Treatment method for CTC rectifying still residues

A treatment method and rectification still technology, which is applied in the field of CTC rectification still residue treatment, can solve the problems of incineration equipment corrosion, unfavorable environmental protection, and environmental secondary pollution, so as to reduce treatment costs, benefit environmental protection, Ease of incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

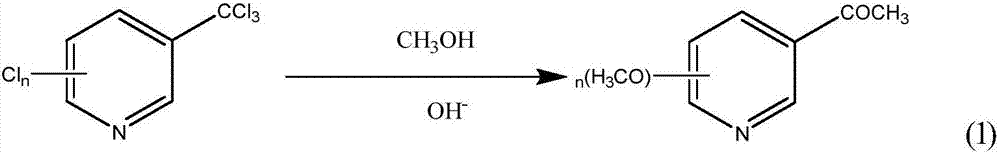

Method used

Image

Examples

Embodiment 1

[0033] 1. In a 1000mL round bottom flask, add 200g of CTC distillation still residue and 500g of methanol, connect the condenser, stir and reflux for 30 minutes, then cool and suction filter to obtain 658.5g of filtrate;

[0034] 2. Return the filtrate to the 1000mL round bottom flask, connect the condenser, reflux under stirring conditions (reflux temperature 80°C), add solid sodium hydroxide to the reaction solution in three batches (the input amount of each batch is basically the same) 8g (0.2mol), gas chromatographic tracking reaction, when the total amount of chlorinated compounds in the reaction solution <2%, stop heating, continue to stir;

[0035] 3. When the temperature of the reaction solution drops to room temperature, add dropwise dilute hydrochloric acid with a concentration of 10-20wt.% to the reaction solution, adjust the pH to 5, continue stirring for 3 hours, then pour the reaction solution into water, wash with water three times, and let it stand Separate the...

Embodiment 2

[0037] The amount of methanol in step 1 in Example 1 is changed to 1000g, and other operating conditions include the same as in Example 1 after treatment steps. 107.3 g of the final residue was obtained, the total amount of chlorinated compounds was 0.7%, and the yield was about 93.2%.

Embodiment 3

[0039] The methyl alcohol of step 1 among the embodiment 1 is changed into ethanol, and other operation conditions comprise the uniform embodiment 1 same of aftertreatment step. 118.5 g of the final residue was obtained, the total amount of chlorinated compounds was 1.8%, and the yield was about 91.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com