Pretreatment method for cathode deposition of molten salt electrorefining

A technology of molten salt electrolysis and precipitation, applied in the direction of grain processing, etc., can solve problems such as environmental pressure and affecting process economy, achieve the goal of reducing environmental pressure, reducing the amount of dilute acid used, the number of washing times with clean water, and reducing the electrolyte content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

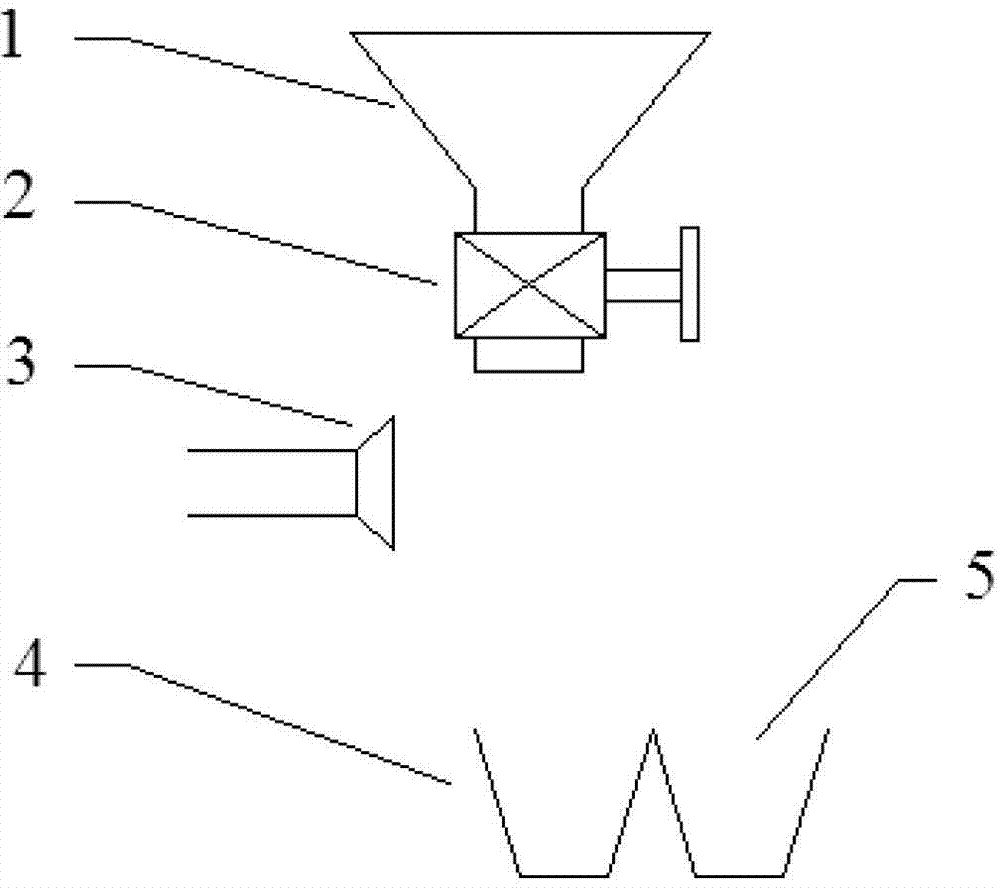

Method used

Image

Examples

example 1

[0027] Take 1500g of titanium cathode precipitate, which contains 85% of the electrolyte. After crushing, it is ball milled in a ball mill to a particle diameter of 150μm. The mixture powder is placed in a separating device, and the feeding speed is controlled to 0.5kg / min through a feeding valve. The flow rate was 5L / min. After the separation, the electrolyte content in the titanium powder was tested to be 9.8%.

example 2

[0029] Take 1500g of titanium cathode precipitate, which contains 85% of the electrolyte. After crushing, it is ball milled in a ball mill to a particle diameter of 44μm. The mixture powder is placed in a separation device, and the feeding speed is controlled to 10kg / min through the feeding valve to control the air flow. It is 25L / min. After the separation, the electrolyte content in the titanium powder is 5.0%.

example 3

[0031] Take 1500g of the vanadium cathode precipitate and crush it. The electrolyte content is 85%. It is ball milled in a ball mill to a particle diameter of 74μm. The mixture powder is placed in a separation device. The feeding speed is controlled to 5kg / min through the feeding valve and the gas flow is controlled. It is 10L / min. After the separation, the electrolyte content in the titanium powder is 8.2%.

[0032] It can be seen that the electrolyte content in the cathode precipitate treated by the method of the present invention can be reduced to 5-10%.

[0033] In summary, the pretreatment method of the present invention is suitable for processing cathode precipitates of molten salt electrorefining; it can realize the separation of electrolyte and metal powder, effectively reduce the electrolyte content in cathode precipitates; and can reduce wet treatment The amount of dilute acid used in the process and the times of washing with clean water can improve process economy and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com