Non-ferrous smelting sewage treatment neutralization slag concrete brick and preparation method thereof

A technology for sewage treatment and concrete bricks, which is applied in the field of non-ferrous smelting sewage treatment and slag concrete bricks and their preparation, can solve the problems of unrecognized market, threats to land and water bodies, and high disposal costs, and saves investment costs and operation. Cost, reduce secondary pollution, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

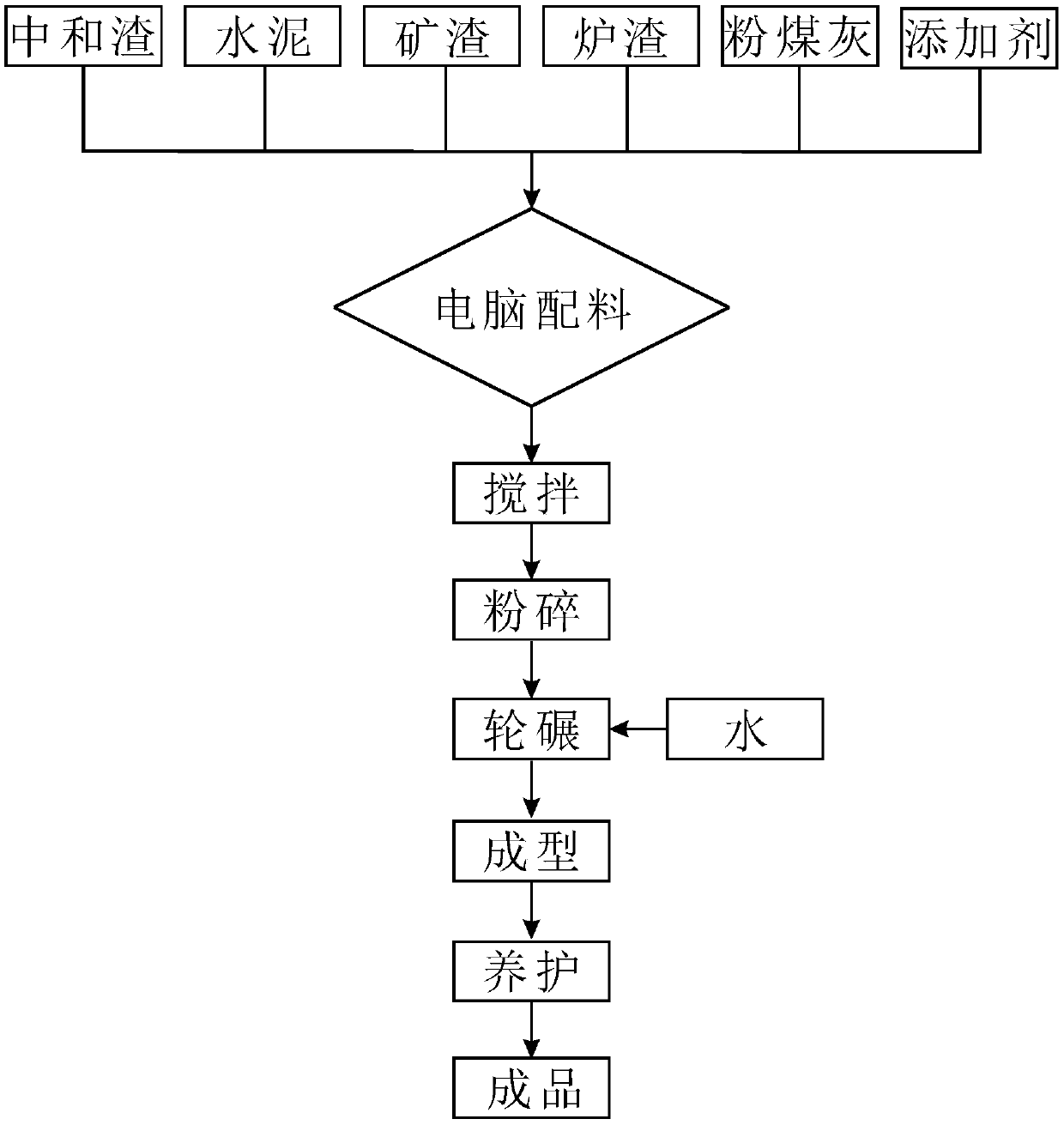

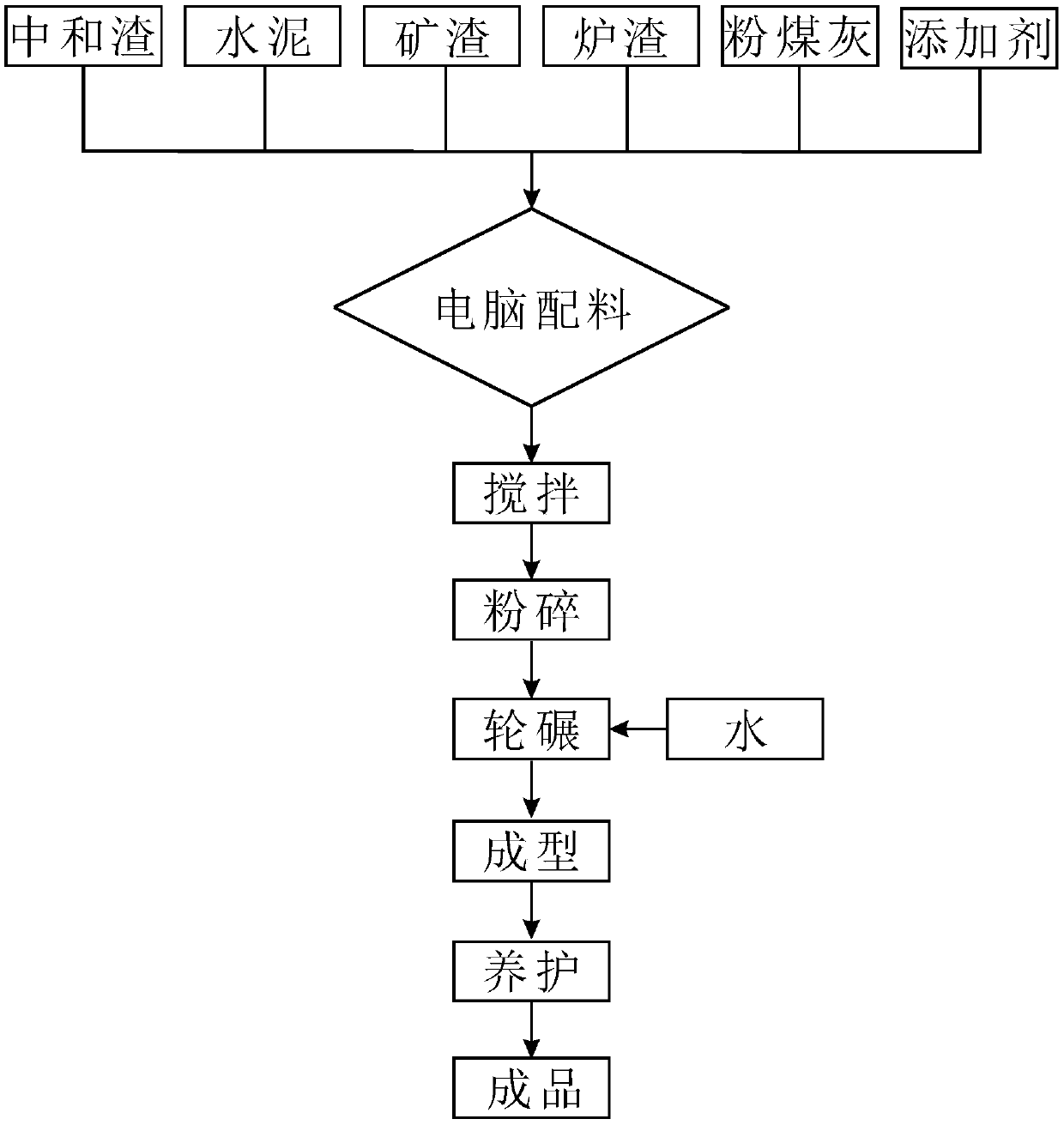

Method used

Image

Examples

Embodiment 1

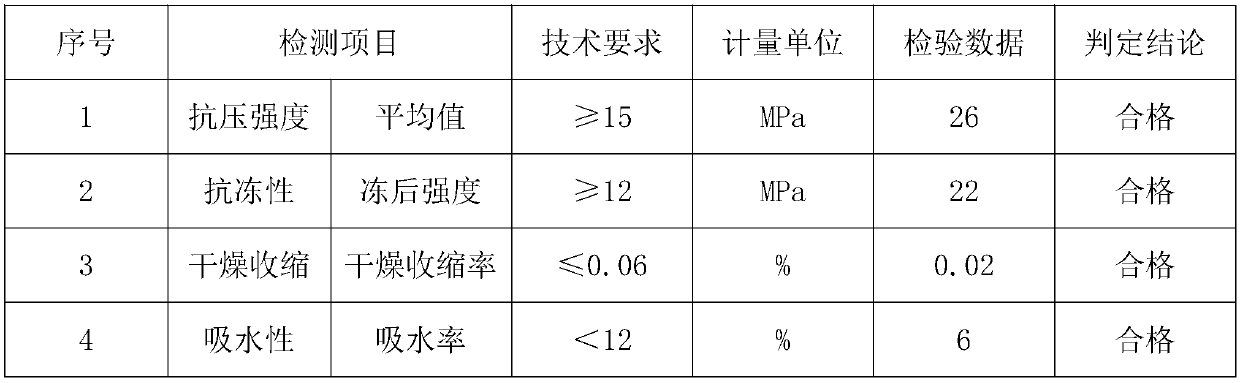

[0033] A neutralized slag concrete brick for non-ferrous smelting sewage treatment, comprising raw materials of the following weights: neutralized slag 900kg, cement 120kg, slag 180kg, slag 1320kg, fly ash 450kg, and admixture 30kg. Wherein, the non-ferrous smelting sewage treatment neutralization slag concrete brick is pressed by a semi-dry method; the neutralization slag is the non-ferrous smelting sewage treatment neutralization slag, specifically the viscous sludge produced in the non-ferrous smelting wastewater treatment process , That is, in the non-ferrous smelting wastewater treatment process, the iron salt-lime / calcium carbide mud method is used as the wastewater treatment agent. After pressure filtration, it becomes a viscous sludge with a water content of 30% and a red-yellow or white appearance. The ingredients are calcium sulfate and calcium sulfite, and also contain traces of heavy metal elements such as lead, zinc, copper, chromium, cadmium, arsenic, mercury, etc....

Embodiment 2

[0049] A neutralized slag concrete brick for non-ferrous smelting sewage treatment, comprising raw materials of the following weights: neutralized slag 1350kg, cement 200kg, slag 190kg, slag 1200kg, and admixture 60kg. Wherein, the non-ferrous smelting sewage treatment neutralization slag concrete brick is pressed by a semi-dry method; the neutralization slag is the non-ferrous smelting sewage treatment neutralization slag, specifically the viscous sludge produced in the non-ferrous smelting wastewater treatment process , That is, in the non-ferrous smelting wastewater treatment process, the iron salt-lime / calcium carbide mud method is used as the wastewater treatment agent. After pressure filtration, it becomes a viscous sludge with a water content of 30% and a red-yellow or white appearance. The ingredients are calcium sulfate and calcium sulfite, and also contain traces of heavy metal elements such as lead, zinc, copper, chromium, cadmium, arsenic, mercury, etc., open-air sto...

Embodiment 3

[0065] A neutralized slag concrete brick for non-ferrous smelting sewage treatment, comprising raw materials of the following weights: 1100 kg of neutralized slag, 240 kg of cement, 300 kg of slag, 1050 kg of slag, 270 kg of fly ash, and 40 kg of additives. Wherein, the non-ferrous smelting sewage treatment neutralization slag concrete brick is pressed by a semi-dry method; the neutralization slag is the non-ferrous smelting sewage treatment neutralization slag, specifically the viscous sludge produced in the non-ferrous smelting wastewater treatment process , That is, in the non-ferrous smelting wastewater treatment process, the iron salt-lime / calcium carbide mud method is used as the wastewater treatment agent. After pressure filtration, it becomes a viscous sludge with a water content of 30% and a red-yellow or white appearance. The ingredients are calcium sulfate and calcium sulfite, and also contain traces of heavy metal elements such as lead, zinc, copper, chromium, cadmiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com