Contact type evaporation system

An evaporation system and contact technology, applied in evaporation, evaporator accessories, chemical instruments and methods, etc., can solve the problems of accelerated scaling process, blockage of flow channels between evaporation tubes or plates, and large investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

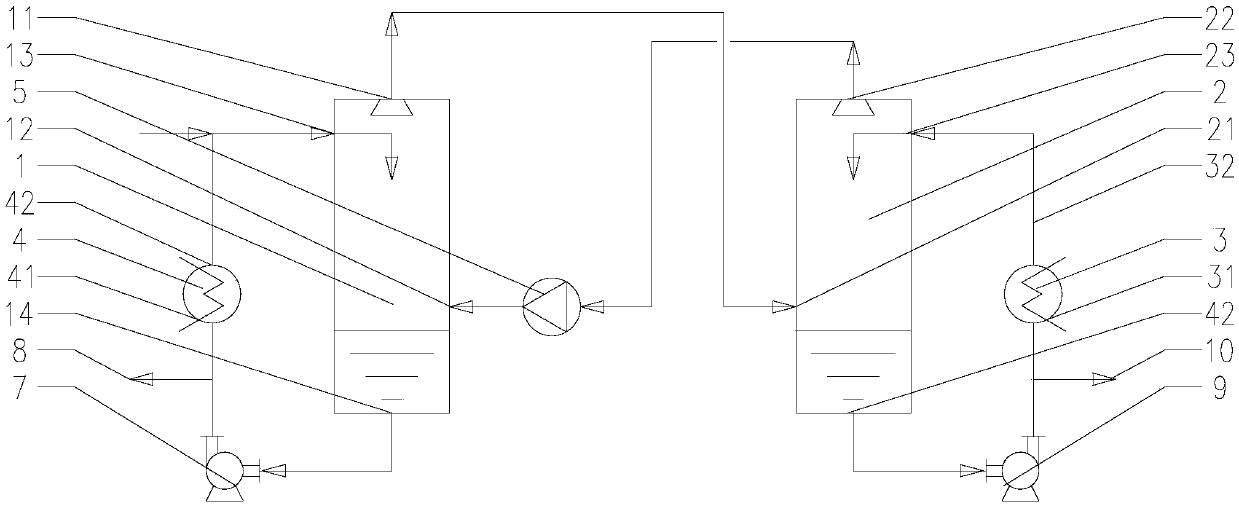

[0144] Take the treatment liquid, such as figure 1 As shown, the treatment liquid is processed through the contact evaporation system in the present invention. First, the treatment liquid flows into the pipeline where the heating heat exchanger is located in the pipeline of the heating cycle under the action of the first circulation pump, and is mixed with the evaporation concentrate. Finally, heat treatment is carried out through the heating heat exchanger. According to the properties of the treatment liquid, the temperature of the cold side is increased, the concentration of the heated treatment liquid increases, and the temperature of the treatment liquid increases. Then the heated treatment liquid is 0.01-500m 3 The flow rate of / h enters the evaporator through the liquid inlet of the treatment liquid. At the same time, the carrier gas is input into the evaporator through the fan at a flow rate of 1-1000000kg / h through the carrier gas inlet. The carrier gas is air or inert...

Embodiment 2

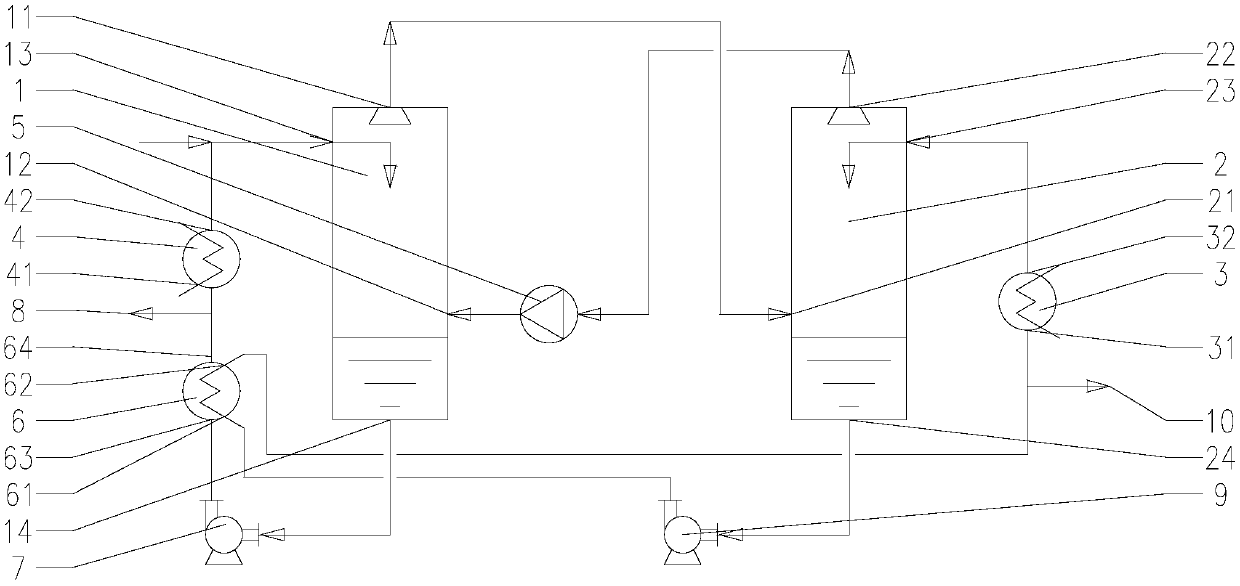

[0147] Take the treatment liquid, such as figure 2As shown, the treatment liquid is processed through the contact evaporation system in the present invention. First, the treatment liquid flows into the pipeline where the heating heat exchanger is located in the pipeline of the heating cycle under the action of the first circulation pump, and is mixed with the evaporation concentrate. Finally, heat treatment is carried out through the heating heat exchanger, and at the same time, the heat released by the condensate is absorbed by the heat recovery heat exchanger to provide heat for further heat treatment. According to the properties of the treatment liquid, increasing the temperature of the cold side increases the concentration of the treatment liquid after heating and increases the temperature of the treatment liquid. Then the heated treatment liquid is heated at 1-100m 3 The flow rate of / h enters the evaporator through the liquid inlet of the treatment liquid. At the same ...

Embodiment 3

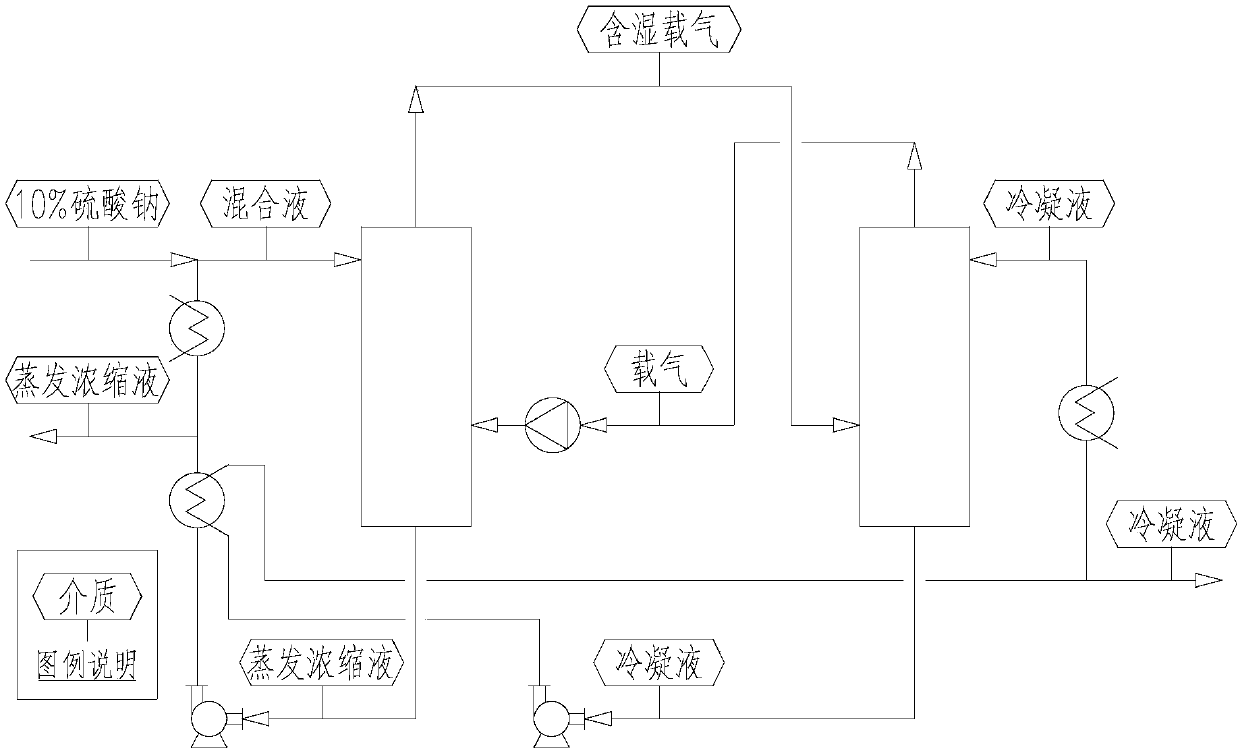

[0150] Take the treatment liquid, such as image 3 As shown, the treatment liquid is a 10wt% sodium sulfate aqueous solution, and the temperature of the treatment liquid is 10-30°C. The treatment liquid is processed through the contact evaporation system in the present invention. First, the treatment liquid flows into the pipeline where the heating heat exchanger is located in the pipeline of the heating cycle under the action of the first circulation pump, and is mixed with the evaporation concentrate to form a mixed The liquid is heated through the heating heat exchanger, and at the same time, the heat released by the condensate is absorbed by the heat recovery heat exchanger, and then the heat is released to further provide heat for the heating treatment. According to the properties of the treatment liquid, the temperature of the cold side is raised from 10-30°C to 40-100°C. Then the heated treatment liquid is heated at 1-100m 3 The flow rate of / h enters the evaporator t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com