Patents

Literature

31results about How to "Improve pyrolysis gasification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

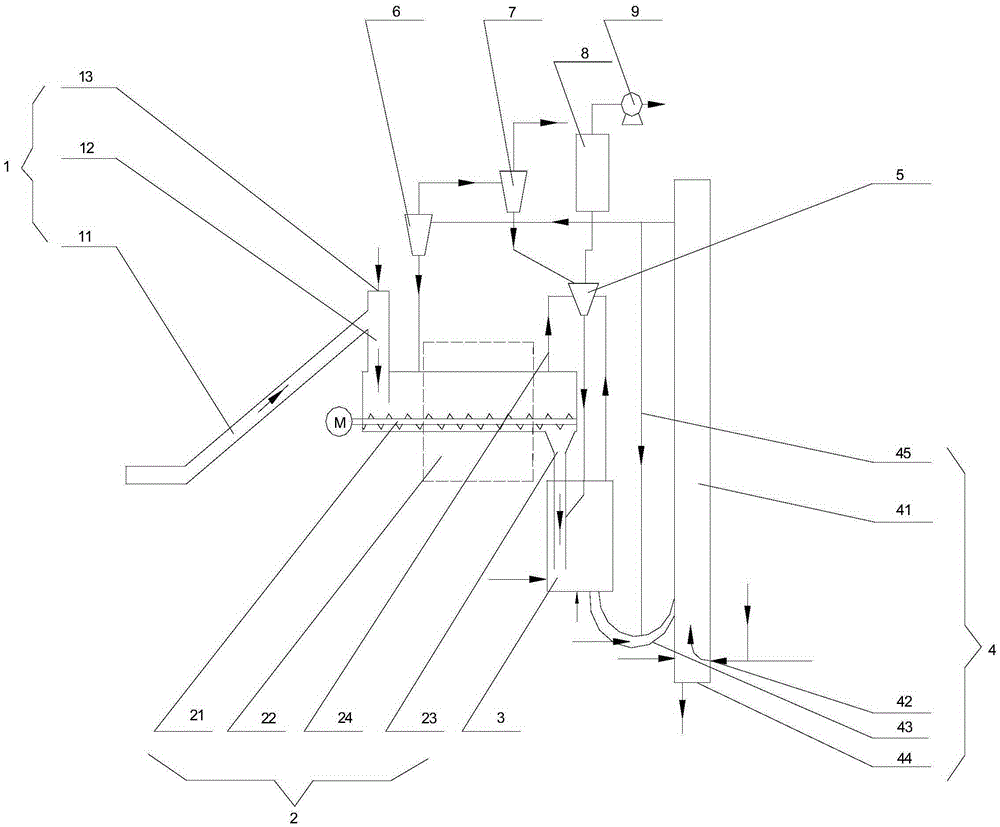

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

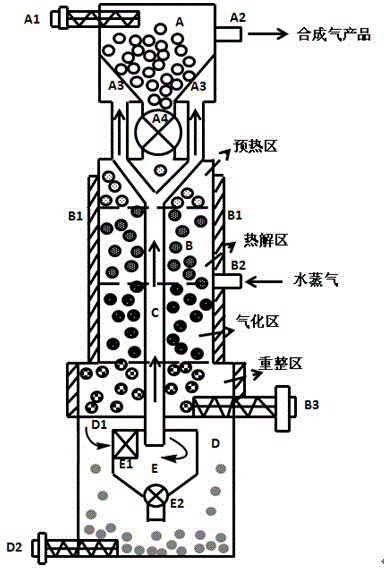

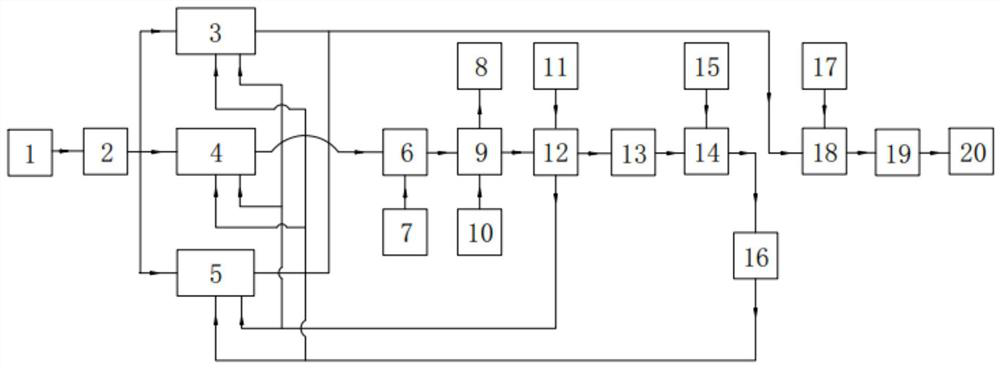

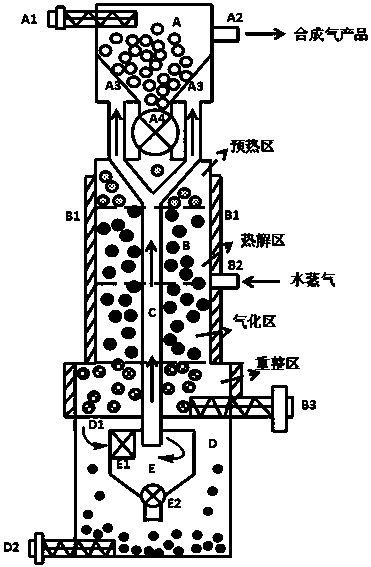

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Method for continuous pyrolysis and gasification of material

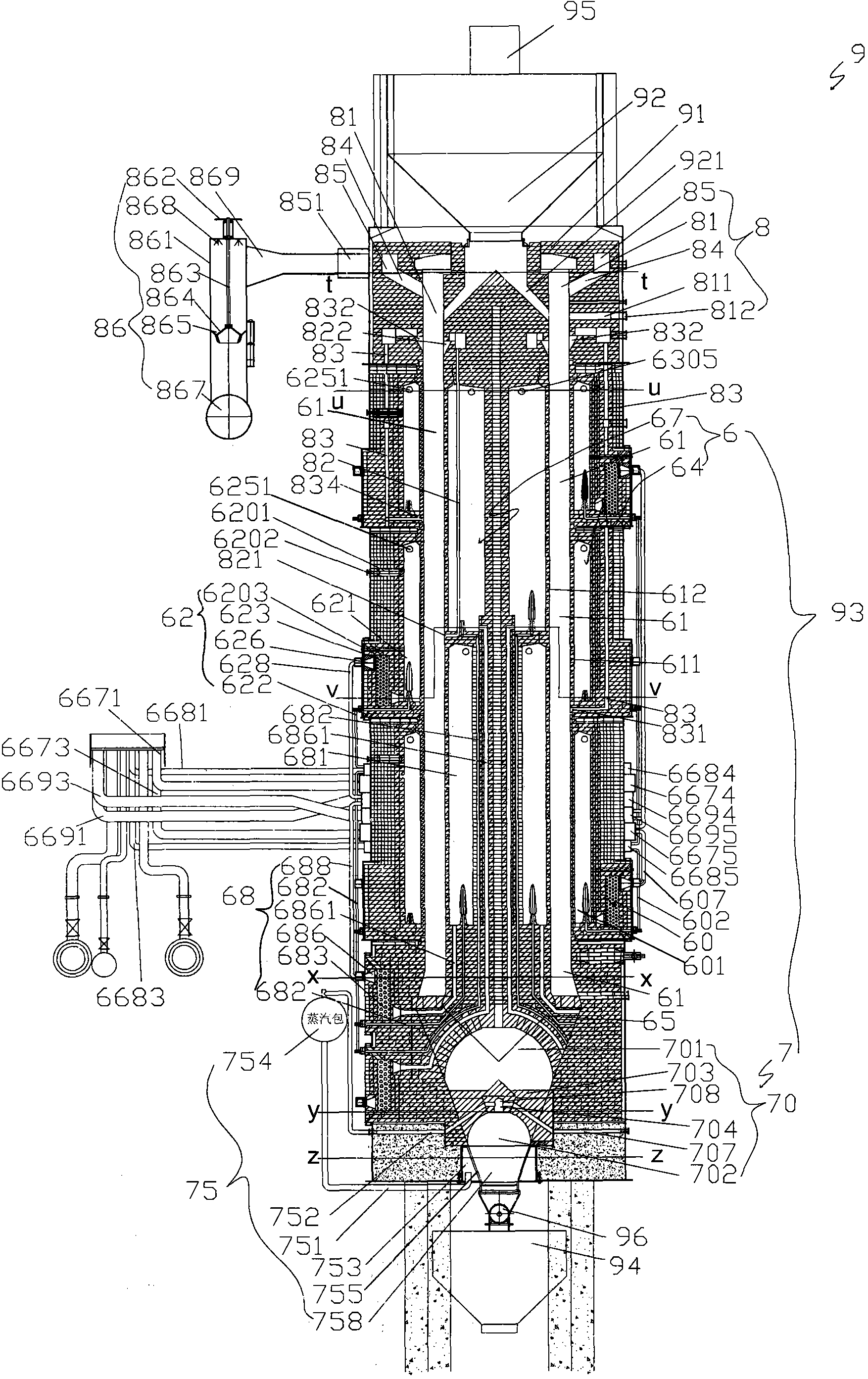

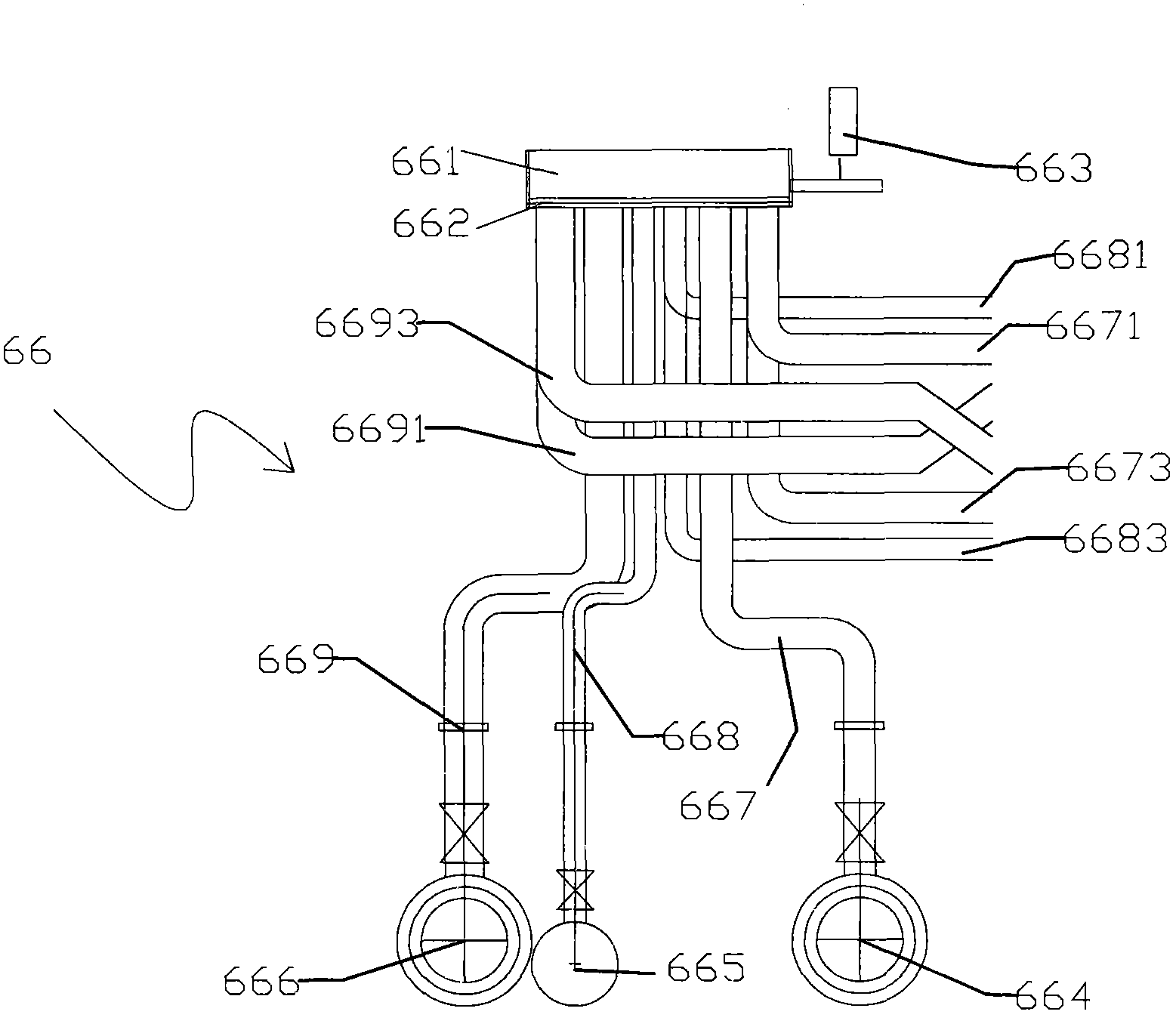

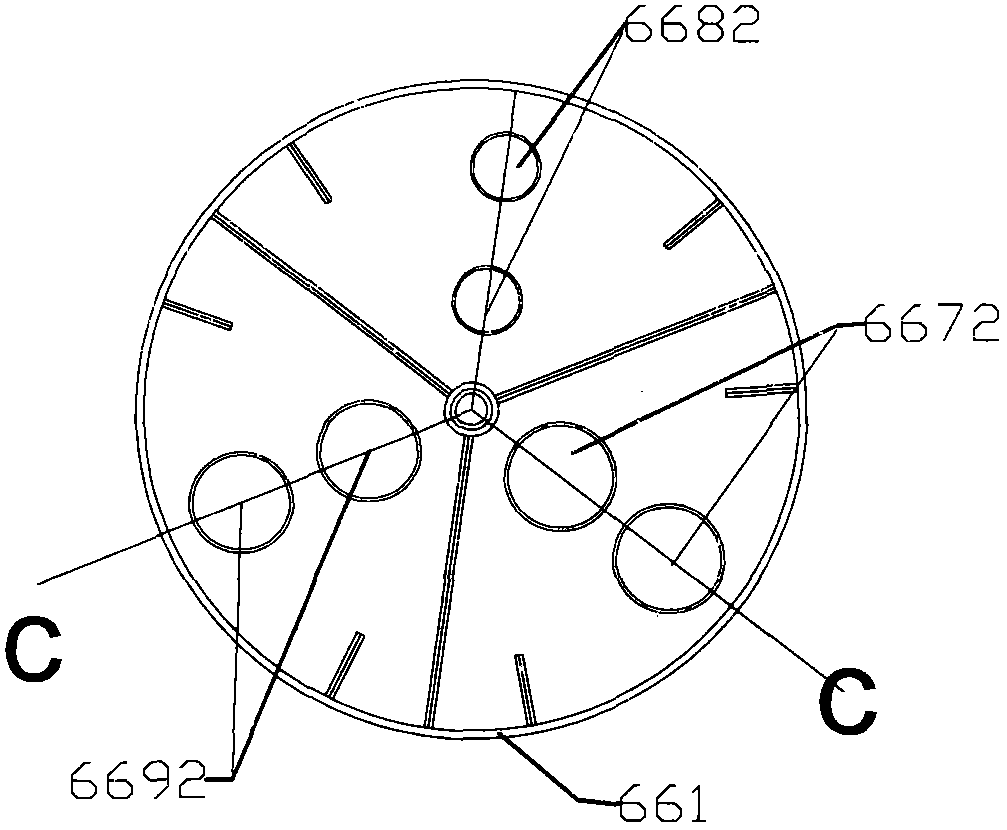

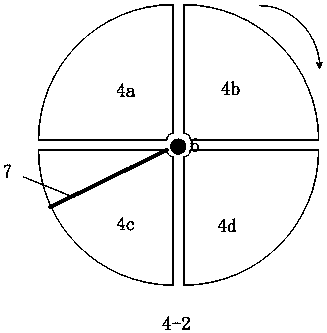

ActiveCN106675661ASmall footprintExtended stayCombustible gas productionMicrowave pyrolysisWater vapor

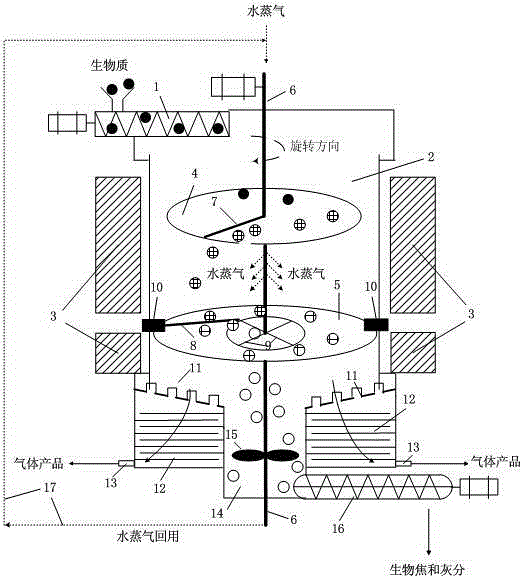

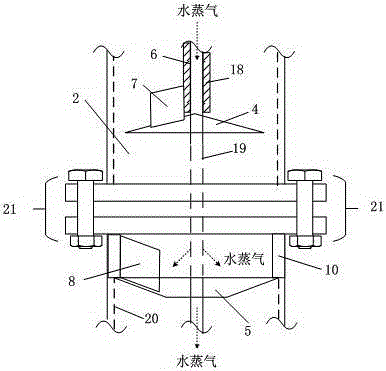

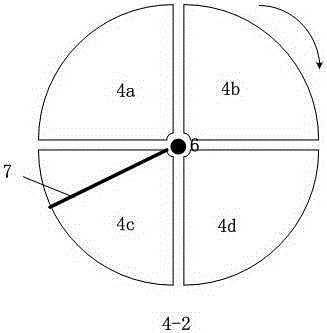

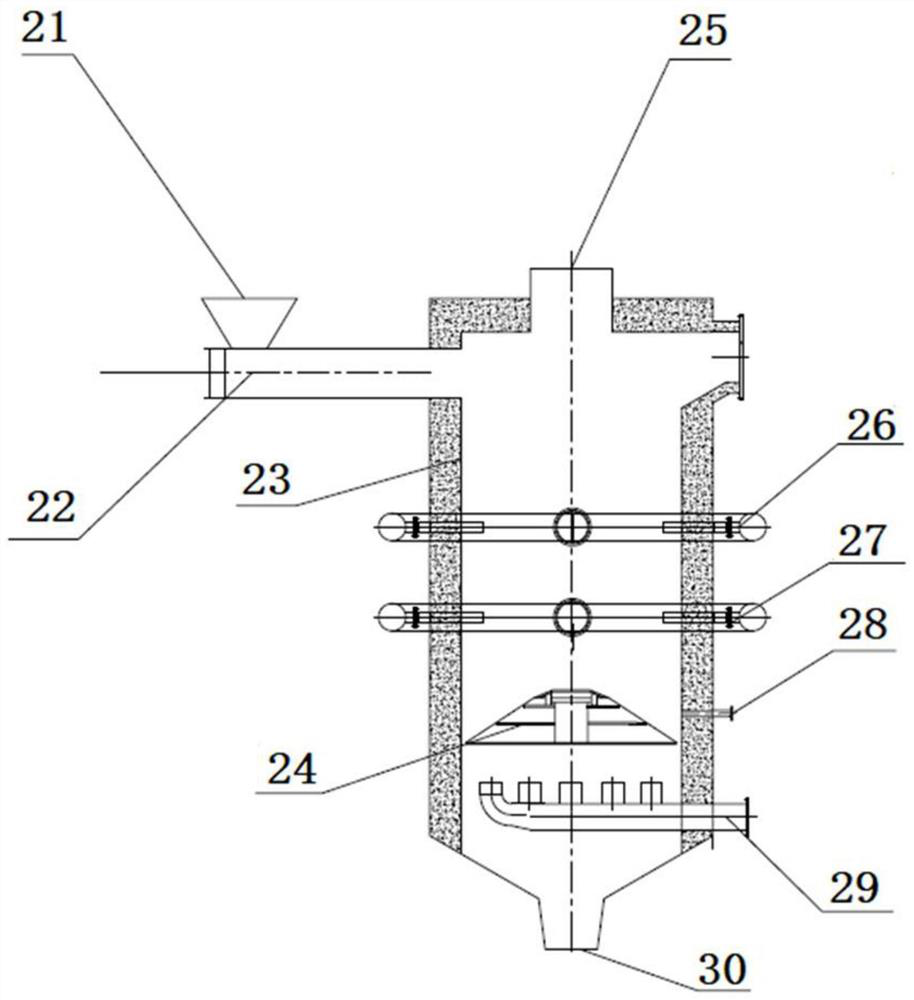

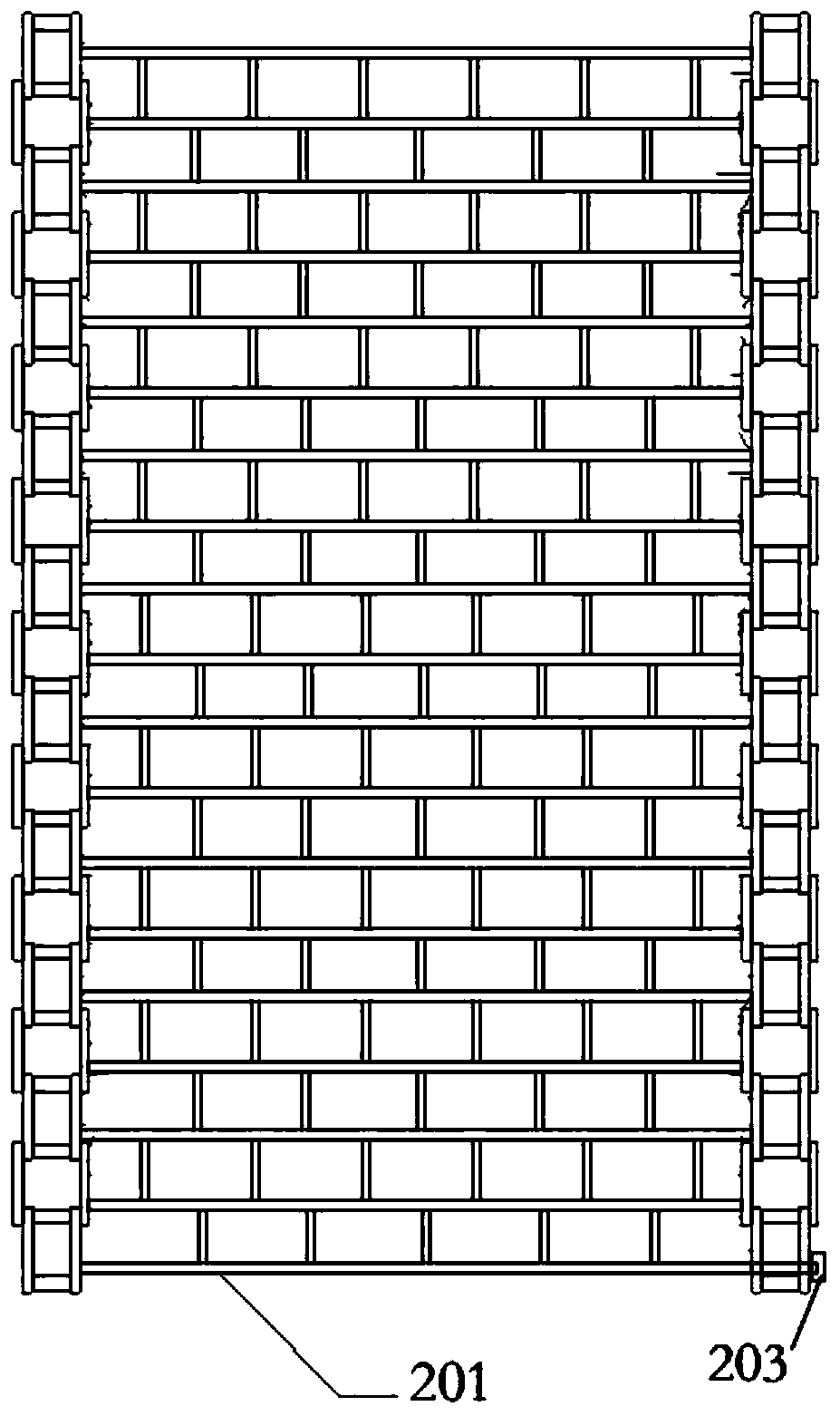

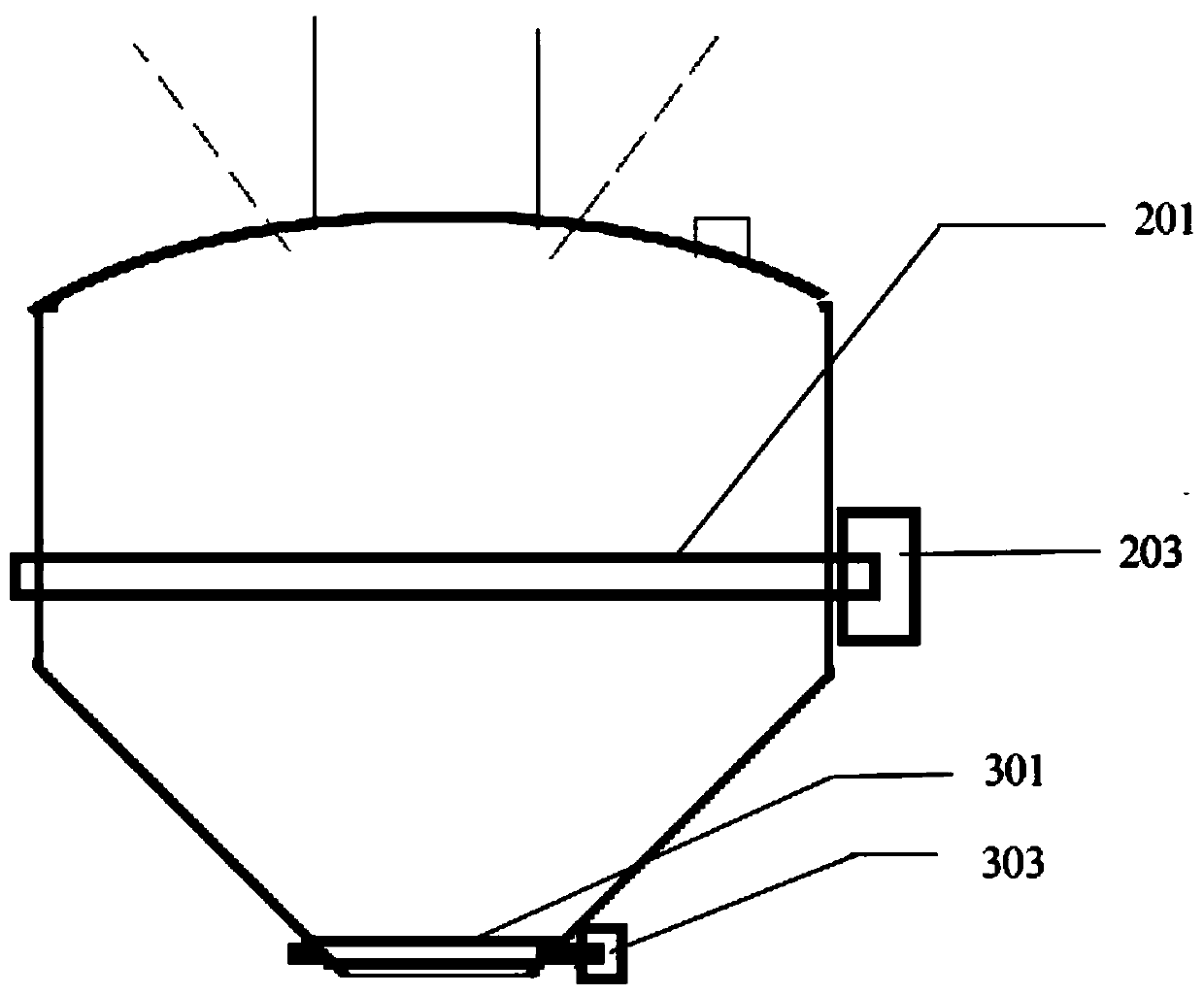

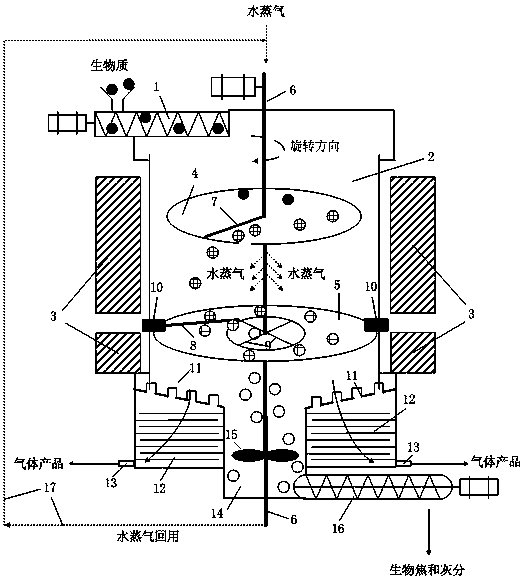

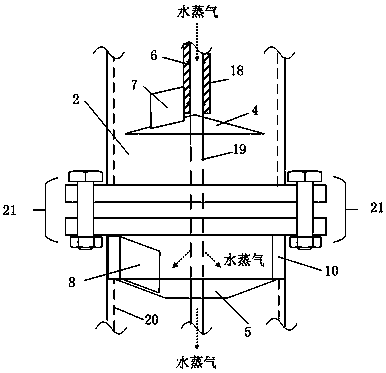

The invention discloses a method for continuous pyrolysis and gasification of a material. The method comprises the following steps: 1, a raw material and a catalyst enter a microwave pyrolysis and gasification system, fall to a first-stage rotating disc of a microwave reaction chamber, and sequentially undergo drying, activating and pyrolysis treatment with rotating; 2, a pyrolysis treated material falls to a second-stage rotating disc of the microwave reaction chamber, and the pyrolysis treated material and a pyrolysis volatile compound undergo a gasification and reforming reaction under the action of water vapor; and 3, a solid product obtained in step 2 falls to a residue storage tank below the microwave reaction chamber from middle holes of the second-stage rotating disc through a second-stage pushing baffle plate, and is discharged from a reaction system under stirring and screw dual action, and a gas product enters a settlement chamber from an annular sieve plate at the bottom of the microwave reaction chamber, and undergoes settlement treatment to obtain the gasification product. The method has the advantages of fast cracking speed, high gasification efficiency, high quality of the gas product, meeting of liquid fuel synthesis requirements, and good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Plasma gasification refuse disposal method and device

ActiveCN102553880AEmission complianceEliminate pollutionSolid waste disposalPlasma technologyProcess engineering

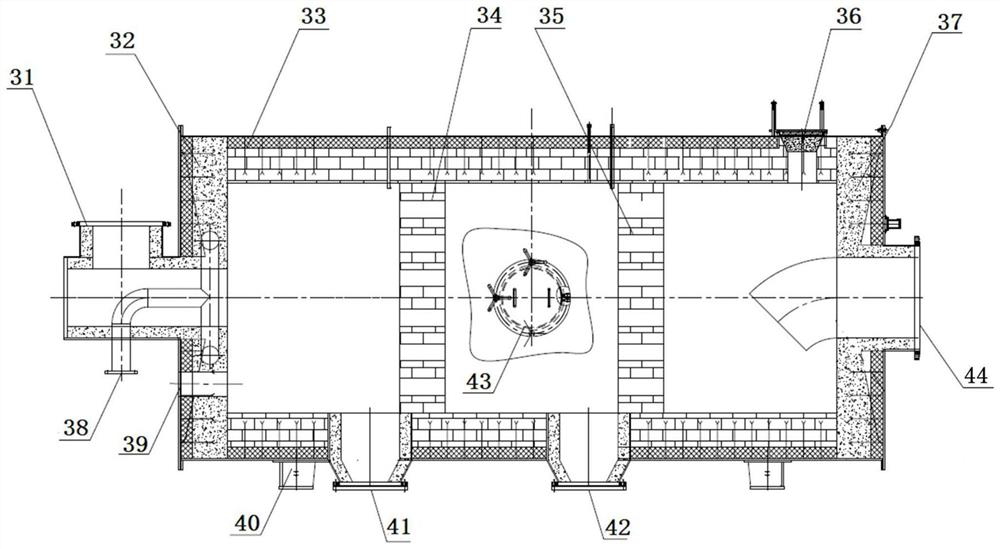

The invention discloses a plasma gasification refuse disposal method and a device, comprising a pyrolysis gasification unit, a quench tower and a turbulent tower. A pyrolysis gasification furnace, an expansion reaction chamber, the quench tower and the turbulent tower are sequentially connected by a channel to form a vertically-alternate curve manifold gas channel. More than two of alternating-current plasma torches are arranged on the wall of the pyrolysis gasification furnace, and an air supply pipe is arranged on the alternating-current plasma torch. The axial lines of the alternating-current plasma torches are tangent with concentric circle taking the axial line of the pyrolysis gasification furnace as the center; a low-power alternating-current plasma torch is arranged on at least one of the expansion reaction chamber or the gas channel of the expansion reaction chamber and the quench tower to perform secondary pyrolysis. The quench tower is used for cooling gas, and the turbulent tower is used for desulfurizing and purifying gas. The invention uses the plasma technology to perform industrial gasification to the municipal solid waste so as to obtain usable gas; and the emission can achieve the environmental standards.

Owner:北京光耀环境科技有限公司

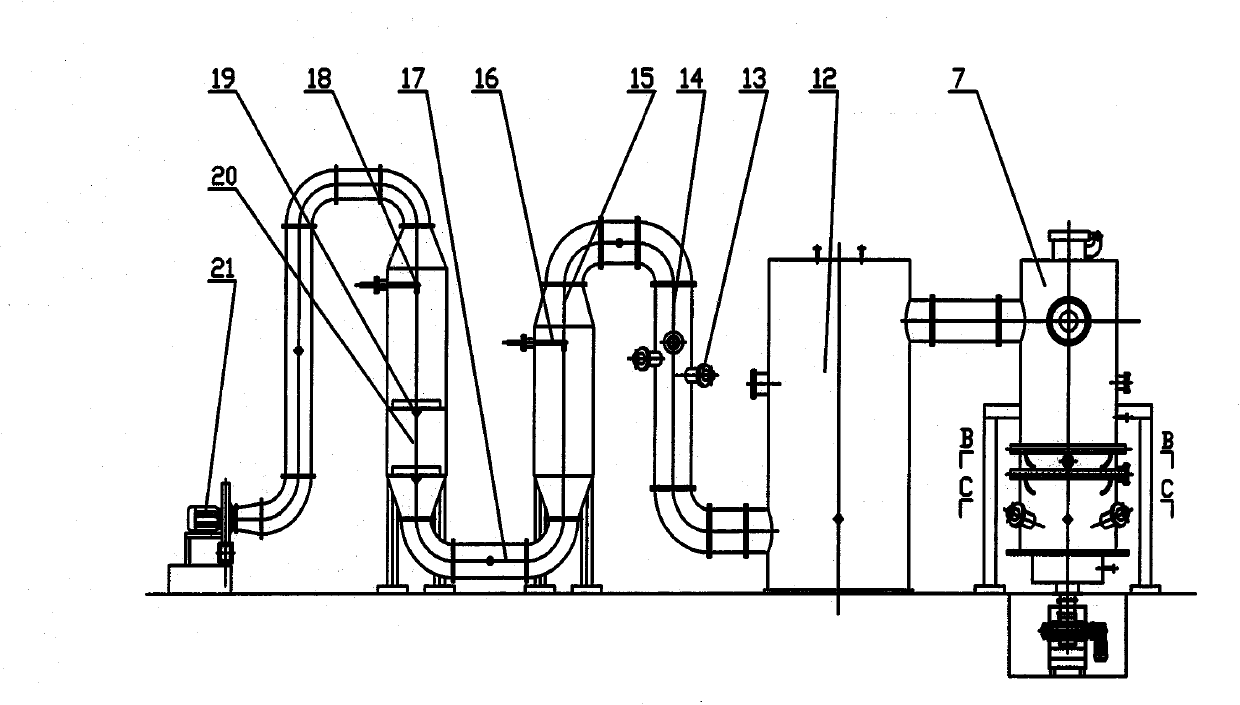

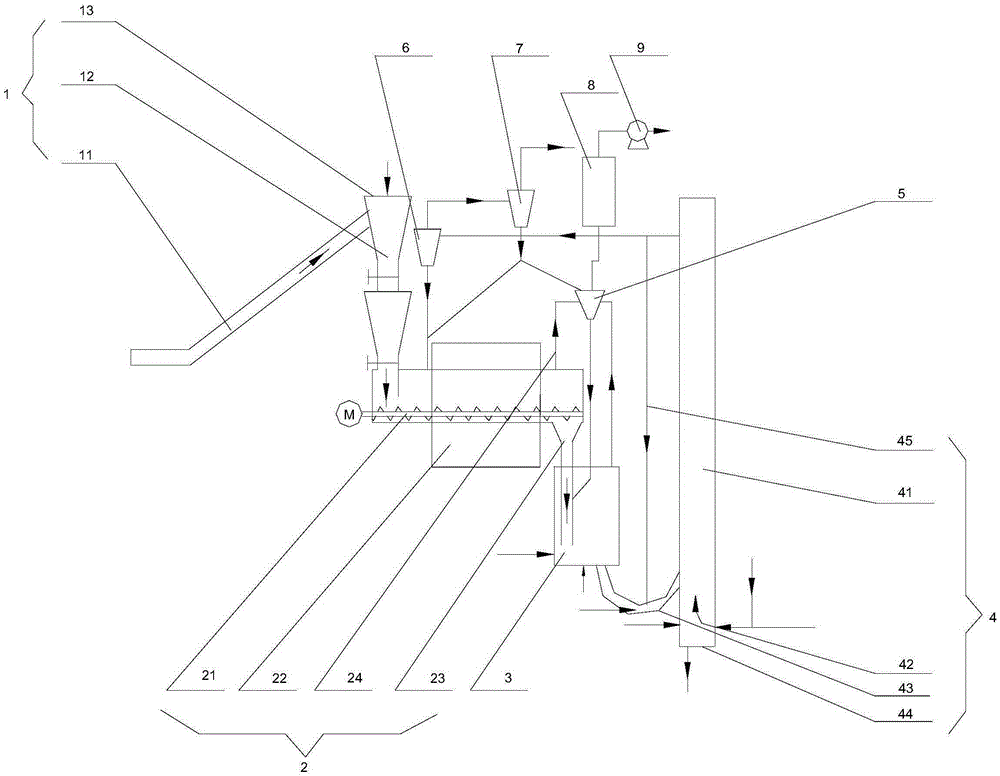

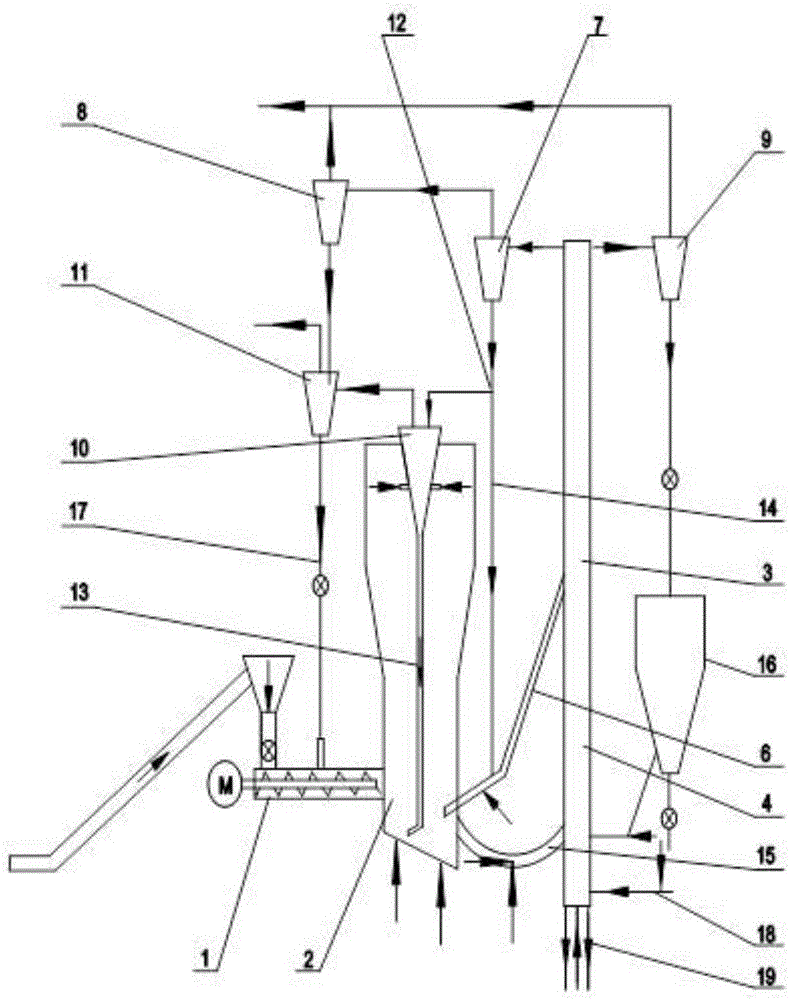

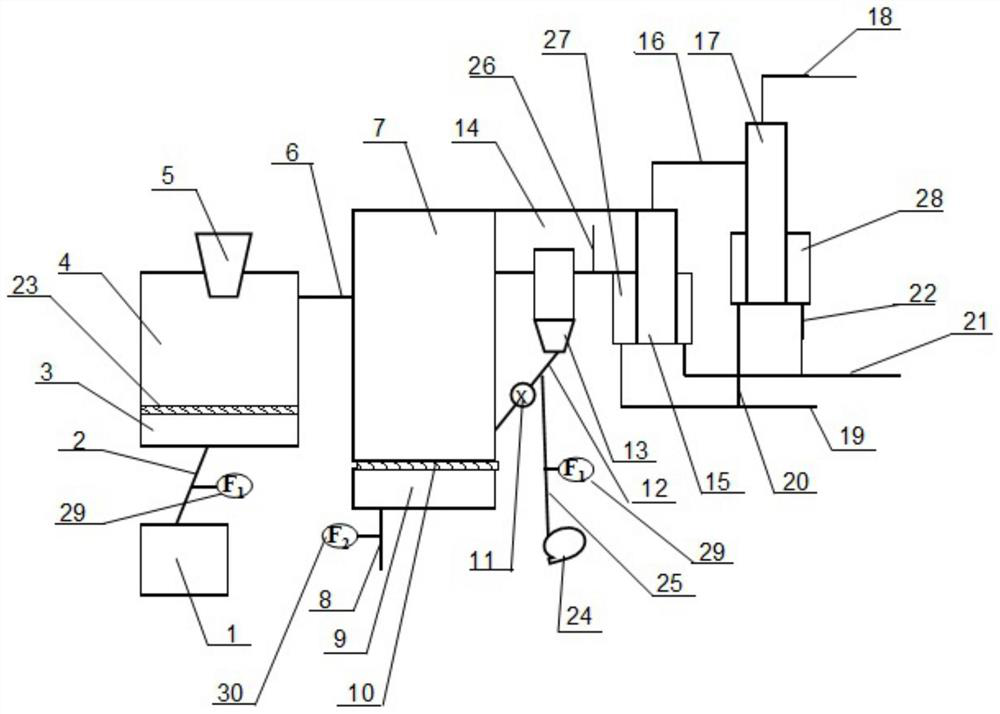

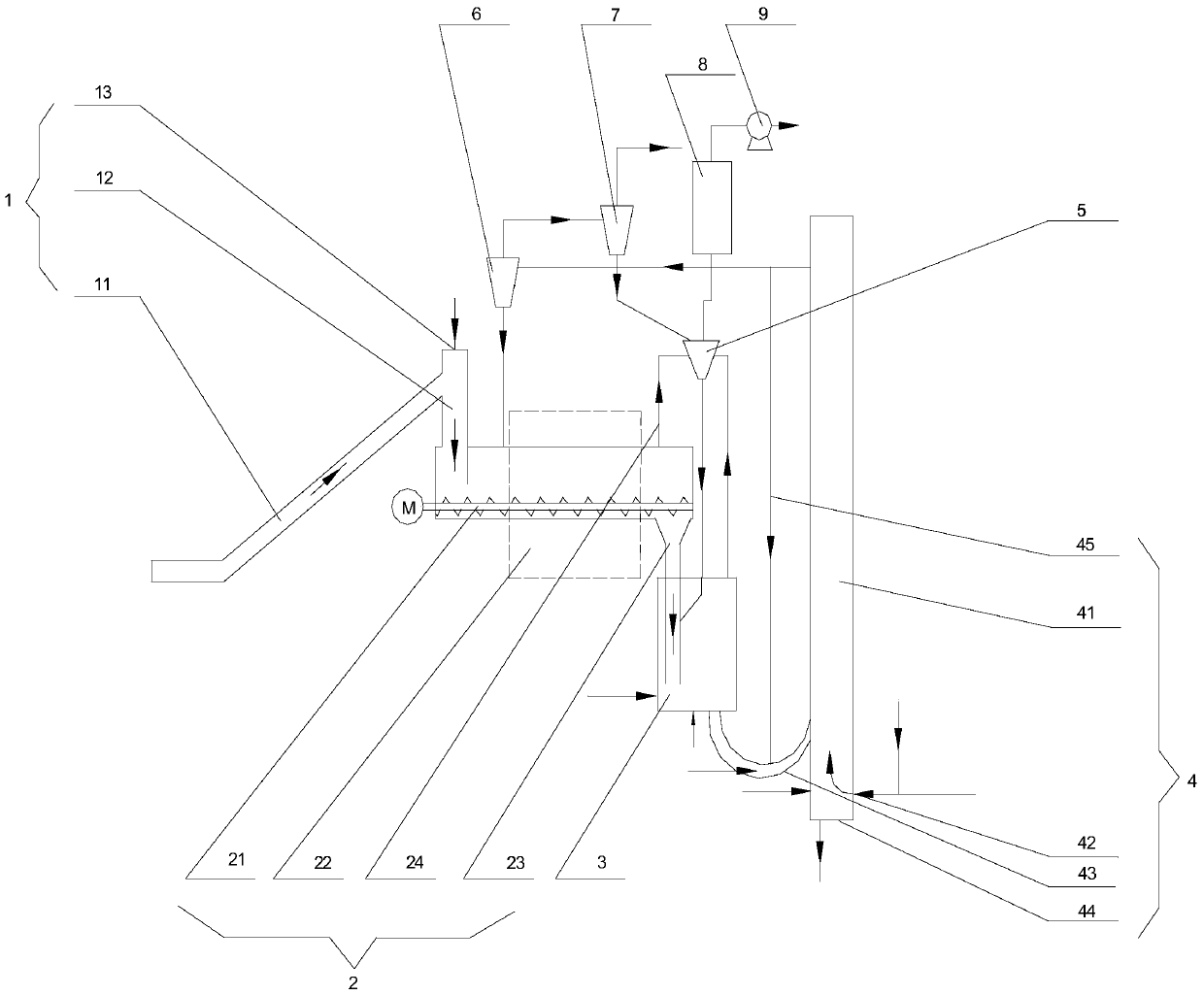

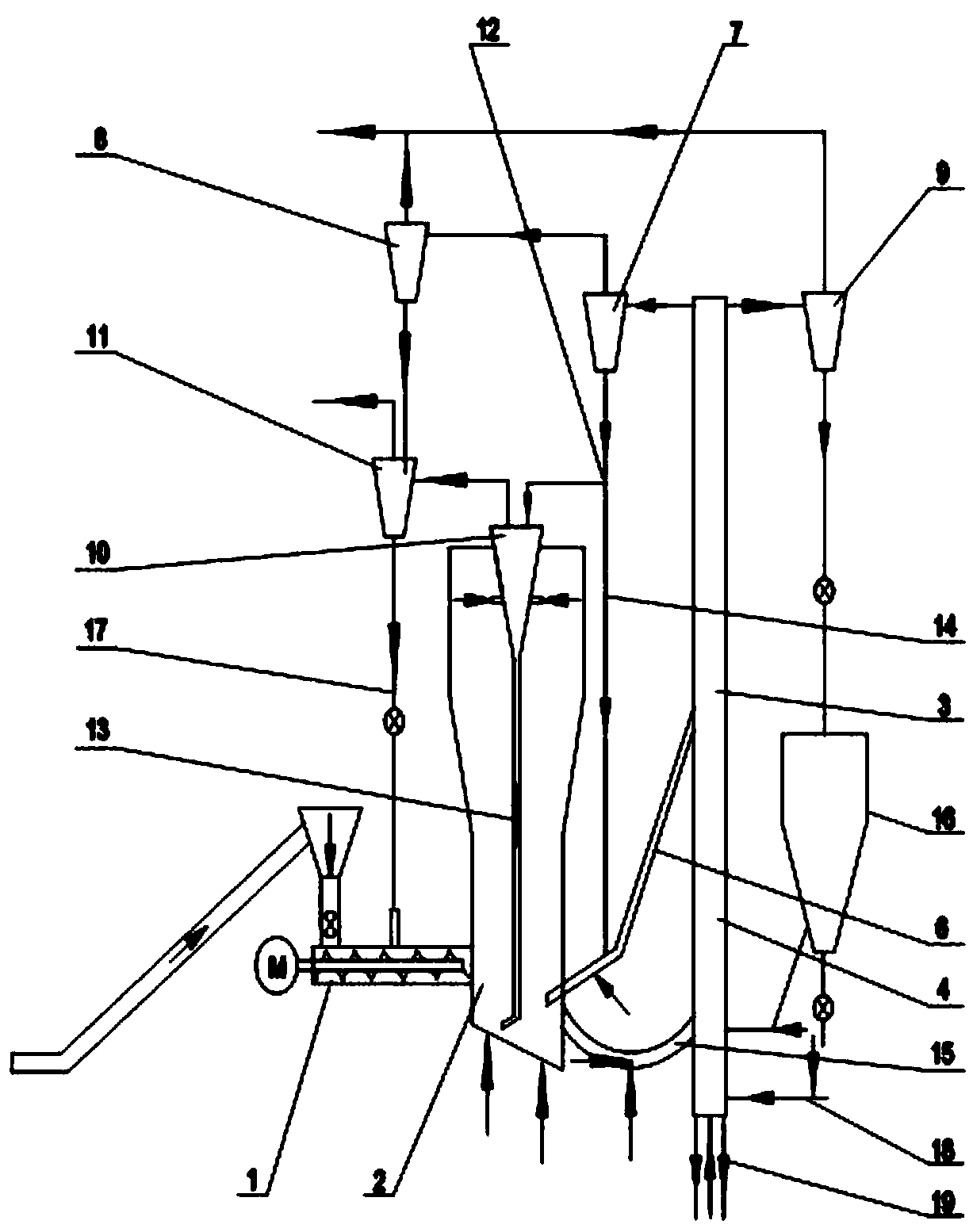

Solid waste two-stage pyrolysis gasification system based on fluidized bed and moving bed

ActiveCN105419877AImprove efficiencyReduce tar and pollutant emissionsGasification processes detailsGranular/pulverulent flues gasificationTarPollutant

The invention relates to a solid waste two-stage pyrolysis gasification system based on a fluidized bed and a moving bed. The system comprises a circulating fluidized bed vaporizer and a secondary cyclone separator thereof, a pyrolyzer and a cyclone separation type reactor thereof, a charcoal collector, a solid waste feed system and the like. The circulating fluidized bed vaporizer and the pyrolyzer of the moving bed are used to realize two-stage pyrolysis gasification, and the cyclone separation type reactor is used to sufficiently mix hot bed materials and pyrolysis gas, thus greatly promoting tar splitting and gas purification. Through optimally designing the vaporizer and pyrolyzer structure form, mixing different bed materials for use, improving a bed material circulation flow system and gas solid mixing level, and improving the feed system, synthesis gas and the pyrolysis gas are produced simultaneously, the overall pyrolysis gasification efficiency and a pyrolysis gas heat value are greatly improved and increased, tar content in the synthesis gas and the pyrolysis gas is reduced, and the synthesis gas and the pyrolysis gas do not contain pollutants such as dioxin, thus effectively preparing the high-quality clean pyrolysis gas and synthesis gas.

Owner:代建军 +1

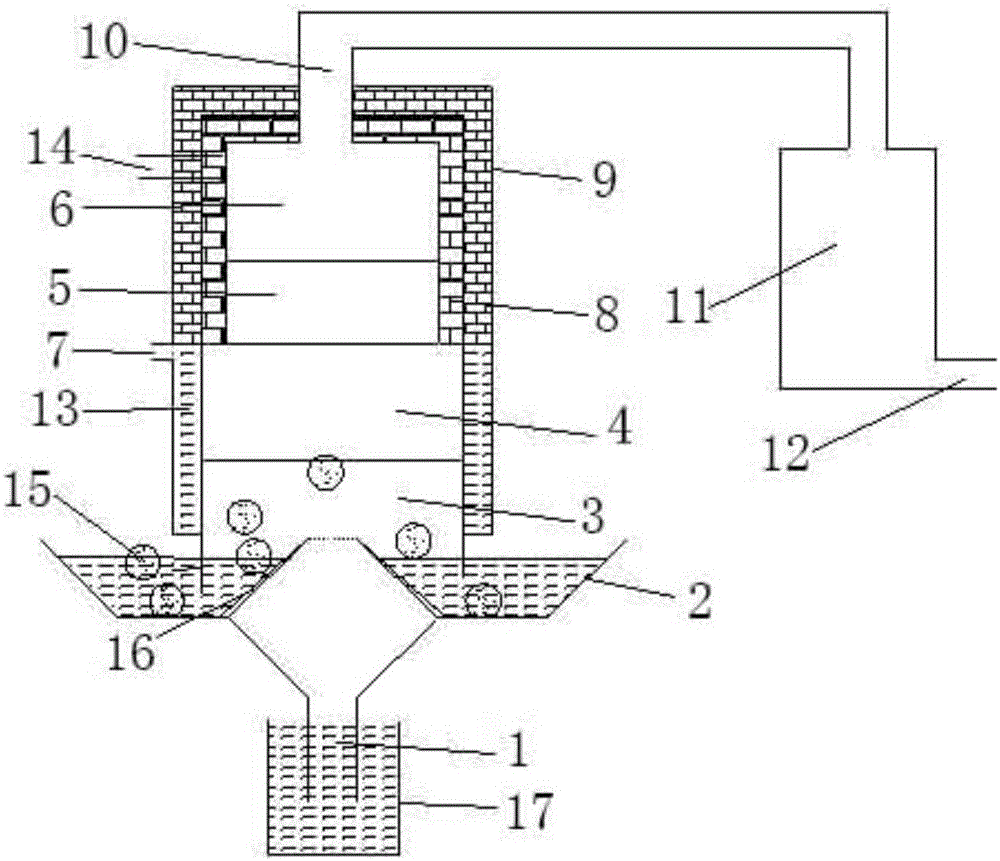

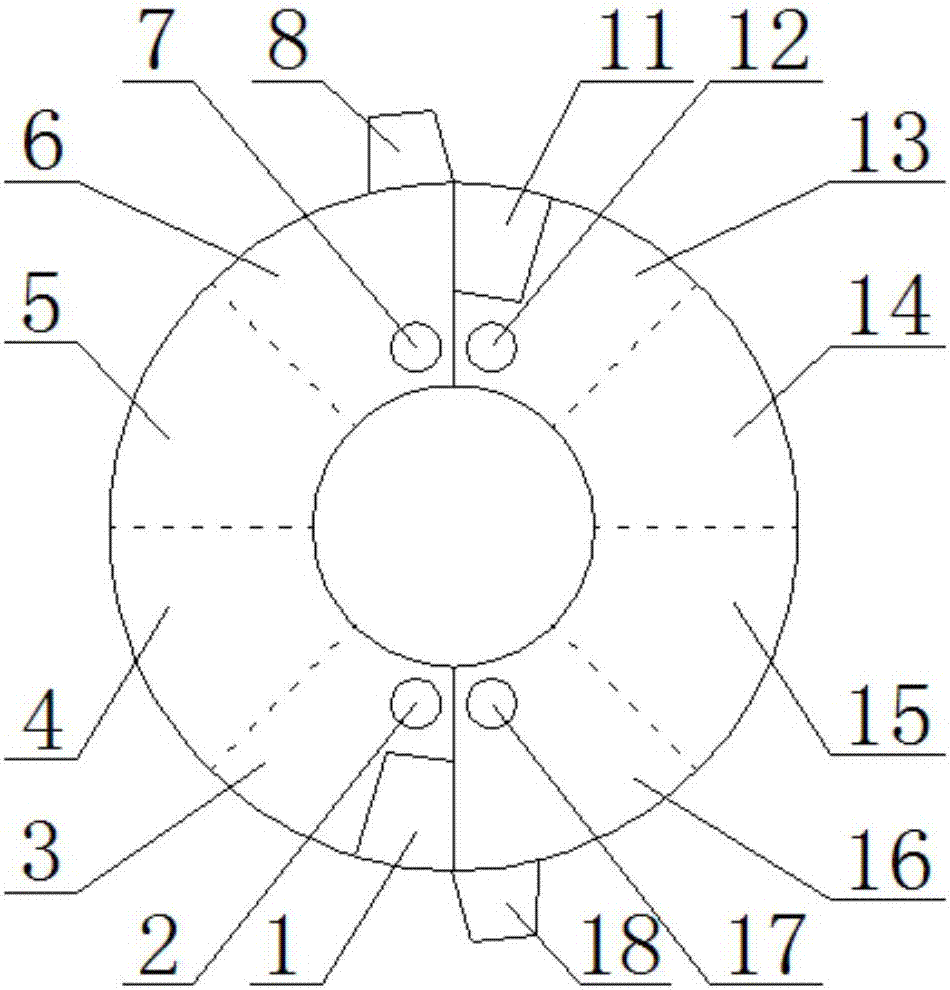

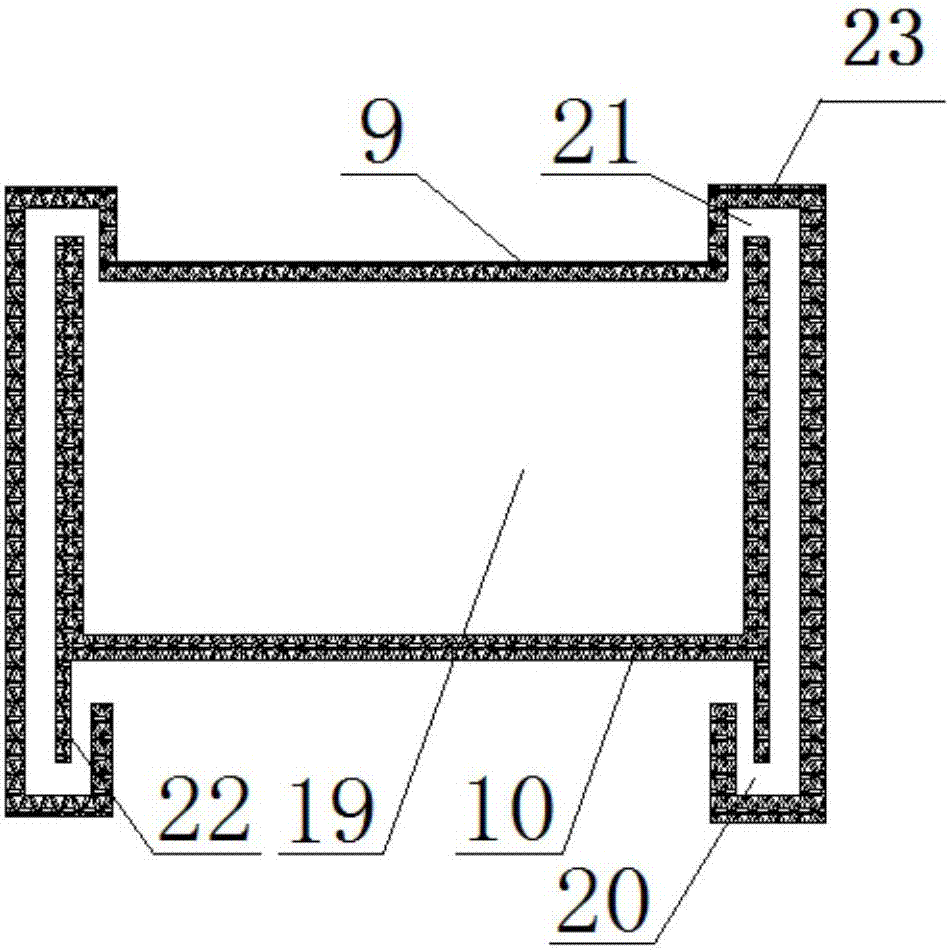

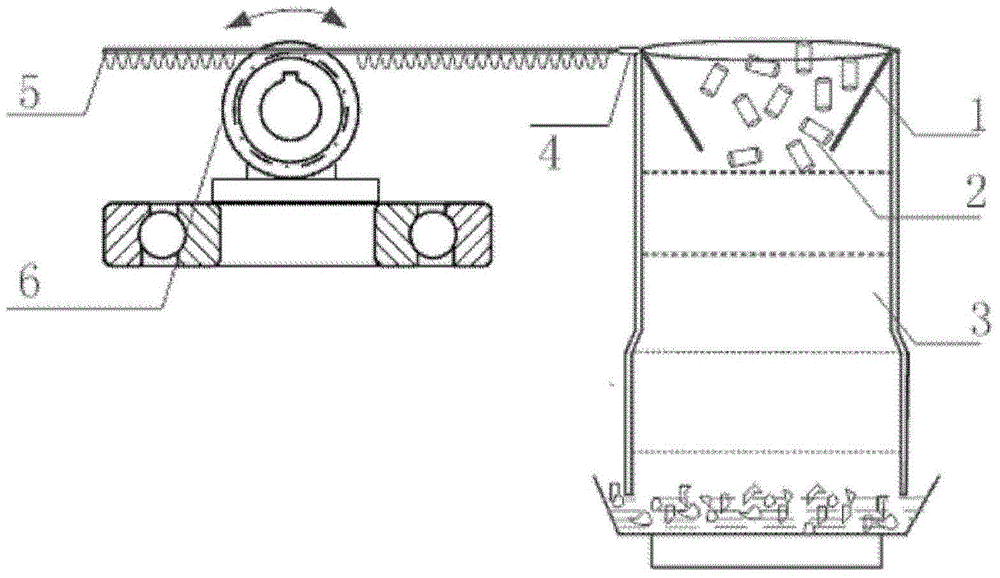

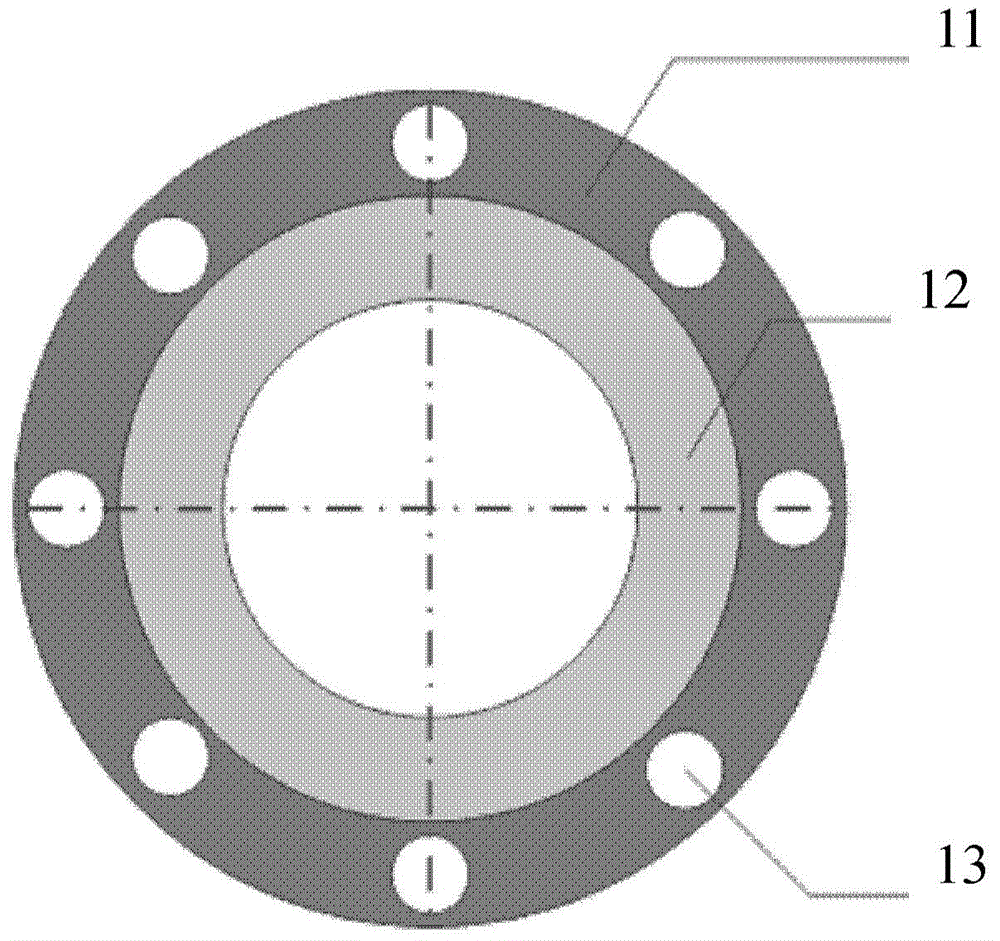

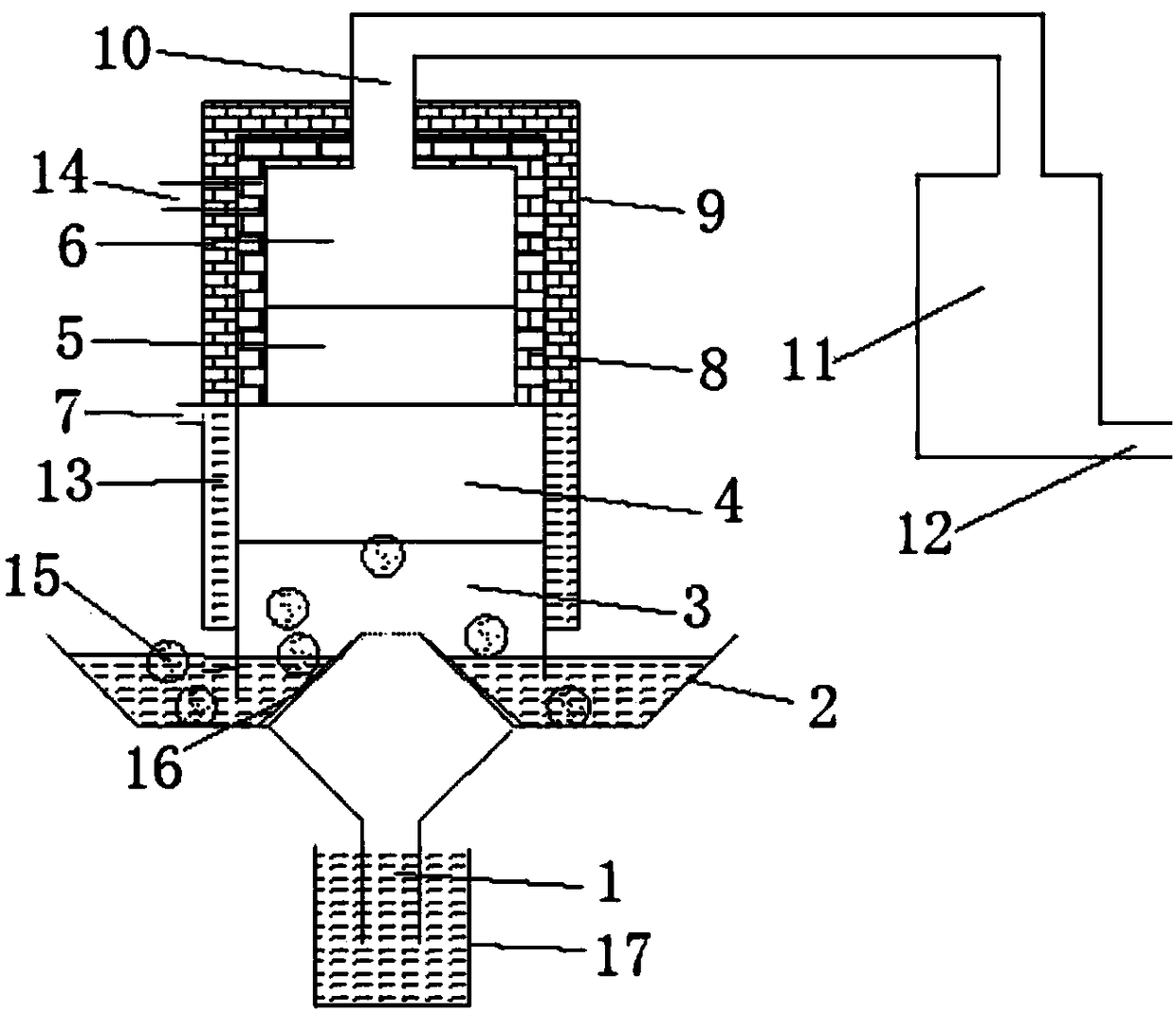

Garbage pyrolysis gasification furnace

ActiveCN105737164AImprove pyrolysis gasification efficiencyReduce generationIncinerator apparatusCombustion chamberInlet channel

The invention discloses a garbage pyrolysis gasification furnace. A base of a furnace body is arranged in an ash pan. An air and steam inlet channel is formed in the center of the ash pan. An air and steam inlet of the air and steam inlet channel communicates with the interior of the garbage pyrolysis gasification furnace. An air and steam outlet is formed in the top end of the air and steam inlet channel, and the lower end of the air and steam inlet channel is connected with an air blower. A pyrolysis gasification chamber in the garbage pyrolysis gasification furnace is provided with an ash layer, a combustion gasification chamber, a destructive distillation layer and a drying layer from bottom to top. The combustion gasification chamber is provided with an ignition opening. A pyrolysis gasification gas outlet is formed in the drying layer and is connected with a secondary combustion chamber. A feeding opening is formed in the top of the garbage pyrolysis gasification furnace. A scraper is welded to the ash pan, the ash pan is driven by a motor to rotate, ash entering the ash pan is brought out by the scraper, and two rows of small gas holes are formed in the two sides of the scraper. According to the garbage pyrolysis gasification furnace, the optimal efficiency of garbage pyrolysis gasification can be achieved, and the garbage pyrolysis gasification furnace is more economical and environment-friendly.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

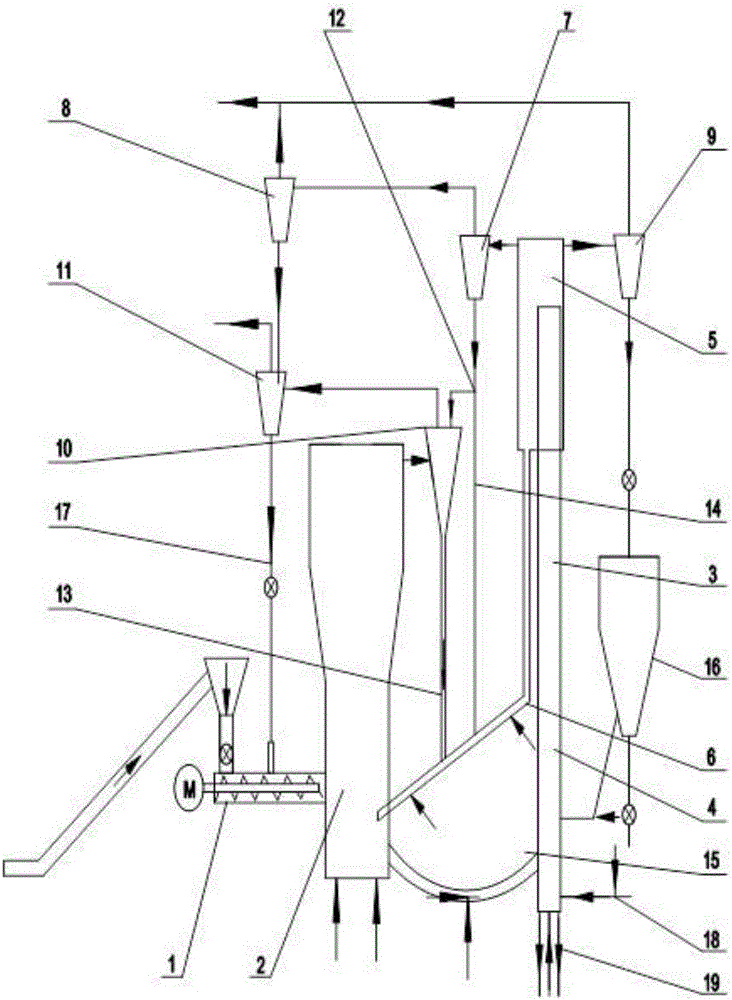

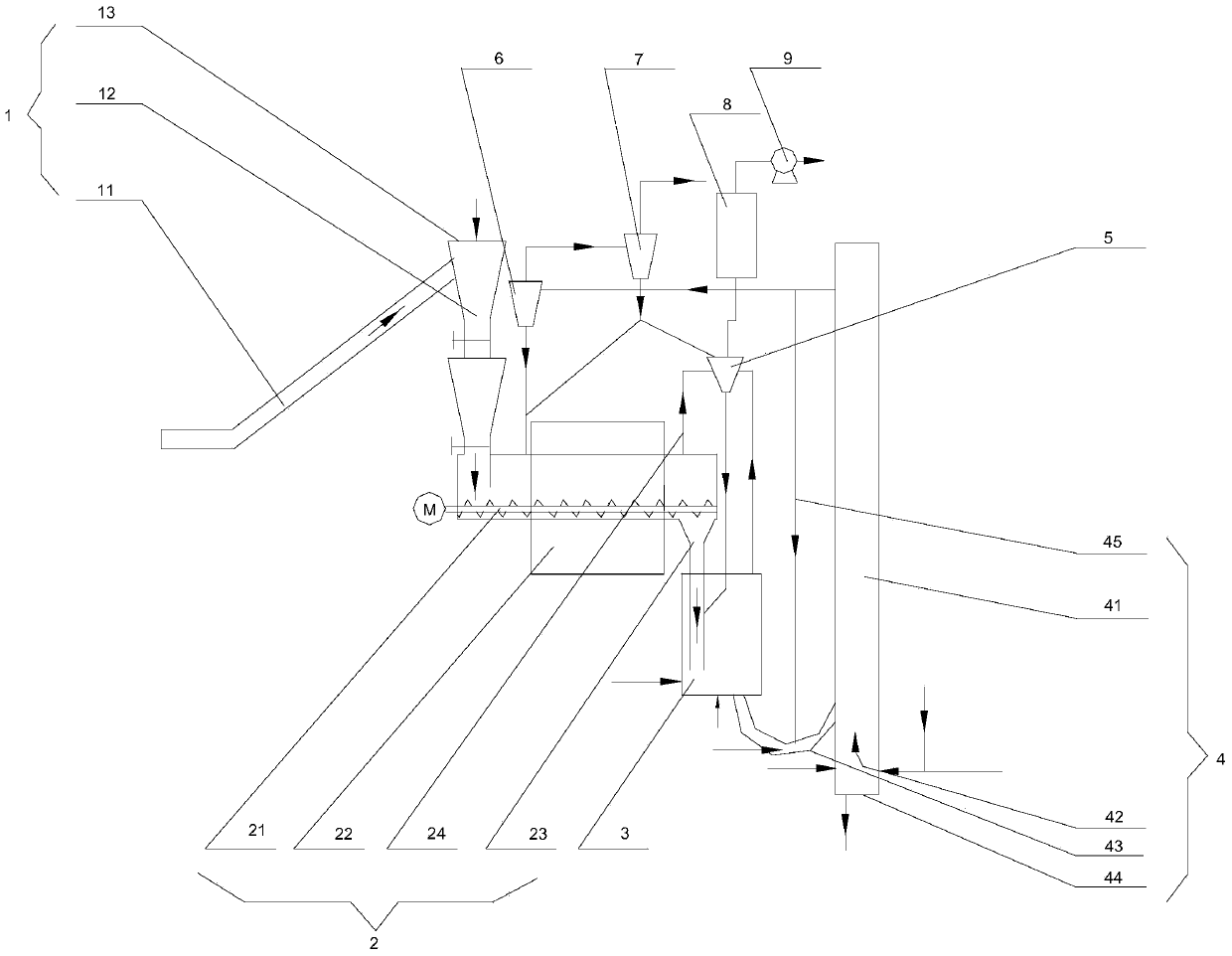

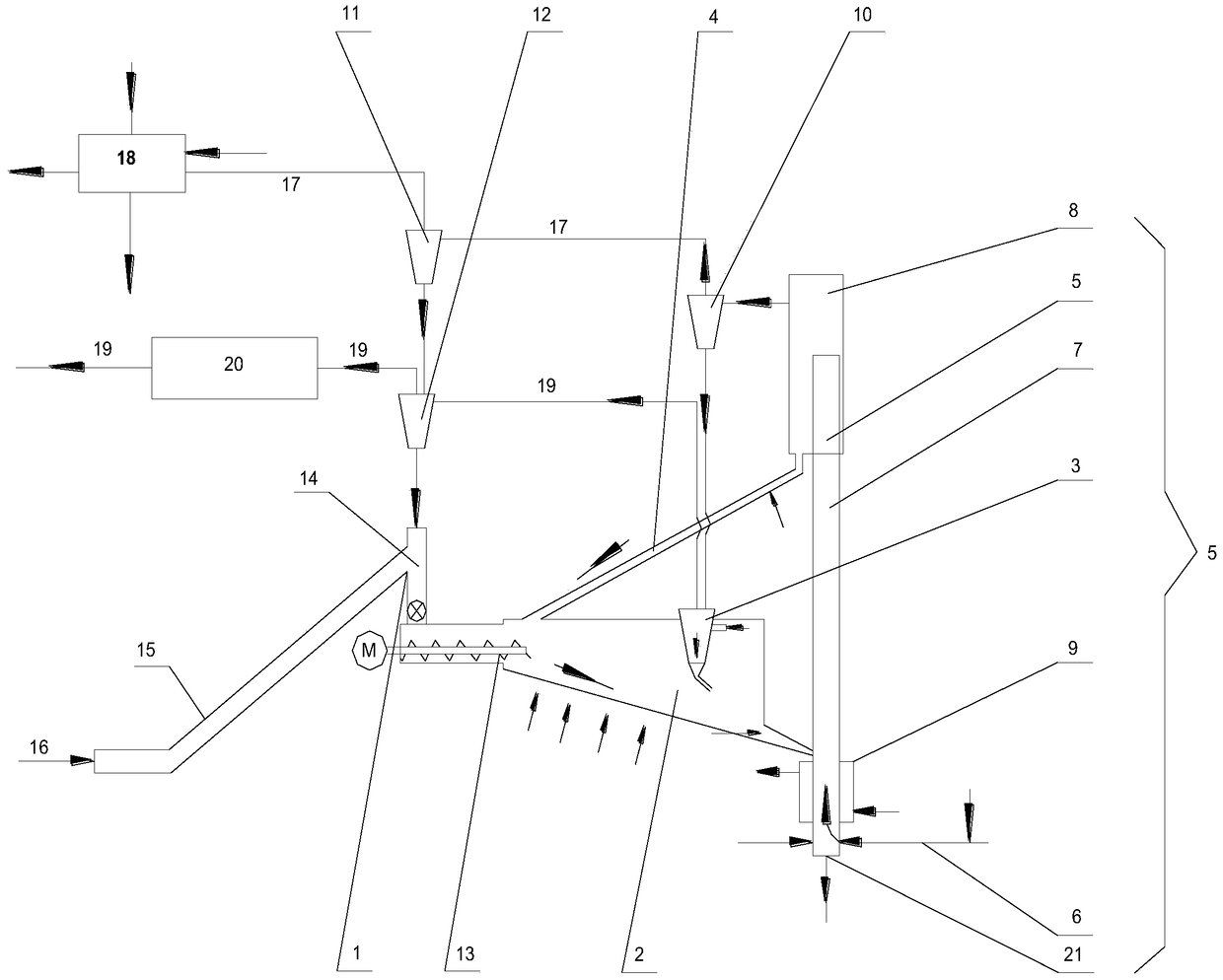

Three-bed combination pyrolysis gasification and tar cracking integrated system for solid waste

ActiveCN105885950AEasy to operateEmission reductionGasifier feeding meansBiofuelsCycloneFluidized bed

The invention discloses a three-bed combination pyrolysis gasification and tar cracking integrated system for solid waste and belongs to the technical field of solid waste treatment. The system comprises a solid waste feeding system, a pyrolyzer, an oxidizer system, an oxidizer cyclone separator and a cyclone reactor. According to the system, the circulating flow of bed materials among three bed is realized by virtue of a circulating fluidized bed oxidizer, a bubbling or turbulent fluidized bed pyrolyzer and the cyclone reactor which are combined with a gas stripping tube and a sedimentation tube, and the adequate mixing between the hot bed materials and pyrolysis gas is realized by virtue of the cyclone reactor, so that the tar cracking and the gas purification are greatly promoted; by virtue of structural optimization of an oxidizer and the pyrolyzer, the mixed use of different bed materials and the improvements of a bed material circulating flow system, the gas-liquid mixing level and a feeding system, the integral pyrolysis gasification efficiency is greatly improved, the heat value of product gas is greatly increased, the tar content of product gas is greatly reduced, and high-quality clean pyrolysis gas / synthesis gas is prepared.

Owner:BEIJING UNIV OF CHEM TECH

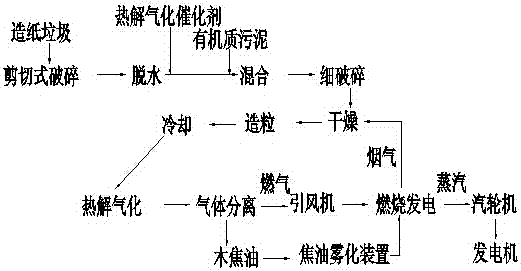

Pyrolysis gasification catalyst and papermaking waste treatment process using pyrolysis gasification catalyst

ActiveCN107497467AGood hygroscopicityImprove pyrolysis gasification efficiencyGasification catalystsOrganic-compounds/hydrides/coordination-complexes catalystsSodium bicarbonateEquivalence ratio

The invention discloses a pyrolysis gasification catalyst which comprises the following components: 35 to 50% of calcium oxide, 10 to 20% of zirconium oxide, 15 to 25% of titanium dioxide, 15 to 25% of sodium bicarbonate and 10 to 20 % of citric acid. The components are crushed to form a mixture; the present invention also discloses a papermaking waste treatment process comprising 1) crushing: crushing papermaking waste into flocculent; 2) dehydration: reducing the water of the papermaking waste to 20-40% ; 3) adding: adding the pyrolysis gasification catalyst accounting for 3-5% of the mass of the papermaking waste; 4) mixing: uniformly mixing the papermaking waste and the catalyst; 5) drying: controlling the water of the mixed material to 15-25%; 6) pelletizing: obtaining organic-matter-derived fuel particles; 7) cooling: cooling the particles to room temperature; 8) pyrolyzing and gasifying: pyrolyzing and gasifying the particles at 600-800 DEG C under micro-oxygen conditions of the air equivalence ratio of 0.1-0.28; and 9) gas separation: removing wood tar from mixed fuel gas through purification; and the pyrolysis gasification catalyst can effectively improve the gasification efficiency of the fuel particles and fuel gas production, can neutralize corrosive gases, greatly improves sludge utilization rate, and effectively protects the environment.

Owner:四川雷鸣环保装备有限公司

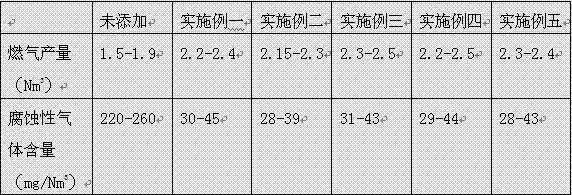

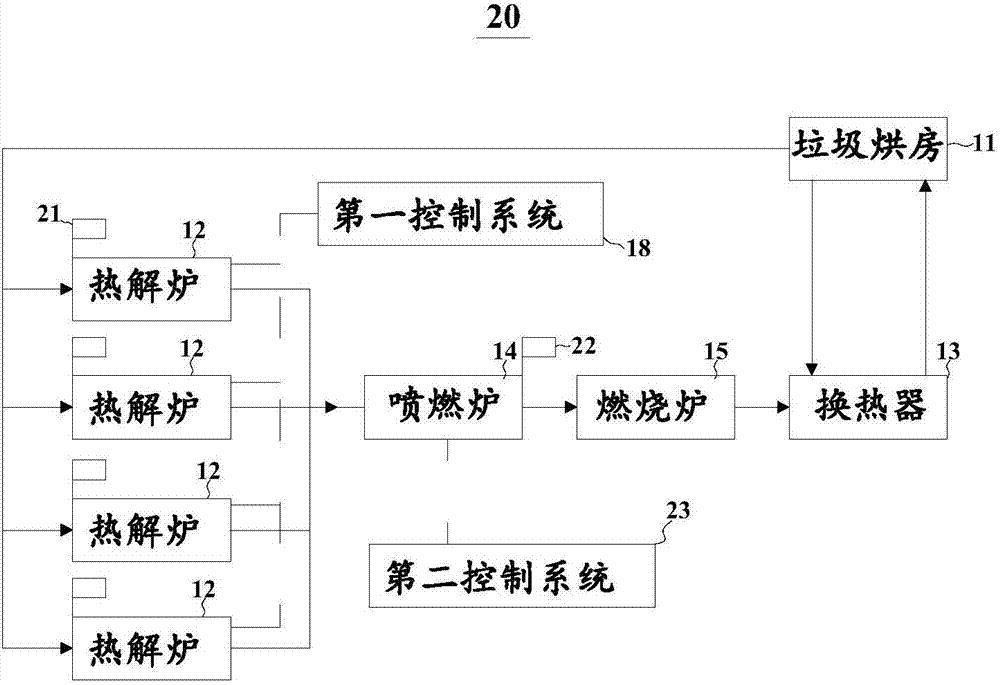

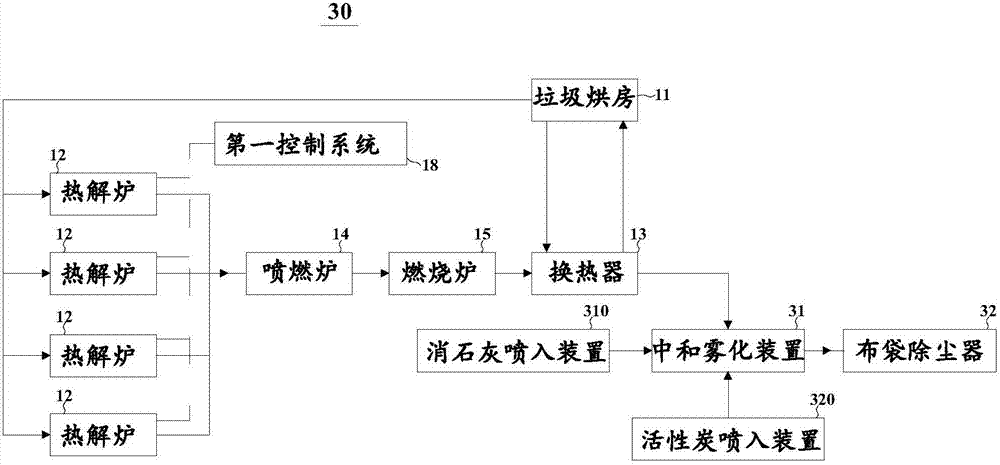

Pyrolysis gasification garbage treatment system and garbage treatment system

InactiveCN107418602AImprove pyrolysis gasification efficiencyImprove purification efficiencySpecial form destructive distillationIncinerator apparatusCombustion chamberCombustible gas

The invention discloses a pyrolysis gasification garbage treatment system and a garbage treatment system, and relates to the field of garbage treatment. The pyrolysis gasification garbage treatment system comprises a garbage drying room, at least two pyrolysis ovens, a secondary combustion chamber and a heat exchanger, each pyrolysis oven comprises a feeding portion and a combustible gas discharging portion, garbage is transferred into the pyrolysis ovens by the feeding portions and subjected to pyrolysis gasification, the secondary combustion chamber comprises a combustion inlet and a combustion outlet, the combustion inlet is communicated with the combustible gas discharging portions of the pyrolysis ovens, a gas inlet of the heat exchanger is connected with the combustion outlet, a heat exchange pipeline of the heat exchanger is connected with the garbage drying room, and heat discharged by the combustible gas discharging portions is converted into heat for drying the garbage by the garbage drying room through the heat exchanger. The pyrolysis gasification garbage treatment system is high in pyrolysis gasification efficiency, the purification efficiency of poisonous gas is improved through the secondary combustion chamber, and energy consumption of pyrolysis gasification is reduced.

Owner:SHENZHEN LONGJISHUN IND DEV

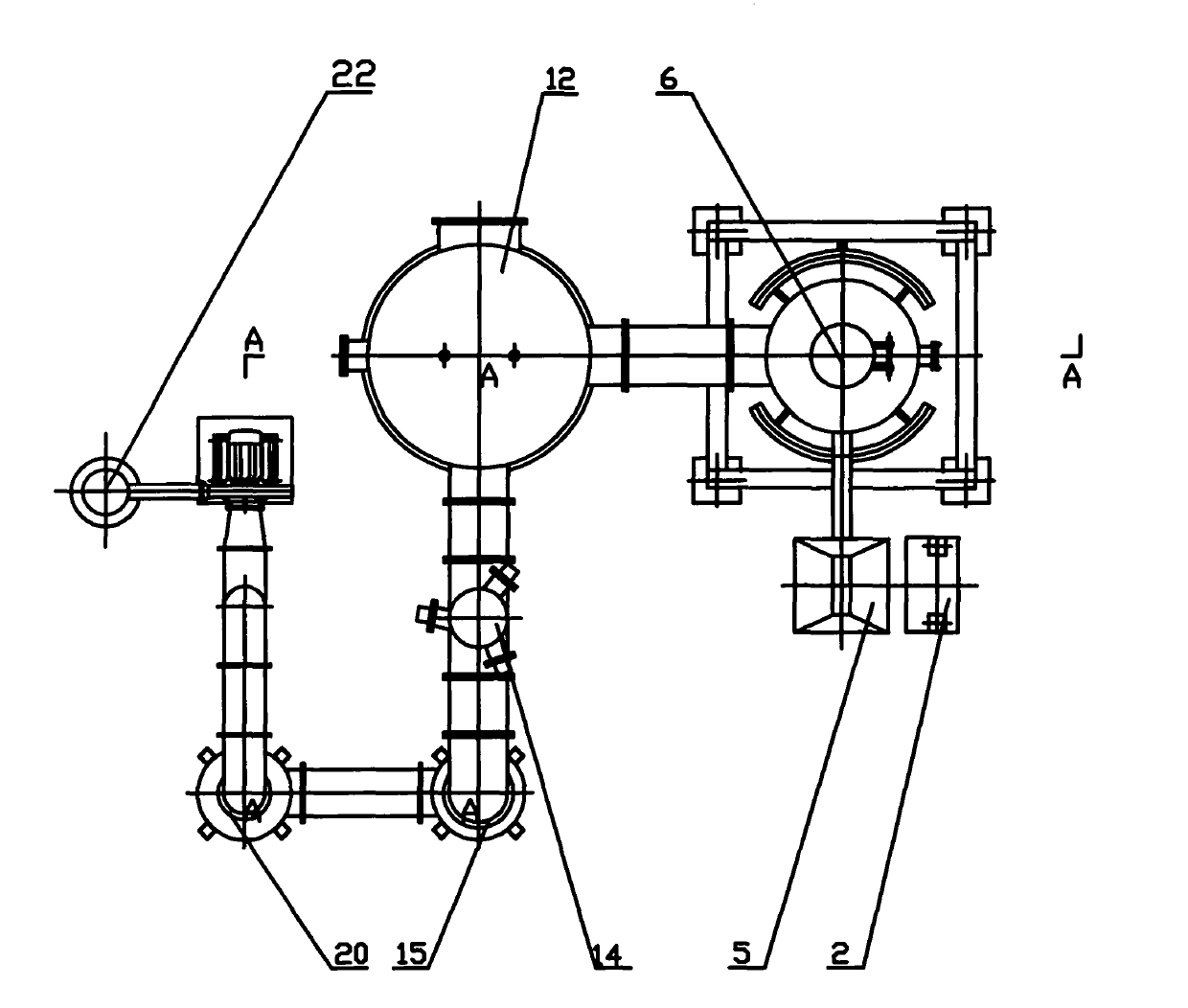

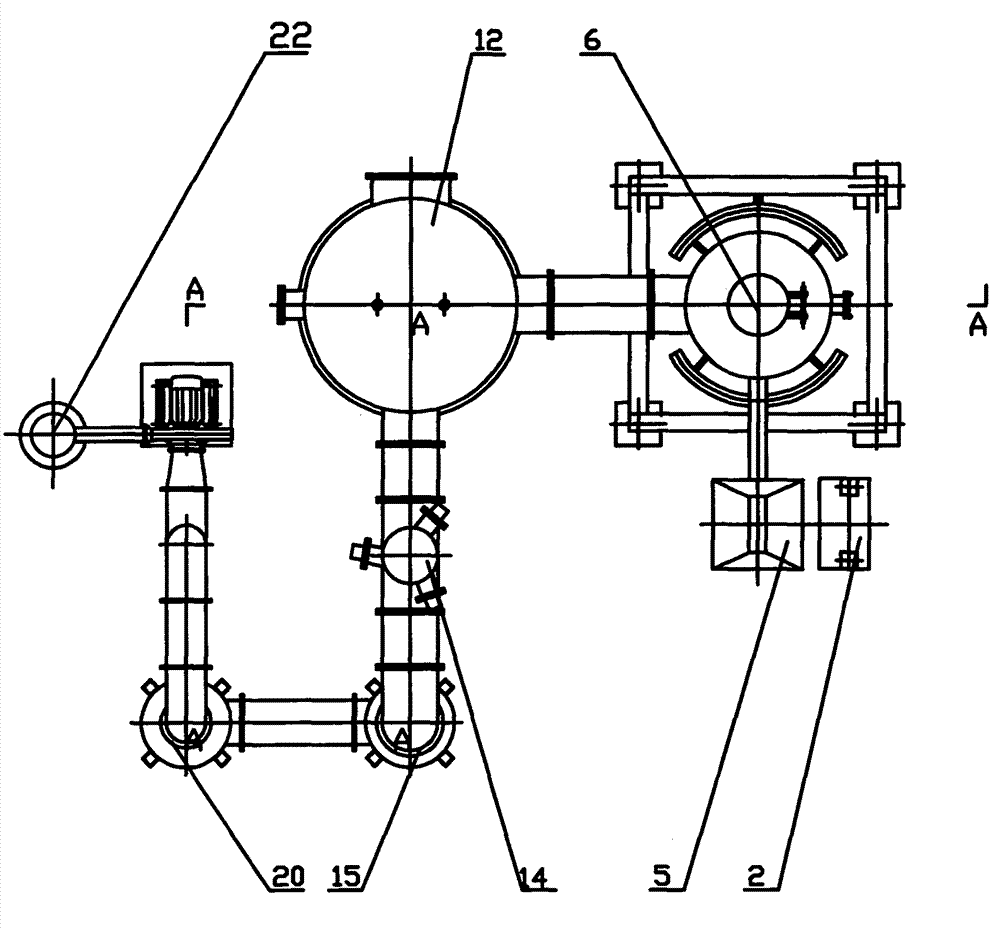

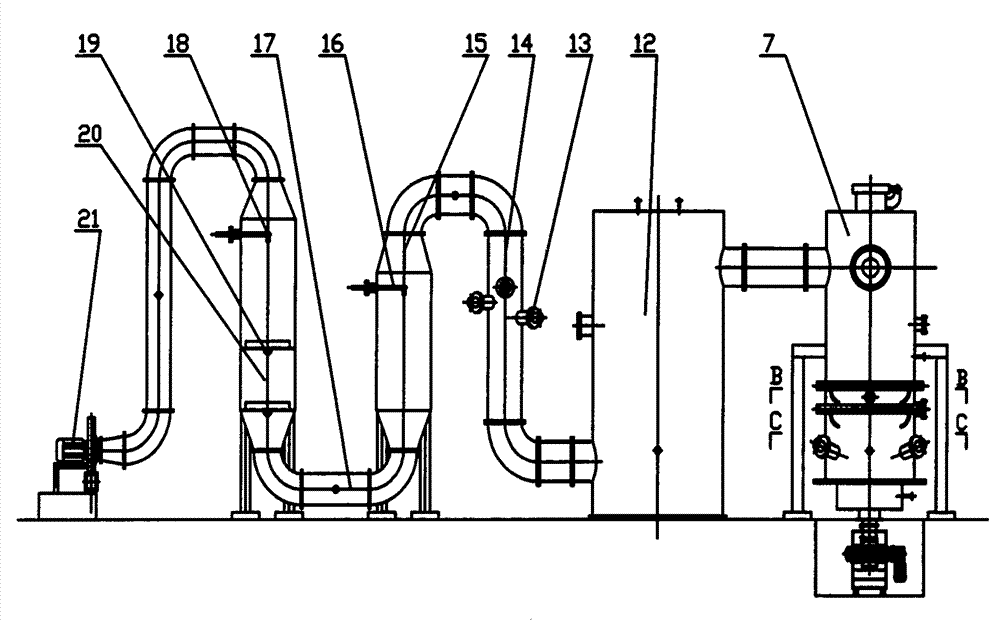

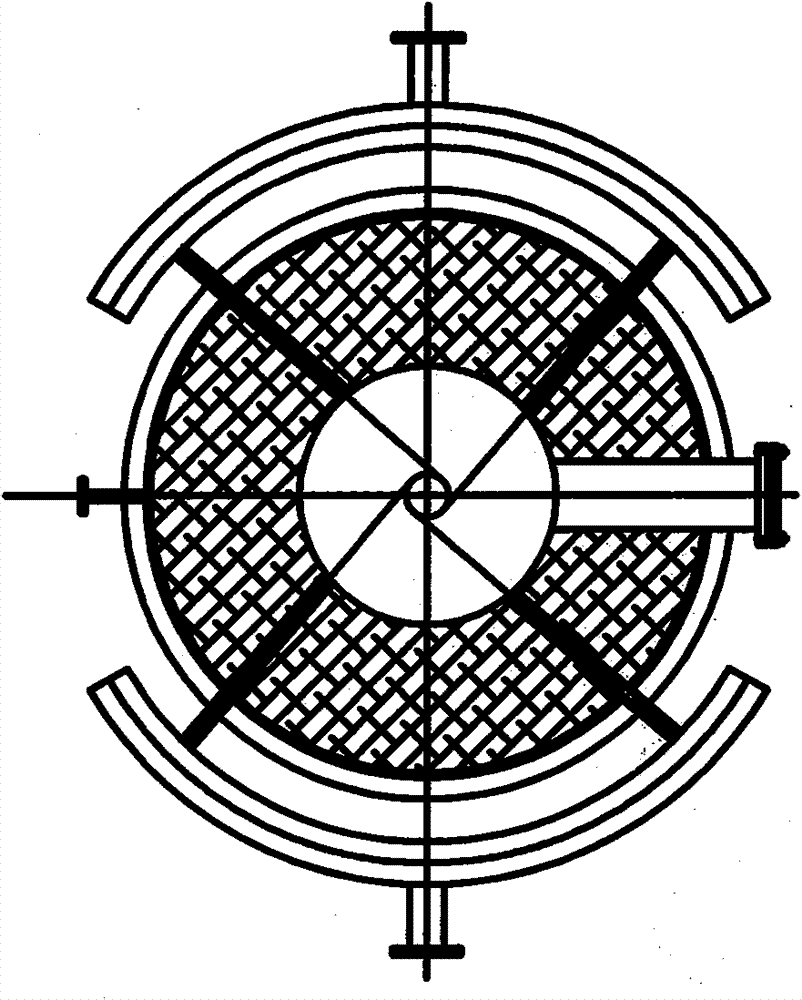

Two-section type pyrolysis-gasification revolving bed for biomass and pyrolysis gasification method

PendingCN106978215APrevent bridgingHigh yieldGasification processes detailsCombustible gas productionOxidation zoneProcess engineering

The invention relates to a two-stage biomass pyrolysis gasification rotary bed and a pyrolysis gasification method. The shell of the rotating bed is ring-shaped, and the shell includes a furnace roof, a circumferential furnace wall and a furnace pan. The furnace roof and the circumferential furnace wall are fixedly connected, and the furnace pan can rotate horizontally relative to the furnace roof and the circumferential furnace wall; The furnace is divided into two sections along the circumference: the first gasification section and the second gasification section, both of which include a drying zone, a pyrolysis zone, an oxidation zone and a reduction zone connected in sequence in the circumferential direction, and the reduction zone of the first gasification section and the The drying area of the second gasification section is connected with a first partition, the reduction area of the second gasification section is connected with the drying area of the first gasification section and a second partition is provided; The first air inlet, the second air inlet, the first gasification gas outlet, the second gasification gas outlet, the first feed port, the second feed port, the first ash outlet, and the second ash outlet. The invention improves the productivity of the gasification furnace and the quality of the pyrolysis gas, and realizes the continuous feeding and operation on the disk.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

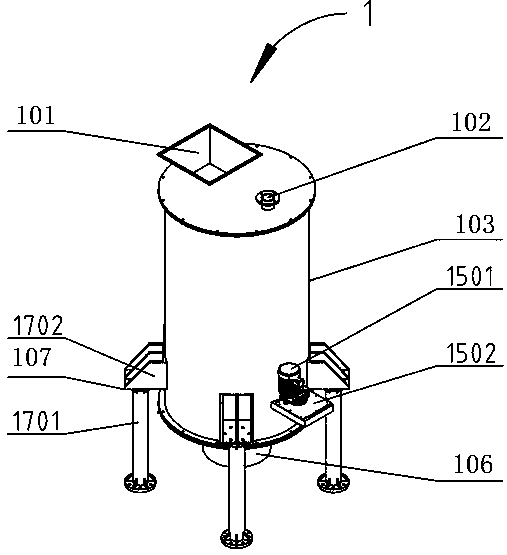

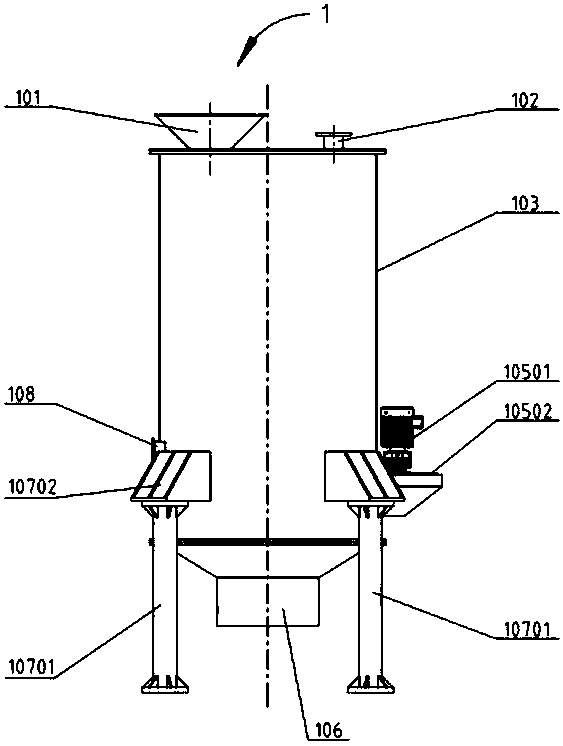

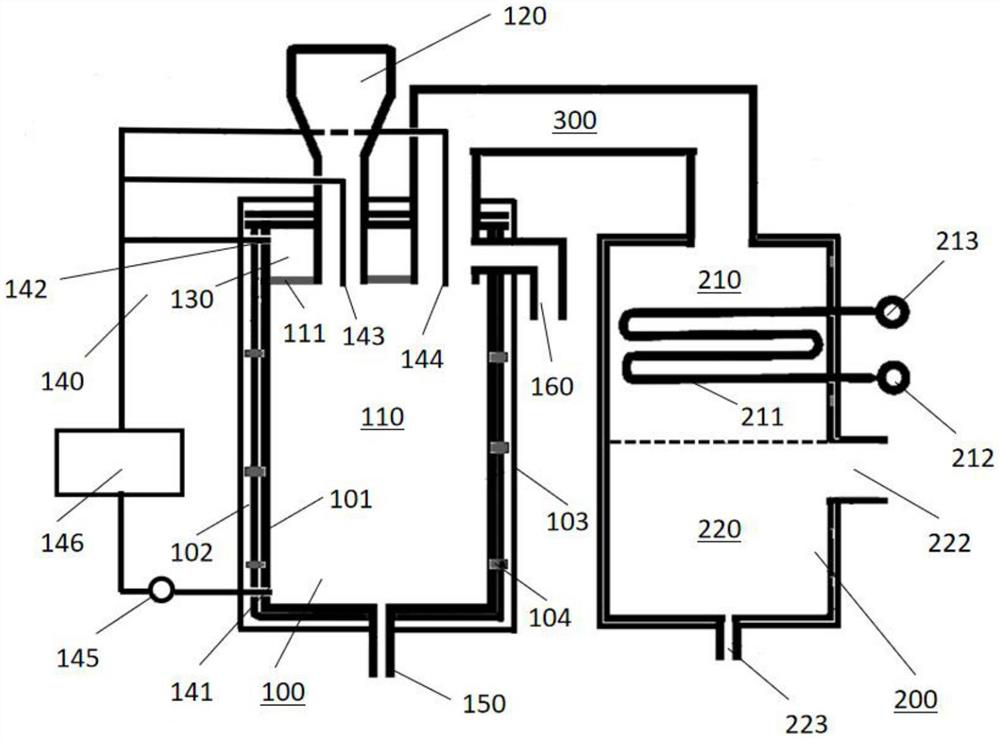

A waste pyrolysis gasification system

ActiveCN107957069BReduce pretreatment costsAvoid stackingIncinerator apparatusWaste heat recovery unitCombustion chamber

Owner:CECEP ENVIRONMENTAL PROTECTION EQUIP CO LTD +1

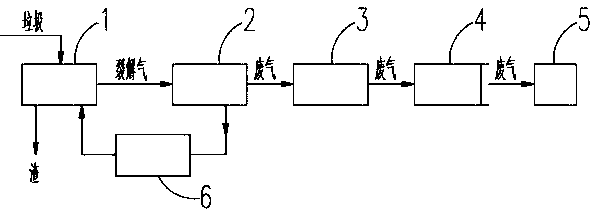

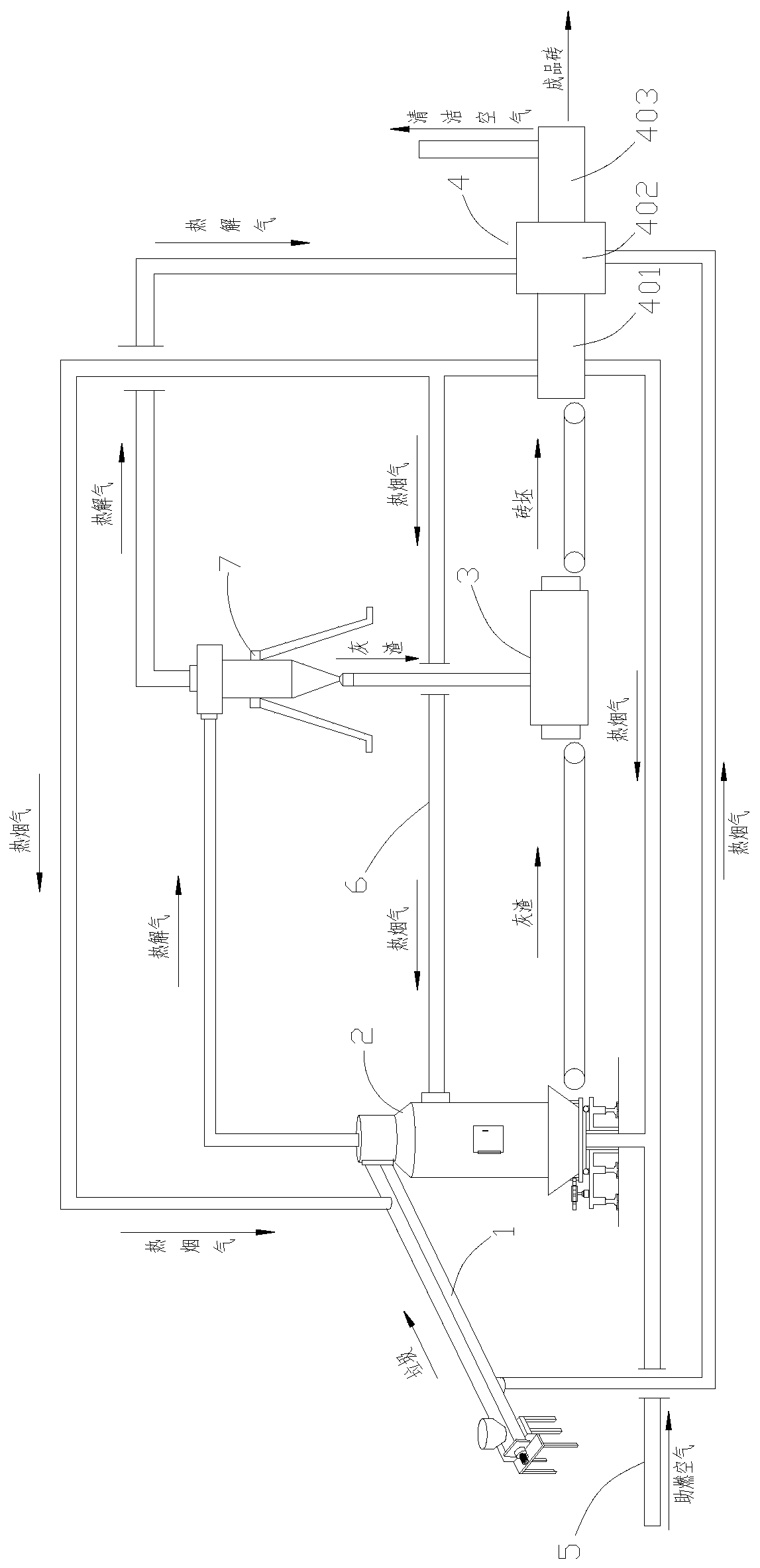

Domestic rubbish disposal system and method based on pyrolysis gasifier and tunnel brickkiln

InactiveCN111412467AImprove pyrolysis gasification efficiencyPlay an adsorption roleFurnace typesHandling discharged materialTunnel kilnTemperature control

The invention relates to a domestic rubbish disposal system based on a pyrolysis gasifier and a tunnel brickkiln. The domestic rubbish disposal system comprises a feeding and drying device, the pyrolysis gasifier, a brick making system and the tunnel kiln. The heat tunnel kiln comprises a preheating segment, a combustion segment and a cooling segment. A first exhaust opening of the preheating segment communicates with a gas inlet of the feeding and drying device. A gas outlet of the feeding and drying device communicates with a first gas inlet of the combustion segment. A second gas outlet ofthe preheating segment communicates with a gas inlet of the pyrolysis gasifier. An exhaust opening of the pyrolysis gasifier communicates with a second gas inlet of the combustion segment. The temperature of the combustion segment is controlled to be 1,000 DEG C, and an air supply pipeline is further connected to a connecting pipeline between the combustion segment and the pyrolysis gasifier. According to the domestic rubbish disposal system and method based on the pyrolysis gasifier and the tunnel brickkiln, dioxin generated by rubbish combustion can be removed thoroughly, generated ash can be cyclically utilized, and the harmless conversion rate is high.

Owner:重庆秋松环保科技有限公司

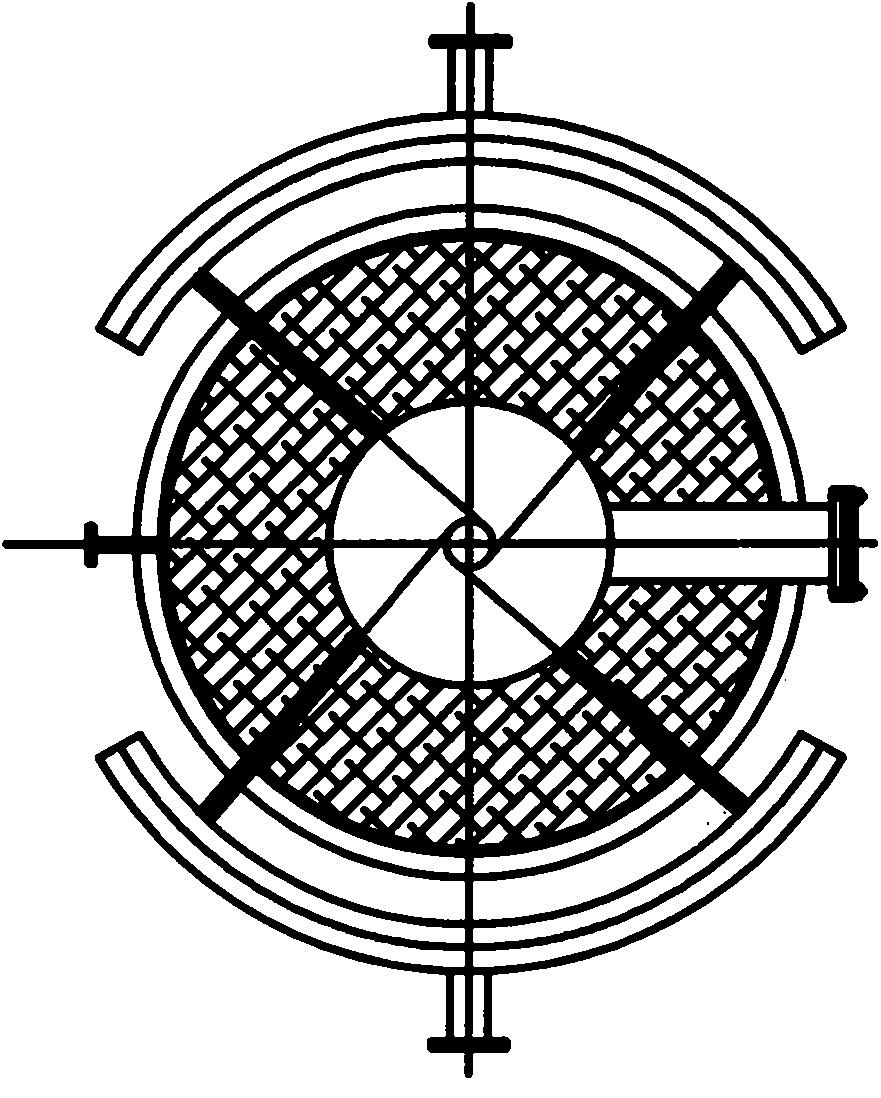

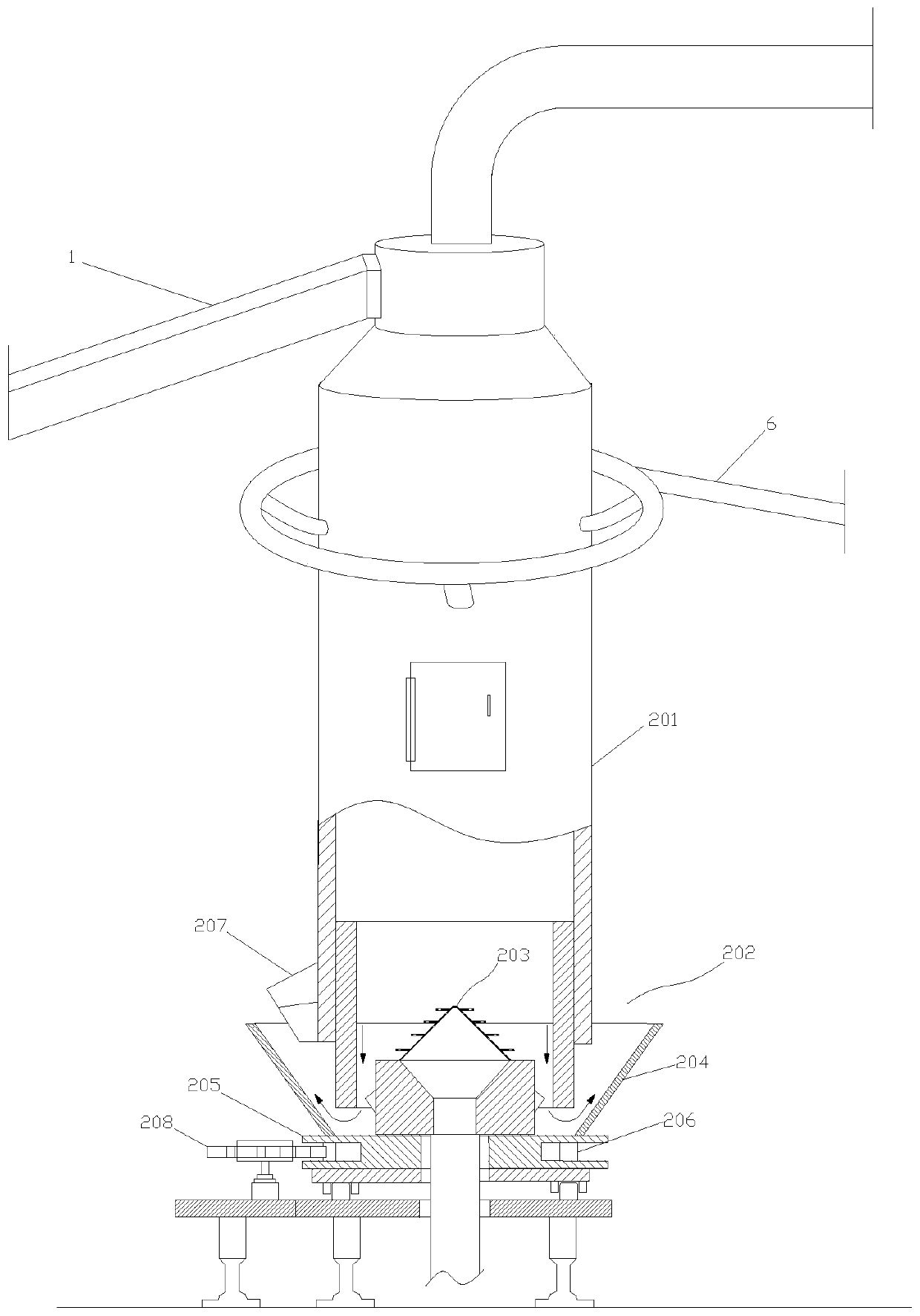

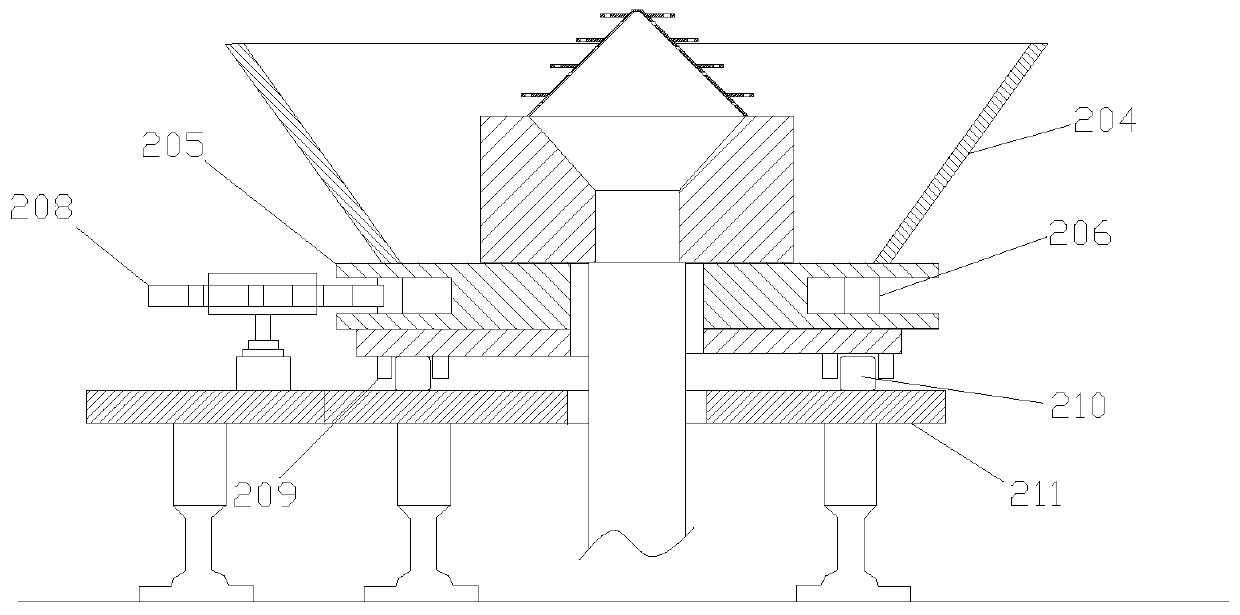

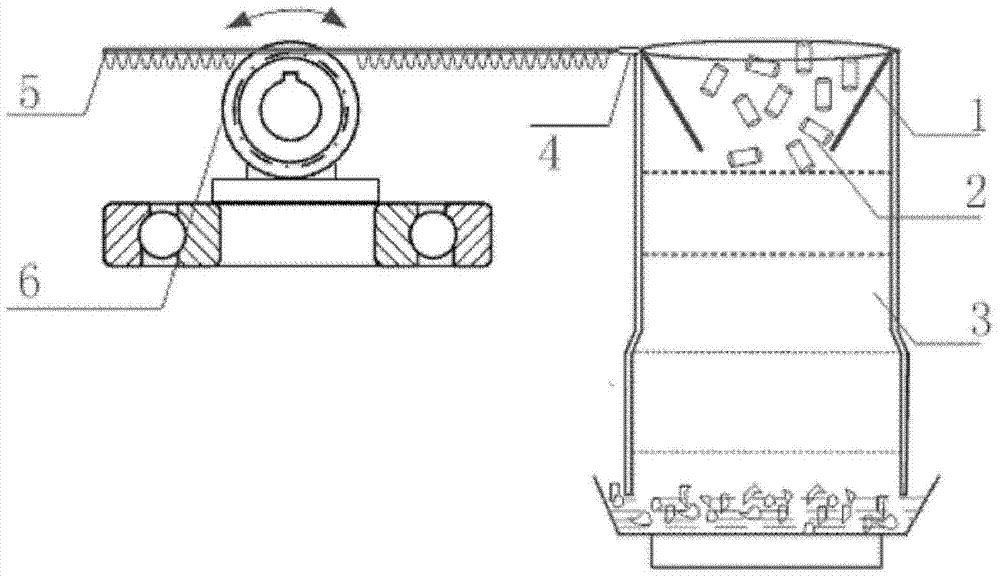

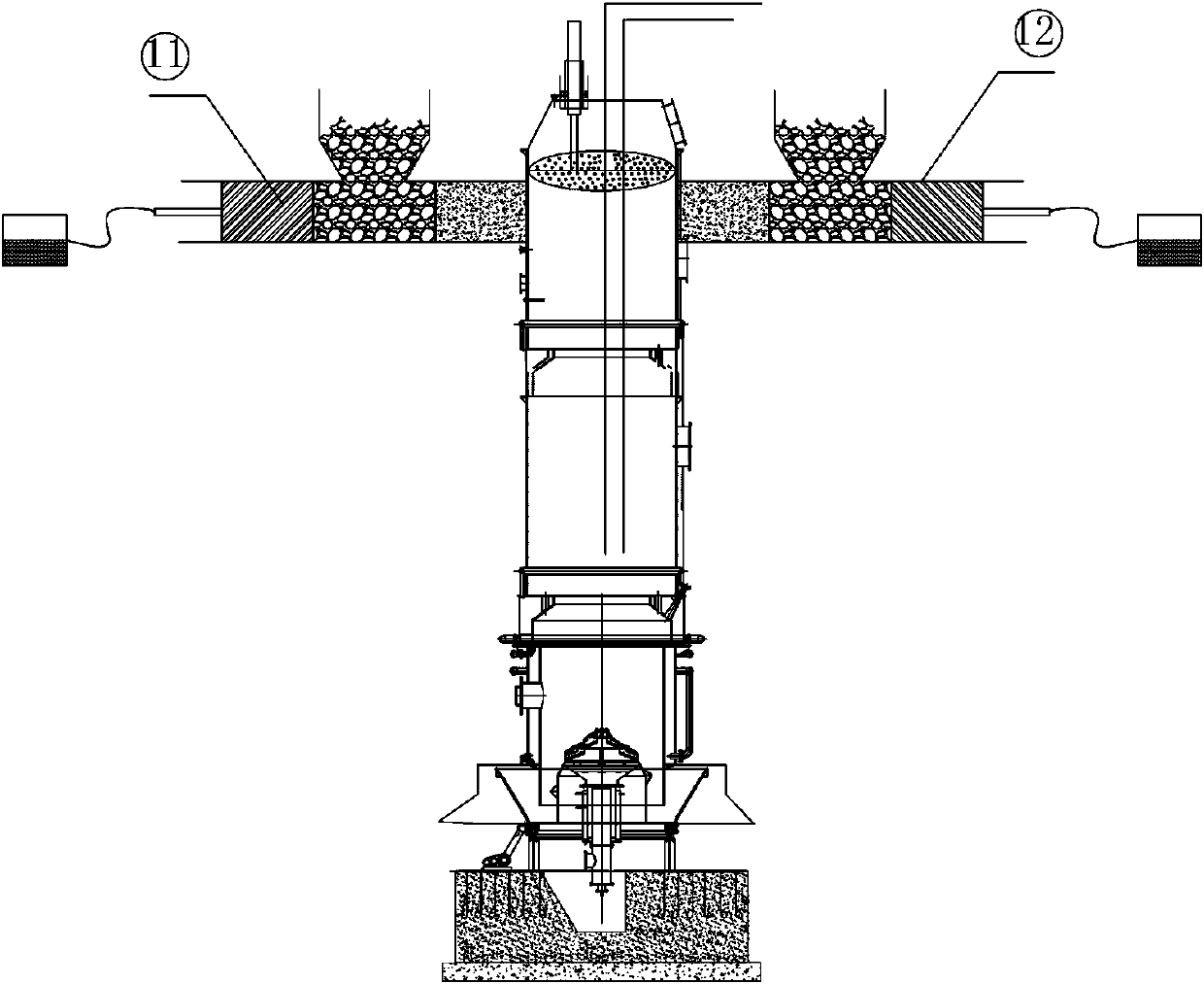

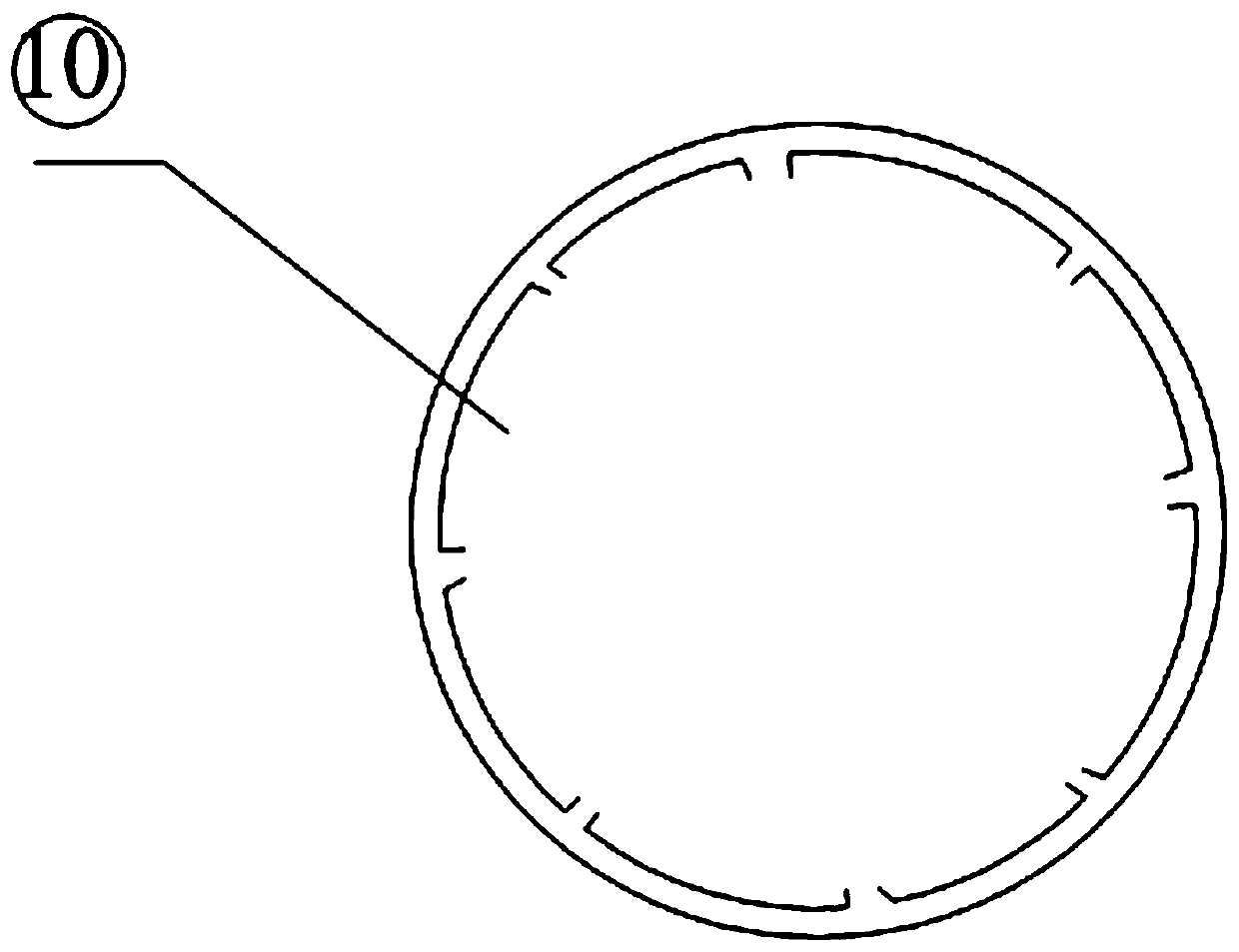

Material-distributing device for refuse pyrolysis gasification furnace

ActiveCN104946276AIntegrated operation processSimple structureIndirect heating destructive distillationSpecial form destructive distillationRefuse-derived fuelIntegrated operations

A material-distributing device for a refuse pyrolysis gasification furnace is arranged between a hydraulic feeder and a feeding port of the pyrolysis gasification furnace. According to the material-distributing device for the refuse pyrolysis gasification furnace, a transmission screw is flatly placed on a cylindrical transmission tooth and connected with a material-distributing mesh screen through a transmission pulley, the material-distributing mesh screen is of a cone frustum type and is placed above the feeding port of the pyrolysis gasification furnace, the middle of the material-distributing mesh screen is provided with a feeding port and a material-distributing outlet, and the edge of the material-distributing mesh screen is provided with a plurality of mesh screen holes. The material-distributing device is suitable for material distribution of refuse derived fuel (RDF) and can achieve the integrated operation process of material feeding and material distribution and improve refuse pyrolysis gasification quality.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

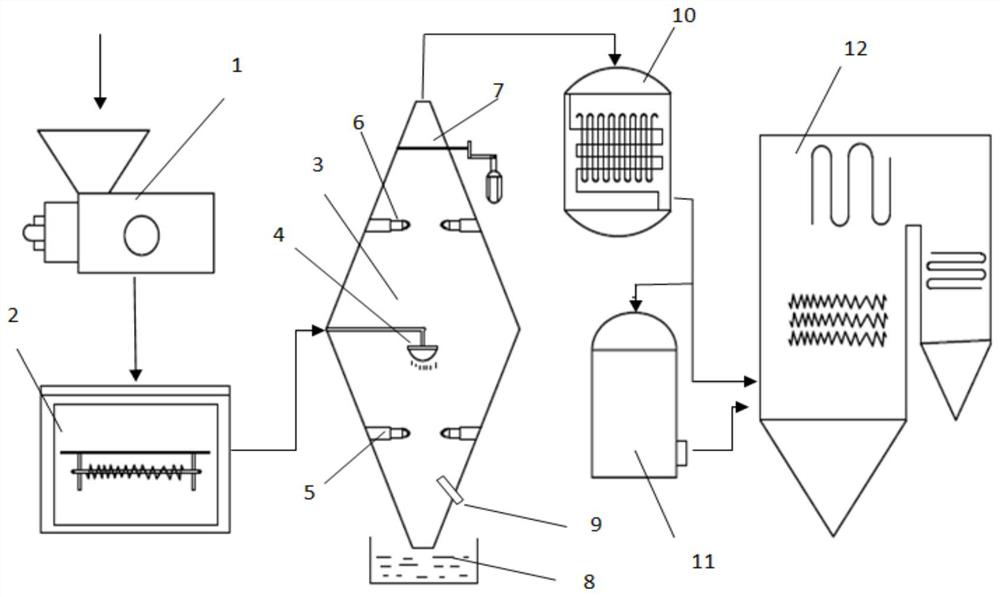

Garbage pyrolysis and gasification system device with drying function and garbage pyrolysis and gasification method

The invention provides a garbage pyrolysis and gasification system device with a drying function and a garbage pyrolysis and gasification method. The device comprises a pyrolysis and gasification unit, a secondary combustion chamber and a waste heat utilization unit which are sequentially connected in the smoke flowing direction, wherein the pyrolysis and gasification unit comprises three pyrolysis and gasification furnaces, which are respectively marked as a first gasification furnace, a second gasification furnace and a third gasification furnace; and the first gasification furnace, the second gasification furnace and the third gasification furnace are respectively connected with the secondary combustion chamber. According to the invention, garbage can be prevented from being stacked in the pyrolysis and gasification furnaces to build a shed, uniform material distribution in the gasification furnaces is realized, the garbage is prevented from being coked on a fire grate, and the pyrolysis and gasification efficiency is improved. Secondary air entering the secondary combustion chamber is evenly distributed, the gas retention time is prolonged, combustible components in gas are thoroughly combusted, harmful substances in the gas are thoroughly decomposed, emission reaches the standard, secondary pollution is avoided, and high organic decrement rate and harmlessness of residual ash are achieved.

Owner:CECEP ENVIRONMENTAL PROTECTION EQUIP CO LTD +1

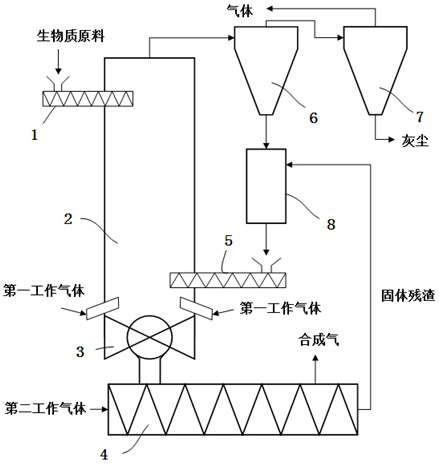

Biomass pyrolysis gasification method and system

PendingCN114479951AImprove pyrolysis gasification efficiencyReduce generationGasification processes detailsCombustible gas productionCarbon layerHeat carrier

The invention discloses a biomass pyrolysis gasification method and system.The method comprises the steps that firstly, a biomass raw material is subjected to rapid heating treatment, and the biomass raw material with the surface carbonized is obtained after treatment; and then feeding the surface-carbonized biomass raw material into a microwave pyrolyzer for gasification reaction to obtain a synthesis gas product and solid residues after the reaction. The biomass pyrolysis gasification system comprises a preprocessor, a microwave pyrolyzer, a gas-solid separation unit and a heat carrier regenerator. According to the method, firstly, biomass raw materials are pretreated, the outer surfaces of the biomass raw materials are subjected to rapid carbonization treatment to form a carbon layer, pyrolysis volatile components released from inside to outside in the subsequent microwave pyrolysis gasification process can be subjected to cracking and reforming reaction with the formed carbon layer, endogenous power formed by tar is inhibited from the source, and the biomass raw materials can be recycled. The biomass pyrolysis gasification efficiency is improved, the economical efficiency of the process is improved, and the method has a good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

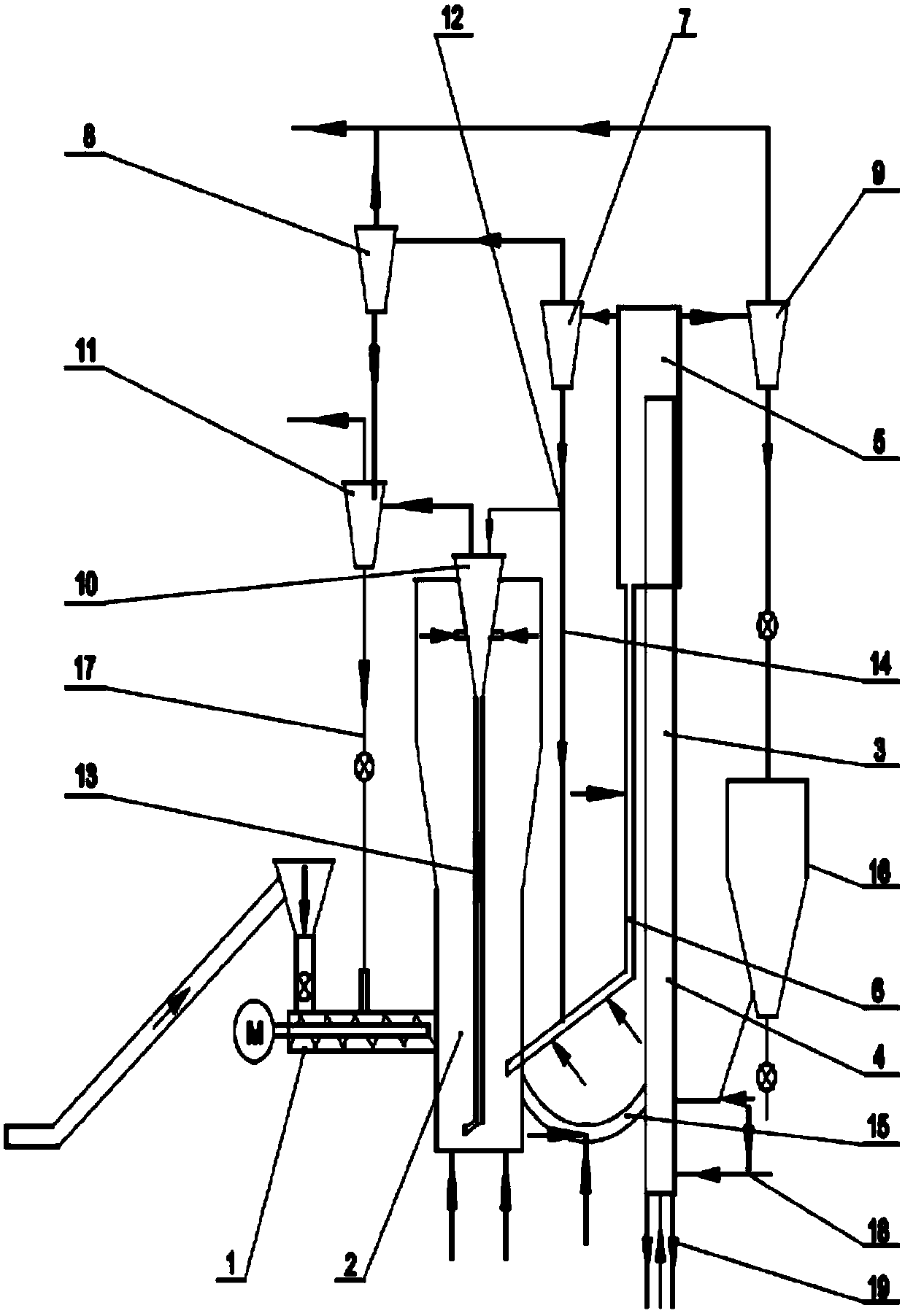

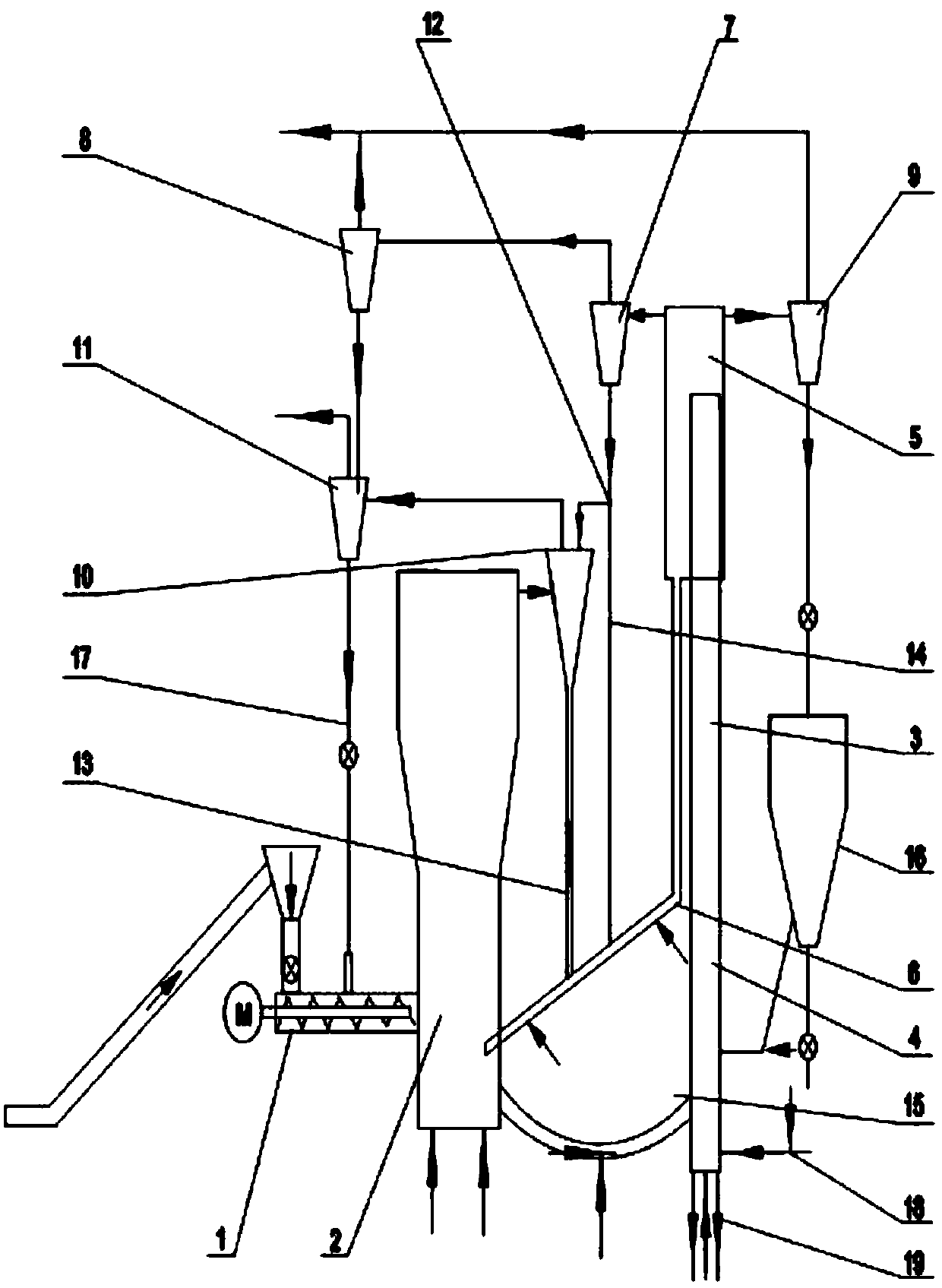

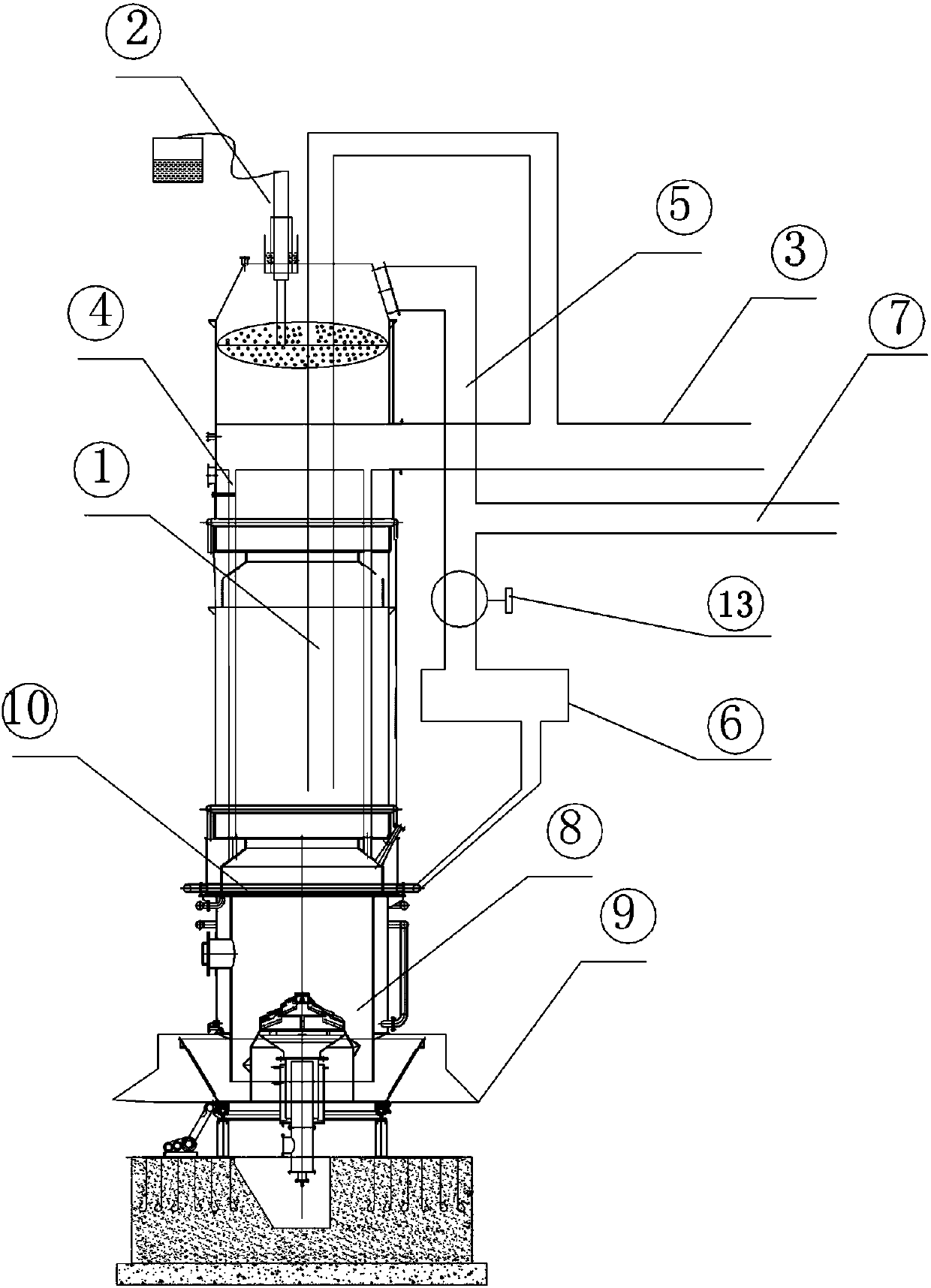

A device for producing hydrogen by coupling biomass gasification with SOFC tail gas and using method thereof

ActiveCN110819391BHigh purityControl flow rateHydrogen separationEnergy inputNew energyProcess engineering

The invention discloses an SOFC tail gas coupling biomass gasification hydrogen production device and a use method thereof, which belong to the technical field of new energy utilization. The device includes structural units such as SOFC system, preheating chamber, premixing chamber, fluidization chamber, gas distribution chamber, outlet channel and separation box I. The device makes biomass firstly dry and volatilize in the waste heat of SOFC tail gas, and then Hydrogen is produced by steam gasification, and the gasified gas after the reaction is cooled and purified. The device comprehensively utilizes the hydrogen and waste heat in the SOFC tail gas to increase the hydrogen production rate of biomass gasification hydrogen production, reduce the energy consumption of biomass gasification hydrogen production, and has the characteristics of energy saving and environmental protection. At the same time, by adjusting the operating parameters of the device, such as material mass ratio, gas flow ratio, air flow rate, etc., the conversion rate of biomass gasification reaction is improved, the energy consumption of the device is reduced, and the production rate is increased. In general, this device uses the hydrogen and waste heat in the SOFC tail gas to increase the hydrogen production rate of biomass gasification hydrogen production and reduce the energy consumption of biomass gasification hydrogen production.

Owner:SHAOYANG UNIV

A garbage pyrolysis gasifier

ActiveCN105737164BImprove pyrolysis gasification efficiencyReduce generationIncinerator apparatusInlet channelCombustion chamber

The invention discloses a garbage pyrolysis gasification furnace. A base of a furnace body is arranged in an ash pan. An air and steam inlet channel is formed in the center of the ash pan. An air and steam inlet of the air and steam inlet channel communicates with the interior of the garbage pyrolysis gasification furnace. An air and steam outlet is formed in the top end of the air and steam inlet channel, and the lower end of the air and steam inlet channel is connected with an air blower. A pyrolysis gasification chamber in the garbage pyrolysis gasification furnace is provided with an ash layer, a combustion gasification chamber, a destructive distillation layer and a drying layer from bottom to top. The combustion gasification chamber is provided with an ignition opening. A pyrolysis gasification gas outlet is formed in the drying layer and is connected with a secondary combustion chamber. A feeding opening is formed in the top of the garbage pyrolysis gasification furnace. A scraper is welded to the ash pan, the ash pan is driven by a motor to rotate, ash entering the ash pan is brought out by the scraper, and two rows of small gas holes are formed in the two sides of the scraper. According to the garbage pyrolysis gasification furnace, the optimal efficiency of garbage pyrolysis gasification can be achieved, and the garbage pyrolysis gasification furnace is more economical and environment-friendly.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

A kind of distributing device for waste pyrolysis gasification furnace

ActiveCN104946276BIntegrated operation processSimple structureIndirect heating destructive distillationSpecial form destructive distillationEngineeringPulley

A material distributing device for a waste pyrolysis gasifier, which is installed between the hydraulic feeder and the feed port of the pyrolysis gasifier, including: a transmission screw placed flat on a cylindrical transmission tooth, and the transmission screw passes through the transmission pulley and the material distribution net The sieves are connected; the distribution mesh screen is a round platform, placed above the feed inlet of the pyrolysis gasifier, the middle part of the distribution mesh screen is the feed inlet and the distribution outlet, and the edge part of the distribution mesh screen is provided with a number of mesh holes. The invention is suitable for distributing the garbage derived fuel RDF, can realize the integrated operation process of feeding and distributing, and improves the quality of pyrolysis and gasification of garbage.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

A method for preparing synthesis gas by microwave pyrolysis gasification of biomass

ActiveCN105524662BRelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationMicrowave pyrolysisTar

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

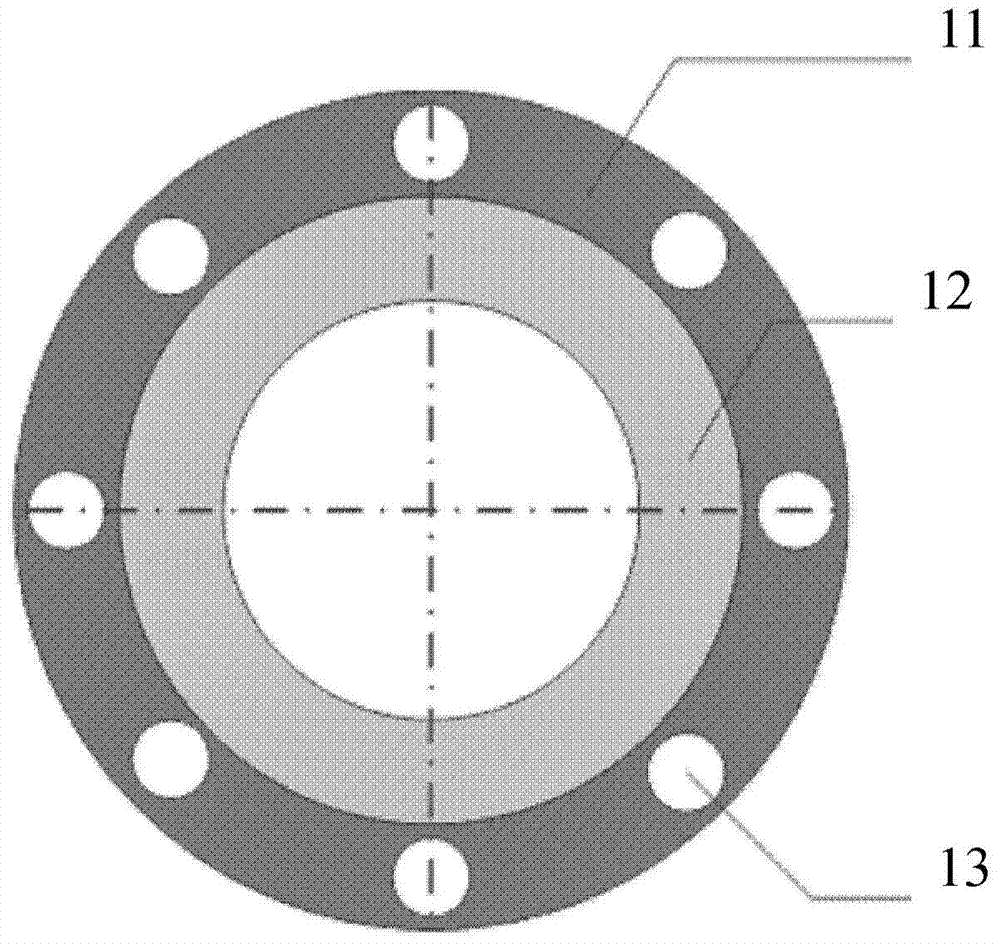

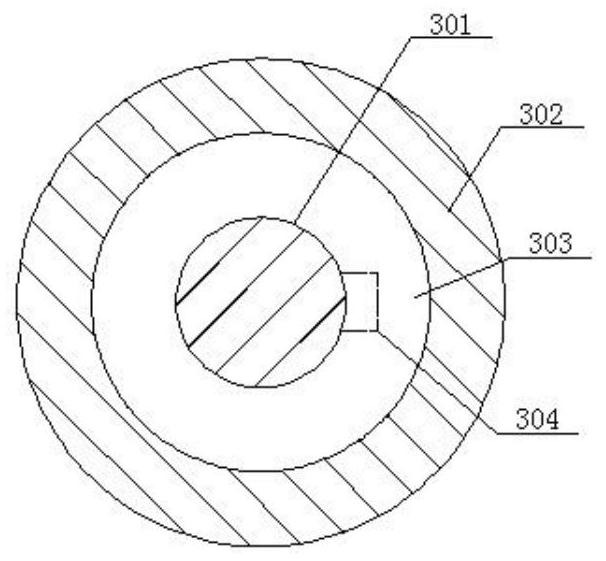

Waste gas export device for coal gangue pyrolysis and gasification

ActiveCN103232864BImprove pyrolysis gasification efficiencyFacilitate the recycling of chemical productsCombustible gas productionBiochemical engineeringMain channel

The present invention discloses a coal gangue pyrolysis gasification raw gas export apparatus, which comprises a raw gas centralization chamber, an inner export channel, an outer export channel, an export main channel, and an export ring channel, wherein the raw gas centralization chamber and a pyrolysis gasification chamber are integratedly molded, the inner export channel is arranged in a flue partition wall, an inner export channel inlet penetrates through the middle portion of an inner ring wall, and is communicated with the pyrolysis gasification chamber, an inner export channel outlet penetrates through the inner ring wall, and is communicated with the raw gas centralization chamber, the outer export channel is arranged in an outer wall of a furnace body, a lower-outer export channel inlet and an upper-outer export channel inlet penetrate through the middle portion of an outer ring wall, and are communicated with the pyrolysis gasification chamber, an outer export channel outlet penetrates through the outer ring wall, and is communicated with the raw gas centralization chamber, the export main channel is arranged the outer wall of the furnace body of a coal pyrolysis furnace, is communicated with the raw gas centralization chamber, and extends upward to the export ring channel on the upper portion of the outer wall of the furnace body, and the export ring channel is provided with a raw gas export port. According to the present invention, raw gas generated during coal gangue pyrolysis gasification is exported so as to easily achieve pyrolysis gasification and raw gas production, recovery and utilization.

Owner:SHANXI XINLI ENERGY TECH

Garbage pyrolysis gasification furnace and method

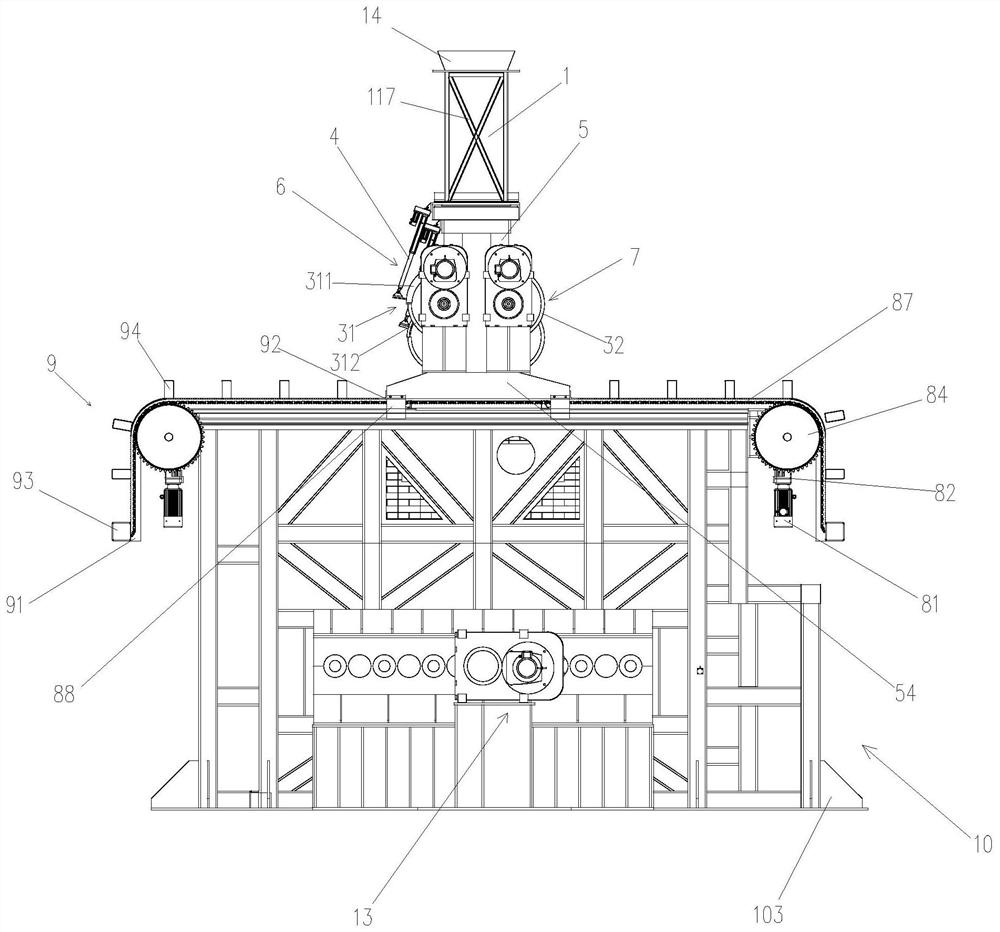

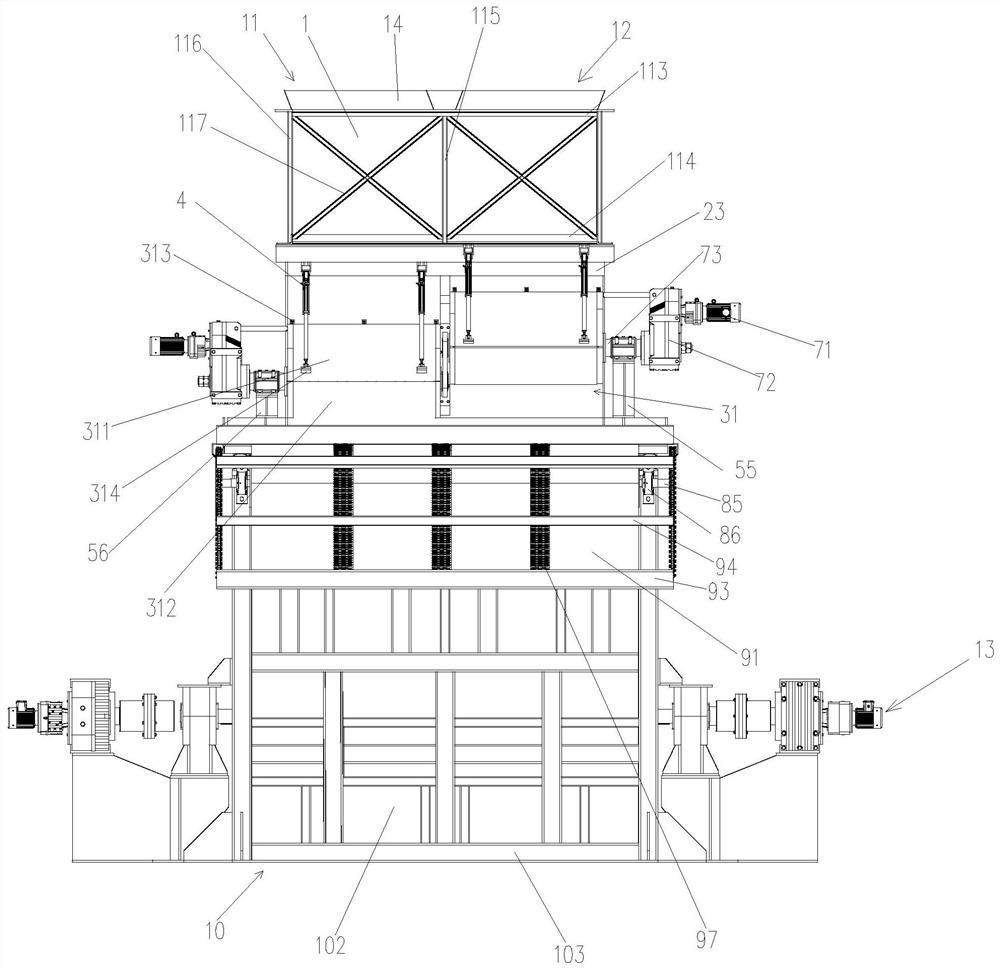

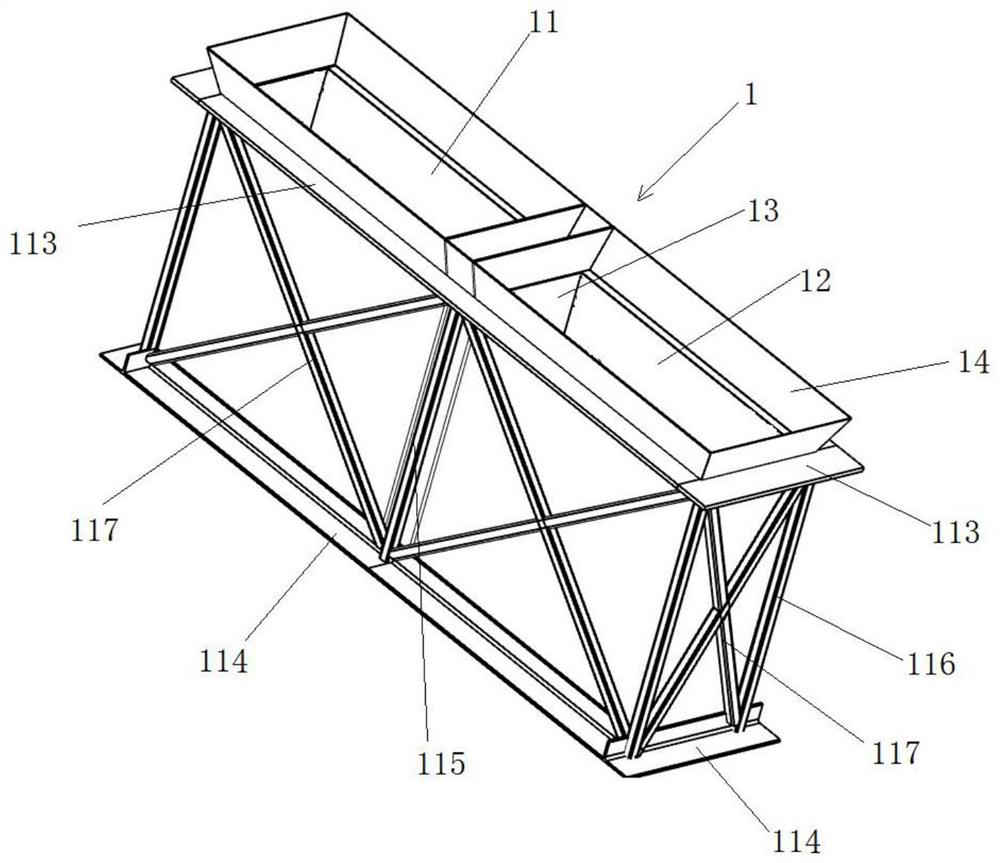

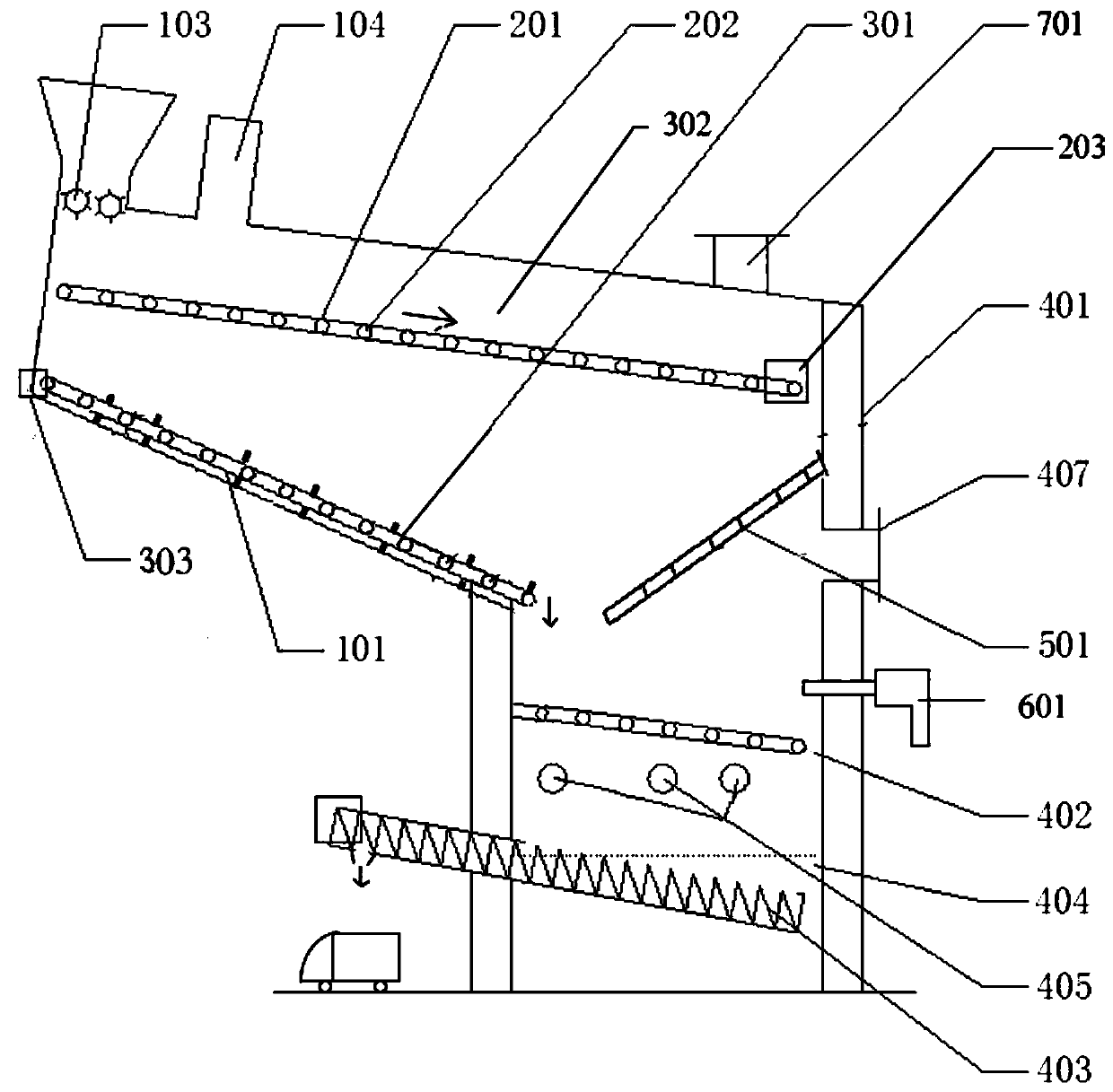

ActiveCN113201357AEasy accessImprove distributionSpecial form destructive distillationProcess engineeringMechanical engineering

The invention discloses a garbage pyrolysis gasification furnace and a method. The garbage pyrolysis gasification furnace comprises a furnace body, a moving device arranged at the top of the furnace body and a discharging mechanism connected with the moving device, the moving device drives the discharging mechanism to reciprocate in the length direction of the feeding port of the furnace body, and the discharging mechanism communicates with the furnace body so that garbage in the discharging mechanism can enter the furnace body, the furnace body is used for pyrolyzing entering garbage, a rotary shifting mechanism is arranged in the furnace body, an ash bin is arranged on one side of the furnace body, a baffle component is arranged on the side face, close to the ash bin, of the furnace body, and the discharging mechanism, the moving device and the rotary shifting mechanism are all controlled by a monitoring module; the method comprises the following steps: step 1, reciprocating garbage blanking; and step 2, pyrolysis and gasification of the garbage. Garbage can enter the furnace body conveniently, so that the garbage in the furnace body is evenly distributed, the pyrolysis and gasification efficiency is improved, ash residues generated after garbage pyrolysis and gasification are prevented from blocking the furnace cavity, and long-term efficient and stable gasification operation of the garbage pyrolysis furnace is facilitated.

Owner:陕西久普环保科技有限公司

Tunnel type biomass pyrolysis gasification incinerator

PendingCN109959013AImprove pyrolysis gasification efficiencyAvoid tunnel buildupIncinerator apparatusSlagBiomass

The invention discloses a tunnel type biomass pyrolysis gasification incinerator, which includes a pyrolysis channel, a chained metal conveyor belt, a slag scraper and an incinerator body. The pyrolysis channel is arranged obliquely, the chained metal conveyor belt is arranged in the pyrolysis channel, a gap allowing air to pass through is formed in the belt surface of the chained metal conveyor belt, and the slag scraper is arranged at the bottom of the pyrolysis channel on the lower part of the chained metal conveyor belt, and scrapes materials falling to the bottom of the channel to the incineration area of the incinerator body. The incinerator body communicates with a discharge port of the pyrolysis channel, by arranging the pyrolysis channel, before incineration of the materials in the incinerator body, hot air in the incinerator body is introduced into the pyrolysis channel and the bottoms of the materials placed on the conveyor belt through the gap of the chain metal conveyor belt, all-round pyrolysis gasification operation is conducted on the materials, the pyrolysis gasification efficiency of the materials before combustion is improved, the slag scraper scrapes the materials falling at the bottom of the channel, and material accumulation in the channel is avoided.

Owner:福建省星球环保科技有限公司

A method for continuous pyrolysis and gasification of materials

ActiveCN106675661BSmall footprintExtended stayCombustible gas productionMicrowave pyrolysisWater vapor

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Fluidized bed reactor for preparing bio-oil from molten salt biomass, reaction system and application of fluidized bed reactor

PendingCN114806623AAvoid local high temperatureEfficient pyrolysis and gasificationLiquid hydrocarbon mixture productionSpecial form destructive distillationHeat carrierProcess engineering

The invention discloses a fluidized bed reactor for preparing bio-oil by using molten salt biomass, which comprises a first chamber and a second chamber, and the first chamber is communicated with the second chamber through a channel structure; the first cavity is provided with a reaction chamber, a biomass particle feeding device, a high-temperature molten salt chamber, a molten salt circulating device, a first discharge port and a second discharge port, the biomass particle feeding device and the high-temperature molten salt chamber are both communicated with the reaction chamber, the high-temperature molten salt chamber is arranged at the upper part of the reaction chamber, the first discharge port is located at the lower part of the reaction chamber, and the second discharge port is located at the lower part of the reaction chamber; the second discharge port is positioned at the upper part of the reaction chamber. According to the fluidized bed reactor, molten salt is used as a fluidized carrier and a heat carrier for cyclic utilization, the fluidized bed is used as a pyrolysis reactor, biomass is pyrolyzed and gasified in a high-temperature environment, and then the biomass is condensed to prepare biomass oil and combustible gas for utilization.

Owner:NORTHEAST GASOLINEEUM UNIV

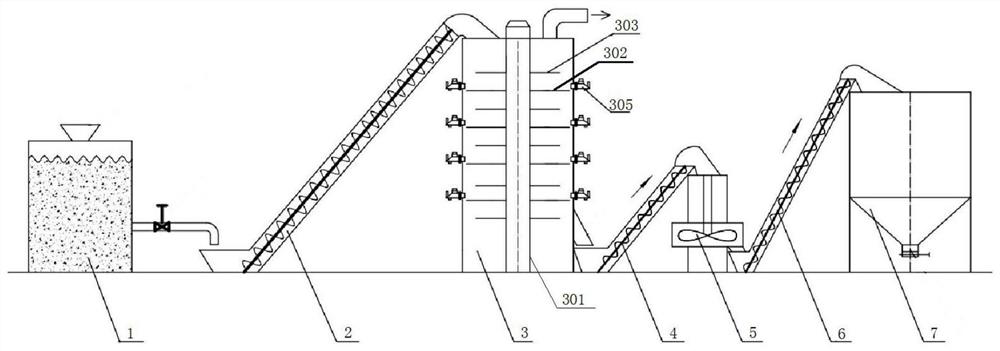

Organic solid waste microwave pyrolysis process and device

PendingCN112592017AEvenly heatedImprove pyrolysis gasification efficiencyWater contaminantsSludge treatment by pyrolysisSlagScrew conveyor

The invention discloses an organic solid waste microwave pyrolysis process and device. The device comprises a sludge powder bin, a 1# screw conveyor, a sludge microwave multi-hearth furnace, a 2# screw conveyor, a Raymond pulverizer, a 3# screw conveyor and a gasified slag storage bin which are connected in sequence; and a plurality of layers of large circular furnace plates and small circular furnace plates which are alternately arranged are arranged on a middle shaft in the sludge microwave multi-hearth furnace, the large circular furnace plates and the small circular furnace plates rotate around the middle shaft, a scraper is arranged on each layer of circular furnace plate, a through hole is formed in the position, close to the middle shaft, of each layer of large circular furnace plate, and a plurality of microwave sources are arranged on the outer wall of the sludge microwave multi-hearth furnace. The sludge microwave multi-hearth furnace is used for treating sludge powder, so that organic matters, fixed carbon and harmful substances in the sludge powder are subjected to pyrolytic reaction, gasified and fully decomposed with inorganic oxide to obtain pyrolytic gasified slag,the content of the organic matters is greatly reduced, the quantity of the slag is also greatly reduced, and the resource utilization range is enlarged.

Owner:湖南隆泰环保能源科技有限公司

Solid waste two-stage pyrolysis gasification system based on fluidized bed and moving bed

ActiveCN105419877BEmission reductionReduce emission contentGasification processes detailsGranular/pulverulent flues gasificationGas solidCyclonic separation

Owner:代建军 +1

A solid waste three-bed combined pyrolysis gasification and tar cracking integrated system

ActiveCN105885950BEmission reductionReduce emission contentGasifier feeding meansBiofuelsCycloneFluidized bed

Owner:BEIJING UNIV OF CHEM TECH

Treatment device and treatment method for high-calorific-value carbon-containing solid waste

PendingCN112175673AEffective pyrolysisAvoid secondary pollutionGasification processes detailsSpecial form destructive distillationOXALIC ACID DIHYDRATESlag

The invention discloses a treatment device for high-calorific-value carbon-containing solid waste. The treatment device is characterized by comprising a crusher, a pulping machine, a pyrolyzing furnace, a cooling and drying device and a gas storage tank which are connected in sequence. The pyrolyzing furnace is of a structure with the diameter of the middle larger than the diameters of the upper end and the lower end, a spraying device is arranged in the middle in the pyrolyzing furnace, and a plasma torch and a filtering device are further arranged in the pyrolyzing furnace. A slag pool is arranged below a slag outlet of the pyrolyzing furnace. The treatment method suitable for the device comprises the following steps of: (1) feeding the carbon-containing solid waste into the crusher forcrushing treatment; (2) feeding the crushed raw materials into the pulping machine; (3) adding an oxalic acid solution to react for 2 hours; (4) adding a potassium hydroxide solution to react for 2 hours; (5) adding industrial water, heating to 80 DEG C, adding formaldehyde and sodium sulfite, and reacting for 1 hour; (6) adding linoleic acid and alkyl phosphorus carboxylate, and reacting for 2 hours to obtain solid waste raw material slurry. and (7) feeding the solid waste raw material slurry into the pyrolyzing furnace for pyrolyzing to obtain fuel gas.

Owner:SICHUAN TIANFA TECH

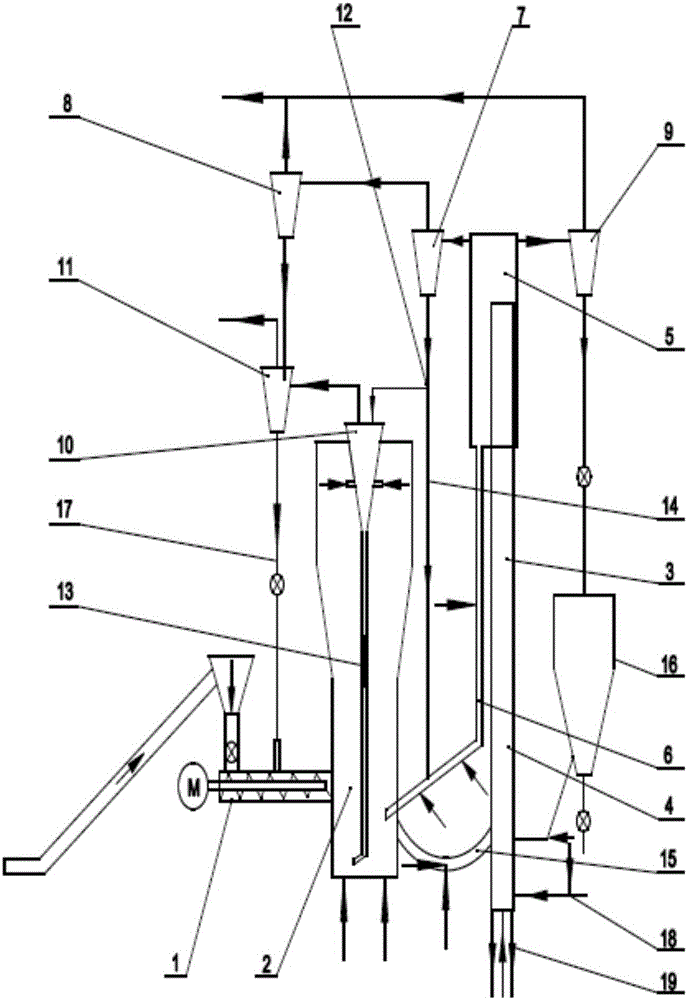

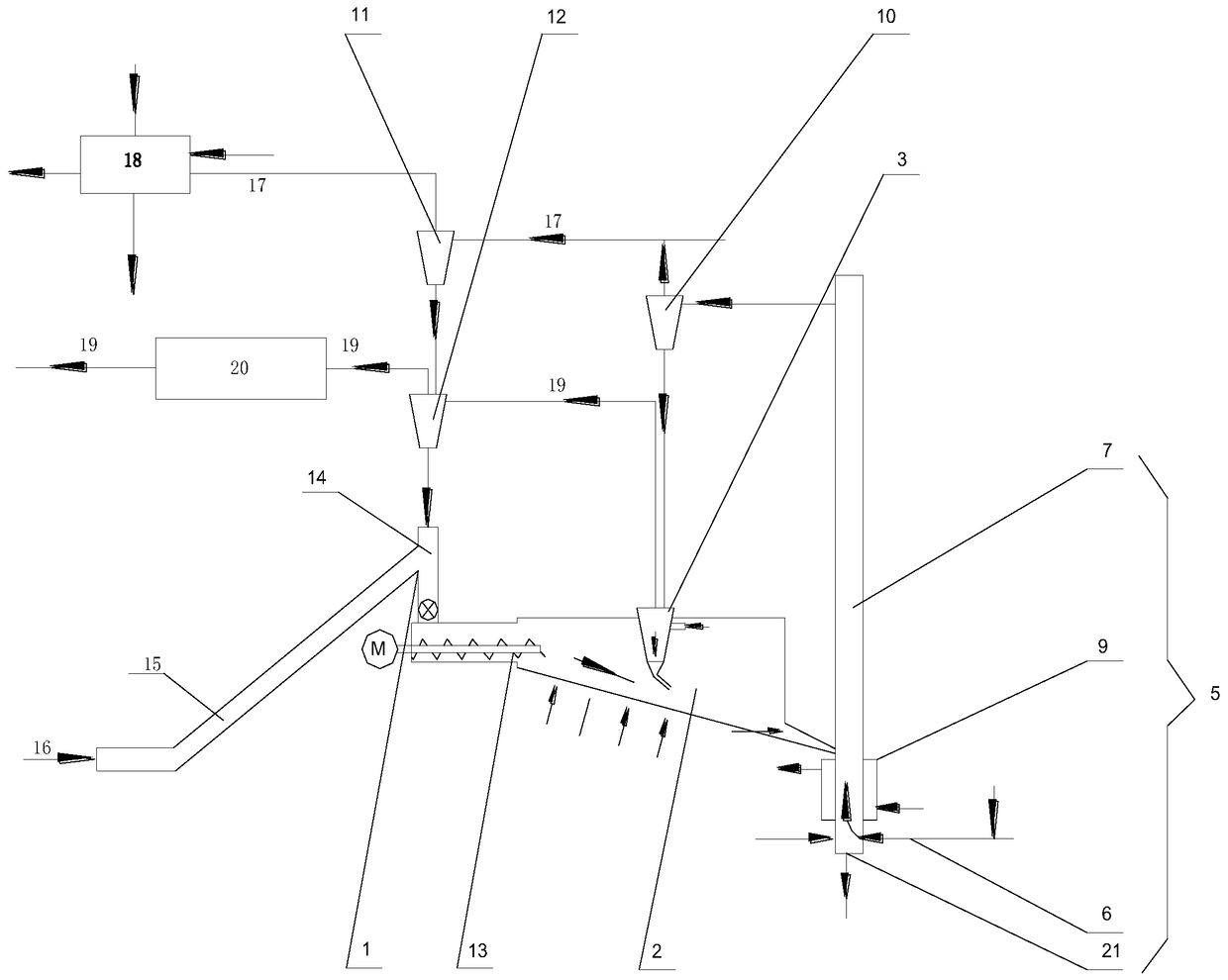

A two-stage pyrolysis gasification system for solid waste

ActiveCN105419878BFully lysedEasy to operateGasification processes detailsGranular/pulverulent flues gasificationCycloneGas solid

The invention relates to a two-section pyrolysis and gasification system of solid waste. The two-section pyrolysis and gasification system is provided with a solid waste material feeding system, a pyrolysis device, a circulating fluidized bed oxidization gasification device system, an oxidization gasification device cyclone separator and a cyclone separation type reactor. Two-section pyrolysis and gasification is realized by utilizing a circulating fluidized bed oxidization gasification device combining a gas stripping pipe and a sedimentation pipe and a pyrolysis reactor combining a moving bed and a fluidized bed, and hot bed materials and pyrolyzed gas are sufficiently mixed by using the cyclone separation type reactor, so that tar cracking and gas purification are greatly accelerated; synthetic gas and pyrolyzed gas can be produced simultaneously through an optimized design of the structures of the oxidization gasification device and the pyrolysis reactor, mixed use of the different bed materials, improvement of a material bed circulating flowing system and a gas-solid mixing level, and improvement of the feeding system, so that the whole pyrolysis and gasification efficiency and the heat value of the pyrolyzed gas are greatly improved and the content of tar in the synthetic gas and the pyrolyzed gas is reduced, and furthermore, the clean synthetic gas and pyrolyzed gas, which have high quality, are prepared.

Owner:代建军 +1

Plasma gasification refuse disposal method and device

ActiveCN102553880BEmission complianceEliminate pollutionSolid waste disposalPlasma technologyProcess engineering

The invention discloses a plasma gasification refuse disposal method and a device, comprising a pyrolysis gasification unit, a quench tower and a turbulent tower. A pyrolysis gasification furnace, an expansion reaction chamber, the quench tower and the turbulent tower are sequentially connected by a channel to form a vertically-alternate curve manifold gas channel. More than two of alternating-current plasma torches are arranged on the wall of the pyrolysis gasification furnace, and an air supply pipe is arranged on the alternating-current plasma torch. The axial lines of the alternating-current plasma torches are tangent with concentric circle taking the axial line of the pyrolysis gasification furnace as the center; a low-power alternating-current plasma torch is arranged on at least one of the expansion reaction chamber or the gas channel of the expansion reaction chamber and the quench tower to perform secondary pyrolysis. The quench tower is used for cooling gas, and the turbulent tower is used for desulfurizing and purifying gas. The invention uses the plasma technology to perform industrial gasification to the municipal solid waste so as to obtain usable gas; and the emission can achieve the environmental standards.

Owner:北京光耀环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com