Method for preparing calcium oxide by using industrial byproduct gypsum

A by-product, calcium oxide technology, applied in the direction of carbon monoxide, chemical instruments and methods, calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of difficult separation of reaction residues, uneven mixing, high reaction temperature, etc., to achieve High convection heat transfer efficiency, improved process economy, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

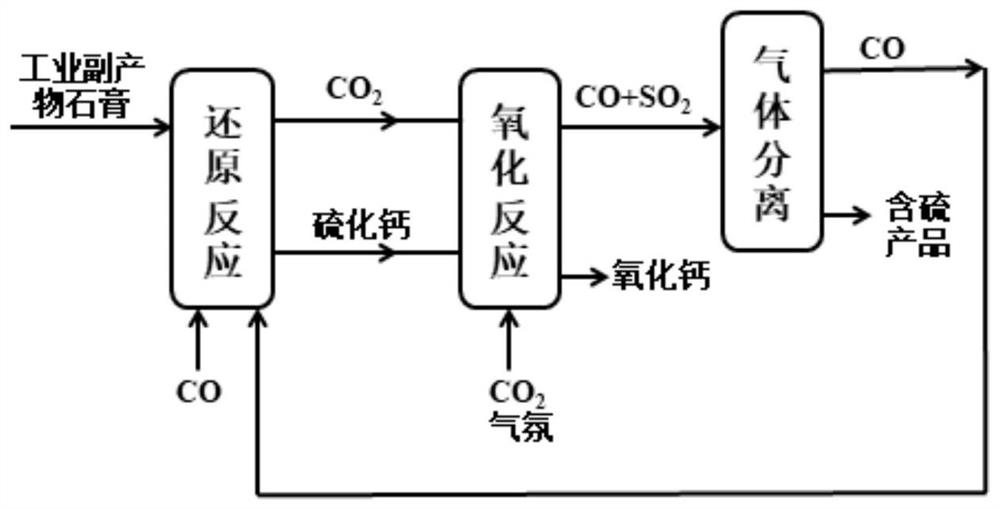

[0053] This embodiment provides a method for preparing calcium oxide by using industrial by-product gypsum, the flow process of the method is as follows figure 2 As shown, the method includes the following steps:

[0054] (1) Reduction treatment: Phosphogypsum is air-dried, crushed, ground and sieved to obtain a solid powder raw material and react with CO introduced at 900°C for 90 minutes to obtain calcium sulfide and CO 2 ;

[0055] (2) Oxidation treatment: the calcium sulfide obtained in CO 2 It is oxidized under gas, heated to 1050°C and reacted for 40 minutes to obtain solid product calcium oxide and gas products CO and SO 2 ;

[0056] (3) Gas separation and recovery treatment: the obtained gas products are separated to obtain independent CO and SO 2 , the CO is used for reduction treatment, the SO 2 For the preparation of sulfur-containing products.

Embodiment 2

[0058] This embodiment provides a method for preparing calcium oxide by using industrial by-product gypsum, the flow process of the method is as follows figure 2 As shown, the method comprises the following steps: except that the temperature described in step (1) is changed to 1100°C, and the reaction time is changed to 30min; the temperature described in step (2) is changed to 1100°C, and the reaction time is changed to 30min; Other conditions are all identical with embodiment 1.

Embodiment 3

[0060] This embodiment provides a method for preparing calcium oxide by using industrial by-product gypsum, the flow process of the method is as follows figure 2 As shown, the method includes the following steps:

[0061] (1) Reduction treatment: Phosphogypsum is air-dried, crushed, ground and sieved to obtain a solid powder raw material and react with CO at 900°C for 150 minutes to obtain calcium sulfide and CO 2 ;

[0062] (2) Oxidation treatment: the calcium sulfide obtained in CO 2 and O 2 It is oxidized under mixed gas, and the temperature is raised to 950°C for 150 minutes to obtain solid product calcium oxide and gas products CO and SO 2 ;

[0063] (3) Gas separation and recovery treatment: the obtained gas products are separated to obtain independent CO and SO 2 , the CO is used for reduction treatment, the SO 2 For the preparation of sulfur-containing products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com