Recycling system and recycling method for waste liquor produced in separation and purification of organically synthesized feed liquid

A technology of separation and purification and organic synthesis, which is applied in the field of chemical industry and can solve the problems of separation and purification operation yield and purity contribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

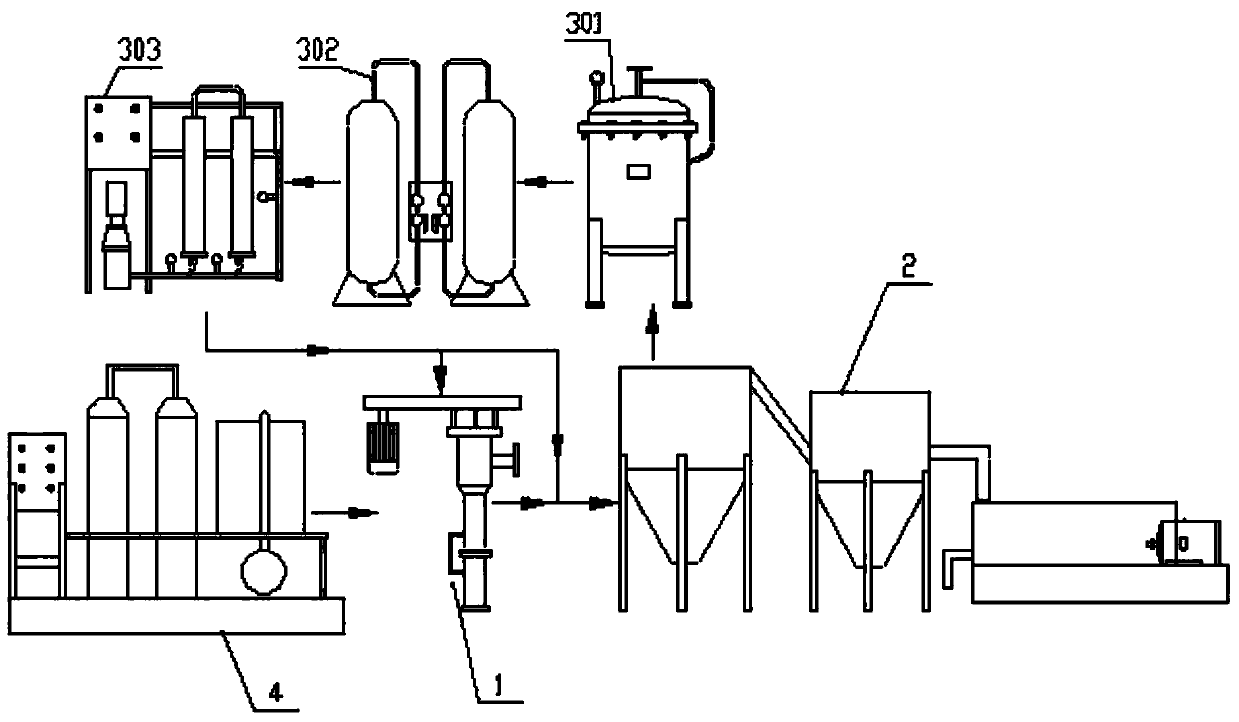

[0105] Refer to the following Figure 8-11 Preferred embodiments of the present invention are described in detail. The organic synthesis material liquid of iminodiacetonitrile in this example is obtained according to the production method of patent CN1331844C; the sulfuric acid added below is used for the neutralization of ammonia in the reaction system. The operation of not specifying specific conditions in the embodiment is carried out according to conventional operating conditions.

[0106] The material extracted from the iminodiacetonitrile reactor (material code: FED1, wherein the iminodiacetonitrile content is 300g / L, temperature 65°C, pH=7.0) is dissolved in 10.5m 3 The speed of / h is sent continuously in the batching tank 5, and the material that is sent continuously simultaneously also includes: product centrifugal filter cake washing liquid and secondary thickener underflow mixed solution (material code name: FED 2; wherein iminodiacetonitrile content is 50g / L, te...

Embodiment 2

[0117] Refer to the following Figure 8-11 Preferred embodiments of the present invention are described in detail. The organic synthesis material liquid of iminodiacetonitrile in this example is obtained according to the production method of patent CN1331844C; the sulfuric acid added below is used for the neutralization of ammonia in the reaction system. The operation of not specifying specific conditions in the embodiment is carried out according to conventional operating conditions.

[0118] The material extracted from the iminodiacetonitrile reaction system (material code: FED1, wherein the iminodiacetonitrile content is 300g / L, the temperature is 65°C, the pH=7.0) is 10.5m 3 The rate of / h is continuously sent to the batching tank 5. At the same time, the continuously fed materials also include: the product centrifugal filter cake lotion mixed with the bottom flow of the secondary thickener, and the clear liquid obtained after filtration (material code: FED 2; the conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com