Preparation method and application of aerogel

An aerogel and wet gel technology, applied in the field of preparation of inorganic nanomaterials, can solve the problems of unsatisfactory product drying process, long production cycle, complicated process, etc., and achieve complete drying effect, short production cycle and technological process. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

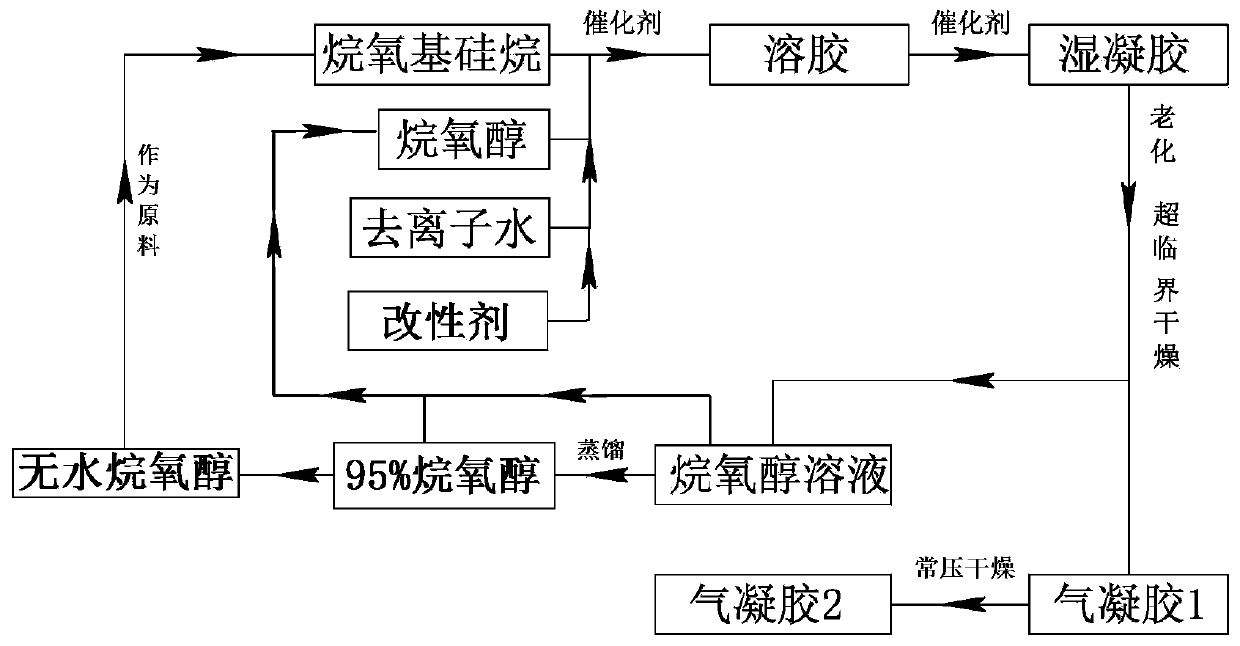

[0033] Such as figure 1 A kind of preparation method of airgel shown, comprises the following steps:

[0034] (1) Prepare a mixed solution with alkoxysilane, alkoxy alcohol, deionized water and modifier to obtain silica sol;

[0035] (2) Prepare silica wet gel with silica sol as raw material;

[0036] (3) Aged silica wet gel;

[0037] (4) A two-step drying method in which supercritical drying is combined with atmospheric pressure drying is used to dry the silica wet gel;

[0038] (5) reclaim alkoxy alcohol.

[0039] Wherein, in step (1), alkoxysilane, alkoxy alcohol, deionized water and modifier are mixed according to the molar ratio of 1: (2-40): (4-25): (0.1-10) Prepare a mixed solution, preferably, alkoxysilane, alkoxy alcohol, deionized water and modifier are prepared as a mixed solution according to the molar ratio of 1:(6~18):(4~12):(0.5~9) solution; gradually add an acidic catalyst to the above mixed solution, adjust the pH value to 2.5-5.5, preferably adjust the pH ...

Embodiment 1

[0054] Prepare a solution by mixing tetraethoxysilane, ethanol, deionized water and trimethylchlorosilane in a specific molar ratio, and the molar ratio of tetraethoxysilane, ethanol, deionized water and trimethylchlorosilane is 1 : 8: 4: 0.5, stir for 20 minutes to mix evenly, keep stirring, then add acid catalyst hydrochloric acid drop by drop, adjust the pH value to 4, adjust the temperature to 50°C, and continue stirring for 40 minutes to fully hydrolyze tetraethoxysilane to obtain Silica sol, then keep the temperature at 40°C, let it stand for 120 minutes, then add an appropriate amount of alkaline catalyst ammonia water drop by drop while stirring, adjust the pH value of the silica sol to 7, and then let it stand for 40 minutes to make the silica sol gel and form Silica wet gel; after the wet gel is formed, slowly add aging solution along the wall of the device to soak the wet gel in it, seal it at 60°C, let it stand for aging for 100 hours, and obtain a silica wet gel wi...

Embodiment 2

[0057] Mix trimethoxysilane, methanol, deionized water and dimethyldimethoxysilane according to a specific molar ratio to prepare a solution. The molar ratio is 1:2:25:10, stir for 40 minutes to mix evenly, keep stirring, and then add the acidic catalyst CH dropwise 3 COOH, adjust the pH value to 5.5, adjust the temperature to 80°C, and keep stirring for 10 minutes to fully hydrolyze the trialkoxysilane to obtain silica sol, then keep the temperature at 50°C, let it stand for 60 minutes, and then add an appropriate amount of alkali drop by drop while stirring Catalyst KOH, adjust the pH value of the silica sol to 6, and then let it stand for 50 minutes to gel the silica sol and form a silica wet gel; after forming the wet gel, slowly add aging solution along the wall of the vessel to make The wet gel is soaked in it, sealed and aged for 60 hours at 30°C to obtain a silica wet gel with a more complete structure.

[0058] Transfer the above-mentioned silica wet gel to a supercr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com