Method for preparing amyl alcohol from 2-methylfuran at room temperature by adopting supported catalyst

A technology of supported catalyst and methyl furan, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as impact, achieve environmental friendliness, mild reaction conditions, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

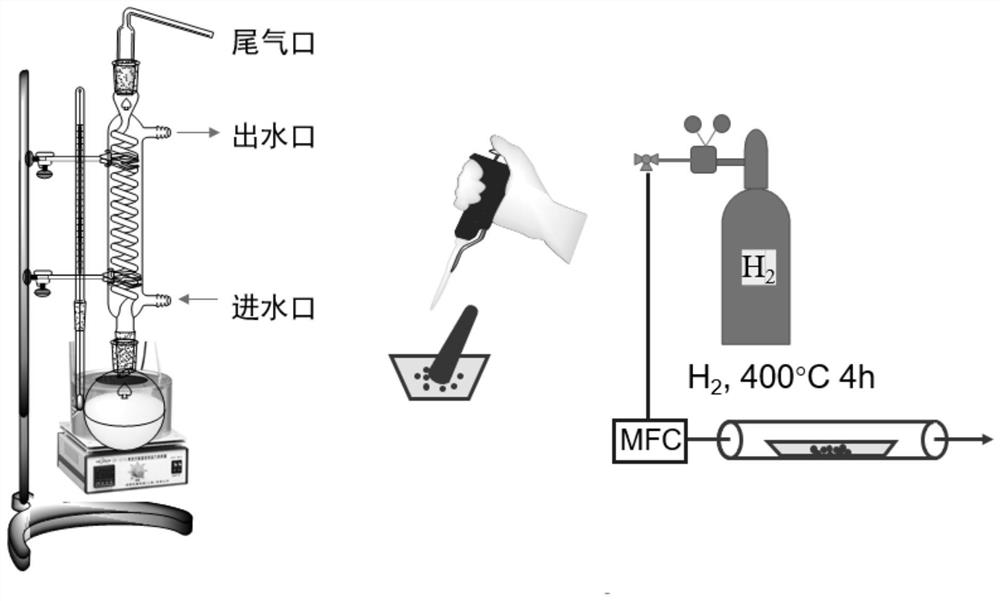

[0048] (1) Add 2 g of multi-walled carbon nanotubes and 200 mL of nitric acid into a round bottom flask, install the round bottom flask in an oil bath, stir at 120° C., condense and reflux for 4 hours. After the purification, deionized water was quickly added to cool down and the acid concentration was diluted, and the suction-filtered carbon nanotubes were repeatedly washed until the final filtrate was neutral, and dried in an oven at 70°C for 12 hours. Take out the dried carbon nanotubes, put them into a mortar for grinding, and sieve through a 100-mesh standard sieve to make a carbon nanotube carrier;

[0049] (2) Take tetraamine platinum nitrate (Pt(NH 4 ) 4 (NO 3 ) 2 )5g was dissolved in 100mL of deionized water, and prepared as a platinum precursor solution (Pt: 25.19mg / mL) for later use;

[0050] (3) Weigh 950 mg of multi-walled carbon nanotube carrier, spread it evenly on the mortar, take 2 mL of platinum precursor solution (taken before oscillating and ultrasonica...

Embodiment 2

[0054] Embodiment 2: the difference between this embodiment and embodiment 1 is: the reaction time is 15min, and others are the same as embodiment 1.

Embodiment 3

[0055] Embodiment 3: the difference between this embodiment and embodiment 1 is: the reaction time is 30min, and others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com