A kind of method that utilizes acarbose fermentation waste residue to prepare soil conditioner

A technology of fermentation waste residue and acarbose, applied in the biological field, can solve the problems of environmental pollution, high processing cost, breeding of mosquitoes or mildew, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

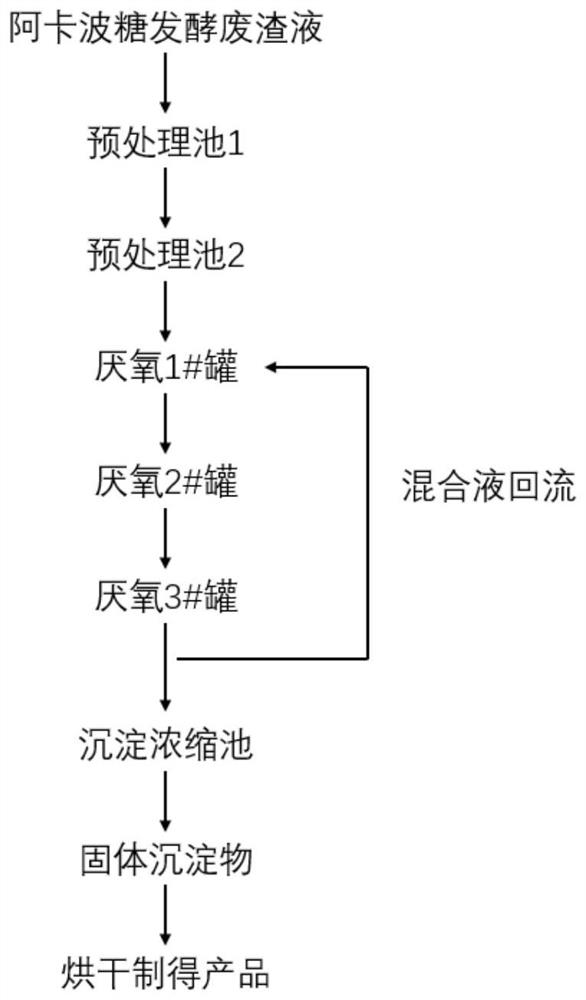

[0063] The acarbose fermentation waste residue was mixed with clean water to form a waste residue liquid with a solid mass concentration of 60g / L, and the waste residue liquid was directly transferred to a three-stage series anaerobic reactor, which was inoculated with commercially available anaerobic sludge , the total volume of acarbose fermentation waste liquid added every day is 1 / 12 of the total volume of the three-stage series anaerobic reactor, that is, the anaerobic residence time is controlled to be 12d.

[0064] Regulate the pH of each anaerobic tank with oxalic acid and sodium carbonate, be that the pH of 1# tank is 6.8, the pH of 2# tank is 7.2, the pH of 3# tank is 7.4, meanwhile, the mixed solution (comprising solid and liquid) is returned to the 1# tank, and the return flow is 50% of the total amount of feed. The remaining mixed liquid discharged from the 3# tank is separated from the solid and liquid through gravity sedimentation in the sedimentation concentrat...

Embodiment 2

[0067] The whole treatment device consists of 2 pretreatment tanks, 3 anaerobic reactors (1# tank, 2# tank, 3# tank) and 1 sedimentation concentration tank.

[0068] In the pretreatment tank 1, the acarbose fermentation waste residue was mixed with clean water to form a waste residue liquid with a solid mass concentration of 60 g / L, and the pH was adjusted to 9.5 with NaOH solid, heated to 60°C, and reacted for 2 hours. After the reaction, the waste residue liquid is transferred to the pretreatment tank 2, the feed liquid is mixed with the commercially available anaerobic sludge (the volume ratio of the feed liquid and the anaerobic sludge is 1:1), and the pH is adjusted to 6.5 with oxalic acid, and the reaction temperature The temperature is 30°C, and the reaction time is 1d.

[0069] The pretreated feed liquid is transferred to the three-stage series anaerobic reactor, and the commercially available anaerobic sludge is inoculated in the anaerobic reactor. The total volume o...

Embodiment 3

[0073] The whole treatment device consists of 2 pretreatment tanks, 3 anaerobic reactors (1# tank, 2# tank, 3# tank) and 1 sedimentation concentration tank.

[0074] In the pretreatment tank 1, the acarbose fermentation waste residue was mixed with clean water to form a waste residue liquid with a solid mass concentration of 70 g / L, and the pH was adjusted to 9.0 with NaOH solid, heated to 55° C., and reacted for 3 hours. After the reaction, the waste residue liquid is transferred to the pretreatment tank 2, the feed liquid is mixed with the commercially available anaerobic sludge (the volume ratio of the feed liquid and the anaerobic sludge is 1:2), and the pH is adjusted to 7.0 with oxalic acid, and the reaction temperature The temperature is 30°C, and the reaction time is 2d.

[0075] The pretreated feed liquid is transferred to the three-stage series anaerobic reactor, and the commercially available anaerobic sludge is inoculated in the anaerobic reactor. The inoculum amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com