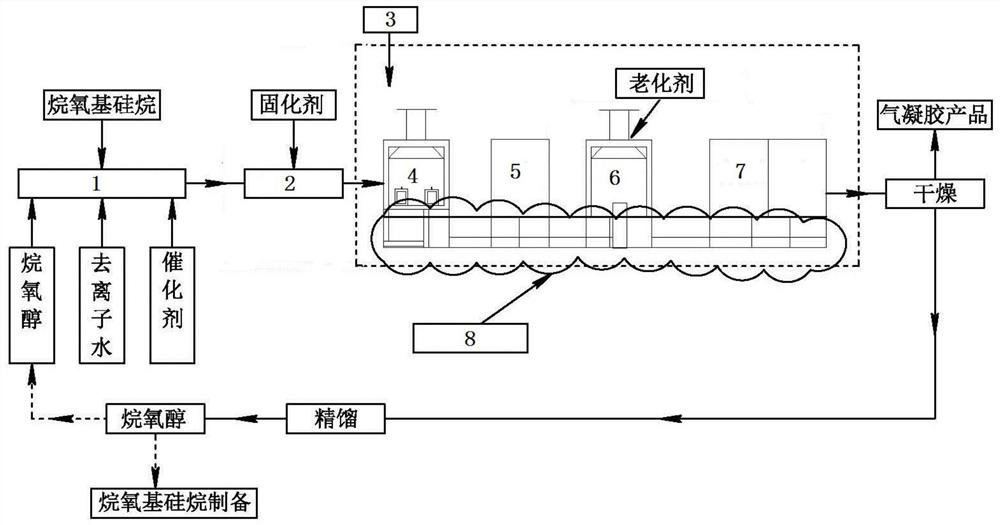

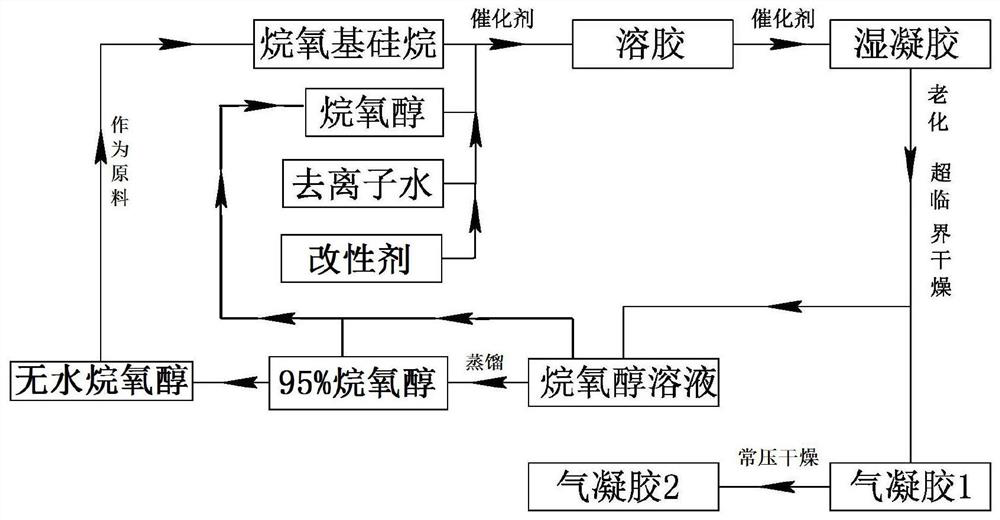

Efficient preparation method and application of aerogel

ActiveCN110775980ARealize continuous production and processingReduce pollutionSilicaGel preparationAlcohol

The invention discloses an efficient preparation method and an application of aerogel. Early-stage liquid preparation and hydrolysis are completed in a reactor, alkoxysilane is used as a raw materialand is hydrolyzed to form a sol, and the sol enters an intelligent aerogel production integration system in the later stage, and the system is intelligently controlled by a computer to realize intelligent control of various electric signals in order to control the operation of a transmission device, control the starting and stopping of a gel spraying gun and the temperature and humidity in a liquid spraying cabin and control the temperature and the heat preservation time in a first heating heat preservation cover and a second heating heat preservation cover; intelligent gel spraying is carriedout to make a mold and the aerogel product in the mold conveyed in the intelligent aerogel production integration system, so continuous production of solidification, aging and modification of wet gelis achieved; and the wet gel is dried to obtain the product, and a hydrolysis byproduct alkoxy alcohol is recovered, and is recycled for preparing the alkoxysilane. The preparation method has the advantages of reduction of material transfer in the gel preparation process, process simplification, reduction of the production cost, reduction of escape of volatile materials, and environmental friendliness.

Owner:徐州绿肯环保科技有限公司

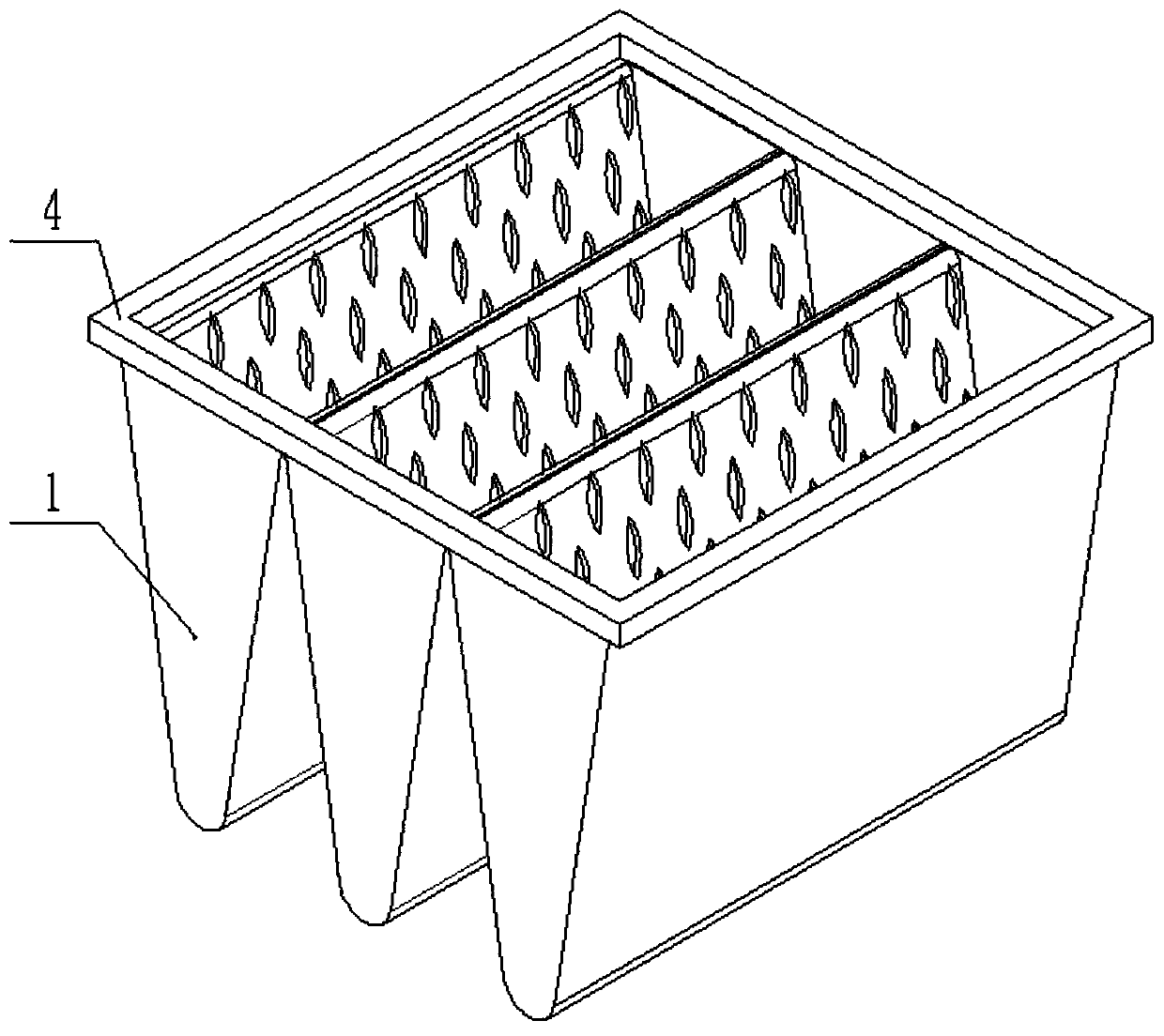

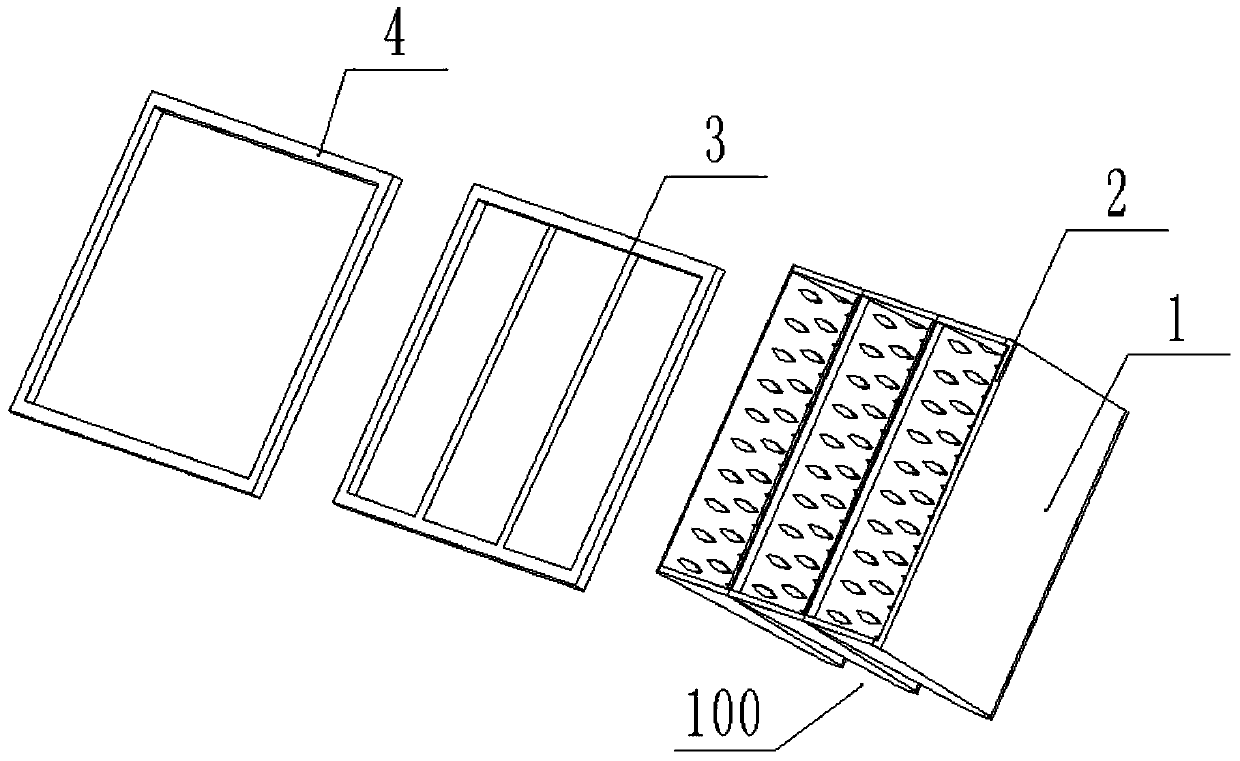

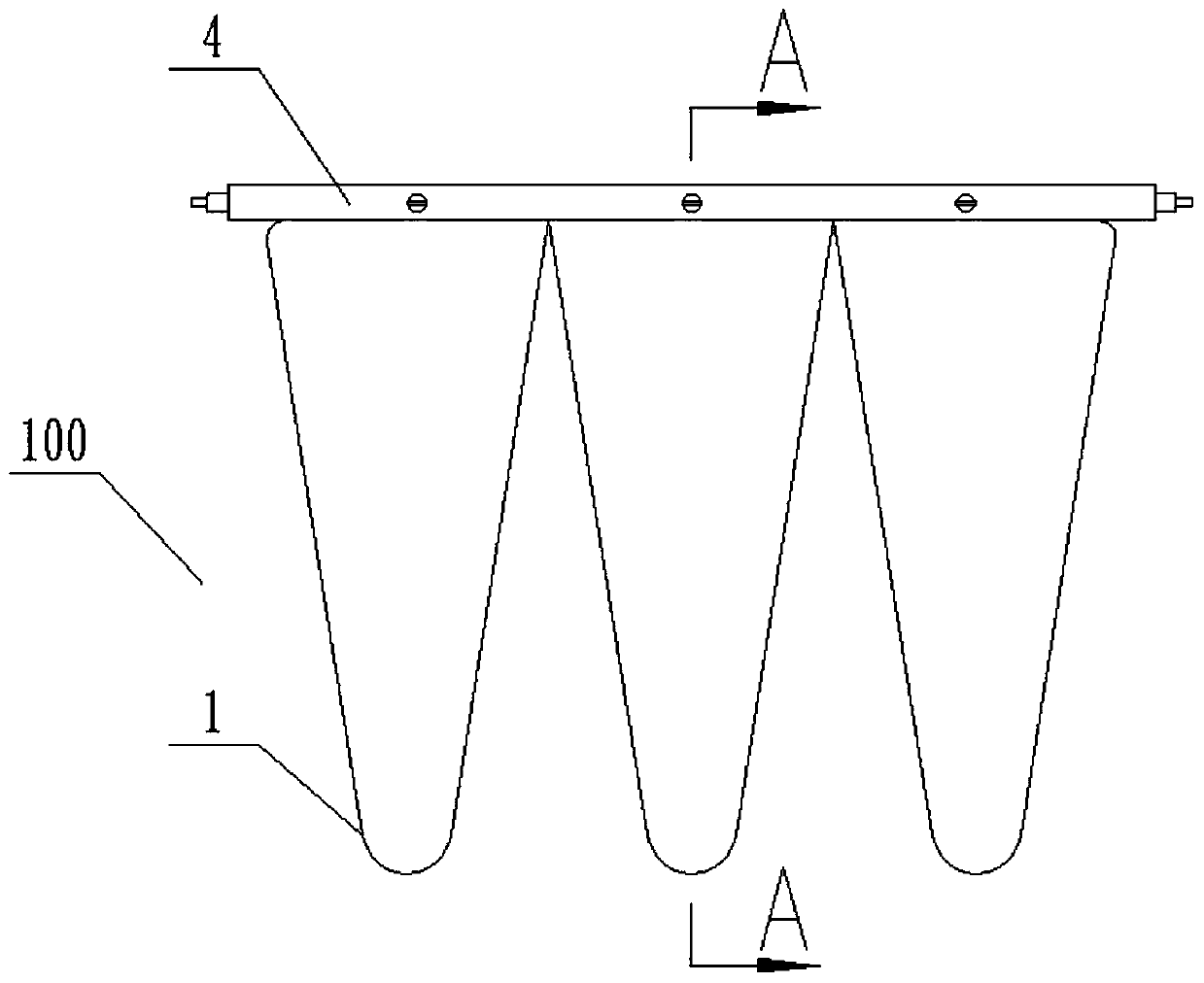

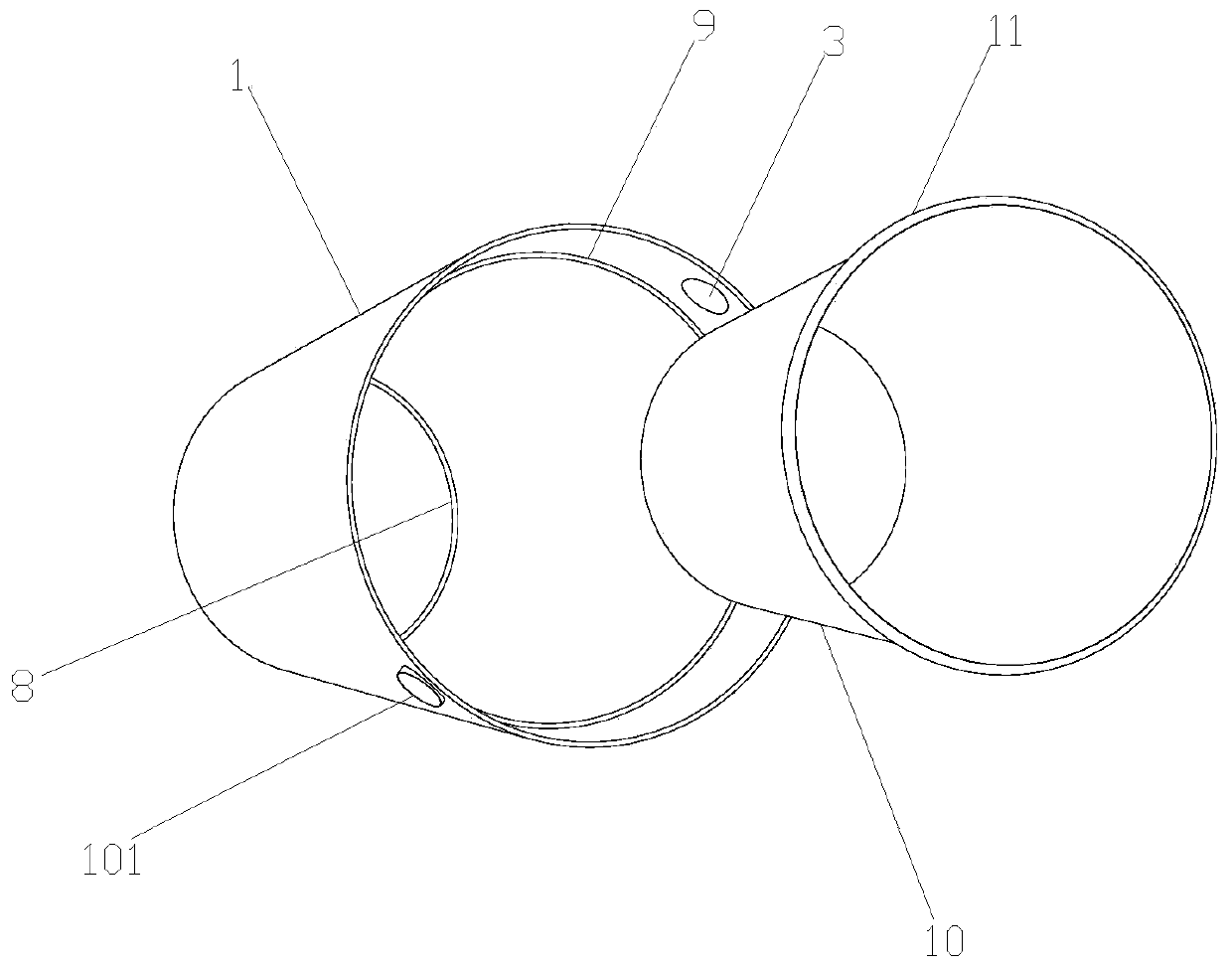

Easy-to-install paint mist filter bag and manufacturing method

PendingCN110102118AReasonable structural designEasy to manufactureDispersed particle filtrationTransportation and packagingMating connectionLacquer

The invention discloses an easy-to-install paint mist filter bag and a manufacturing method. The easy-to-install paint mist filter bag includes a filter bag body, which comprises a fixed frame, an internal connection frame and an external connection frame; the fixed frame is disposed at the openings of single filter bags in press fit, connection lugs are integrally arranged on both sides of the fixed frame symmetrically; the internal connection frame is embedded to the fixed frame, two side frames of the internal connection frame dent inward and are provided with connecting grooves, a lug connection frame for cooperative connection with the connection lugs is integrally disposed at the bottom of the internal connection frame close to two ends; two ends of the external connection frame stretch downward, and the external connection frame is internally equipped with elastic connecting pieces in cooperative connection with the connecting grooves. The easy-to-install paint mist filter bag provided by the invention has the characteristics of simple and reasonable structure, convenient disassembly, rapid replacement and stable structure, and a filter surface adopts equally spaced diamond-shaped through-holes, so that the filtering effect and ventilation effect of the filter bag are better than those of the existing plane filter layer, and the service life of the structure is prolonged.

Owner:刘树立

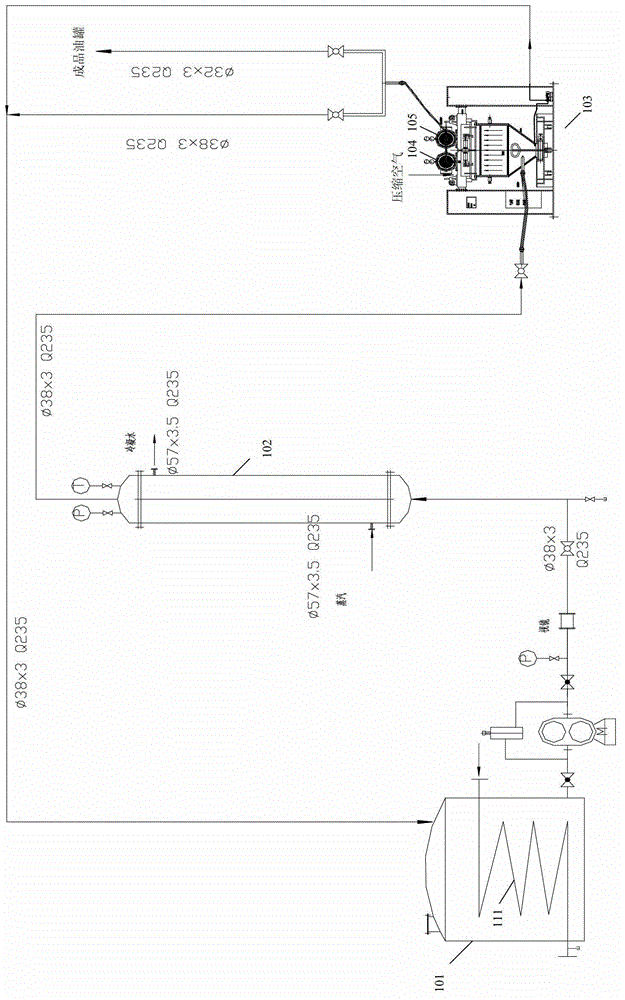

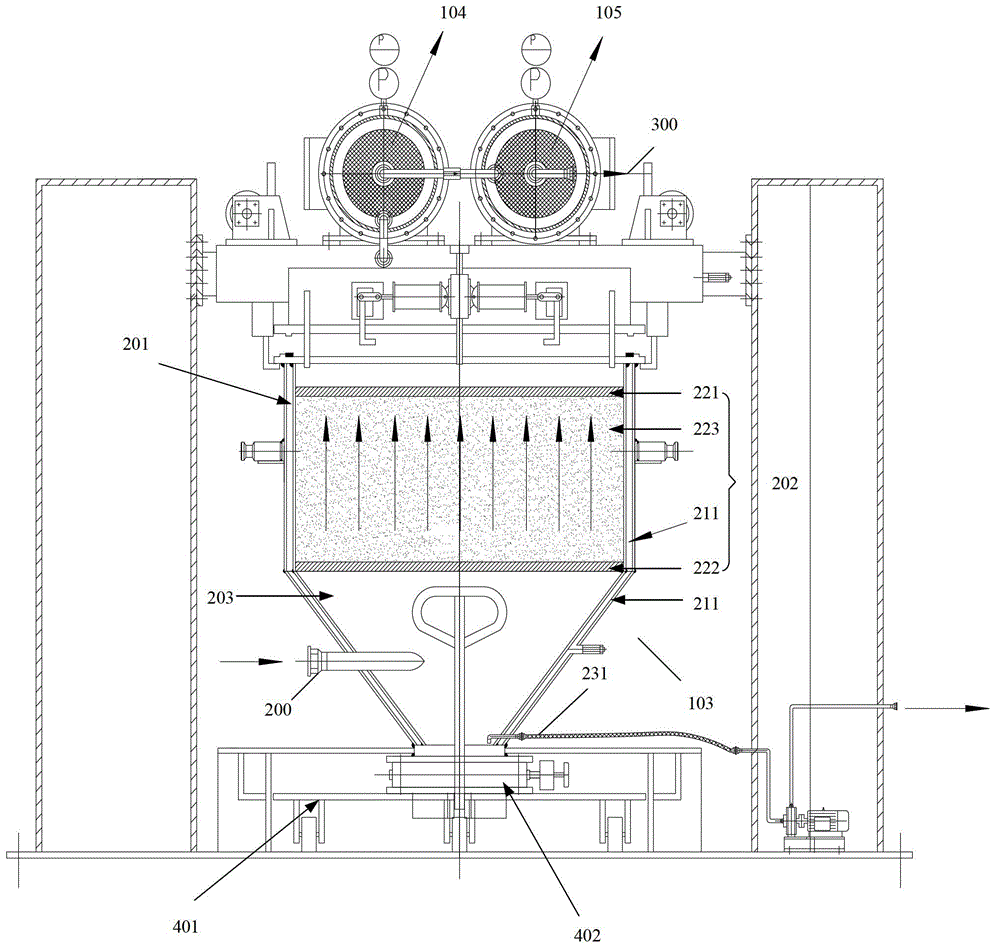

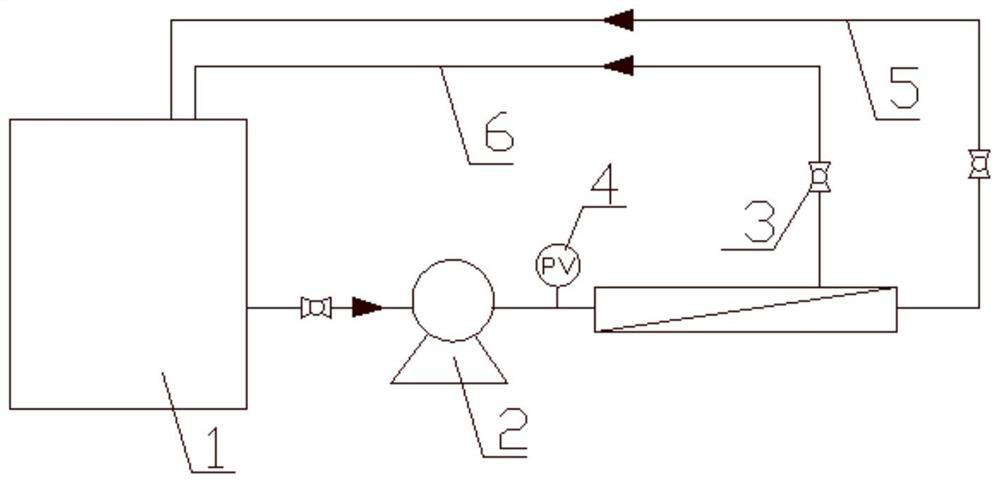

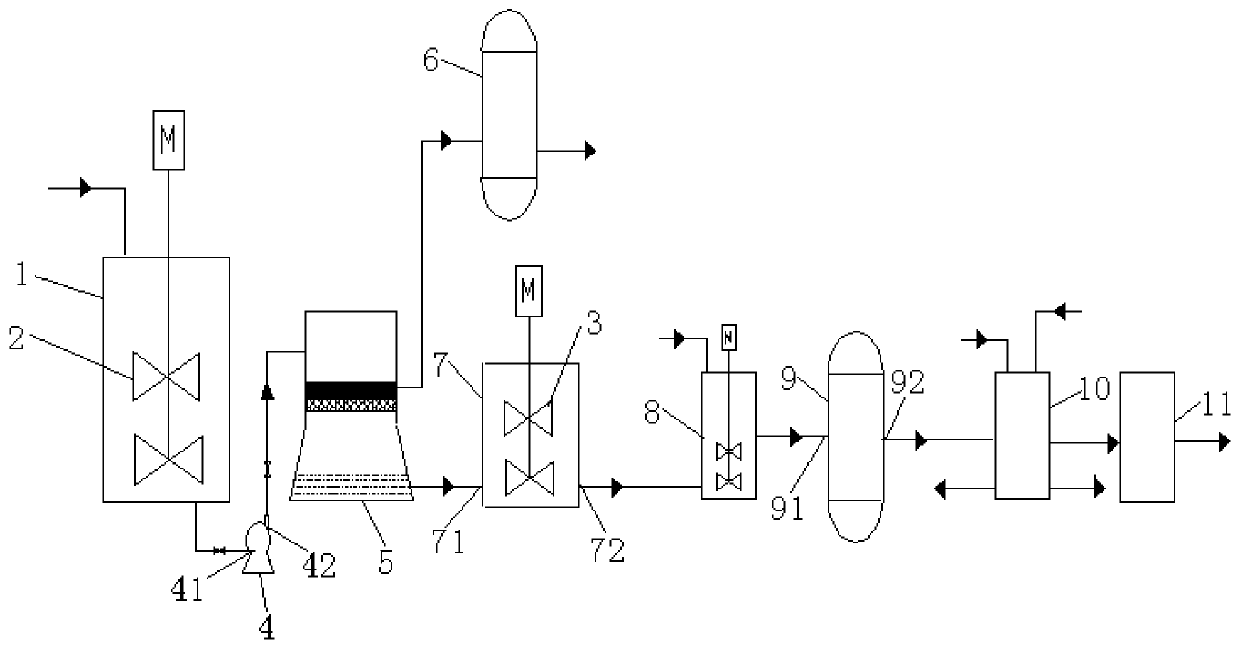

Fixed bed adsorbing device for basic oil

ActiveCN102698468AOmit to useLow investment costSolid sorbent liquid separationSilicon compoundsFixed bedEngineering

The invention provides a fixed bed adsorbing device for basic oil. The fixed bed adsorbing device comprises an input port, a fixed bed absorber, a filter and an output port, wherein the fixed bed absorber comprises a tube-shaped casing, a fixed bed layer arranged in the tube-shaped casing and an input cavity communicated with the tube-shaped casing and arranged under the fixed bed layer. The input cavity is a cone body with the upper top face larger than the lower bottom face, and the input port is horizontally arranged on the lateral wall of the cone body. The fixed bed layer comprises an upper partition board, a lower partition board and an absorber pressed tightly between the upper partition board and the lower partition board, wherein the upper partition board and the lower partition board are arranged in parallel mode. The basic oil is input into the input cavity through the input port, output into the filter after absorbed by the fixed bed layer and discharged through the output port after being filtered by the filter. The fixed bed adsorbing device for basic oil has the advantages of being simple in structure, high in automation degree, small in pollution and good in adsorbing performance.

Owner:BEIJING ECO ISLAND SCI & TECH

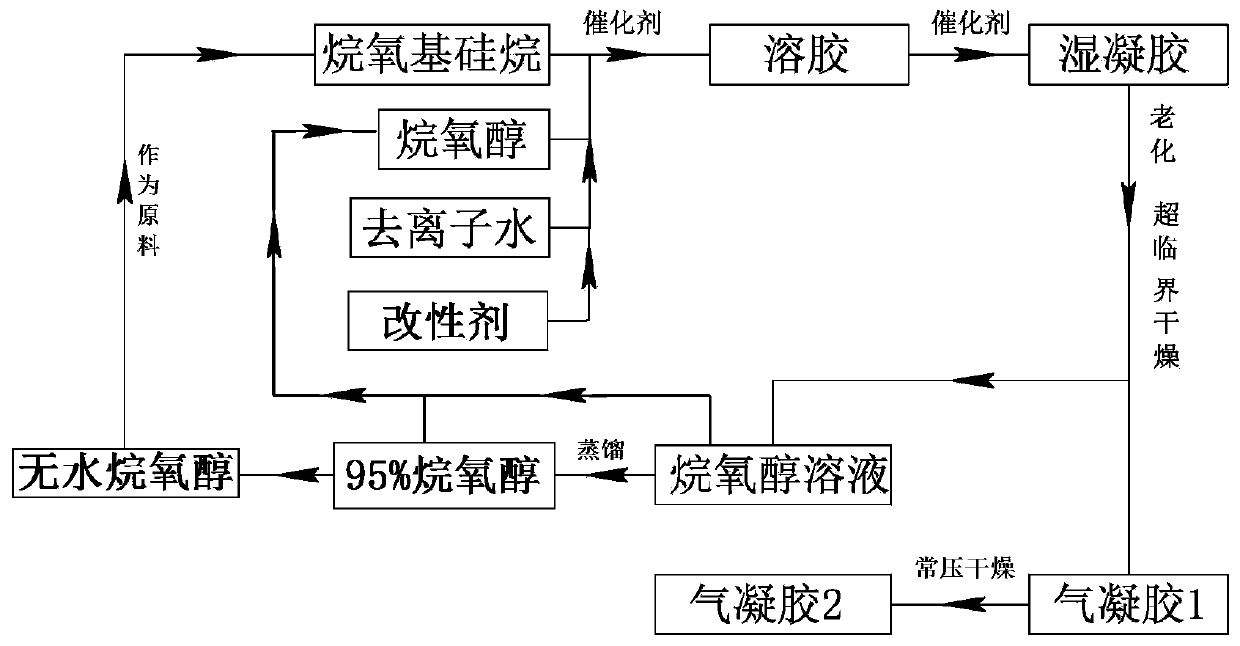

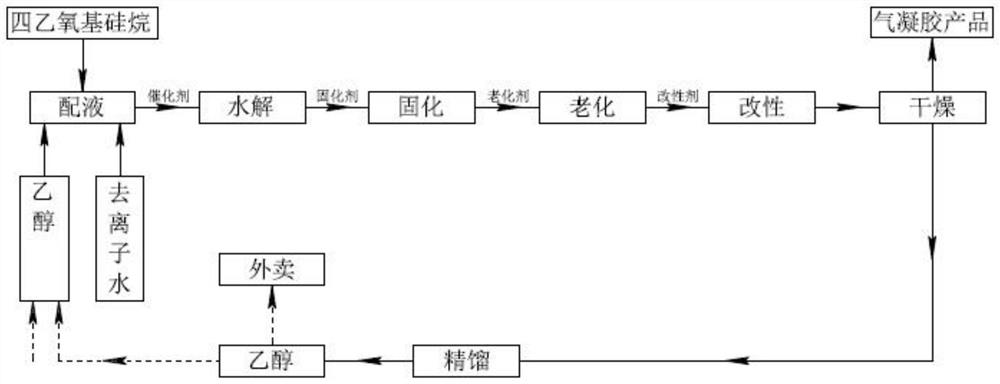

Preparation method and application of aerogel

ActiveCN110817888AEasy to prepareImprove controllabilitySilicon organic compoundsSilicon compoundsSupercritical dryingAlcohol

The invention discloses a preparation method and application of aerogel, alkoxy silane is used as a raw material and hydrolyzed to form a sol, a silicon dioxide aerogel product is prepared through thesteps of modification aging, supercritical drying and normal-pressure drying, and alkoxy alcohol as a hydrolysis byproduct is recycled for preparing the alkoxy silane after being recycled; the aerogel prepared by the method is applied to preparation of aerogel composite fibrofelts, aerogel plates, aerogel glass and aerogel ball raw materials. By adopting the technical scheme, the preparation method is simple, the overall reaction is stable, the controllability is strong, the investment cost is low, the production period is short, and the process technology can realize continuous production and is environment-friendly; the prepared silicon dioxide aerogel product is excellent in heat insulation performance and heat resistance, and has relatively high processability.

Owner:徐州绿肯环保科技有限公司

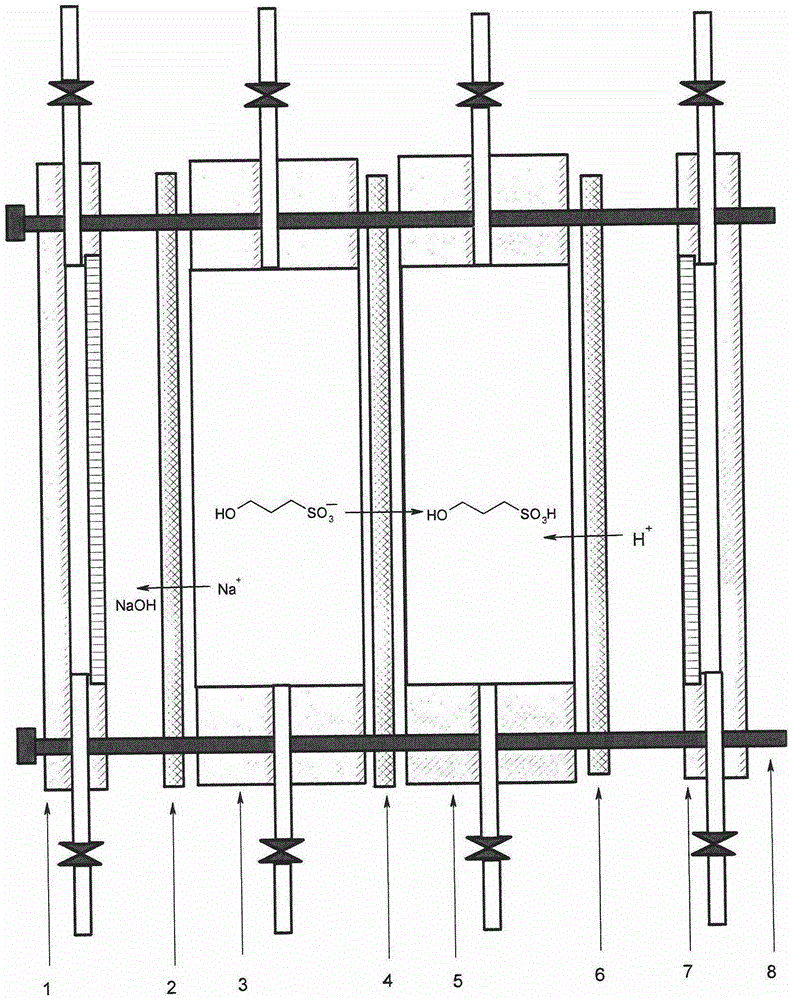

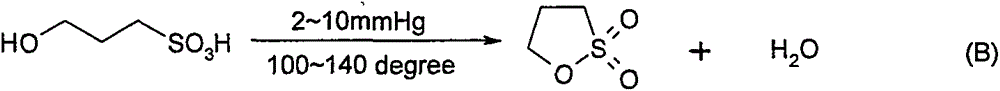

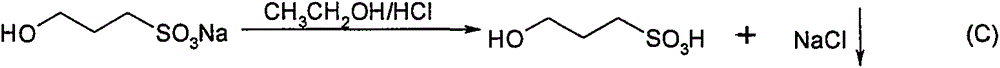

Clean method for separating and refining 3-hydroxypropanesulfonic acid

InactiveCN105648467AAvoid it happening againAchieving zero emissionsCellsElectrolytic organic productionAlcoholOrganic solvent

Provided is a clean method for separating and refining 3-hydroxypropanesulfonic acid. An electrolytic film sodium-removal device is used for separating a weak-acid 3-hydroxy sodium proparesulfonic acid coarse aqueous solution into a 3-hydroxypropanesulfonic acid aqueous solution and a sodium hydroxide aqueous solution by directly carrying out electrolysis sodium-removal to reduce the PH value to be not higher than 0.5. Hydrochloric acid or anhydrous hydrogen chloride used for acidizing the 3-hydroxy sodium proparesulfonic acid aqueous solution is avoided, and an organic solvent such as absolute ethyl alcohol does not need to be used for extracting and separating the 3-hydroxypropanesulfonic acid, so that sodium chloride solid waste is not generated any more, and production cost and three-waste discharging of the 3-hydroxypropanesulfonic acid are substantially lowered.

Owner:王永军

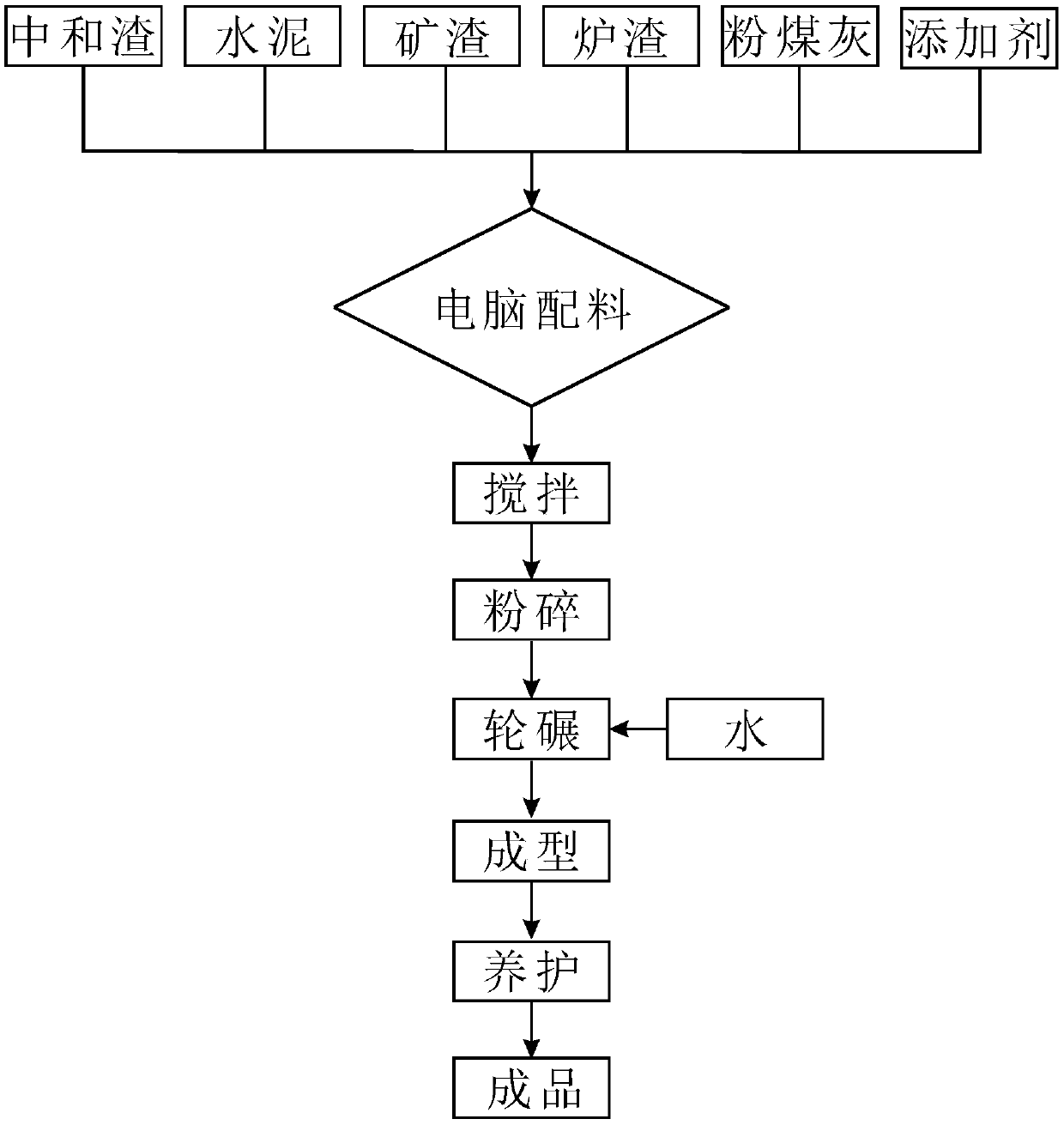

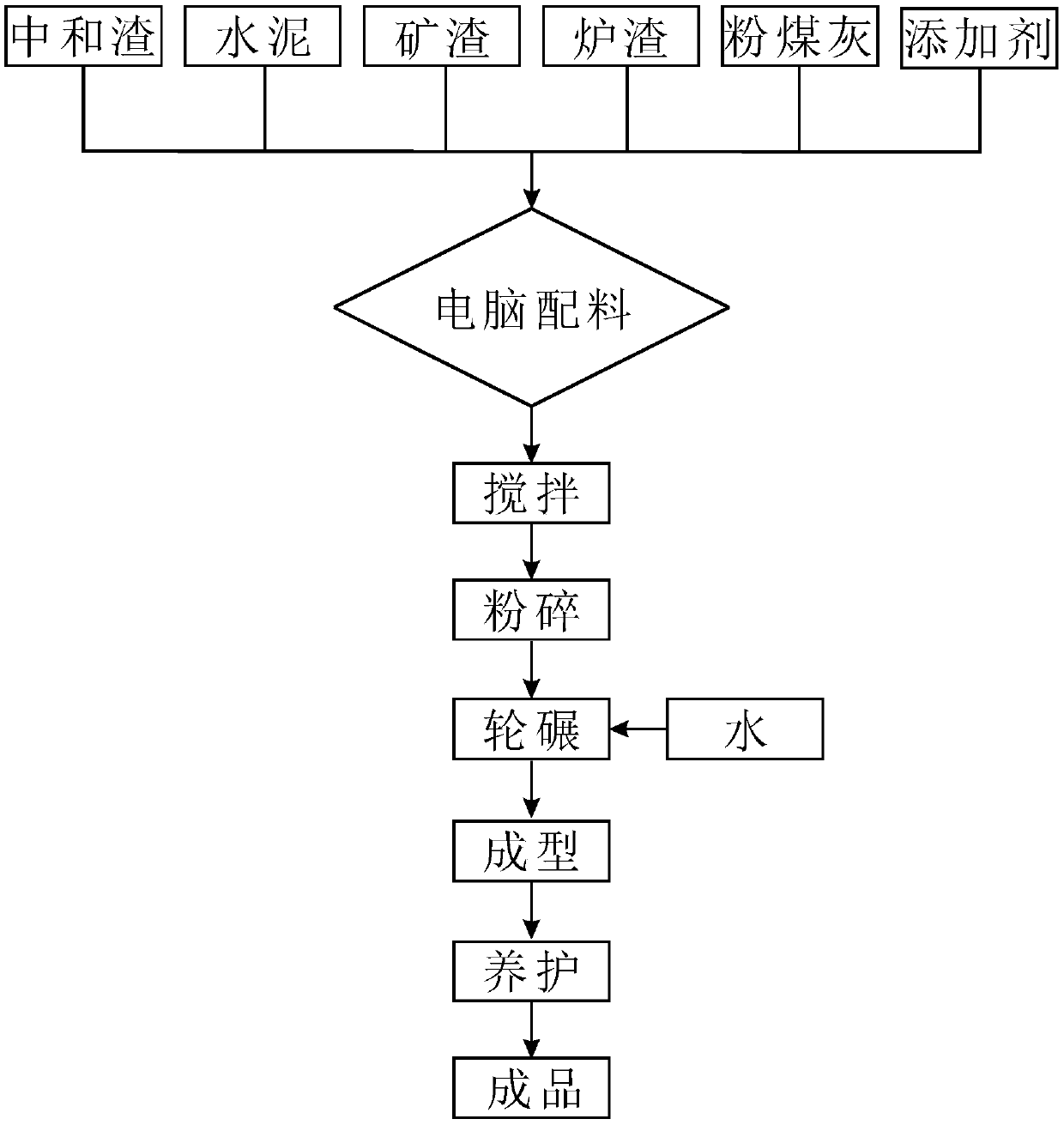

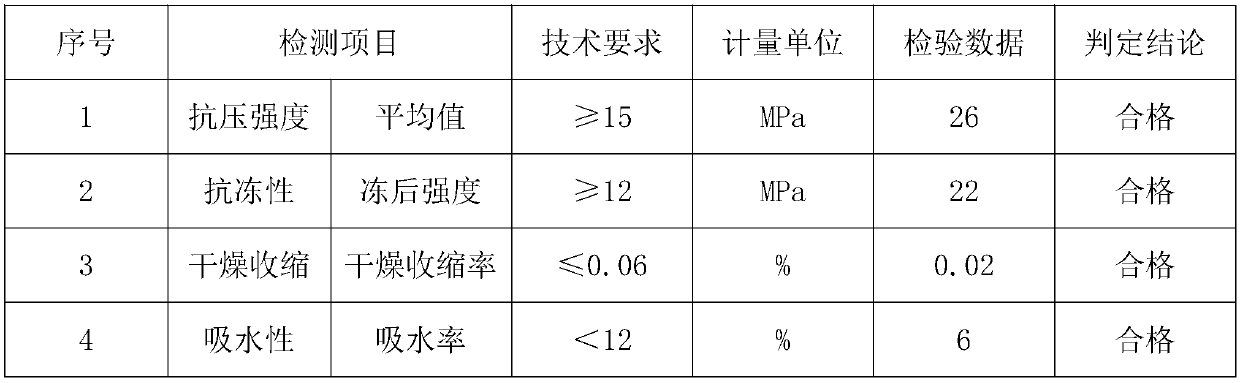

Non-ferrous smelting sewage treatment neutralization slag concrete brick and preparation method thereof

The invention discloses a non-ferrous smelting sewage treatment neutralization slag concrete brick and a preparation method thereof. The concrete brick comprises the following raw materials in percentage by mass: 25 to 35% of neutralization slag, 3 to 6% of cement, 8 to 12% of mineral slag, 35 to 45% of furnace slag, 0 to 15% of fly ash, and 1 to 2% of admixture. The invention also discloses a preparation method of the non-ferrous smelting sewage treatment neutralization slag concrete brick. The prepared neutralization slag concrete brick has excellent performance, the leaching toxicity meetsthe environmental protection requirement, and many problems such as environmental pollution, waste of land resources and high disposal cost caused by the non-ferrous smelting sewage treatment neutralization slag are solved, and the non-ferrous smelting sewage treatment neutralization slag is used as a resource and is harmless, and other raw materials are conventional industrial solid waste which are cheap and easy to obtain, therefore, waste is used to treat waste, the cost of non-ferrous smelting wastewater treatment neutralization slag is greatly reduced, and a broad market prospect is provided.

Owner:CHANGSHA HAIHONG BUILDING MATERIALS

Method for refining base oil for lubricating oil

ActiveCN102746885AImprove liquidityFully adsorbedTreatment with plural serial refining stagesLubricant compositionFixed bedBase oil

The invention provides a method for refining the base oil for the lubricating oil, comprising the following steps: A, heating the base oil for the lubricating oil, which is stored in a storage tank, to a first temperature, and outputting into a heat exchanger; B, heating the base oil for the lubricating oil, which is outputted into the heat exchange, to a second temperature by the heat exchange, and outputting into a fixed bed; C, adsorbing the base oil for the lubricating oil by the fixed bed, and outputting into filters; D, filtering the base oil for the lubricating oil by a coarse filter and a fine filter in sequence; E, observing the chrominance of the filtered base oil for the lubricating oil, carrying out the step F if the chrominance of the filtered base oil for the lubricating oil meets the output requirement, and outputting the filtered base oil for the lubricating oil into the storage tank if the chrominance of the filtered base oil for the lubricating oil does no meet the output requirement; and F, outputting the base oil for the lubricating oil into a refined oil tank. The method for refining the base oil for the lubricating oil adopts the fixed bed to adsorb the base oil for the lubricating oil, thereby having the advantages of mild pollution and good adsorption performance.

Owner:BEIJING ECO ISLAND SCI & TECH

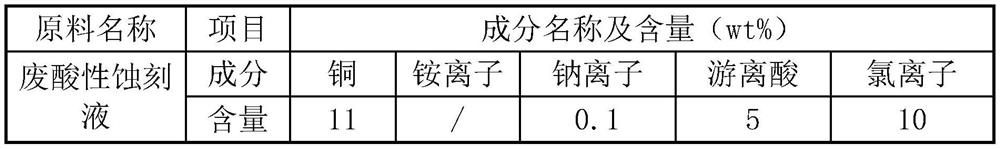

Method for producing copper chloride by using waste acidic etching liquid

PendingCN112939055AReduce solid waste treatment costsReduce investmentCopper chloridesCopper chlorideEnvironmental engineering

The invention provides a method for producing copper chloride by using waste acidic etching liquid, and solves the technical problems that the waste acidic etching liquid belongs to dangerous solid waste and needs to be treated and recycled by professional companies, and high solid waste treatment cost needs to be consumed in the prior art. The method comprises the following steps: (1) deacidification purification; (2) solid-liquid separation; (3) evaporation and concentration; (4) crystallizing; and (5) solid-liquid separation. According to the method, all the used main raw materials are from dangerous solid wastes generated in the electronic industry, so that the method is an energy-saving and environment-friendly resource regeneration cycle path, is small in investment, low in cost, environment-friendly and capable of realizing cyclic regeneration, can reduce the solid waste treatment cost of the waste acidic etching liquid, and can produce copper chloride.

Owner:湖北林泰环境科技有限公司

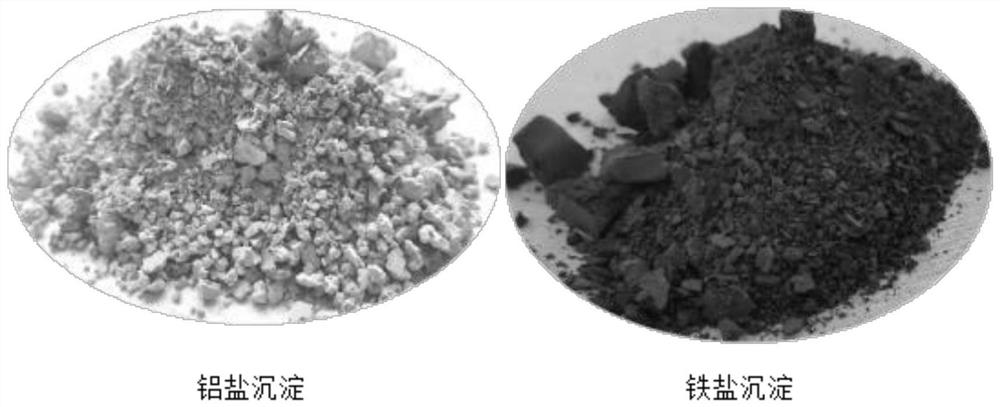

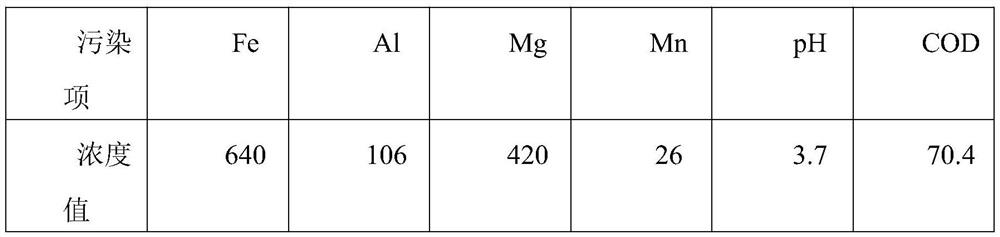

Treatment method for acid mine water metal ion resource recovery based on low cost

PendingCN114014462AIncrease processing costReduce solid waste treatment costsWaste water treatment from quariesTreatment involving filtrationResource recoveryWater treatment

The invention discloses a treatment method for acid mine water metal ion resource recovery based on low cost, which comprises the following steps: step 1, purification of acid mine water: the acid mine water is pumped into purification equipment for purification work, and in the purification process, the metal ions in the acid mine water are precipitated step by step in a successive precipitation manner; a large number of metal ions such as Al, Fe, Mg and Mn contained in the acid mine water are selectively removed, and sediments which are high in purity and can be recycled are obtained. Different metal precipitates are selectively removed, the sediments which are high in purity and can be recycled are obtained, the number of solid wastes formed in the acid mine water treatment process is greatly reduced, even solid-waste-free mode operation is achieved, the cost required by solid waste retreatment and the total operation cost of the acid mine water purification process can be greatly reduced, and according to the overall purification requirement, resource recycling can be selectively carried out on all or part of metal precipitates according to the water quality condition and the value of precipitation resources.

Owner:河北驰田环保科技有限公司

Reverse osmosis membrane repairing agent and reverse osmosis membrane offline repairing method

ActiveCN112473389AReduce solid waste treatment costsReduce wasteWater treatment parameter controlGeneral water supply conservationMeth-Polyvinyl alcohol

The invention discloses a reverse osmosis membrane repairing agent which is characterized by comprising a component A and a component B which are independently prepared, wherein the component A is prepared from the following raw materials in parts by weight: 5%-15% of one of polydimethyl ethylene propyl ammonium chloride, polymethallyl amine propyl trimethyl ammonium chloride, polymethacrylamide trimethyl ammonium chloride and dodecyl dimethyl benzyl ammonium chloride; 25%-35% of glutaraldehyde; and the balance of purified water. The component B comprises the following raw materials in parts by weight: 5-10% of one of polyethylene glycol and polyvinyl alcohol; 30%-40% of one of sodium polyacrylate, anionic polyacrylamide, polyacrylic acid and polyacrylate; and the balance of purified water. The invention also discloses a method for realizing offline repair of the reverse osmosis membrane, the desalination rate of the reverse osmosis membrane after oxidation can be recovered to 97% or above, the recovery rate of a single membrane can be recovered to about 15%, and the repair effect can be stably maintained for half a year or longer.

Owner:天津市尚拓环保科技有限公司

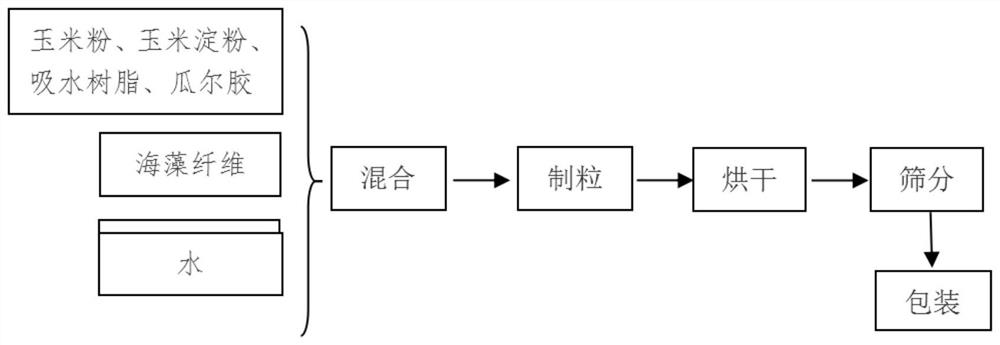

Natural alginate fiber cat litter and preparation method thereof

PendingCN114793921AImprove usability and securityReduce solid waste treatment costsAnimal housingCorn starchGuar gum

The invention discloses natural alginate fiber cat litter and a preparation method thereof. The natural alginate fiber cat litter comprises the following components in parts by weight: 30-60 parts of alginate fiber, 20-30 parts of corn flour, 10-30 parts of corn starch, 3-8 parts of guar gum, 2-6 parts of water-absorbent resin and 0.5-3 parts of essence. According to the invention, the natural alginate fiber is taken as a main raw material, so that the cat litter product is endowed with good water absorption and expansibility, and meanwhile, the corn starch, guar gum and water-absorbent resin have adhesiveness and formability, so that cat litter particles have pelletizing property, caking property and the like; the natural alginate fiber not only can meet the basic properties of water absorption and expansion of the cat litter product, but also has natural raw materials, is not easily polluted by mould and mycotoxin, and has a certain inhibition effect on harmful bacteria such as large intestines and staphylococcus aureus, so that the usability and the safety are greatly improved; in addition, the problem of unstable supply (shortage) of bean dreg fibers at present can be solved, and the method has a good application prospect.

Owner:浙江上方生物科技有限公司

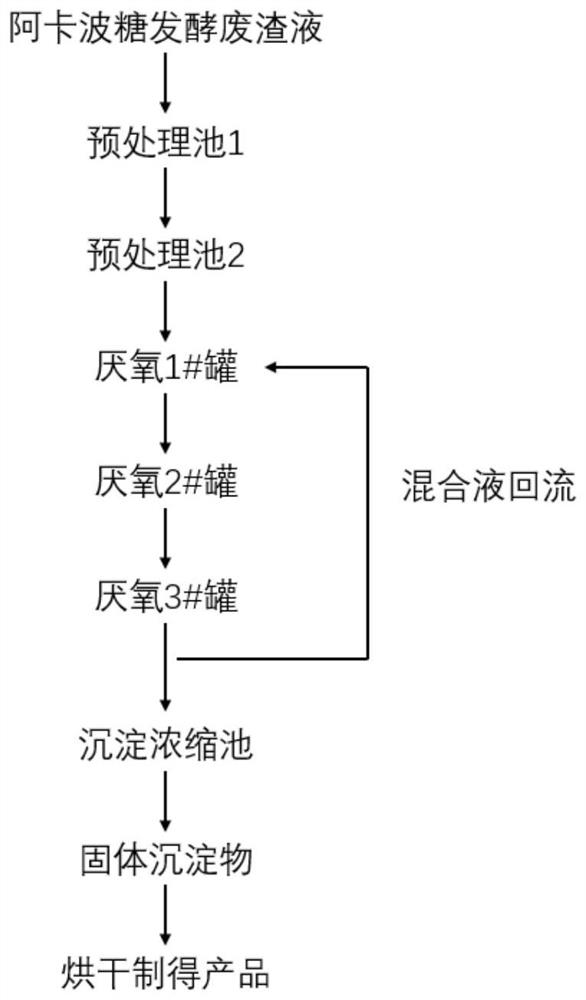

A kind of method that utilizes acarbose fermentation waste residue to prepare soil conditioner

ActiveCN110586611BImprove start-up efficiencyReduce drug residuesSolid waste disposalOrganic fertilisersEnvironmental engineeringSoil conditioner

The invention provides a method for preparing a soil conditioner by using acarbose fermentation waste residue. Specifically, the present invention treats acarbose fermentation waste residue through reasonable control of anaerobic reaction conditions and combined with pretreatment steps. Experimental results show that the method of the invention can significantly shorten the time of anaerobic treatment, and the removal rate of drug residues in waste residue can reach more than 90%, and the removal rate of solid matter can reach more than 70%. The invention also provides a method for making the soil conditioner by dehydrating and drying the remaining solid residue after multi-stage anaerobic treatment.

Owner:SHANGHAI JIAOTONG UNIV +2

A kind of efficient preparation method of airgel and its application

ActiveCN110775980BRealize continuous production and processingReduce pollutionSilicaProcess engineeringHeat conservation

Owner:徐州绿肯环保科技有限公司

Method and catalyst for recovering diphenols by catalytic hydrocracking of phenol-containing tar

ActiveCN109647387BReduce solid waste treatment costsHigh yieldOrganic chemistryOrganic compound preparationPtru catalystHydroquinone products

The invention relates to a method for recovering diphenol by catalytic hydrocracking of phenol-containing tar, a catalyst and a catalyst used in the method. The method uses cesium salt-modified titanium dioxide loaded with palladium and silver as a catalyst, and uses phenol-containing tar as a reaction raw material in an ethanol solvent to directly synthesize ortho / hydroquinone through catalytic hydrogenation. The method is simple to operate and environmentally friendly. On the one hand, the residual hydroquinone product in the phenol-containing tar is recovered, and at the same time, the tar produced by phenol dimerization and deep oxidation is rehydrocracked into a high value-added diphenol product. , which not only reduces the treatment cost of solid waste, but also significantly increases the yield of diphenol products.

Owner:WANHUA CHEM GRP CO LTD

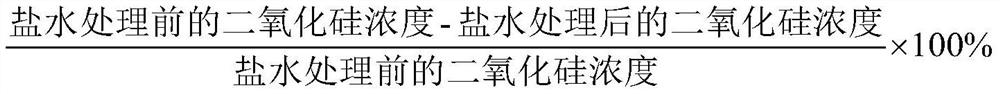

Method for reducing content of silicon dioxide in chlor-alkali primary brine

PendingCN113533322ASimple processReduce solid waste treatment costsMaterial analysis by observing effect on chemical indicatorChemical industrySea salt

The invention relates to a method for reducing the content of silicon dioxide in chlor-alkali primary brine, and belongs to the technical field of chlor-alkali chemical industry. The method comprises the following steps: adjusting the pH value of the brine, adding a magnesium chloride solution, adding a sodium carbonate solution, stirring for a certain time at a proper temperature, and filtering to remove the generated precipitate, thereby obtaining the primary brine meeting the requirements of an ionic membrane process. The method for reducing the content of silicon dioxide in the chlorine-alkali primary brine is simple in process, and does not need to change an original chlorine-alkali brine treatment device; and only a magnesium chloride solution adding facility needs to be additionally arranged on the original device; compared with a sea salt method, the salty mud amount can be reduced by 80%-90%, and the solid waste treatment cost is greatly reduced; the method is high in applicability and suitable for saline water with various silicon dioxide concentrations; the operation cost is low and the magnesium chloride addition amount is low.

Owner:常州新东化工发展有限公司

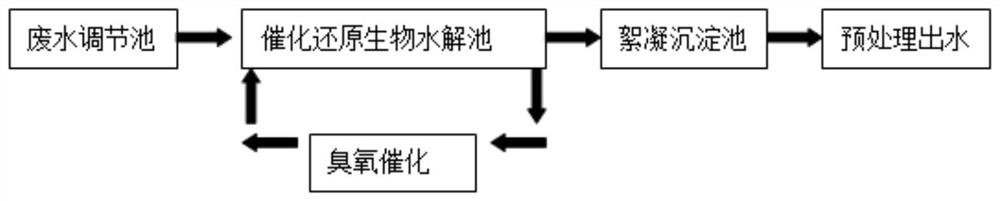

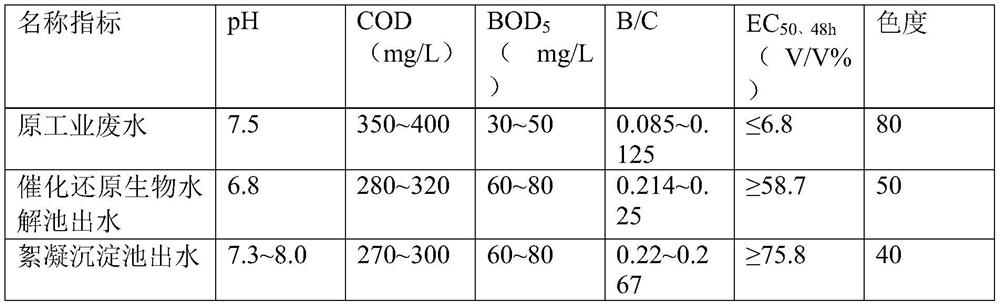

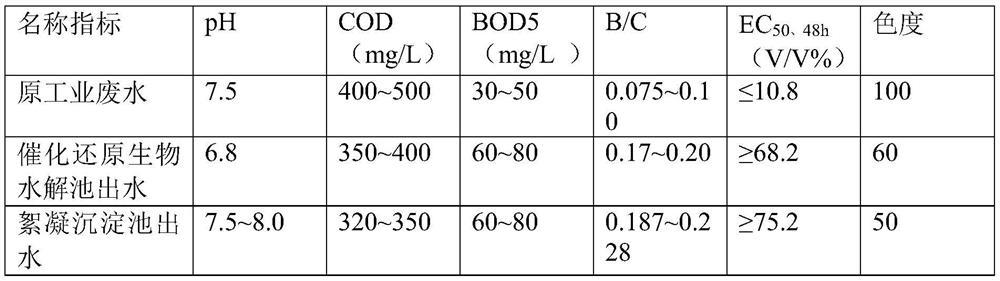

A kind of catalytic hydrolysis pretreatment method for industrial park wastewater

ActiveCN111410376BImprove biodegradabilityLow biological toxicityWater treatment compoundsMultistage water/sewage treatmentIndustrial waste waterPretreatment method

A catalytic hydrolysis pretreatment method for industrial park wastewater relates to the technical field of industrial wastewater treatment. In order to solve the problems of traditional industrial park wastewater pretreatment, the invention has poor pretreatment effect, cumbersome acid-base adjustment, large amount of oxidative pretreatment, large amount of sludge and unstable operation. Method: 1. Add packing and pretreated industrial wastewater into the catalytic reduction biological hydrolysis tank, add ozone catalytic packing and hydrogen peroxide into the ozone catalytic reaction tank, and pump the upper layer liquid of the industrial wastewater in the catalytic reduction biological hydrolysis tank to the ozone catalytic reaction Catalytic oxidation is carried out in the tank, and the industrial wastewater in the ozone catalytic reaction tank is returned to the catalytic reduction biological hydrolysis tank; the industrial wastewater flows into the flocculation sedimentation tank through the water outlet, the pH is adjusted to 7-8.5, polyacrylamide is added, and precipitation is completed to complete the industrial wastewater. Catalytic hydrolysis pretreatment. The invention can obtain a method for catalytic hydrolysis pretreatment of industrial park wastewater.

Owner:工大环境股份有限公司

Fixed bed adsorbing device for basic oil

The invention provides a fixed bed adsorbing device for basic oil. The fixed bed adsorbing device comprises an input port, a fixed bed absorber, a filter and an output port, wherein the fixed bed absorber comprises a tube-shaped casing, a fixed bed layer arranged in the tube-shaped casing and an input cavity communicated with the tube-shaped casing and arranged under the fixed bed layer. The input cavity is a cone body with the upper top face larger than the lower bottom face, and the input port is horizontally arranged on the lateral wall of the cone body. The fixed bed layer comprises an upper partition board, a lower partition board and an absorber pressed tightly between the upper partition board and the lower partition board, wherein the upper partition board and the lower partition board are arranged in parallel mode. The basic oil is input into the input cavity through the input port, output into the filter after absorbed by the fixed bed layer and discharged through the output port after being filtered by the filter. The fixed bed adsorbing device for basic oil has the advantages of being simple in structure, high in automation degree, small in pollution and good in adsorbing performance.

Owner:BEIJING ECO ISLAND SCI & TECH

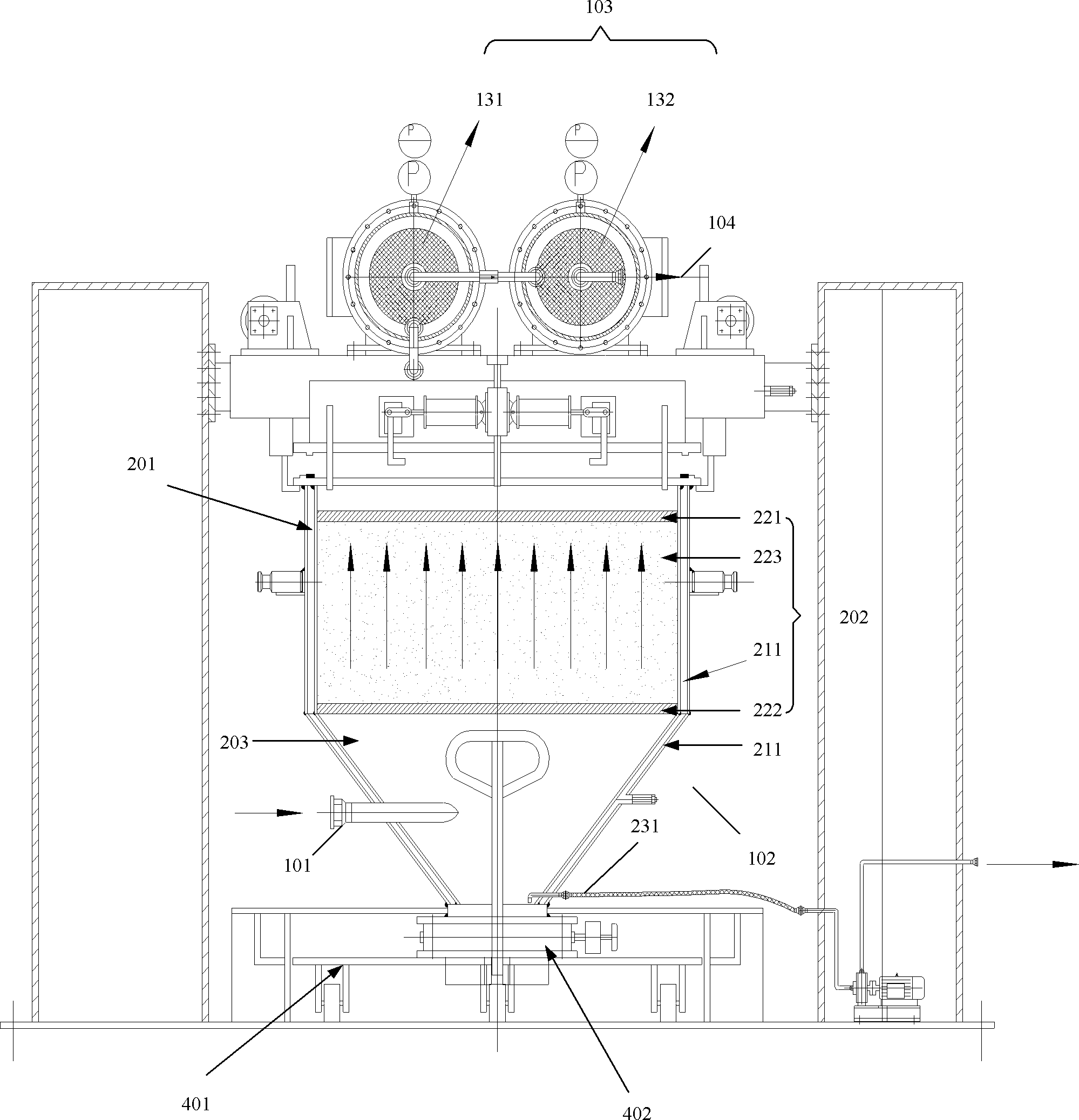

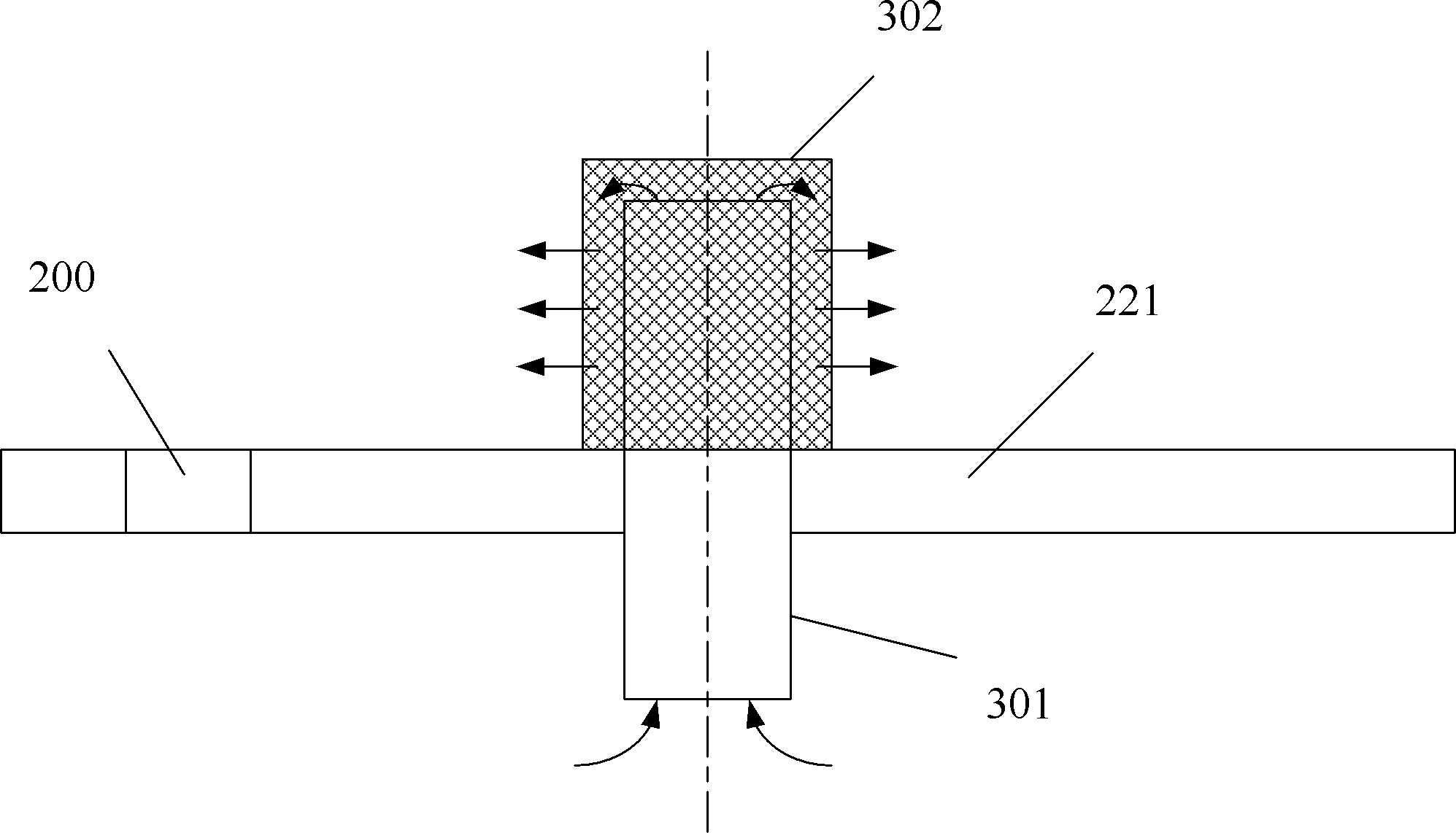

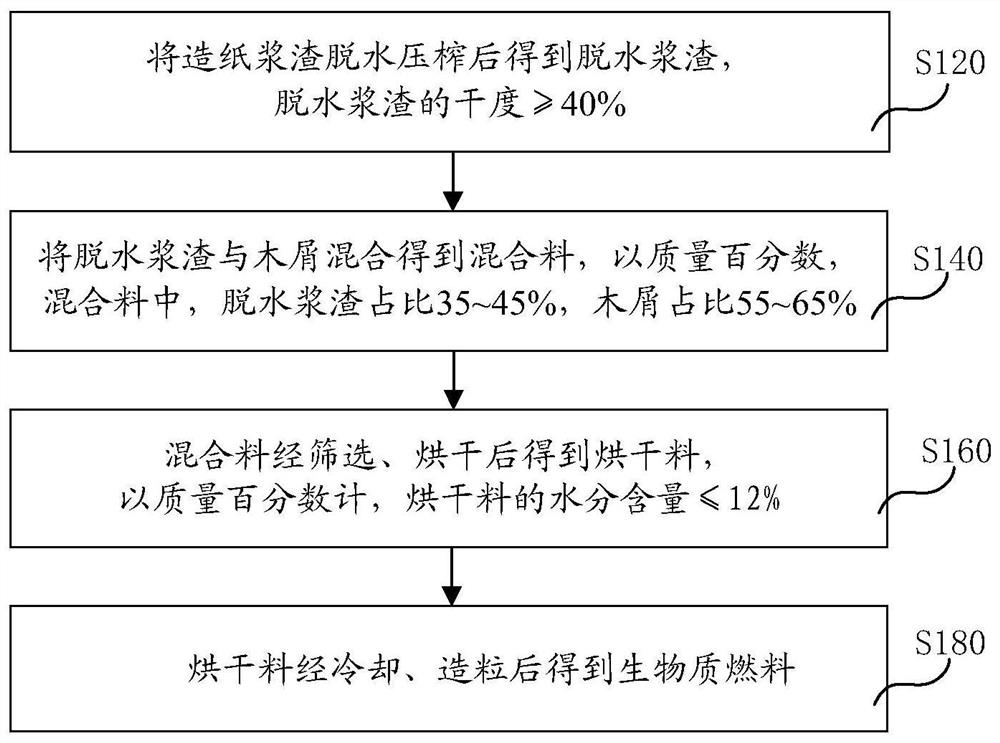

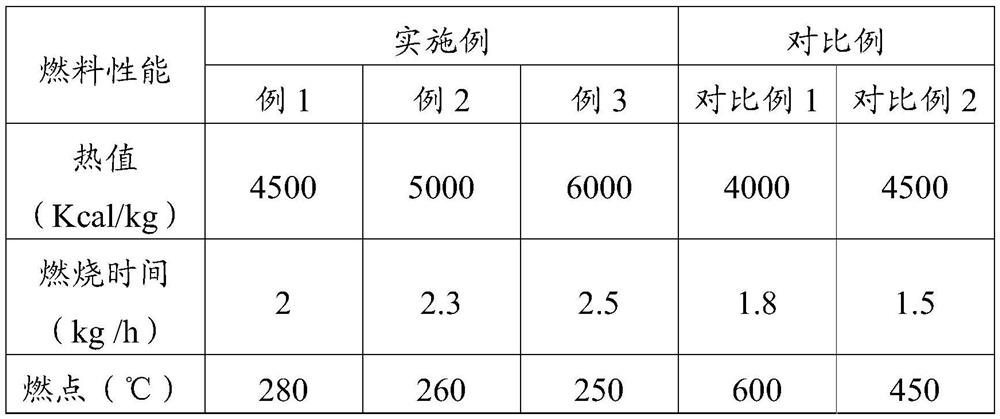

Biomass fuel and preparation method of biomass fuel

PendingCN112410089AHigh calorific valueEnvironmentally friendlyBiofuelsSolid fuelsSawdustBiomass fuels

The invention discloses a biomass fuel and a preparation method of the biomass fuel, the biomass fuel is prepared from the following production raw materials in percentage by mass: 35-45% of dehydrated pulp residue and 55-65% of sawdust, the dehydrated pulp residue is prepared by dehydrating and squeezing papermaking pulp residue, and the dryness of the dehydrated pulp residue is greater than or equal to 40%. By means of the mode, the biomass fuel can promote recycling of resources.

Owner:GUANGXI JINGUI PULP PAPER

A kind of treatment method of ctc rectification still residue

ActiveCN106902489BEasy to incinerateReduce solid waste treatment costsChemical protectionChemical industryChloride

The invention discloses a treatment method for CTC rectifying still residues and belongs to the technical field of treatment of solid waste in chemical industry production processes. According to the method, a solvent is added into the rectifying still residues for an impurity removing technique at first; and then solid alkali is added into a mixed liquid subjected to impurity removing in batches, a temperature increasing refluxing reaction is conducted, high-content pyridine chlorides are converted into carbon, hydrogen, oxygen and nitrogen compounds, and incineration treatment is facilitated. The economic pressure of enterprises for treating the still residues is relieved, and the environment is protected.

Owner:内蒙古佳瑞米精细化工有限公司

Method and system for preparing silica aerogel

The invention discloses a method for preparing an aerosil and a system thereof. The method comprises the following steps: 1) slag slurry in polysilicon production and water are mixed, a hydrolysis reaction is carried out to generate silica sol, and a solid-liquid mixture is obtained; 2) the solid-liquid mixture is subjected to solid-liquid separating, and a solid mixture and a liquid mixture are respectively obtained, wherein the liquid mixture comprises silica sol; 3) an alkaline solution is used for adjusting pH value of the liquid mixture to alkalescence, gelating treatment is carried out,and silica sol in the liquid mixture generates silicon gel; 4) the silicon gel is subjected to solvent replacing, and water in the silicon gel is replaced; and 5) drying is carried out to obtain the aerosil. The method employs the slag slurry in polysilicon production as a silicon source of aerosil, raw material cost for preparation of the aerosil is reduced, environment pollution, solid waste processing cost and material waste are reduced, and enterprise economic benefit can be increased.

Owner:新疆硅基新材料创新中心有限公司

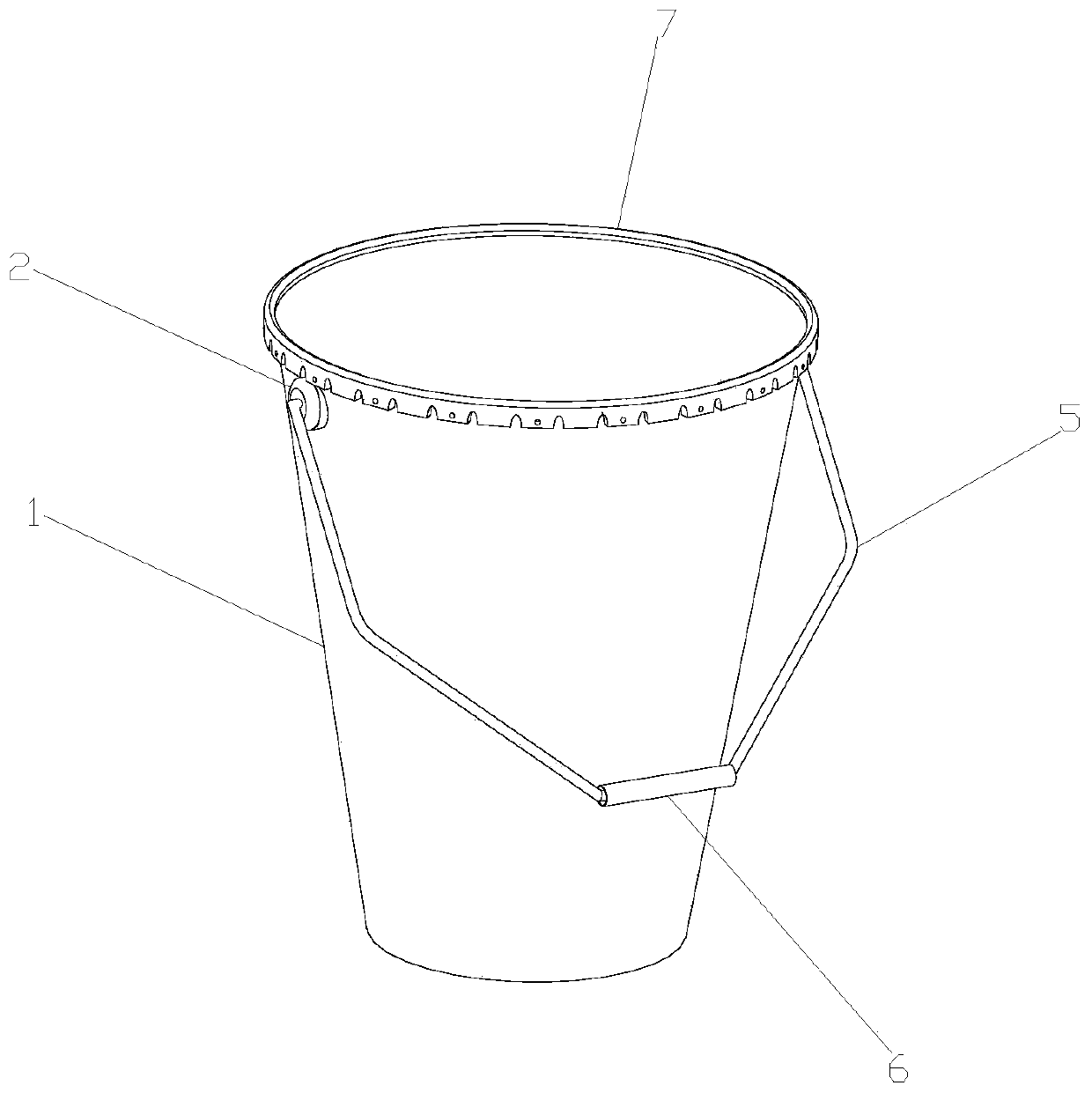

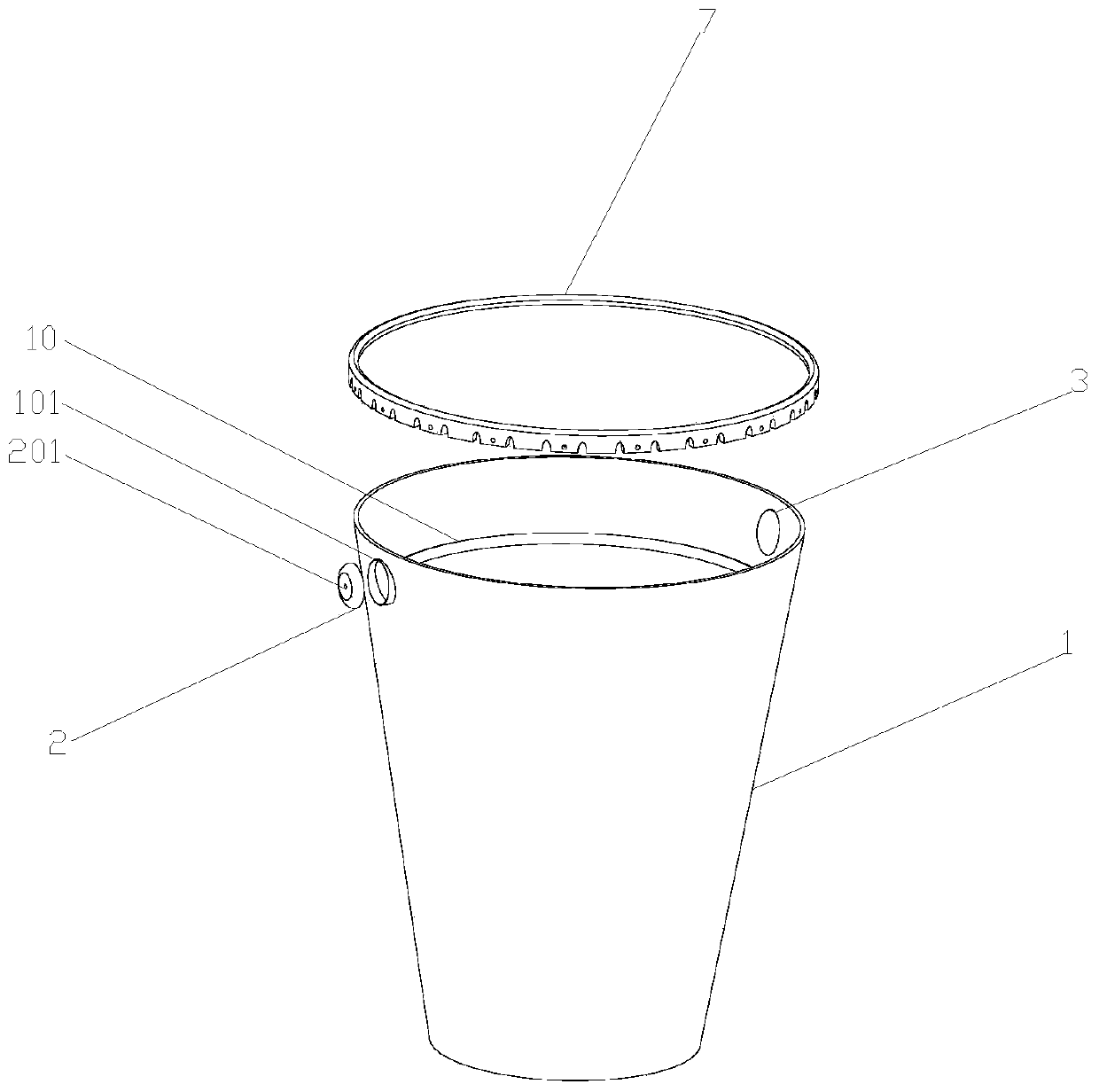

Liner barrel of an antistatic chemical raw material barrel

ActiveCN109178597BPrevent static electricityReduce bondingLinings/internal coatingsRigid containersWaste treatmentMechanical engineering

Owner:安徽洁纯生物科技有限公司

Baking-free brick containing aluminum mud

The invention discloses a baking-free brick containing aluminum mud, which is prepared from the following materials in percentage by weight: 15-25% of dry aluminum mud powder, 3-10% of fly ash, 5-20% of water-quenched slag powder, 5-15% of Portland cement and 20-50% of sandstone aggregate, and the aluminum mud is a solid waste filler. The sandstone aggregate can also be replaced with industrial and mining solid waste to serve as aggregate besides a common sandstone material, and the aggregate comprises but is not limited to tailing sand, barren rock and construction waste. The curing cementing material comprises but is not limited to fly ash, water-quenched slag powder and Portland cement. The invention relates to the technical field of construction materials, in particular to a baking-free brick containing aluminum mud. The expansion damage of the baking-free brick caused by water absorption of the aluminum mud is inhibited, and the stability of the product is improved. The characteristics of a volcanic ash material and dense filling of coarse and fine aggregate gradation are fully utilized, so that the use amount of cement is reduced, the cost is greatly reduced, the volume weight and strength of a product are increased, and the negative influence of light aluminum mud on the strength of the product is reduced.

Owner:江苏瑜工环保科技有限公司

A kind of preparation method of airgel and its application

ActiveCN110817888BEasy to prepareImprove controllabilitySilicon organic compoundsSilicon compoundsSupercritical dryingFiber

The invention discloses a preparation method and application of an airgel. Alkoxysilane is used as a raw material, which is hydrolyzed to form a sol, which is then modified and aged, and prepared through supercritical drying and normal pressure drying steps to obtain aerogel Silica airgel products, after hydrolysis by-product alkoxy alcohols are recovered, are recycled for the preparation of alkoxysilanes; the aerogels prepared by the method are used to prepare airgel composite fiber mats, airgel panels, Application in airgel glass and airgel ball raw materials. Adopting the technical scheme of the present invention, the preparation method is simple, the overall reaction is stable, the controllability is strong, the investment cost is low, the production cycle is short, and the process technology can realize continuous production, which is friendly to the environment; the prepared silicon dioxide gas condensation Rubber products have excellent thermal insulation performance and heat resistance performance, and have high processing performance.

Owner:徐州绿肯环保科技有限公司

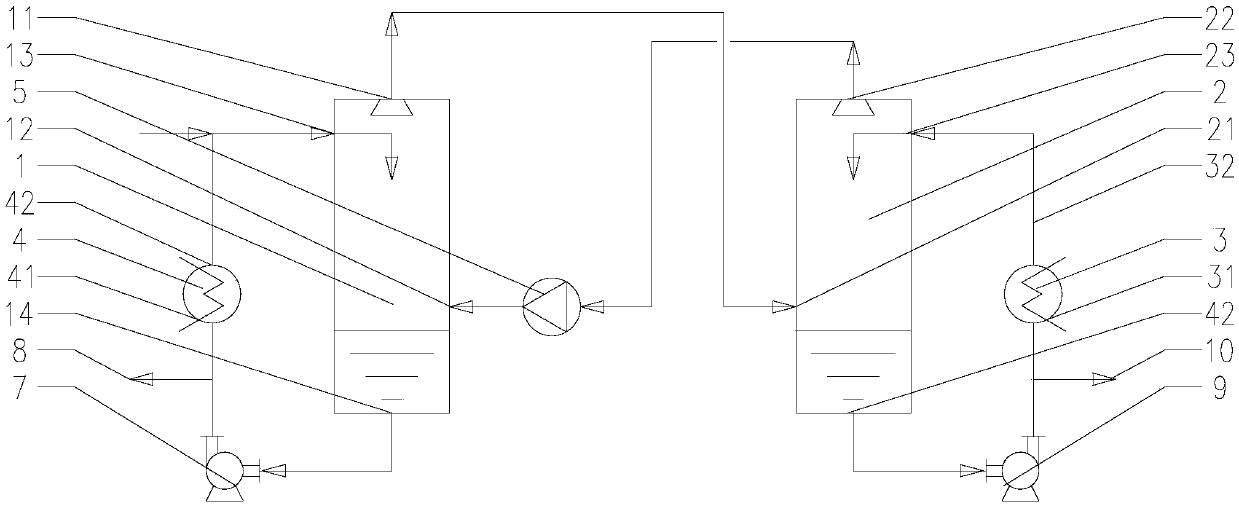

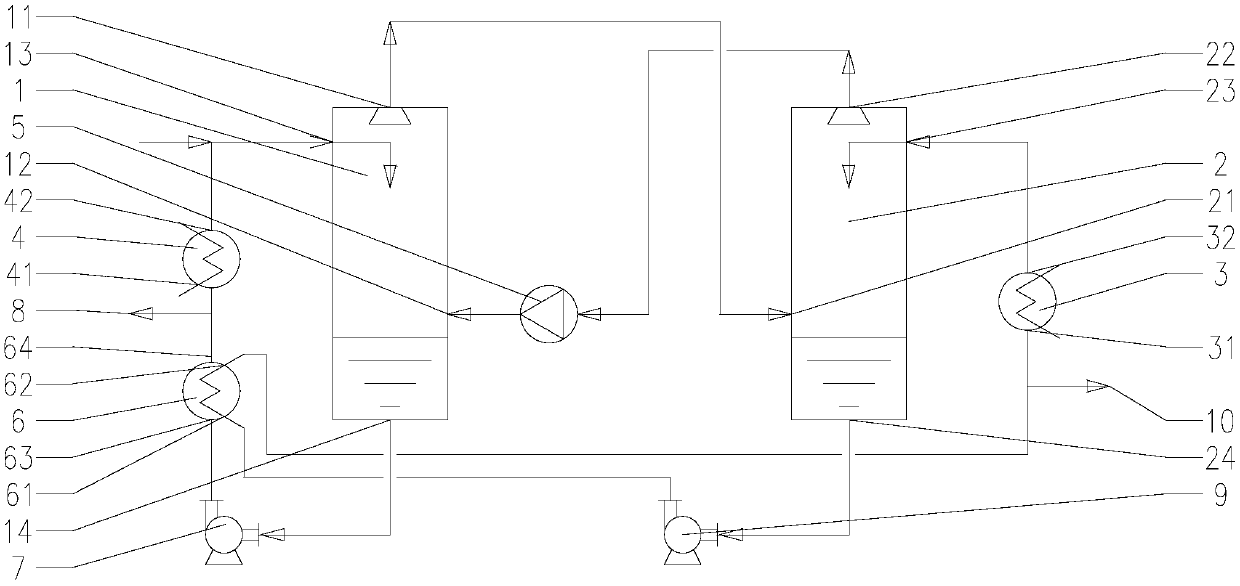

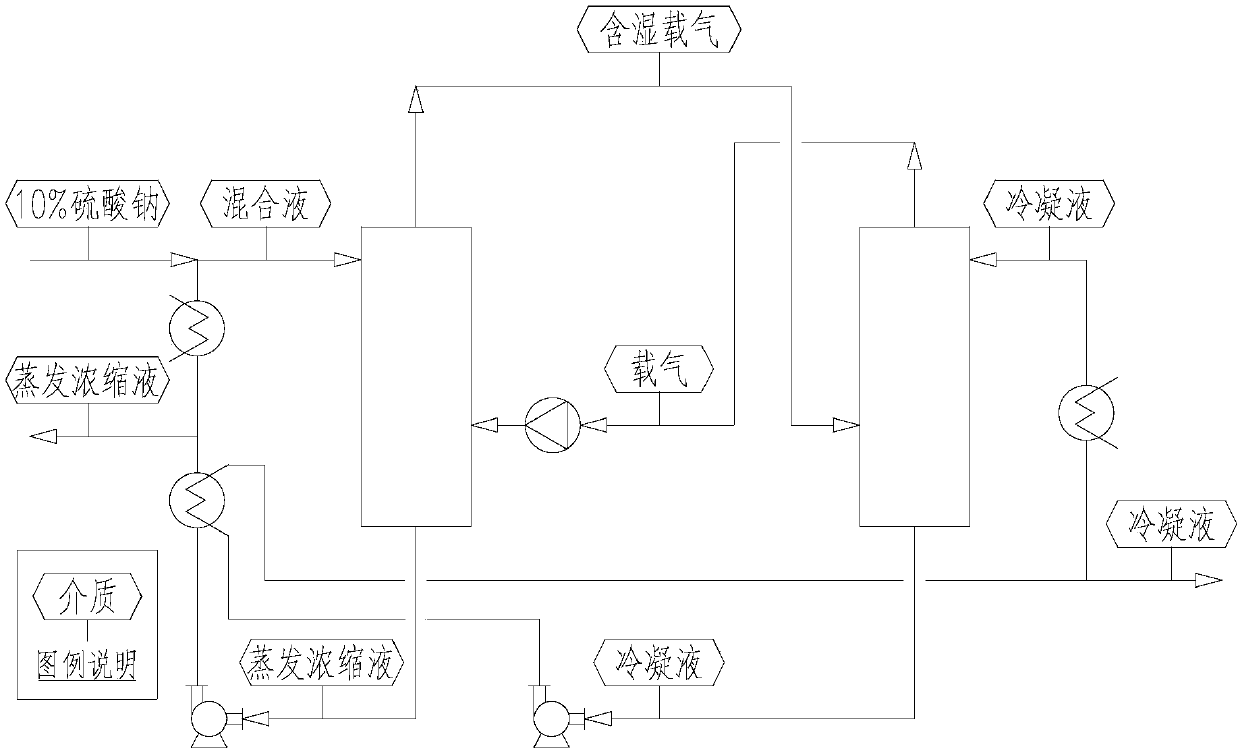

Contact type evaporation system

InactiveCN110947191AImprove toleranceDoes not affect heat transfer efficiencyEvaporator accessoriesCondenser (heat transfer)Heat recirculation

The invention provides a contact type evaporation system, which comprises an evaporator, a condenser, a heating heat exchanger and a cooling heat exchanger, wherein heating circulation is formed between the evaporator and the heating heat exchanger through a pipeline so as to make a treatment liquid be mixed with carrier gas in the evaporator to form moisture-containing carrier gas after being heated by the heating heat exchanger, the evaporator is communicated with the condenser through a pipeline so as to input the moisture-containing carrier gas into the condenser from the evaporator, and cooling circulation is formed between the condenser and the cooling heat exchanger through a pipeline so as to make the moisture-containing carrier gas be separated into carrier gas and condensate after being cooled by condensate water generated by the cooling heat exchanger in the condenser. The invention further provides a contact type evaporation method. The contact type evaporation system provided by the invention has the characteristics that the quality of a required heat source is low, the material price of evaporation equipment is low, and mass transfer and heat transfer positions can beseparated so as to significantly prevent scaling.

Owner:韩林辰 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com