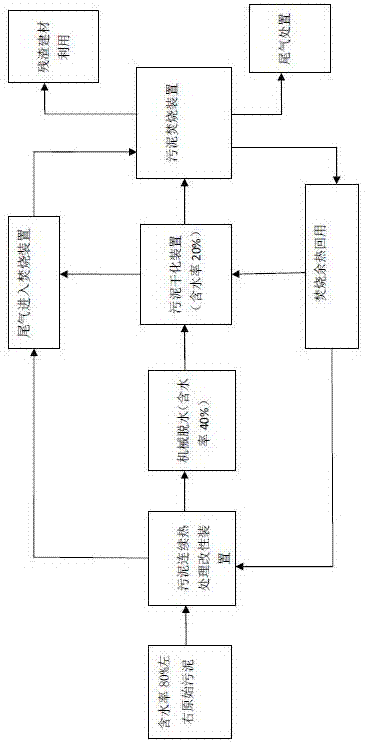

Sludge continuous-heat-treatment modification device and technology of deep dehydrating, drying and incineration

A heat treatment modification, sludge technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problems of high valve damage rate, long time-consuming, short service life, etc. Improve dehydration performance, reduce energy consumption and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

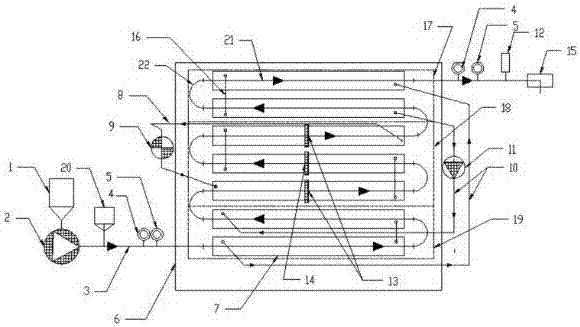

[0035] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following will be combined with the drawings and preferred embodiments, and the specific implementation, structure, features and effects of the present invention will be described in detail as follows .

[0036]The modification device for continuous heat treatment of sludge comprises: a sludge conveying pipeline 3 and a heat medium spacer 7, the sludge conveying pipeline 3 includes a preheating section 19, a reaction section 18 and a cooling section 17, and the preheating section 19 1. The pipes of the sludge conveying pipelines of the reaction section 18 and the cooling section 17 are all sleeved with heat medium spacer pipes 7, and the heat medium spacer pipes of the reaction section communicate with the heat medium heating converter 9 to form heat medium first Circulation loop, the heat medium spacer tube of the preheating section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com