Device and method for continuously isomerizing epoxide

An epoxide and isomerization technology, applied in chemical instruments and methods, isomerization preparation, chemical/physical processes, etc., can solve the problems of solvent loss, high back mixing, and many side reactions, and improve reliability. , Product yield improvement, the effect of simplifying the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

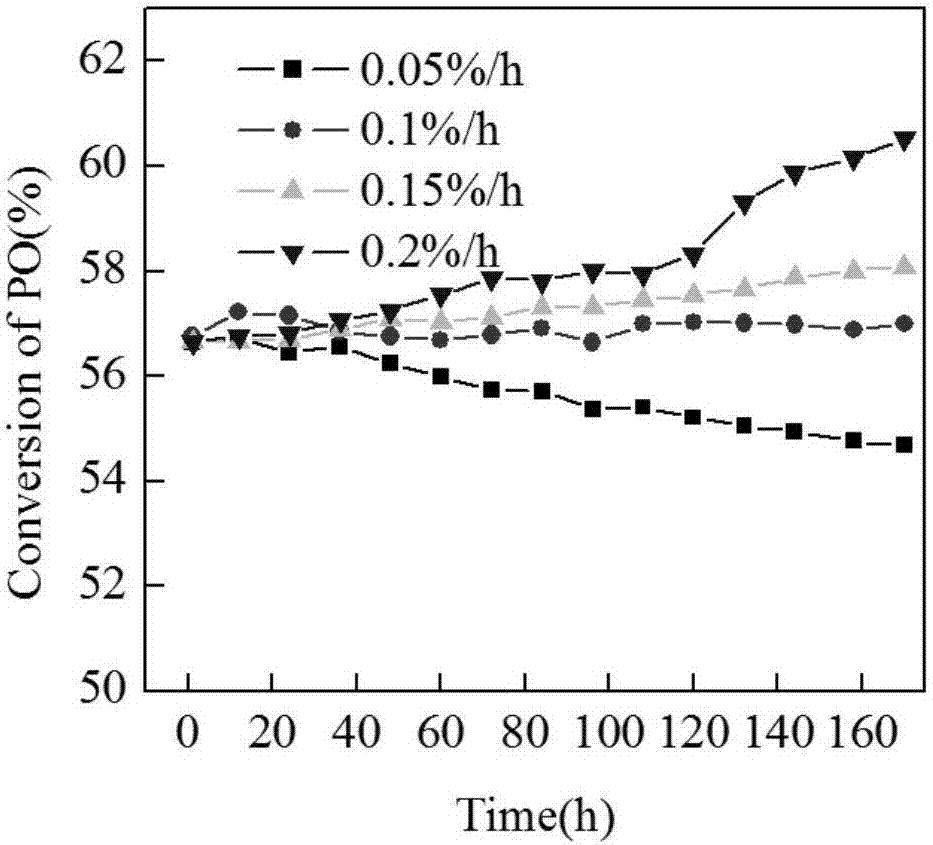

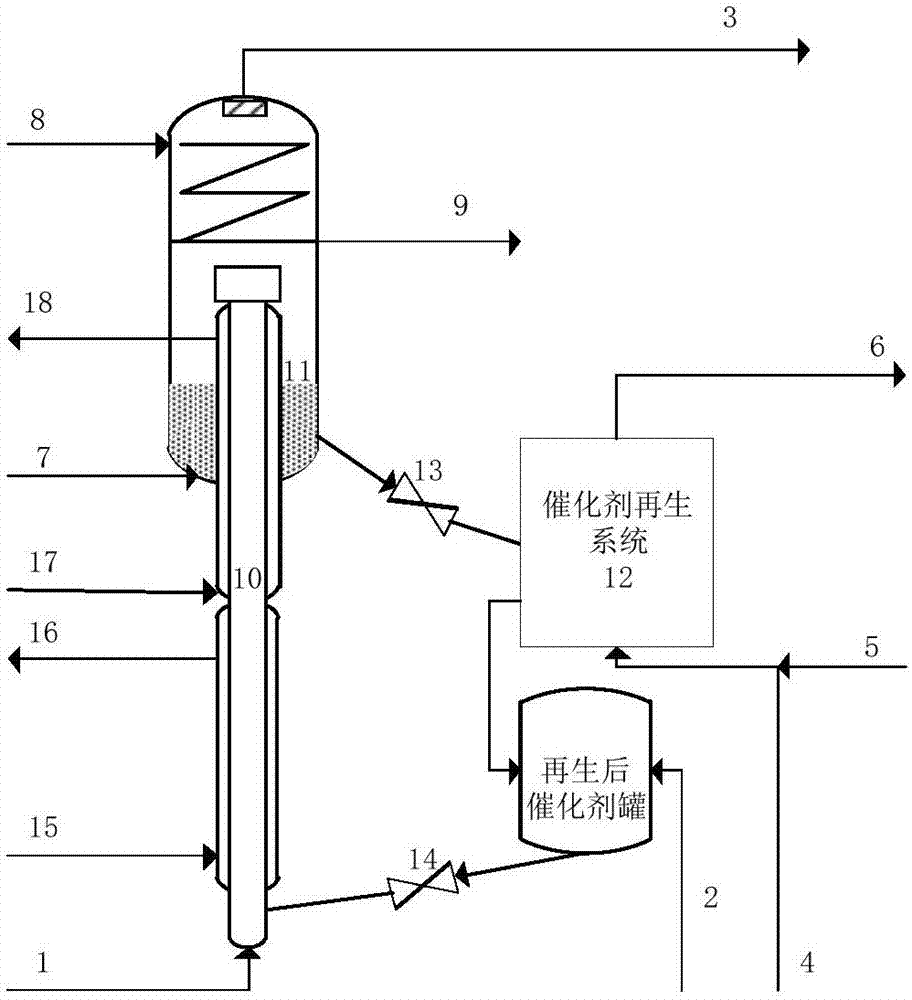

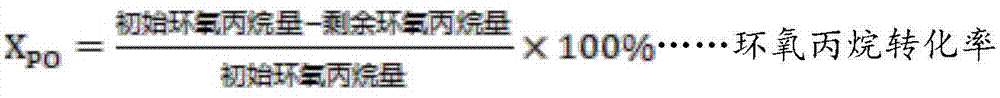

[0060] The reactor used in this process is as figure 1 The shown two-stage riser fluidized bed reactor has an inner diameter of 40 mm and a height of 4 meters; the outlet of the second stage of the riser reactor is located in the settler to realize rapid separation of catalyst, reactant and product, and the reaction product sent to the subsequent separation system.

[0061] First, heat nitrogen and propylene oxide to 280°C and enter the riser to contact with the regenerated catalyst and new supplementary catalyst. The nitrogen flow rate is 10L / min, the feed rate of propylene oxide is 7.8kg / h, and the circulating catalyst is 3.9kg / h. The feed rate of the catalyst is 3.9g / h, the temperature of the heat transfer oil outside the riser is 280°C, the contact time between the material and the catalyst in the riser reactor is 3 seconds, the outlet temperature of the riser is 290°C, and the outlet reaction liquid and the catalyst mixture are exchanged The heater can be cooled to 180°C...

Embodiment 2

[0070] The difference from Example 1 is that the isomerization performance at different preheating temperatures was investigated. See Table 2.

[0071] Table 2: Response performance results at different temperatures

[0072] Preheating temperature / ℃

Embodiment 3

[0074] The difference from Example 1 is that the influence of different cooling temperatures on the final reaction performance was investigated, see Table 3.

[0075] Table 3: Response performance at different cooling temperatures

[0076]

[0077]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com