Method and catalyst for recovering diphenols by catalytic hydrocracking of phenol-containing tar

A technology for catalytic hydrogenation and phenol tar, which is used in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical recovery, etc. Process economy, effect of reducing disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

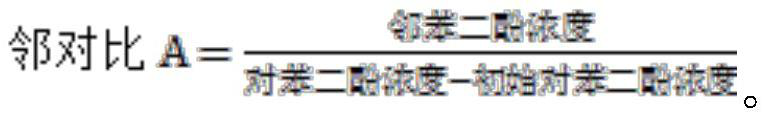

Method used

Image

Examples

Embodiment example 1

[0037] Weigh 10g of titanium dioxide and dissolve it in 10ml of aqueous solution in a round-bottomed flask, add 0.1g of palladium nitrate dihydrate solid, 0.1g of silver nitrate solid, and 0.01g of cesium carbonate solid under constant stirring, and continue stirring for 10 hours, then turn off the stirring. After standing still for 8 hours, the excess aqueous solution was removed by rotary evaporation, dried overnight, calcined at 300°C for 8 hours, and finally reduced at 300°C for 6 hours under a hydrogen atmosphere to obtain a catalyst supporting palladium and silver on titanium dioxide, wherein palladium is 0.45 wt%, silver is 0.62wt%, and cesium oxide is 0.08wt%. Take 0.1g of the titanium dioxide-supported catalyst prepared above, 10ml of water, and 5g of tar into the reaction kettle, replace the air in the reaction kettle with hydrogen 5 times, react at a temperature of 80°C, a pressure of 1MPa, and a stirring speed of 600rpm for 5 hours, and cool to room temperature , T...

Embodiment example 2

[0039]Weigh 10g of titanium dioxide and dissolve it in 80ml of aqueous solution in a round-bottomed flask, add 0.5g of palladium nitrate dihydrate solid, 0.5g of silver nitrate solid, and 0.03g of cesium carbonate solid under constant stirring, and continue stirring for 12 hours, then turn off the stirring. After resting for 10 hours, the excess aqueous solution was removed by rotary evaporation, dried overnight, calcined at 400°C for 5 hours, and finally reduced at 300°C for 5 hours under a hydrogen atmosphere to obtain palladium and silver catalysts supported on titanium dioxide. Among them, 2.17wt% of palladium, 2.99wt% of silver, and 0.23wt% of cesium oxide. Take 0.2g of the titanium dioxide-supported catalyst prepared above, 50ml of water, and 5g of tar into the reaction kettle, replace the air in the reaction kettle with hydrogen for 5 times, react at a temperature of 100°C, a pressure of 2MPa, and a stirring speed of 800rpm for 2 hours, and then cool to room temperature ...

Embodiment example 3

[0041] Weigh 10g of titanium dioxide and dissolve it in 100ml of aqueous solution in a round-bottomed flask, add 2g of palladium nitrate dihydrate solid, 2g of silver nitrate solid, and 0.1g of cesium carbonate solid under constant stirring, and continue stirring for 16 hours, then turn off the stirring and stand still for 12 After one hour, the excess aqueous solution was removed by rotary evaporation, dried overnight, calcined at 500°C for 5 hours, and finally reduced at 350°C for 4 hours under a hydrogen atmosphere to obtain a catalyst of palladium and silver supported on titanium dioxide. Wherein, palladium is 7.42wt%, silver is 10.2wt%, and cesium oxide is 0.65wt%. Get the titania-supported catalyst 1g prepared above, water 100ml, and tar 5g and join in the reactor, and hydrogen replaces the air in the reactor for 5 times. , at a temperature of 120° C., a pressure of 3 MPa, a stirring speed of 900 rpm, and react for 1 h. After cooling to room temperature, the reaction solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com