Three-bed combination pyrolysis gasification and tar cracking integrated system for solid waste

A solid waste, pyrolysis gasification technology, applied in gasification process, gasification device feeding tool, coke oven and other directions, can solve the problem of high tar content, hindering commercial promotion and application, low calorific value of product gas problems, to achieve the effect of reducing emission content, increasing stability and flexibility of operation, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

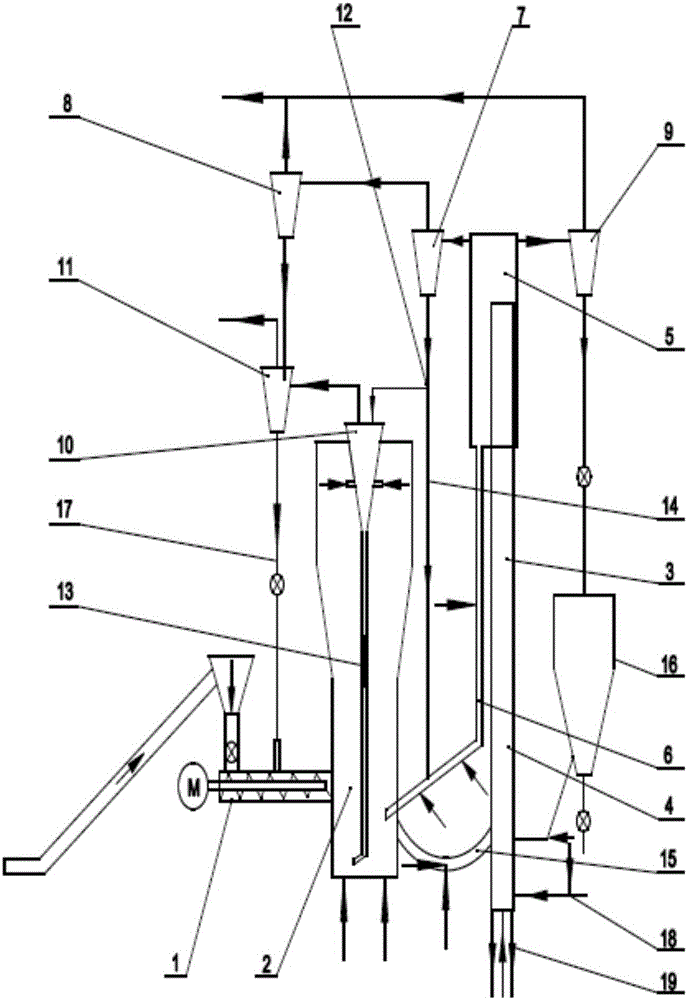

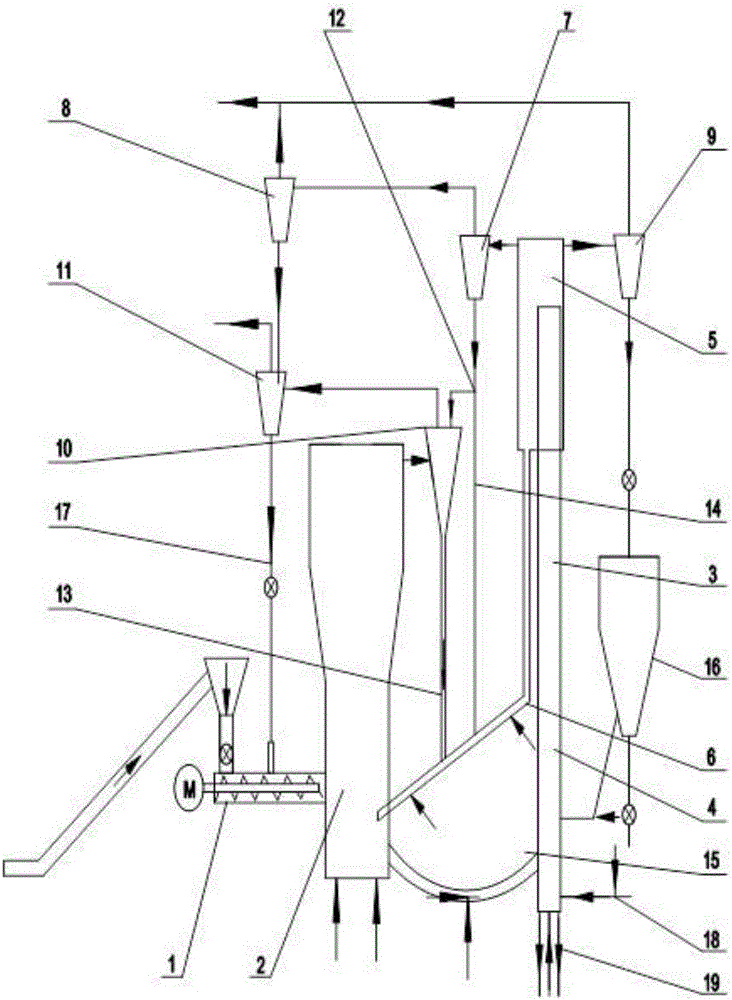

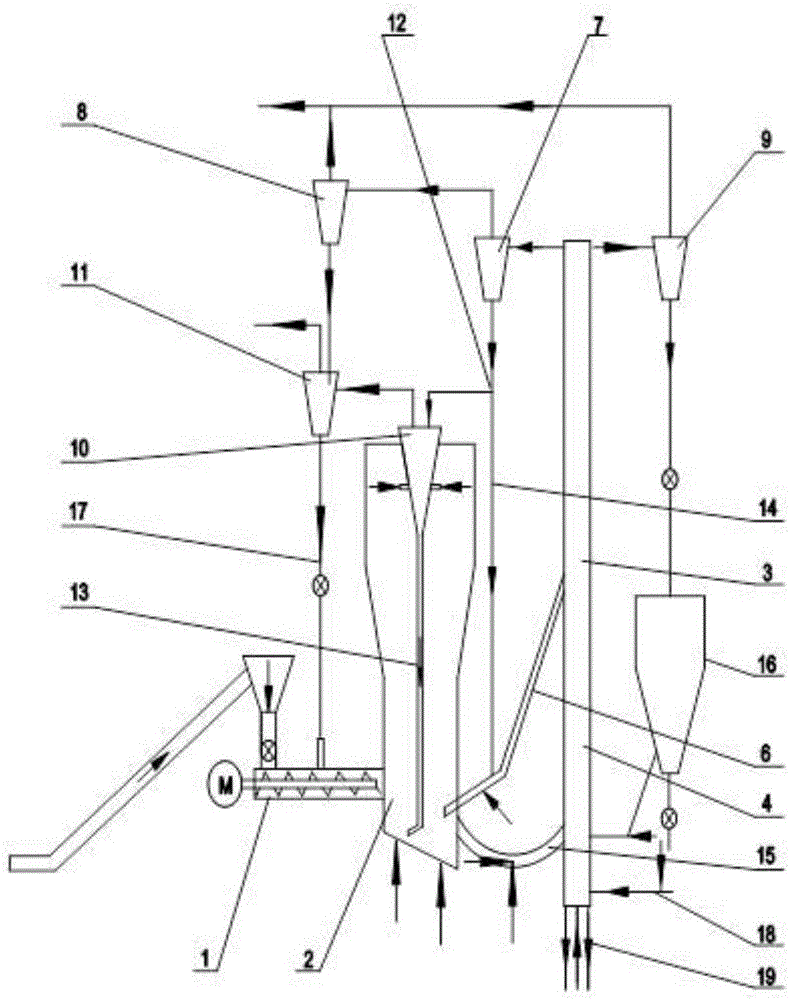

[0030] See figure 1 As shown, the present invention is a solid waste three-bed combined pyrolysis gasification and tar cracking integrated system, which has a solid waste feeding system 1, a pyrolyzer 2, an oxidizer system 3, and an oxidizer cyclone separator and a cyclone reactor, wherein the solid waste feed system 1 is communicated with the pyrolyzer 2; the bottom output port of the pyrolyzer 2 is connected with a mechanical valve or a screw conveying system or a non-mechanical valve pipeline (such as a circulation return pipe 15) The oxidizer system 3 is connected; the output end of the oxidizer system 3 is connected with the input end of the oxidizer cyclone separator, the output end of the oxidizer cyclone separator is connected with the input end of the cyclone reactor through a non-mechanical valve, and the cyclone reactor 10 is connected with the input end of the cyclone separator. The pyrolyzer 2 is connected in communication.

[0031] The oxidizer system 3 is a cir...

Embodiment 2

[0039] See figure 1 As shown, the difference from Implementation 1 is that the circulating fluidized bed oxidizer system 3 adopts the mode of insufficient air supply and insufficient combustion, that is, the operation mode of partial oxidation, and the product gas of the gasifier is syngas, which It includes a riser 4, a settling tube 5 and an air intake system 18 at the bottom thereof in sequence.

Embodiment 3

[0041] See figure 1Shown, the difference with implementing 1 is that cheap industrial waste iron rust (Fe 2 o 3 ), power plant desulfurization gypsum (CaSO 4 ) and other oxygen carriers, the release of lattice oxygen contained in the oxygen carrier promotes the partial oxidation of the pyrolyzer, thereby increasing the temperature of the pyrolyzer, and the fluidized bed pyrolyzer 2 operates in the operating mode of the gasifier, Its product gas is synthesis gas. The circulating fluidized bed oxidizer system 3 operates in complete combustion mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com