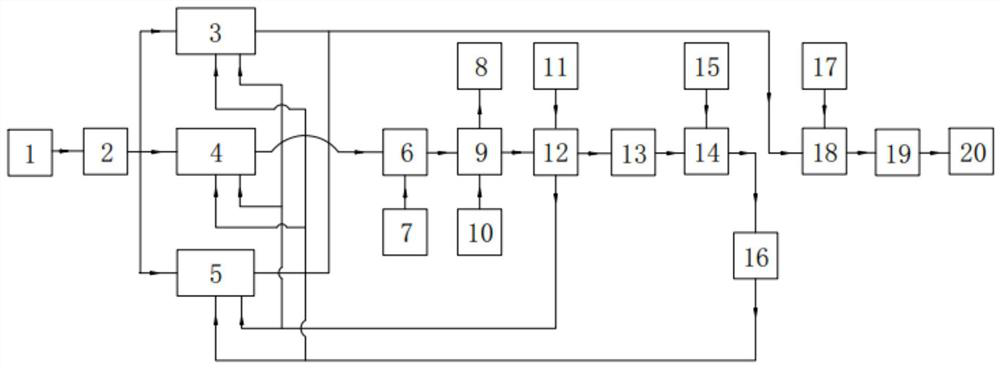

Garbage pyrolysis and gasification system device with drying function and garbage pyrolysis and gasification method

A technology of pyrolysis gasification and system equipment, which is applied in the field of solid waste treatment and garbage treatment, can solve the problems of poor flexibility of equipment, inability to unload coke, uneven distribution of materials, etc., achieve harmless high residual ash, shorten construction period, The effect of prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

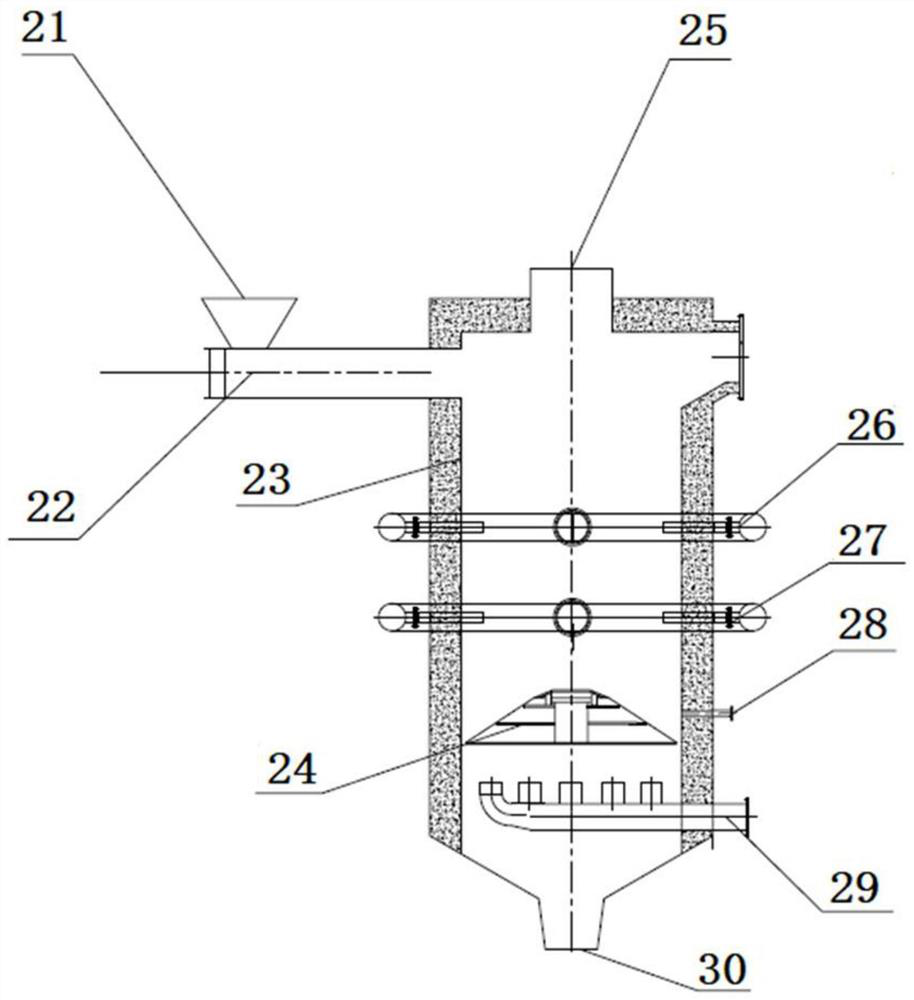

[0092] Using a method for pyrolysis and gasification of waste in a specific embodiment to carry out pyrolysis and gasification of waste, specifically includes the following steps:

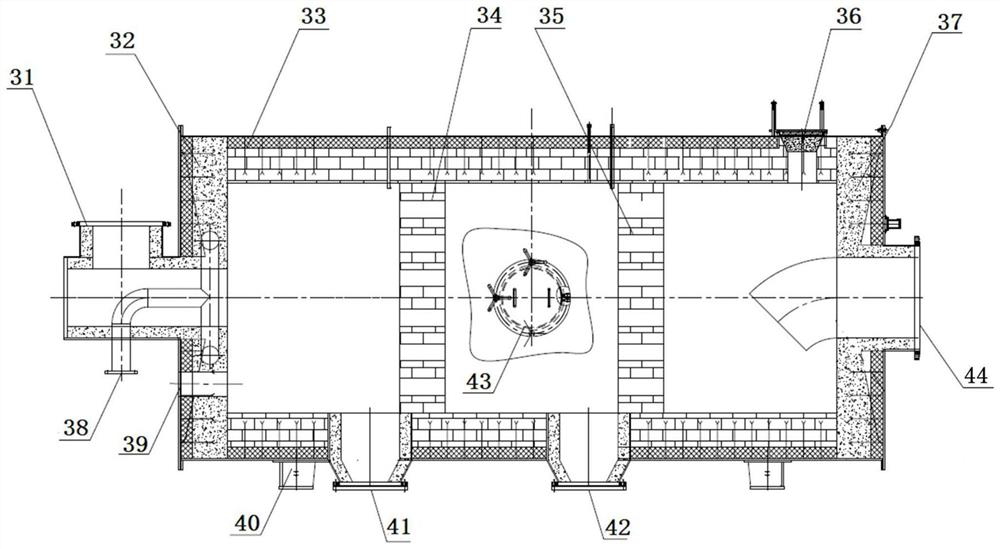

[0093] (1) After rubbish is sent into the first gasifier 3, carry out the drying process in the middle part of the body of heater. Now, the second gasifier 4 is opened to start charging, and the third gasifier 5 remains closed. After a period of time, the garbage in the first gasifier 3 falls on the rotary grate 24 for pyrolysis and gasification. At this time, the garbage in the second gasifier 4 reaches the middle of the furnace body for drying, and the third gasifier 5 is opened at the same time. Start feeding. The temperature of pyrolysis and gasification in the first gasification furnace 3 is 300°C.

[0094] (II) Preheat the second combustion chamber 6 for 1 hour to raise the temperature to 850°C, and the combustible flue gas generated by pyrolysis and gasification flows through the first cham...

Embodiment 2

[0097] Using a method for pyrolysis and gasification of waste in a specific embodiment to carry out pyrolysis and gasification of waste, specifically includes the following steps:

[0098] (1) After the rubbish is sent into the second gasification furnace 4, the drying process is carried out in the middle part of the body of heater. At this moment, the third gasification furnace 5 is opened to start charging, and the first gasification furnace 3 remains closed. After a period of time, the garbage in the second gasifier 4 falls on the rotary grate 24 for pyrolysis and gasification. At this time, the garbage in the third gasifier 5 reaches the middle of the furnace body for drying, and the first gasifier 3 is turned on at the same time. Start feeding. The temperature of pyrolysis and gasification in the second gasification furnace 4 is 400°C.

[0099] (II) Preheat the second combustion chamber 6 for 1.2 hours to raise the temperature to 870°C, and the combustible smoke generate...

Embodiment 3

[0102] Using a method for pyrolysis and gasification of waste in a specific embodiment to carry out pyrolysis and gasification of waste, specifically includes the following steps:

[0103] (1) After rubbish is sent into the third gasification furnace 5, carry out the drying process in the middle part of the body of heater. Now, the first gasification furnace 3 is opened to start feeding, and the second gasification furnace 4 remains closed. After a period of time, the garbage in the third gasification furnace 5 falls on the rotary grate 24 for pyrolysis and gasification. At this time, the garbage in the first gasification furnace 3 reaches the middle of the furnace body for drying, and at the same time, the second gasification furnace 4 is opened. Start feeding. The pyrolysis gasification temperature in the third gasification furnace 5 is 500°C.

[0104] (II) Preheat the second combustion chamber 6 for 1.4 hours to raise the temperature to 900°C, and the combustible smoke gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com