Method for continuously preparing ethylene carbonate

A technology of ethylene carbonate and ethylene oxide, which is applied in the field of continuous preparation of ethylene carbonate, can solve problems such as slow reaction rate, achieve the effects of reducing risk, shortening residence time, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) prepare catalyst solution A: take 100g of ethylene carbonate, heat to 34~50 ℃, weigh catalyst 36g, water 7.5g and join in ethylene carbonate successively, obtain catalyst solution A after thermal insulation stirring 1~2min, density About 1.24 ~ 1.26g / mL.

[0040] (2) Using CO 2 Mass flow meter delivers CO at standard flow rate of 470mL / min 2 Entering the reaction system, there is CO at the exit 2 After the gas is ejected, open the back pressure valve, and the back pressure is 3MPa.

[0041] (3) The catalyst solution A prepared in the step (1) and the ethylene oxide are respectively passed into the micro-mixer a at 0.3 mL / min and 1 mL / min to obtain the ethylene oxide mixed solution B in which the catalyst is dissolved .

[0042] (4) The mixed solution B of ethylene oxide obtained in step (3) is used as continuous phase, gas CO 2 As the dispersed phase, it is continuously passed into the micro-mixer b to obtain the gas-liquid mixture C, and the mixed liquid C is ...

Embodiment 2

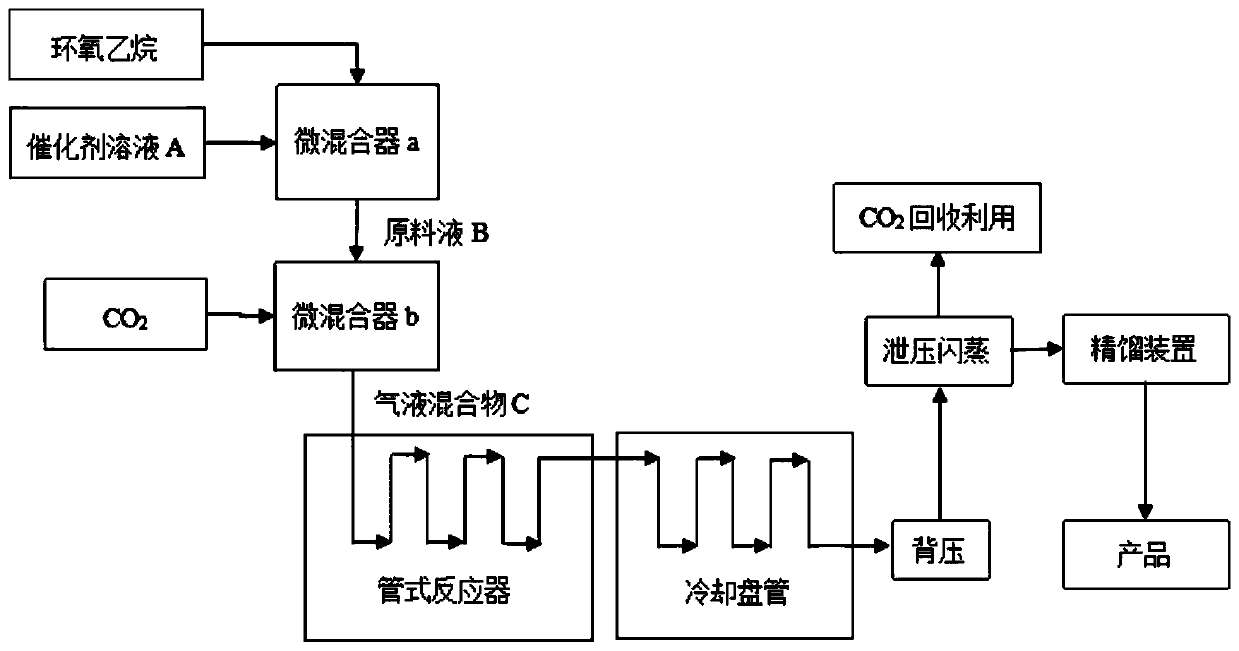

[0045] refer to figure 1 Shown technique continuously prepares ethylene carbonate, a kind of method for continuously preparing ethylene carbonate, comprises the following steps:

[0046] (6) prepare catalyst solution A: take 100g of ethylene carbonate, heat to 34~50 ℃, weigh catalyst 36g, water 7.5g and join in ethylene carbonate successively, obtain catalyst solution A after thermal insulation stirring 1~2min, density About 1.24 ~ 1.26g / mL.

[0047] (7) Using CO 2 Mass flow meter delivers CO at standard flow rate of 645mL / min 2 Entering the reaction system, there is CO at the exit 2 After the gas is ejected, open the back pressure valve, and the back pressure is 3MPa.

[0048] (8) The catalyst solution A prepared in the step (1) and the ethylene oxide are passed into the micro-mixer a at 0.3 mL / min and mL / min, respectively, to obtain the ethylene oxide mixed solution B that the catalyst is dissolved in. .

[0049] (9) The mixed solution B of ethylene oxide obtained in s...

Embodiment 3

[0052] refer to figure 1 Shown technique continuously prepares ethylene carbonate, a kind of method for continuously preparing ethylene carbonate, comprises the following steps:

[0053] (1) Preparation of catalyst solution A: take by weighing 100 g of ethylene carbonate, heat to 34~50° C., weigh 36 g of catalyst and add it to ethylene carbonate, 7.5 g of water, keep stirring for 1~2min to obtain catalyst solution A, with a density of about It is 1.20~1.26g / mL.

[0054] (2) Using CO 2 Mass flowmeter delivers CO at standard flow rate of 940mL / min 2 Entering the reaction system, there is CO at the exit 2 After the gas is ejected, open the back pressure valve, and the back pressure is 3MPa.

[0055] (3) The catalyst solution A prepared in the step (1) and the ethylene oxide are respectively passed into the micro-mixer a at 0.3 mL / min and mL / min to obtain the ethylene oxide mixed solution B in which the catalyst is dissolved. .

[0056] (4) The mixed solution B of ethylene o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com