Automatic sorting device of pipette tip

An automatic sorting and gun tip technology, which is applied in packaging and other directions, can solve the problems of poor reliability, poor effect, and low sorting efficiency of sorting devices, and achieve high reliability and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

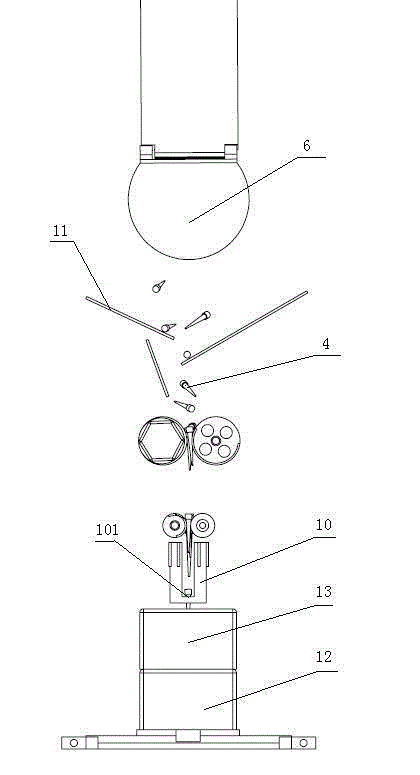

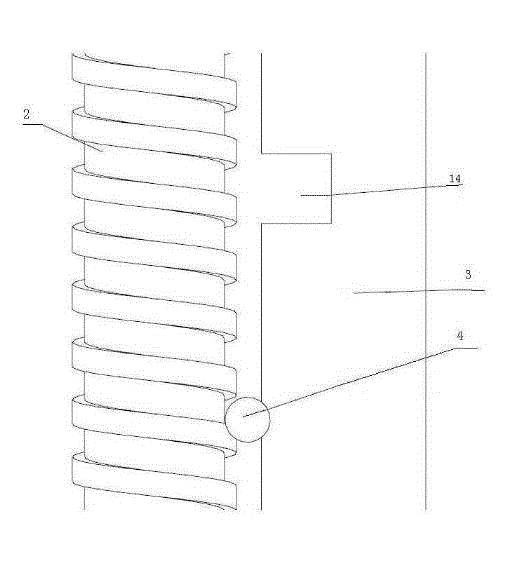

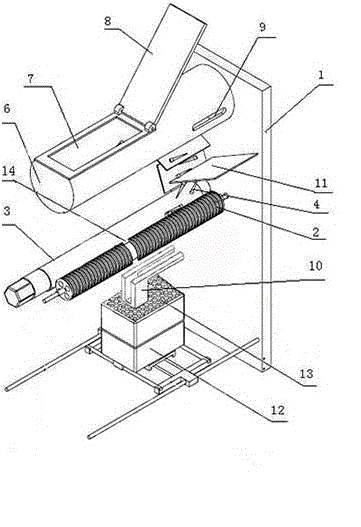

[0032] figure 1 Shown is the pipette tip automatic sorting device of the present invention, which includes a tip delivery device, and a tip receiving device arranged on the lower side of the tip delivery device, and the tip delivery device includes a screw 2 and a slide Rod 3, the screw rod 2 is rotatably connected to the frame 1, and the screw rod 2 is connected with a driving device; the slide rod 3 is fixedly connected to the frame 1, and is arranged in parallel with the screw rod 2; There is a gap between the rod 3 and the screw rod 2, the maximum gap between the slide rod 3 and the screw rod 2 is smaller than the maximum diameter of the gun head 4, and greater than the minimum diameter of the gun head 4, on the gap A gun head discharge port 14 corresponding to the position of the gun head 4 receiving device is provided, the gap of the gun head discharge port 14 is greater than the maximum diameter of the gun head 4, and the gun head 4 is transported to the gun The head d...

Embodiment 2

[0038] This embodiment is a more preferred implementation of the present invention, such as Figure 2-3 As shown, in order to avoid the problem that the pipette tips 4 are stacked on the gap of the conveying device, and some pipette tips 4 cannot be hung on the conveying device to maintain a vertical state for sorting, the pipette tips in this embodiment are automatically sorted The device is provided with a multi-layer conveying device along the vertical direction, and the positions of the gaps in the multi-layer conveying device correspond up and down, that is, the gaps of the multi-layer conveying device are parallel to the vertical direction. In this embodiment, two layers of conveying devices are selected, and the conveying device on the lowest layer is provided with a pipette tip discharge port 14 corresponding to the position of the pipette tip receiving device. When a plurality of the gun heads 4 were stacked horizontally and fell to the gap of the upper layer of the c...

Embodiment 3

[0048] This embodiment is basically consistent with Example 2, and the difference is that: the slide bar 3 in this example is a rib, and the slide bar 3 is in line contact with the gun head 4. The edge of the slide rod 3 is opposite to the screw rod 2, and the edge rod is controlled to move toward or away from the screw rod 2 through the adjustment device. The adjustment device is a long hole arranged on the frame 1, one end of the rib passes through the long hole, and the rib can move on the long hole, when the rib moves to the set When the position is fixed, the rib is fixed by a positioning device, and one end of the rib passing through the long hole can be provided with a screw thread, and the positioning device is a fixing seat, and the fixing seat is provided with a connecting part and the rib The thread fits and connects, and the fixed seat is fixed with the frame 1 by screws, so that the positioning device can position the rib, and the rib is not easy to move.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com