Plasma gasification refuse disposal method and device

A waste treatment device and plasma technology, applied in the direction of solid waste removal, etc., can solve the problems of nodular molten slag discharge, difficulty, uneven feeding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

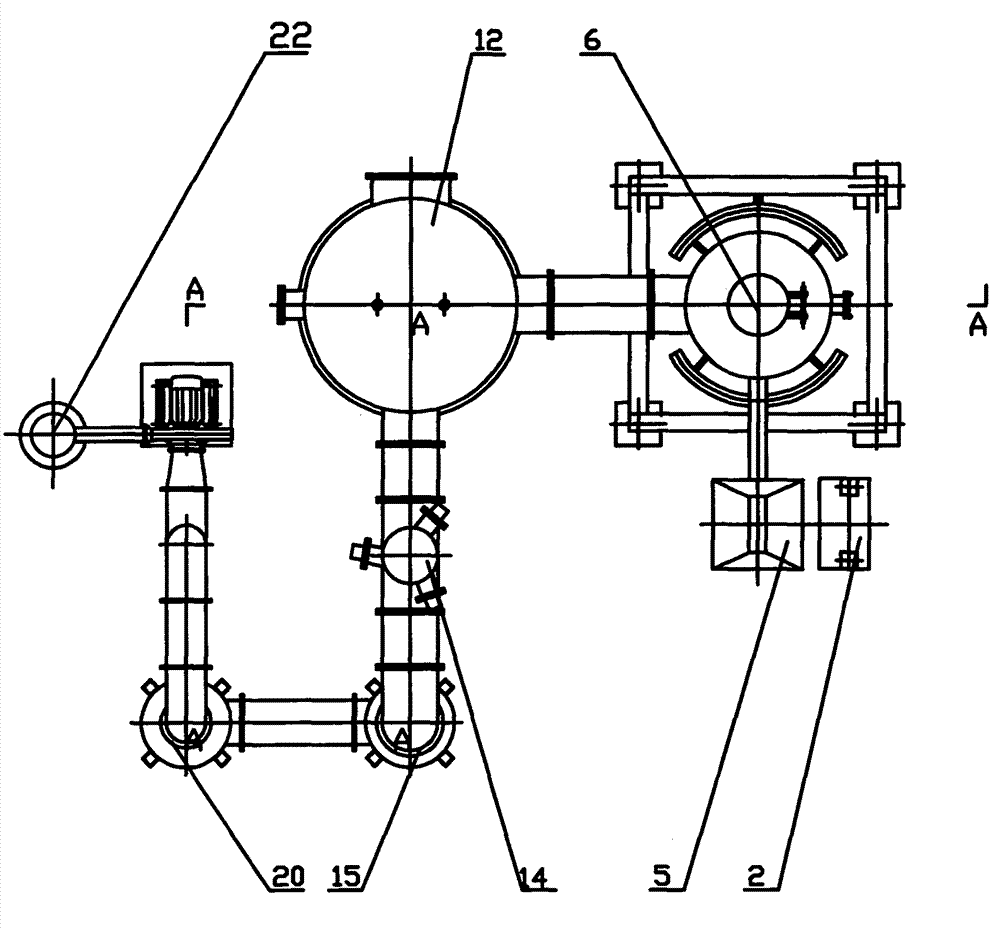

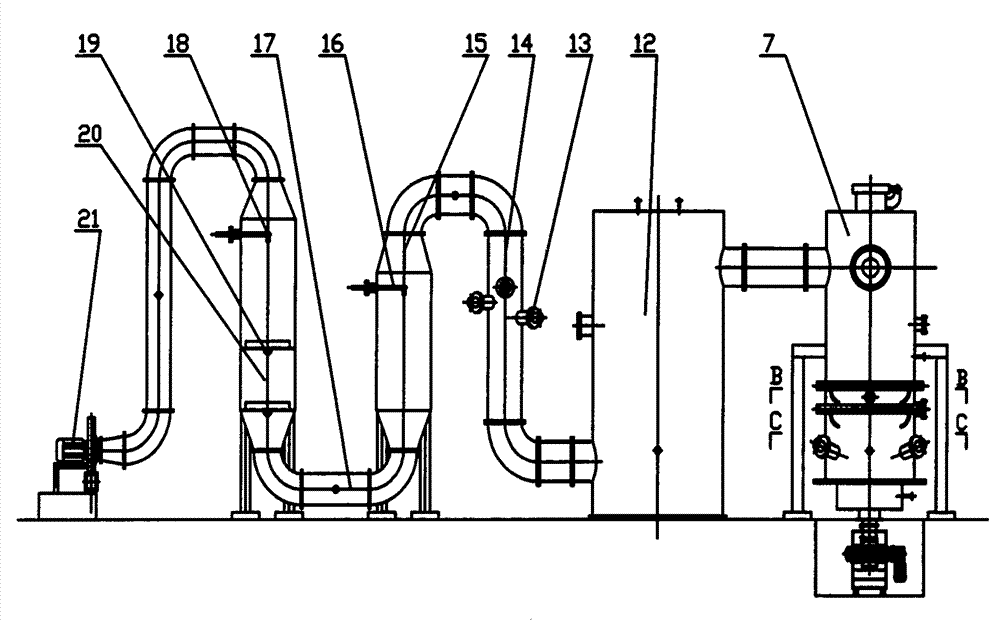

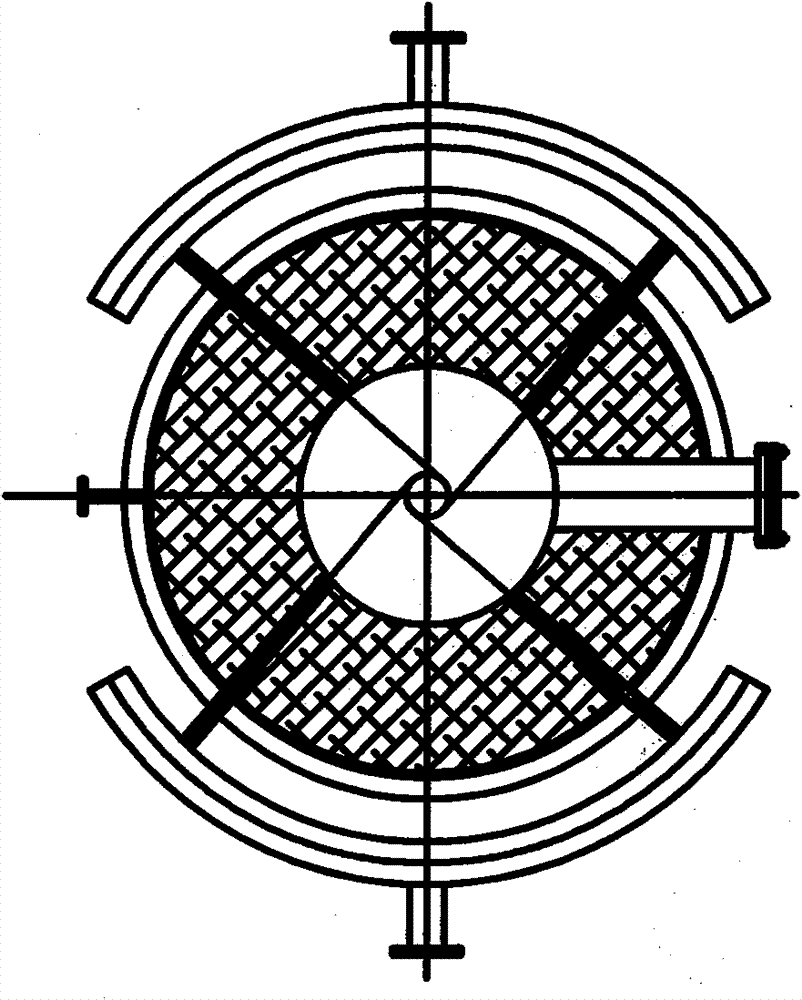

[0055] Air supply: The pyrolysis air supply of the present invention directly adopts industrial oxygen, because the oxygen content in the air is about 21%, which can effectively reduce the gas volume of the pyrolysis gas and improve the purity of the pyrolysis gas. The air supply pipe 8 is arranged in a circular shape cut at four corners, divided into upper and lower layers, and forms an angle of 20 to 30° downward with the plane where it is located, so that the gas in the furnace rises spirally, increasing the residence time and disturbance, and reducing the temperature of the pyrolysis gas. It has a good promoting effect on the formation of tar particles and the reduction of tar particles. The air supply speed is controlled at 40-60m / s, which has a strong penetrating power, which can make the material contact with oxygen well and improve the pyrolysis efficiency. Each air supply official road is equipped with a separate regulating valve, which can adjust the air pressure and...

Embodiment 2

[0063] Position selection of the secondary gasification plasma torch: The secondary gasification plasma torch can be arranged in two positions, which can be arranged in the middle of the expansion reaction chamber 12 or in the vertical gas channel 14 . Adjust the number and power of the plasma torch according to the different requirements for the quality of the gas produced.

Embodiment 3

[0065] Selection of the position of the air supply device: the air supply pipe 8 can be arranged above the plasma torch of the gasification furnace 7, or arranged according to the position of the secondary gasification plasma torch. When the secondary gasification plasma torch is arranged in the expansion reaction chamber 12, The air supply pipe 8 is arranged under the plasma torch of the expansion reaction chamber 12 , and when the secondary gasification plasma torch is arranged in the vertical air passage 14 , the air supply pipe 8 is arranged under the plasma torch in the vertical air passage 14 . Choose different positions and air volumes according to the material composition and gas quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com